Professional Documents

Culture Documents

Deutz 3 PDF

Deutz 3 PDF

Uploaded by

Miguel Ruivo Almeida0 ratings0% found this document useful (0 votes)

36 views56 pagesOriginal Title

Deutz_3.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

36 views56 pagesDeutz 3 PDF

Deutz 3 PDF

Uploaded by

Miguel Ruivo AlmeidaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 56

Technical Circular

0199 - 99 - 2090 en

6th Exchange

Product:

Medium-sized and large engines

‘Company Osormont (62)

fia enupmnt manicures (EM)

Vem Plone: 229 62-

Fax fen 2

Lube oil

‘The Bh exchangeie made forthe folowing reasons:

‘© change Seaton

1 Ghange Secton2

Comacions kbs table Enciosixe 1 and2

‘Scopeotappcation

This Technica Creuse apes tothe folowing DEUTZ medium ang engltes engines:

byte 234, TBD 616, SBAMB"G, TD GOH, TBD 6048, TBD €20,

‘SBVA628, RISIBVRA G40, TBD 645

Pease rocaed analogous for engines nolonge ined inthe ble progam Incase you need

furtheGarieaton, please cota yournoaret DEUTZ SERVICE

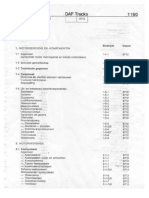

Table of contents

Lubooiigrade

Lube otvisoosty

Lueolchengeitsras

Senvcingoftne engine mounted ube ci iter

Lube ofr seat estom

1 Lube oil grade

Forth engines of srs O/TBD 234, TBOE16,SIBAM B16, T8D.604, TAD ED4E.and TADE2D ube

‘ols atcordngtotne existing spoiicatons have been determined. Enclosure? somareerence

‘olsare indicated wth which postive operating resus have been achieved

Forth usein onginos of saris S/B/8VM4629, RISIBVMG4D and TAD 645, Encosure Ioomerises|

‘ference le ois Hero, The esignment pend onthe ful ps fhe engine

Lube os ntinsesteabuthaving the same capscty loves those mentioned in Enclose tan

canbe used upon agreement Ps ellpredueeand~compulsory during Newari period

‘line approvalotoeurz,

‘Tho indicated be ol grades ae minimum equkoments, Higher quality avs canbe uted,

‘Themanufacturrisresponsibe for supelynglubels of constant qualty and witthose adives

hich were tho bass for tneroloase,

14 Engine sores DITBD 234, TBD 616, S/6AM816, TBD 604, TRD 6O4B, TBD 620,

‘The abe os myst at east moat th oloning ie ol spodestons

Ergne Tbe of epoarieaions

ACER oP

[orEozr

SIBAMBTE £2.96, £3-06, cr,

Tap cos e4o.6509 | codch4

‘Tap6o4e

TeDeTe Engine spood n> Zoom Tobe or quai edo

Engine speed < 2100 “Lube a ual rade

e062

Lube otlaualty grade

‘Mier oa Lube ol quality ade

Labo olguaity grade Tab o pocticatons =

7 AGEA E498

" AGEA ES0GE50 _APIOPA CGA CHA

Som reference lbeols ube ol qualy grades ican be taken rom Enclosure

{837 In be ol quay rede |, only uy or party syehetic os ae prmited fo be used

112 Engine soros SIBVI 628, RISIBVM 64, TBD 645,

For angines of series IBV 628, we recommend tho useof uss lh a sulphur conterofless than

0.25:byweightto avo thefomationolanng nthe cyander ners, praferaby tha useot ube lsc

‘ual ass APICG-4 or APICH

For miosis ith sulphur contents> 1.0%, we recommend fr heft fitinglouse an ot weha TEN

ofa myKOHIg for slp contents «+08, TEN of 30 MgKOHIG

Toachiove he maximally possible economic operation for rfilng, ancl wthlowar or higher TEN is

parmited tbe used. Te producer of mineral ol mus! be invcved nhs reas, who ge hat

Focommandatonson te basissroguaaralysosoftousedots Moreover accoringlimt values

Imostbe observed sve secon 3.2)

Acordng nour experience, when beng elle, th engine 645 ater needsan olllh@ TEN 40

‘maIKOH, the engines 628 and 643, however, rather ancl witha TEN of 20 mgKON,

‘honing ant-crosivolemergency genset, contact the parent company.

Lube oll viscosity

Selostonenetubsovscosy shallbsbasedon SAE-dassfestonJ300 98 (Secey of Automata

Engincers). Solon ofthe SAE-lass does not ge ny indicat f tho rato

[Engine sores D/TBD 234, TBD 616, SIBAM 816, TBD 604, TBD 604B, TBD 620

‘Thearbenttemperatuels deckveforseectonotine proper SAE: cass. Mutigradeolsmay be used

foral'year appleaton summer andwine e.g, SAE SH 40

Viscosity specication:

2% m 1s 0 5 oC Ss

sc buse —

>|

kK

ix SAE awa

Le.

kt

>|

lel

22 Engine sores SIBVI 628, RISIBVI 640, TBD 645,

Generally fr tse engines viscosity class SAE 40s speed. Al-omperatio os SAL 10W-40 or

151.40 can ago bo usd, rouded Bose otk aro ndeated nth tof ube os oar equate

‘The BVM628 engines noporation whlch wer prevously operated haute ol isos of SAE 30

(previous versen:alcolerupsreamet charge acecle.maybe operat NSA 40orSAE 10¥%-40

OFSAE 19¥40 rom now on

3 Lube oil change intervals

‘Theoshouldbechangedoniy withthe engine warmed untasenieatemperature;thaois then highly

‘uidandrains oft machete

31 Engine

TBO 234, TBO 616, S/BAM 816, TBD 604, TaD E048, TBD 620

“Thefstubeolchsnge ser alcommissonngorre commissioning folgung aloes wskshal

Deford ater 50 running hous a holes Thereafter to ooning boos change vats shall

oacheresta:

TaourtoaSoragaTaba oir

trout | wan

Engine Typesttua

Distilatefvel | MOFmiedall | Distitefuel | MDF modo

1808217 0M 1808217 M8

Das | Boop rs_| 2500p.

Teoz56 | 2506p. tws._| 1280p.

“TaD616 | 2800p. s._|—1250p.ws._| _s000p.fvs_| 25008.

‘SBA 676 | 250 op. 500 0p.

TaD 604 |~25000p.trs. | 1250p.1vs. | s000p.tvs._| —_26000.ts.

0820 | 25000.hvs. | 1250p. tes—| 8000p. ws. | 2800p hes.

‘itehange once a yr ata minimum

‘Thocichangointevalmay be extended depending onthe engine parsing modeand thebbeol rade.

‘This must be determined by a srios of used analysos. Tholubo ol rust ba changed any caso

lfonecrneolguinglime values snot roschod or exon

‘Kirematicviscosiy at 100°C (DIN 51 562)

Lbs of SAE 20, SAE W.30 rin. 93 mas (0)

Lube ol SAE 40, SAE” W.40 min. 125 mse)

Viscosity increase ‘max 25% oFvalue whan sea

Finenpola(ONENZ2719) rnin 80°C.

Toalcontaminaton(INS19OS2centtoge) max. 20% by mass

Water cortan(O1NS1777) max 0.2% by mass

Totalbasonamber(OINISO3771) ‘ni 0'%of value when aw

82 Engine sores SIBVM 626, RISIBVM 640, TBD 645,

Intheceseoftese engines, abeolchangealvaystakes pcwaftera povoususedolnahyss Upon

agreement th he mineral i produce, tolube otmust bo pany replacedorexorangea. rane ofthe

Timtvalus i excooded or Tallon boow Fo nginas SEV 628 operat ith dtu (ede

‘lime ithe pa) we general recommenda be ilchange ater 000 op hours, respective ct

tho rosut oto vse of analy.

open operation wth med el he TBN-vale shoulda beow heniated mininunvalu, fing

'spostiewth alte oltavnge TON valve 40 mgxOHG or SOmGKOH esheningun), oe secon 2.

Kinematic viscosty at 10°C (ON 51 562)

ub ot SAE 40 min. 12.8 mrs 81)

Viscosity nroase trax. 25% of valuswhonnew

Flash port(OINEN22719) min 120°C

‘ofalcortaminaton(OIN51965Scentivge) ma. 1.5% by mass

Witercortnt(O1N51777) Imax. 0.2% by mass

Totals number (01NIS03779)

witht us min. 6mgkOHg

ith mikes fst wha sulphurcortaneS = 1% by wt. min. ‘2mgKOHg

‘nih ves Wot wih sulphur content S > 1% by wt. min. 18mgKONS

33 Usedoltanalysis

‘The ol sample shale rpresertativche entre of fing an shalbe taken in good ne beer the

cilchange bcomes de (ste operaton manual Nisbesto start aeriescl analyses ding or shorty

alter comissioningsoastodetne apossbioveratonot eube ol Jependeonthaduretonct engine

‘operator,

‘he ol analysis must bo madofor engnes S/BVI 628 and RISIBVM 640 alas very 500 operating

hows, for enginos THD 64S atlas every 1000 operating hours

‘The usec snayss can becariedoutin te laboratories ofthc producers, nstutescr at DEUTZ,

‘The DEUTZ tet it sllows quick determination ofthe ibe oll era. This quick est permits a rend

or

Dv s18005 or

‘cleulaton|

Fash pointn closed pan . min 85 Dov EN 22719

In acoordance with Pensky Martens

Kpamatic vecoiy at 20°C ms macéo | oINsts624

Disttation curve DN 51751 or

toll evaporated votume amcunt Asma 86

up t0250°C. % max.65

upto360°C. % rnin 65

Pour Point < maxc-2 | omisoso16

Carton restive Mase % macos | OWStsS1

Inacoocdanoe with Conadson

from 1036 tila roi

‘Sulphur cortont, ass% | maca2 | OINEN2a«00°

‘ON S100 and

IN S1400-20r

DINst400.8

‘ater content mora rmax.200 | onsi7779

Tota contamiation mara macao | oINsta0

‘sh cents ase% | maxon | ONENTorIS0 6245

FuloilC4N51609-€L-1 may not contain any nganic acids test posible in accordance wAhDIN 1658-1 a

alogensted yckocarbons est posible mascardance with ON S1577 3.

Fuel Specification

(Minimum requirement)

Appendix 8 to

‘TR 0199-99.2089

‘Ast Exchange

Light fuel oil in accordance with

Le 4 British Standard 2869 : Part 2: 1988

Characteristics Units Bs 2069 | Test procedure

Class D

Density a 15°. ain max. 900°"

Fash point Pony: Martens) c in. 56 158 2000: Pan 94

Wiater Vol. 9 macoos | as4ses

Segments Mass % macoot | asae2

‘Boling eve at 85 Vol “c vain 360 | 68 2000: Pan 129

Kipemate vost a 40°C ams | 55 2000: Part 74

ns

ash ass | max oor | as.44s0

Sulphur ass 6 max. 08 336

(ane number ‘in 40

can resisue Mass % maco2 | asst

In aecocdance with Ramsbotom

from 109% dita este

Lm vabe of teraity 5 61a

‘Summer (16.03. 30.09), so max 4 enn,

Winter (0110 15:09) c mac i2

(Copper cooson Degeo of 1 1S 2000: Pant 164

[DEUTZ MWM minimum requiement

Fuel Specificatic

(Minimum requirement)

ny

Appendix 9 to

TR 0199-99.2060,

Light fuel oll in accordance with ‘Ast Exchange

‘ASTM Designation: D 396-06

Characteristics Units] ASTM D 396 | ASTM D 396 | Test procedure

No.4 No.2

Density at 15°C tom | max.e50 | macere | asmso r29e

Fash pot c | rin 38 mins [asmupoe

Water and sagiments| vous | maxo0s | maxoos | asmueroe

Boling curve STUD 86

80 v0L % at “ : rin. 282

1Ovol % at ce | mac ats ss

80 voL 96 at ce | imax 25 | max 238

‘Kamat viscosity at 40°C mms [omnis | mnie [astuoass

mms | omac2a | macsa

| Sulphur Mass % [max a5 maxos | ASTD 129

‘Copper carson Degeeot | No.3 Nes [asmeova0

(max. 3 hat 0G) cores

‘Catare cumbe rmin40 | min 0

‘Gabon restive aswosa |

Imaccodence win Ramsbottom | Mass% | macass | max.oss

from 1036 distil esue

Pour Point vo | max-18 | mac-6 | astuosr

8 DEUTZMWM mum eqrement

‘ava isp ru eur eg ta 218 01

peer sai

o.oo conexe | tcccmas | .onwud | wosaxoie

exronusy | 1 eatzoainane| a Del oma Tass veo 0

roa ae ed

- : Spence | nea Twos re

wameone| sows sew Bure Tae

[ be w= oo a oa

a aa 2 Br nS

amos ane] woe eo = me wy

Gerais | 0-02-wse~mw vessiswal over ey er) o.orm sro Ey Fan RH

ees slaw seo o

wero | _ sewer or oa mr Bren Ame

ie nun Sense

ores | yusearmetty a

oT c al c

sonosoanteas | “donsonoeds | anpeoad so ‘esode: dina) uewe20e

tra srs ms sea/tea

po OuyN 2909" OLN

‘s6ueyorg 384 Pa Zango

6002-666610 HL

104 xipuoddy (quowozjnbes wnwiuyy) uoneoyfoeds ong |

frien regret Appanlic 1 to

‘when dsvered) ‘076-00-2080

Intermediate fuel in accordance with ney

1s0 e217 1908,

Charactertos unis | category iso-r | Tos: rocecure

owe |” ‘ome

Dont a6-6 vom | mocew | meceoo [sosersenco ee

ec

Fagot © | me

‘ian a

Se = [ome

Sion was | men 20

Care abe nna

(carbon resiue mass | max 020

7 va | wear

seam vss | mac 007

edi aba ves |

te wax | neces

Von rata

aba wo al

© DEUTZ MYM minimum requirement

Water and sede

‘Kipematloviscosty a 40°C

Lt vaio of eratity

‘DEUT2 MVM minimum queer

Depending on tne of oar and region

Fuel Specification

(Mioimum requirement

‘when delivered)

Intermediate fuel in accordance with

‘ASTM Designation: D 975-96

Appendix 12 to

‘TR 0199-99-2089

Test procedure

cones Zina een ea

‘9661 60°91 10 L1Z@ OSI Mi¥m ooueps090e UI ;paLeAOp YOU SjueWRuINbeR

ox coe st st ome

eect og occu stent ol aor

Scie eae esem eis ste

ooo oF aD NTN ONDE

a

om co [ol olor) m for] om | =| am

= we = eo_ [ae mu [ae

omex | -[ 2 = = |e eo | me | wee

‘acca @ = = ~ Jill =

sees & & & % ie] ms] 3

zee @ « « [« w fe

= Touro cies] = Jooinfores ooo] orcs | ove [vow | ce Joxe| ma] wm | anieanno

reson, wun | sven easeamemo

s]s] slo] »] «| |] «| 2) «lolol o al

cots ie] viel el tl ils] vita onan ns] ci | oul ots we] son cusicog- voneowoods

‘eBueyoxa Ish

(6802-66-6610 81

‘veh xipuoddy

Wo Axeow) Ho wenprso4

(Quawerynbos wnuwnu) UoReouIedg yang,

Zinga

V

Technical Circular

0199-99 -2091 en

5° Exchange

Prot

Medium and large size engines

(aba pi is

+ conan parts

+ oral eupeat mnt 58)

“This 5 Exchange is issued amongst otter hings because of

{© Rovison of the data on water quality

Irvoducton a the DEUTZ protect agent for cooing cut in 20 te cans

© Upiting of preduct recommendations Encosuos 1 ard 2

Contents

+ Goneea

2 Water quaey

Protective agen fr cooing cut

31 Chemical antcoroson agent

32 Antkosze agonts wth corosion inhibitors

83 Comoson nhs

4 Daas on cooing crcut

41 Nontorng of cooling excl

42 Cleaning of cooling circuit

43 Conlant esposal

Enclosures $ and 2: Prodvt recommendations for cooling ckcult protective gents

Enclosure 3: Disposal of DEUTZ cooing systems protective agont ony n German issue)

1. General

Coolants of iquc-cooed engines must bo rested ard montored since damage may sustined by

‘engine oerwse duo

© cavitation

© roozing

2 Water quality

‘The correct water quay important forth propaaton of the coon. no spselicaons are

provided bythe manufectrrsuppl, cer ang clean water must be usd within fe OXDWing

Frnt vales of nays

Lit vats fanaa

ofan 206 :

oe on content moda

Sulphate ioncorore_ mom

Fomtnerdnoss “oGH

“share ct carbonate harnae nha over hanes in, ach

or mare ifrmation on tho wator quality plesse consul your local waterworks oruse th OEUTZ

toate, Order No. 12190382.

Water treatment is inciated water quails gfe rm the above nested int valve of

analysis,

© pitvalve too low

‘Ad dst cast soda or potash hye and mi

Proparation of smal sample mists ie recommended

“otal water nardnoss too high:

‘Macwith stoned water"

Total hardness andor carbonate hardness too low

Mx with waar of ahighernaronese

chloride andor sulphate content too high

Nex wih sft water

" _Sotaned waar ded alr, natal endarel or wale eled by on exchanger

* terete Wonerharnes aaa nt ass nformof potable water own we).

se the DEUTZ test Hi ord No. 12180382) fora determination, theives of ara of

the water to be samised are unknown,

For salty easons its mandstory to cary out anaher water analysis ater wae Yeatnent

‘Sea water, iver waar, bescish wate onus waste water aren nocagesulabiofor

‘ne preparation of he coolant since damago may bo sustained bythe engine,

3, Protective agent for cooling circuit

“The coolants prepared by acing a protective agent othe cooling waters @ poection of he

cooing crcl. The folowing aaaives are commonly uss

‘© Chemica anticoresion agent

“Aresze agent wit) corrosion nibs

© Corosion ining of

“The typeof advo can be selected according tothe following abe

‘harvest —— | Aicza sae wih Caroma

anicmoaonsaet_ | “eomeaon nn intr ot

an va el wos

cos tn von etn

~ Only the aatrezo fox chokes normaly 10 be exchanged every 2 years

Enclosure 1 lists up some representative products which ae recommend by us and which as

indicated bythe manufacurisuppers aro sutabl forthe processing of coolants. Alo chet

nual products of oer manfacturrsupprs may be used as analtematve.Sutabiy ofthe

protective agente the cooing crcultmostbe warrartetiquararted by the ranufacurersuppl

No abt is accopted by us.

ne vanous protec agents tr the cotng excl ara deserbed belon

3.4 Chemical anticorrosion agent

Chomicalanticoroston agents ae compounds whichby vay of cheieaeacon forma protective

fimon te metal sufeces. Ther advantage compared coresion bing 3 es nthe ene oF

‘application and mentorng,

LUguidadatves maybe admixed dec inthe engin, addves powder fom aretobe pre mised

‘The manufacturer sinsvuctons mustbo adhere to wahreqartothconceraton ofthe chemies

anicorrosion agent and subsequent motoring,

“The manufacturrsupiler shal warrant hat his adives donot have a detent oct on the

matrils used nthe engine (eg sealsiaskets)

Bo careful wih aluminium component inthe cooing ccut. Not llchemialanticaroson agents

‘ae sulabioin sun cases, cect dosing of parca mportanca since os Iw a concentration

{tthe chemical anicaresion agont wi have a Garaging effect on the system. Alo considered

‘ha it of rcommendoa products (900 Enos 1) the Sula ofthe akeoresion agent or

‘engines ith alumni componscts.

‘Mako sure that aluminum components ae property grounded , no adatonallecccurens may

be ndced by tase alumanism comgonants Wa doecive sults (single poe sensors an

‘montring sensors.

Chemica entcorosion agents containing sia may have anagatve eect onthe service fe

of ho anatface seats Such products should only to used fr engines which seperately

‘mourtecootan pumps equpped lh seals whicharrestanktothesa chemical anisasion

‘gents,

Fier systems are avalable as an aerate, capable offitring outsold partls om the

cooing cut in addion to providing» protection aginst comoton. These firs cota &

‘homical anioorosion agent old form which gradually Sealed nth cooing water

(Chemica enticontosion agents snd atieezes a per Secon 8.2 aro compat

[EF Notalichomicalanicorrsion agents and antfreeze agent are compatible. Carcnogenic

hirsarines wll fom wen taxing amine based chemieal antoorasion eget, uh

Irate based antiteeze agents. For compatilty please consut the marwacuret|

supper.

Nostofhorocommendedchomicalontcorosionagats maybe mxeduththeantironze

‘gon fom DEUTZ (an antiroaza based on style ye) wihout incurng ny Fk.

32 Antifocze agents with corrosion inhibitors

‘Anttoaza agents ar gonerly usd for OEUTZ engines ony ambient temperatrés below

‘zeoare aly tooccur. The akéreaze agent may bead tothe chemical antcrrasen agent

(aouoctresuppi o be contacted for comeatiity) or may be added to the wat asthe

‘ony protctive agent gainstfeezre endcorosion.Antiroaze agents basodon oto gol

‘a7 Used n goneral. The anoeosiesubstanos containas nthe anreezs are agerts wich

rovare corso by forming & groove fm onthe sre ft components

Prove fr tho fling concentrations:

[aresre agent [10x | ses | 20m | asx | oom | aon 25x | som

[water oo [osx [oom | 75% | 70m | oom sox | com

Jnuteare stave wie] we | 70 [00 | wo |480 [arc sso [4c

‘nan the anéroeze agen is used as the ony antrrosion gant (without any chemical

anizorosonagan tut ba leftin te colt Dott during wor and sme ime: rm

oncontaton 35%,

[ES Use of antteezereducs the heat tansfor confer thermal capac) of he coolant,

(hack wheter tho coolng crook ln out according.

Adie of corsion inhibiting ol emulsion is nt permissible

‘Best resis ao obsinod wh the DEUTZ protective agent for cooling circuits a8 an

ntreeze vith ancorrsio psbtrs. This eylene glycol based protective agent: cookng

{rcs Is matched tothe matrls usod on DEUTZ medium and large size enghes and

Subject to permanent contol and monoxng, This agent fs obainable from the DEUTZ

‘aniston ana is supe norm of

5 tro containers Pant no, 0101 1400

20 tire containers Part Mo, 0701 6416,

210 to bare art No. 1221 1500

ifthe OEUTZ protective agentfothe cooing rout shoul4notbe aval erimporant reasons

‘uch as supply resictons aboad, ther products may be used mn excotonal cases, Such

‘ternative produits have been grouped together in roduc groups sn at Isto pn Anox

{Products ofthe same rut group may be mid. Product ferent predict groups may

‘not be mixed. Tho entre cooing cet most be cleaned thoroughly belores proses change,

£33 Corrosion inhibiting ot

Uso corrosion ining os is a protiem bocauso ofthe poor sabi tho rulsion, the

resuling dfcutes i montoring and the potntal damage involved.

CCorosion iting a are emulsve mineral os with adstveswhichforathiprtectiv fm

Cn to components ofthe cooing cul preventing corrosion and faring.

‘he emulslon must bs prpared ina container outside the engin cooing water ckout aden

the speciiad amour of coreseninhbiing ol fo the water sing the Mate MexougN,

Concertraton as speci by tho manuactrersuppt.

Loss of coolant to be mado up fr, excessively ow concetations of carelon inhibiting eto

bo compensate by adeing a hay concentrated emulsion.

Comosion nhibng ois must not bo used fo:

cooling cuits win connacon to a comfort heating system

‘928 engin

4. Details of the cooling circuit

44 Regular checking ofthe cooling circuit

“The cooling ict mist be checked regulary (S60 custent Operating instructions) which

eludes checking or contamination and cocking othe coolant vel as wallasthe concanta-

Ton of he protective agents fhe coolng ecu

‘© Chemical antiarosion agent

(Chock concentaton sugabo tos fer testing such as lst rods ze supped by the

‘manufacurrssuppts.

Antirooze agent wt cotoson nibs

Chock atteszo and anizarosion effects wih anttesze tester.

Corsten inning ot

(Chock conconraton of coroson inhibing ol with reactometr, check contin of

fenulson,

Renew coolant alas in c356 of

1 ingross of ran water

© Inross of be of

{© pronounced uri dus to caresion residues or other suspended mater

12 spent coroson iting emuision

tne antes

42 Cleaning of cootng circuit

‘Tne cooling cull mist be cleaned # contaminated, cortosion inibitg ol emulsion sent rn

{he caso of ube olor raw water ngross. Tho ena coolant must be caied Insvch as case od

‘ne cooing creut must be hushed using a suable datergort. Te cooling Grout mus 0 be

‘leaned when changing over fo anor ype of recive agent or he coating eeu

Sutable dtergent are offered onthe markt suabity must be guarantood bythe manufacturer

suppl, however.

43 Coolant disposal

‘The coolant musi not be rainediniotho sonage system, Deposaltobotaken carat byazameny

specialised inwastedsposainaocordanco itntnenstionallgalrqocemonts nde navuctons

the manvfacurersuppr.

{837 For disposal fhe DEUTZpreestve agent fe the cooing ckcut wthin he Federal Republic

‘of Germany please rte to Annex publned n German ony

DeUrZ AG

Serve Infrmaton Systems

aM, the

Somniag “ssctoarn =

Annexes

Recommended Products

Protective agents for cooling circuit

‘annex 110

TR Y199 - 99 - 2091

° 5 Exchange

z 12004

Antifreeze Agents with Corrosion Inhibitors

Product Group A: for medium and nage sie engines

Product Group 8 for medium sie engines,

Product Paanutsctuer? | Prodvet Name Notes

Group |Suppier avalon

evrene | cxngeytm rena coe me

Protos cate 20 irecomainer

PN 1221 $800 240 fre bel

Namassiya | WAAnINZAL Super

reacousa | savotna Etna conten HELAC) | ISA wo Mt na Maton

unfedteSeomn et)

Recommended Products

Protective agents for cooling circuit

Chemical Anticorrosion Agents

‘Annex 2 to

TR 0199-£9- 2091

‘5 Exchange

12004

Wanufacurer) | Product name TGenienores | Garenpres [omtengnes [Noles

supoer meses | “asete | eeu,

Tan x

er x

ay ‘in ey” x x

(wasn ya x 5 rmaspten

nocontinse

Corrosion inhibiting oils — not for gas engines —

anutactred rode name ‘lose sgines Tos

supplier 294,616, 2070, 4,620, 2020,

‘28, B40, 648

Technical Circular

0199-99 - 2094 en

5” Exchange

DEUTZ fecal

Medium and large size engines

(aerogenes

Faw yt

Fe” Satan

Engine coolant for DEUTZ medium and large-size engines

‘This 5* Exchange is issued amongst other things bocause ofa

1¢ Rovision ofthe deta on water quay

Ineducton ofthe DEUTZ protective agent for cooling cut n 20 is cans

‘¢ Upsating of product ocommendatons, Encosures and 2

Contents,

2 Water quatty

Protective agent or cocking cect

3.1 Chemical antcaresion agent

82 Airocze agons with corrosion nhbtors

33. Comosion inhibitors

4. Datals. on cooing cet

4.4 Monitcng of coating cet

42 Clearing of coling excut

43 Coolant eisposal

Enolosues 1 and 2: Product racommendstios for coolng crcl protective ages

Enclose 3: Discos of DEUTZ coating systems protective agent onlin German issue)

1 General

‘Cools of qu salad engines must be reted and mentored since damage may suaained by

‘engine othrwisa duo to

© conesion

© aviation

© roszing

2 Water quality

“Th cere water quay ingetat for he preparation ofthe cola. tro specfeabons are

provided by tno marufsturesuppler, er and clean wator must be used wihintolotowing

Font values of analy:

Limit vas of anais

PH vaue at 20°C .

{ioe on content ald

Sulphate on content ald

Totalherdnese "3GH

For moc inermaton onthe water quay please consult your local waterworks cr us th» DEUTZ

{wath Order No. 12130382

‘later treatment i indicated water quali der rom the above Insted ln alues of

analysis

(© value too tow

‘aiuto cause soda ox potash yo and mix

Dreparston of small argo mature ie acornmendod

“otal wator hardness too high:

ie with softened water"

“otal hardness andlor carbonate hardness too low

Nex with water of higher hardness

Chori andor sulphate contont too high

‘x ith stones water ™

> sofenos water sting ler 9 eure cndentle waar eae by on exchanger

Wl ta irene aaeiein most ass nom cf polbewater on vate).

seth DEUTZ test ht (order No. 12130382} fara doterminaton, fhe it valios of analysis of

the water to be admixed are unknown.

For soe reasons tis mandatory to carryout anchor water analysis after water tesmont

‘Sea water, ror war, brackish wale orinustial waste wate aren nocasesitabofor

the preparation ofthe conan sine damage may be sustained bythe engine

3. Protective agent for cooling circuit

‘The coolant is prepared by adding a protective agent othe cooing water aa protection ofthe

ootng oxcult The allowing adtves are commonly used

‘© Chemical antearosion agent

© Aicesze agent wit corrosion nibs

© Comrsio inning ot

‘The typeof advo can be selected acoaxdng tothe folowing abe:

‘hana | ean aarti Corea

anteoresen agent | “Soros bis long ot

aan ma = oo

Saetcornon

een sation sattcry wot

Spelt

erasure oe veorn|

psn tity wos rst

™ Oniy the anireze effects chockos normaly 0 be exchanged every 2 years

Enclosure 1 ss up somo representative produts whieh are reconmmended by us and which as

Indicated by the menulacturrssupplrs a sotabo forthe grovessing of olets. Also et

equivalent products ofcer manufactre/supplors may be used as an atenabve, Sub othe

protective agent forthe cooling cul must be warartlguaranteeaby the mrwtacutr/sppa

No taba is accoptd by us.

ne venous protective agents forthe cooling cut ara deserbed below.

CChomical antcorrosion agent

Chemical anticrosion agent are compounds which by way of chemicaleacton forma protective

fimon te meta sufeces. Ther advantage compared fo caresion inhibiting as bs inthe case at

application and monorng.

quid dives may be admixed ectynthe engine adtives in powder lormareto be pre mixes,

‘Themanufacteresinstuctons mustbe sahecoaowithtegand tothe conoentston of thechemcal

fantorasion agent and subsequent montorng

‘The manufactureisupler hal warrant that his adtves do no have a detrimental elect on the

maatils used ne enghe eg sealigakel),

‘8 careful wt aluminium components nthe cooking excl. Nt a chemical artcrrosion agents

{af sulabiain such cases cect osing of parca portance singe tolow a concentration

‘ofthe chemical anticarosion agont wat have @ damaging fect on the system. Ako considered

the ist of recommended products (seo Enciosu 1) te sua of he sncorosion agent ot

‘engines th akminium components,

‘Mako sure that aluminum comgonent are property grounded no adatona elec currents may

be induced by these aluminum components va Oolecve mauiston (ing poo sensors ond

monitoring snsors}.

CChomicalanticoresion agents containing sites may have anogatvofctonthe seven Me

ofthe axatface seals. Such products should only bo used fr engines which separately

‘mounted cootantpumps equpped ih seals whichafereistantothese chemical anicoosion

agents,

Fier systoms aco avait as an atamatne, capale of ang out sl patcles om the

oolng cteut in aditon to proving 2 proecion aganst cortoson. These Mrs conan 3

‘homiealatearsion agent in sold form ich gradual deel into coking water

‘Chemical entcorosion agents and anireszos as per Soxion 3.2 ae compattle.

[8 Notallchomicalantcorosion agers and aifroeze agents are compat. Cachogonic

hiresamines wil frm whon mixing amine based comical anzayroson ages with

hate based antifesze agents. For compatity please consult the manttecturer

supp.

'Nostotherecommended chemical ancrosion agents maybe mixed witht enéroez0

‘agent tom DEUTZ (on anifecze based on eylne geo) whut curing ay sk

‘3.2 Antirooze agents with correson inhibitors

Anttroeze agers are general used for OEUTZ engines only ambient temperatures belom

207 teat oon. The akéreeze agent may beaded tothe chemiealanicoroson agent

(manitactore/supler tobe contacted for comet) or may be ade fo the wat asthe

‘only proteive agent aga eezra end corosion_Antffeeze agentsbasod on etyine gel

fre usedin ones. Ths anteorrasie substances contained inthe sireaze are agonts which

‘rover coroson by fonring a retocve fm on the srtace of tho components

Provide forte folowing conconations:

[antoezeaoee ox | asx [on om som

[anttoezs techn] 0 | -re [oe] wo] tee [are | are asc

whan the antifosze age is used as tho ony antcrosion agent (wibout any chemical

inorasion agent must bo tin the cootnt both ding wor and summer tm: rnin

concentration 35%

[ES Use of antifosze reduces he hast ranatr coon thermal capacity) of the coolant,

(Chock whoter te ool cut is ad out accor.

-Admiture ofa carsion inhibit of emulsion isnt permis

Best resuts are obtained uh the DEUTZ protective agent for cooling circuits as an

_antosza with artiste nites. This elena gel based prtecva agent fr colng

{outs is mated to fhe mataals used on DEUTZ maciom ard lrge so engines and

Subject parmanort cone and renting, This aponts obtainable fom bw» DEUTZ

‘xganisatin ad is suppl in fom of

{5 re containers art No. 0104 1490,

20 ite containers PartNo. 0701 8416

210 re bare art No. 1224 1500

ine DEUTZproteobeagonttorthe cooling cout should nto avaiable foringortantcensons

such as supply restictons abroad, cher products may be used in excaponal cases, Soch

‘trative produts have bean groupes togehern roduc groups sha af sta up In Annox

4 Products tha samo grout groyp may be mixed. Product of fret oduct groups may

‘ot be mised. Tho entire coling cout must be cleaned thoroughly before produc han,

33 Corrosion inhibiting ot

Uso of corrosion ining ls @ problem because of he poor saily the amuse, the

resuling dete in montoring and the potel damage ved

‘comosonianbiting os ar emul mineral wth adstives which frm thin protective fm

‘onthe components ofthe cooing ercul preventing corrosion an fring,

“The emulsion must bo propre in container outs. he engin coalng wae cet adding

tha spected amount of coosion ining ol the water String the nature thorough.

‘Concenration a speed by the manufacturersupl.

038 of coolant to be made up fr, excessively iow concentrations of corrosion inning ito

‘be compensated by adn 2 high concentrated emulsion,

CCorsion inhibiting ols most nt be usd fe:

= cating crc with conection oa comfort heating syter

988 engines

4. Details ofthe cooling circuit

44 Rogular checking ofthe cooling circuit

‘he cooling cru must bo checked regulary (S60 cunt Oparating instructions) which

Includes checking fr contamination and checking of to coolartavelas wa as tho conconta

‘ton of te protective agents othe cong exc

‘© Chomicalantcerrsion agent

(Chock coneoriraton, sutabo too for testing such as fst reds te supped by the

‘manufacturers supp

Ariitoezeagont with corosionahbtors

(Check anteeze and ancorsion eects wih antioezo tester.

Corrosion ating of

(Chock concentaton of carosion ining ol with reacomster, check condon of

malin

‘Renaw coolant alway in cas6 of

1 ingossofraw water,

© Ingress of be of

1 pronounced twit due to corosion esdues or cther suspended mater

1 spent cozosoniibiting emusion

1 tne ansroeze agent to be renowed avry 2 years.

42 Cleaning of cooling circuit

“Te cooing cxcit must be cloned if contaminate, corrosion ning ol emulsions spent on

{no ca60 ube oor raw watr ingress. Tho entre coolant must be dalnedn such seas and

the cooing Creu must bo fused using 2 sutable detergent. Te cooling creut mus also be

‘Slane when changing ero another type of protective agont forthe cooking circu

Stabe detergents are ofered on the mark, suabity must be quaanteed by he man acters

suppl, however.

443 Coolant disposal

‘The coolant musth drsinedintote sewagesysem Disposaltoetaken care of by acompany

pacatsedin wast iaposalinacordsnosvthtnenatonallagalrequeements ad the suction

of the manufacturer supper.

{83° For dlsposal ofthe DEUTZ protective agont fr tho cooing cut within tho Fedora Republic

(of Germany please retro Annex (pubshed in Garman on),

beurzas

Service iformation Systems

Recommended Products

Protective agents for cooling circuit

‘Antifreeze Agents with Corrosion Inhibitors

Protet Group A: for masum and ange ize engines

Pret Group B: for mad se engines

‘Annex 11

R199 -99 - 2001

5 Exchange

1/2004

Froavet uonociw! — | Prodi Name ots

oun. |Siocier Seta n

ecurzxc | coongsyaam once out

foray et 2 insconaer I

ea ss00 20 inebura!

eucter emma

ramausris — | WAAL Sper

sm ensiat

‘otuoanes

roneatmscoanttecey

‘Annex to

TR 0199-99 - 2001,

5" Excrange

07/2008

Recommended Products

| Protective agents for cooting circuit

DEUTZ

Chemical Anticorrosion Agents

Tiare) —[patataas | ace ma

=

ee mi

in ae or l

roaigee [see ceo ico

Correson bing sar 8 eres

aan RS pees os

ene

Technical Circular

0199 - 99-2116 en

2 Product:

DEUTZ | _ceurzuosumonl ian enone

Copa: exo

+ Save: Paret Ao 04 Road

Serie Catone

Copan Beare (02)

‘nl eqn mance (028)

Dawnupty YS: Por: ora) 2607

Teoma noe Pore Ben} 207

No ‘he art nbs cn dort re aaa etree

Engine corrosion protection for medium and large engines

1 Genera

2 Removal of ceoson protacton

21 Removal of corrosion protection rom extaior pats

2.2 Removal of corosien protection rom ntrie spaces

2.24 Lubeatng of system

2.22 Cooling i system

4 Subsoquont corrosion protaction or enghes wich have not yet beon installed

31 Gover operations

32 Exteorcorsion protection

2.3 Interior comosion protection

283 Labicatng of system

232 Fuslsystam

333 Staring ak and intake systom

334 Cooling ti system

34 Packaging

4 Corrosion protection in the event of lng pais of inperation

5 Comosionprotetion agents /cearng agents

1 Generat

‘The engines taching parts snd placement prs ar protected against corrosion bof beng

shipped fom the plant. The duration of potacton aganst corrosion depends onthe ype of

‘corosion protacton, packaging and storage conditions atthe placs of metalation

ful comosion protection fr upto 24 months fs possible, ands cao out special seed by

the customer

2 Removal of corrosion protection

Porto tho int operation of an engine or eptacement pat, the corosion potecton must be

removed nhs cas, th engine must be checked fer crtsson damage de to mole and

other damage.

Moving parts must be chacked for ese of movermat. Tun the crankshaft once with th incor

valves open and te spark o glow plugs removed, and ensure that te components move in

hora manner

2.1 Removal of corrosion protection from exterior parts

‘xtror corrosion protection must be removed a allows:

© Romove packaging

© ttnecessary, remove drying agents

© Wash off a srfaces which are coated wth comosion protection agent th us site or 8

sultablo leaning agent. see Table-on Page 5.

© ttnecessay, wash V-belt psy groowes oft

© Romove all covers tom sealed spectre, e.g rom intake aperture tor combustion ait

‘oxhaust gas ott, cooling ld ines, ote,

22 Removal of corrosion protection from interior spaces

2.21 Lubricating ol system

'¢ to engine contains conosin poteton fie thi must be drained or pumped

‘© Fattne engin wit the hbiating ot spactid fo operation,

Fushing sn necessary.

2.2.2 Cooling tid system

'¢ _inthoevontoftoeabilty between the exiting coxtosion protection agent andthe coating ad

mintire whieh isto bo Used, tis can be fied decty lo the cooling sytem

ss spect,

‘© the tolerabty ofthe exstng cooson protection agent andthe cool fi istro

whic iso be used Is not knowin vith solo catainy fishing mst be cd ut wh

lean water for approx. 18 meses, before filing the system wth the cooing hkl

3 Subsequent corrosion protection for engines which have not yet been

Installed

tthe maximum dation of corrosion protection has been reached the engies or oplacomant

arts rust bo subjected to subsequont corrosion protection,

‘Subsequent corosion protection prtects the engine of replacement par for approx. Kathir 3

‘month Ta procedure fr this flows:

BA Goneral operations

‘© Mark the poston of the flywheel or the crankshaft flange. Deposits may form on the

fender ner the area of the piston rings. For this roason, the pions must be set to 3

ffferene postion each time caresion protcton scared ot

Clean engine with cleaning agent, Remove any inleations of ceresion with clearing

‘agent or mechanical.

© Folbwing trios and exter corrosion pretation, all engin apotures (rake aperture

exhaust gas outet cool Mid thes, tc) must bo equppod wl al and water ight

‘overs in oreo provi protection against dit and condensation

32 Exterior corrosion protection

‘© Brush or spray corrosion protection agent ont al bare pats

‘© Gronse contol ods and jos with peotectve grease

‘© Brush crankshaft flange wih cortsbn protection agent, and wrap tightly oF cover wth

follor packing coh

‘© Rub rubber pats o.V-bat ith alum power.

[EG] Rubber parts must not come ko contact we fi, gease orp.

{23 Interior corosion protection

{33.1 Lubricating ol system

‘Ths cludes the ollpan,heseatng of pump, hbricating ol cooker, id pressure contol vate,

‘Mbiatng ote, resting of channels, erankshat con ed and camshat bearings, push rods

‘ot vale ters and kanes of nes.

© Wash engine compartment anol pan outwith dst fe

‘© Spray ort cleaned spaces and components with cottosion protection tid. Creat tho

‘roson protection hid which has been fl in wth 2 maruol pump oF soprata pum.

inthis ese, rotata the crankshaft marualy or with an eleteal turing dove, 0 that

ff the bearings and ners are costed

Ifo manual punp oF soparata pump Is avalabl, tho Ru may be forced tough the

lubricating of ercut ath the attached tbresting 08 pump. To achieve th, arn the

fngine over wah the starter wshout sath the engi

‘© Remove the eynder nead cover and spray tho vas, together wit the rocker arms, oe

th corrosion protection fd.

i

‘© Remove the injection vakes and spark or gow plugs. With pistons in BDC postion

spray the combustion chambers Uwough the apertie. In the case of ences ith

lankesse cover, sbsequorty tring the pistons to TDC poston and spay the ey

liners and engine compartment fom below.

© Drain wbrcating of from all altos! faces wh separate hid fing ard top up

‘wah new corso protection hd

2:22 Fuel system

‘This inches tho injection vals, us ie, a pun, ovariow vo, el Koes a tak

© Fite hel tank with a mixture of

1596 ‘coosion protection his

and pump onwards unt the ful system has been filed. Fuel msy remain stn the

Syston

3.35 Starting ar and intake system

1© nthe case of engines whlch ar stated with composted a, pour approx. 14 | corrosion

Protection tui into the man starter ine and tun the engie over bey with exposed

Si hut starting

‘© Spray conosion protection fil ito the intake pipe.

3.244 Coofing uid syst

{© Fatt cooing id systom wath a icure of

5 to 1% cotrosionprotosion agent

the est clan water

and ckeulate wth an external pump. Then ein the mbxure of, Leave the drainage

vaes open,

4 Packaging

(©The packaging must be replaced,

4 Corrosion protection in the event of long periods of

joperation

Irengins which have sendy boon installed ae not operate for long patos af tne, engine

‘corrosion protection recortmondod. The engine fs protocted for approx. S months via Ns

atosion protection In this case, jrocaed as folons

‘© Engines which ee operated with ful mite must bo sched to, and operated wih

‘sil ol for at aes hours before belng st of

© Drain Wel, brain and cooking ti

© Thoroughty lean engine compononts engi compartment, ol pan, eyder head wth

rocker ams and vas wah vale sping wth dite uso leaning ag

‘© Fi comosion protection fd at east up to the lower fd level mark, and overate the

engine a fl speed for approx. 15 minutes without oad

‘© Subsequenty cay out futher interior snd exterior corrsion prtection as in Sections

3310333

‘© Foloving introe and exterior cortosion protection, all engin apertures (take aperture,

‘exhaust gas outet. ete) must be ogulpped with ae and watertight covers In cet to

provide protection against dt and condetston,

© Fotowing corrosion protection, store the engine in dy, wal vetlated rom,

5 Corrosion protection agents / cleaning agents

‘The folowing provides reference Is of applicable cortsion protection agnts and cleaning agents

\wth wich optimum esis hae been achved, Equant products may ss) be used where the

Supper must quran the stat ofthe product fr the relevant usage,

Name Usage Product designation

eat ‘Omnigenge components Dosa ccaaHg

‘tg aon news

Carson retacion 4a | tubing ot syrancovasin pean | Beek ¥ naa SAEIOW.I0

‘Coreson eae or seat act | BENE SO

vatnoun eg

{Sian dts nxn

Caren cena | amgtasora concn | Pe

‘canosen pasion ager ‘en

Prac yas Forcoolos rans Seeauee

‘Casing agent Asreqaed atpe S258

Fem a Cre Gi

oEUTZAG.

Service: Engng

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Parts Catalogue DI 16 Marine EnginesDocument745 pagesParts Catalogue DI 16 Marine EnginesMiguel Ruivo Almeida89% (9)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Daf 1160 User ManualDocument80 pagesDaf 1160 User ManualMiguel Ruivo Almeida0% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CENTA - Compact Seal - Assembly & Operating ManualDocument20 pagesCENTA - Compact Seal - Assembly & Operating ManualMiguel Ruivo AlmeidaNo ratings yet

- DF4 5 6Document60 pagesDF4 5 6Miguel Ruivo Almeida0% (1)

- DF4 5 6 MedidasDocument2 pagesDF4 5 6 MedidasMiguel Ruivo AlmeidaNo ratings yet

- Materiais Dentarios-BiomateriaisDocument9 pagesMateriais Dentarios-BiomateriaisMiguel Ruivo AlmeidaNo ratings yet

- The Machine 5hown Here 15 Without Guard5 For Pre5Entati PurpoDocument4 pagesThe Machine 5hown Here 15 Without Guard5 For Pre5Entati PurpoMiguel Ruivo AlmeidaNo ratings yet

- Grundfosliterature 970920 PDFDocument36 pagesGrundfosliterature 970920 PDFMiguel Ruivo AlmeidaNo ratings yet

- Id Dcu Marine 2.2.2Document168 pagesId Dcu Marine 2.2.2Miguel Ruivo AlmeidaNo ratings yet

- Jonhson Pump F9B-5600 - E2011Document32 pagesJonhson Pump F9B-5600 - E2011Miguel Ruivo AlmeidaNo ratings yet

- Johnson Pump F8B-5001 - P96Document24 pagesJohnson Pump F8B-5001 - P96Miguel Ruivo AlmeidaNo ratings yet

- CENTA - Assembly and Operating InstructionsDocument18 pagesCENTA - Assembly and Operating InstructionsMiguel Ruivo Almeida100% (1)

- Pagina 14-38 (Manual Boxcoolers)Document26 pagesPagina 14-38 (Manual Boxcoolers)Miguel Ruivo AlmeidaNo ratings yet

- Deutz 1Document256 pagesDeutz 1Miguel Ruivo Almeida100% (1)