Professional Documents

Culture Documents

Ug-32 Formed Heads, and Sections, Pressure On Concave Side (A)

Uploaded by

Shukri NasirOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ug-32 Formed Heads, and Sections, Pressure On Concave Side (A)

Uploaded by

Shukri NasirCopyright:

Available Formats

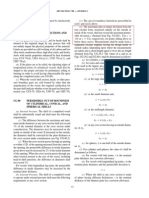

UG-32 FORMED HEADS, AND SECTIONS, PRESSURE ON CONCAVE SIDE

(a) The minimum required thickness at the thinnest point after forming22 of ellipsoidal, torispherical,

hemispherical, conical, and toriconical heads under pressure on the concave side (plus heads) shall be

computed by the appropriate formulas in this paragraph,23 except as permitted by Mandatory Appendix

32. Heads with bolting flanges shall meet the requirements of UG-35.1. In addition,m provision shall be

made for any of the loadings listed in UG-22. The provided thickness of the heads shall also meet the

requirements of UG-16, except as permitted in Mandatory Appendix 32.

(b) The symbols defined below are used in the formulas of this paragraph:

D = inside diameter of the head skirt; or inside length of the major axis of an ellipsoidal head; or

inside diameter of a conical head at the point under consideration , measured perpendicular to the

longitudinal axis

S = maximum allowable stress value in tension as given in the tables referenced in UG-23, except

as limited in UG-24 and (d) below.

E = lowest efficiency of any joint in the head; for hemispherical heads this includes headtoshell

joint; for welded vessels, use the efficiency specified in UW-12

L = inside spherical or crown radius. The value of L for ellipsoidal heads shall be obtained from

Table UG-37.

t = minimum required thickness of head after forming

(c) Ellipsoidal Heads With t s/L 0.002. The required thickness of a dished head of semiellipsoidal

form, in which half the minor axis (inside depth of the head minus the skirt) equals onefourth of the inside

diameter of the head skirt, shall be determined by

NOTE: For ellipsoidal heads with t s/L < 0.002, the rules of 1-4(f) shall also be met.

An acceptable approximation of a 2:1 ellipsoidal head is one with a knuckle radius of 0.17D and a spherical

radius of 0.90D.

You might also like

- UG-23 UG-24 (D) : UG-32 Formed Heads, and Sections, Pressure On Concave SideDocument2 pagesUG-23 UG-24 (D) : UG-32 Formed Heads, and Sections, Pressure On Concave SideLinh0% (1)

- Asme BPVC 2021 Section Viii Div. 1-2 - Ug-32Document2 pagesAsme BPVC 2021 Section Viii Div. 1-2 - Ug-32canizales70No ratings yet

- Asme Secc 8Document9 pagesAsme Secc 8mario valenzuelaNo ratings yet

- 1-6 CUBIERTAS Forma Plana (Cabezas Atornilladas)Document5 pages1-6 CUBIERTAS Forma Plana (Cabezas Atornilladas)Luis EduardoNo ratings yet

- Pressure Vessels Lectures 95Document1 pagePressure Vessels Lectures 95Adeel NizamiNo ratings yet

- Flange Calc Design BasisDocument2 pagesFlange Calc Design BasisfaizalNo ratings yet

- Pressure Vessels Lectures 93Document1 pagePressure Vessels Lectures 93Adeel NizamiNo ratings yet

- Ug-27 Thickness of Shells Under Internal PressureDocument2 pagesUg-27 Thickness of Shells Under Internal PressureJ Angel HdzNo ratings yet

- ASME VIII CalculationDocument15 pagesASME VIII CalculationJoao Osmar Correa100% (1)

- ASME VIII CalculationDocument14 pagesASME VIII CalculationWan Wei100% (1)

- Basic Thickness Calculation of Shells Under Internal PressureDocument1 pageBasic Thickness Calculation of Shells Under Internal PressureRiaan PretoriusNo ratings yet

- Asme-Viii Re-Pad Calc's and MoreDocument15 pagesAsme-Viii Re-Pad Calc's and MoreDavid LambertNo ratings yet

- Pressure Vessels Lectures 96Document1 pagePressure Vessels Lectures 96Adeel NizamiNo ratings yet

- TL3 - Domed Head DesignDocument3 pagesTL3 - Domed Head DesignAfif RuzainiNo ratings yet

- Asme Ug-27, Ug-32 & Appendix 1Document5 pagesAsme Ug-27, Ug-32 & Appendix 1แบด พิษ100% (2)

- Pages From Asme Viii Div 1-2007Document2 pagesPages From Asme Viii Div 1-2007kaustubh_dec17No ratings yet

- Stress Analysis of High-Pressure Test Vessel: Introduction and SummaryDocument20 pagesStress Analysis of High-Pressure Test Vessel: Introduction and SummaryRones JúniorNo ratings yet

- API CalculationsDocument11 pagesAPI CalculationsMohammed Illiasuddin100% (1)

- Ibr BookDocument33 pagesIbr BookRaja JayachandranNo ratings yet

- ASME BPVC - VIII.1-2015 UG-27: UG-27 Thickness of Shells Under Internal PressureDocument2 pagesASME BPVC - VIII.1-2015 UG-27: UG-27 Thickness of Shells Under Internal PressureLinhNo ratings yet

- What Is Design Interpretation?Document17 pagesWhat Is Design Interpretation?Qaisir MehmoodNo ratings yet

- FA2015 Torispherical HeadDocument4 pagesFA2015 Torispherical HeadAshok SureshNo ratings yet

- Sec Viii d2 Art D-3Document12 pagesSec Viii d2 Art D-3Yuber Rodriguez HNo ratings yet

- Design of Heads and ClosuresDocument23 pagesDesign of Heads and ClosuresboiroyNo ratings yet

- Stresses in Cylindrical ShellDocument1 pageStresses in Cylindrical ShellmumNo ratings yet

- Design of HeadsDocument42 pagesDesign of HeadsSuresh SjNo ratings yet

- Aisi Example II-7Document24 pagesAisi Example II-7LauraMilenaHernándezTorresNo ratings yet

- Unit2B SSDocument8 pagesUnit2B SSRahul YadavNo ratings yet

- 1) Cylindrical Shells (Internal Pressure & Longitudinal Seams, Circumferential Stress) : When P 0.385SEDocument2 pages1) Cylindrical Shells (Internal Pressure & Longitudinal Seams, Circumferential Stress) : When P 0.385SEUmer Iftikhar AhmedNo ratings yet

- Press and Shrink FitsDocument11 pagesPress and Shrink FitsAhmed M TNo ratings yet

- Appendix 9 Jacketed Vessels: 9-1 ScopeDocument9 pagesAppendix 9 Jacketed Vessels: 9-1 ScopeYetkin ErdoğanNo ratings yet

- API 510 BasicsDocument40 pagesAPI 510 BasicsBalakumarNo ratings yet

- Shear DesignDocument17 pagesShear DesignAyez Sassin100% (1)

- Thickness API 510Document11 pagesThickness API 510Aleiser Quevedo Acuña100% (1)

- Perhitungan Konstruksi DasarDocument32 pagesPerhitungan Konstruksi DasarIhsan AskaNo ratings yet

- Mathcad - 539900-050-130 Padeye Pulling Skid 9.5 TDocument7 pagesMathcad - 539900-050-130 Padeye Pulling Skid 9.5 TPablo Diego Didoné100% (1)

- Lecture 3 External Pressure C1c8e496 66e8 4086 A720 0e726ced7edfDocument29 pagesLecture 3 External Pressure C1c8e496 66e8 4086 A720 0e726ced7edfAriHara SudhanNo ratings yet

- APPENDIX C - Determination of Embedment Lengths and Edge DistancesDocument1 pageAPPENDIX C - Determination of Embedment Lengths and Edge DistancespawkomNo ratings yet

- Anexo A. Parte 2 (Brida Cabezal A)Document2 pagesAnexo A. Parte 2 (Brida Cabezal A)Juan Diego QuevedoNo ratings yet

- Calculo de Brida Segun ASMEDocument29 pagesCalculo de Brida Segun ASMEakarcz6731No ratings yet

- What Is Design Interpretation?Document15 pagesWhat Is Design Interpretation?dhirajNo ratings yet

- Analyzing Taper Fits For ManufacturingDocument7 pagesAnalyzing Taper Fits For Manufacturingsalgado_24No ratings yet

- Combined Shell-Ring InertiaDocument13 pagesCombined Shell-Ring Inertianeurolepsia3790No ratings yet

- ASME CalculationDocument25 pagesASME Calculationalinor_tn100% (1)

- Part A1 Chapter 2 - ASME Code Calculations Stayed Surfaces Safety Valves FurnacesDocument25 pagesPart A1 Chapter 2 - ASME Code Calculations Stayed Surfaces Safety Valves Furnacesfujiman35100% (1)

- Loading On Pressure VesselDocument2 pagesLoading On Pressure VesselmumNo ratings yet

- Asme-Thickness Calculation FormulasDocument13 pagesAsme-Thickness Calculation FormulasSundara Moorthy100% (1)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Pressure Vessel and Stacks Field Repair ManualFrom EverandPressure Vessel and Stacks Field Repair ManualRating: 4 out of 5 stars4/5 (4)

- Stress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsFrom EverandStress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsNo ratings yet

- A Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderFrom EverandA Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderNo ratings yet

- Projek CniDocument21 pagesProjek CniShukri NasirNo ratings yet

- Projek CniDocument21 pagesProjek CniShukri NasirNo ratings yet

- Technical Writing: Community IssueDocument9 pagesTechnical Writing: Community IssueShukri NasirNo ratings yet

- Projek CniDocument21 pagesProjek CniShukri NasirNo ratings yet