Professional Documents

Culture Documents

Kawasaki 65ZV-2

Uploaded by

Nguyen Ngoc100%(16)100% found this document useful (16 votes)

4K views503 pagesKawasaki 65ZV-2 workshop manual

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentKawasaki 65ZV-2 workshop manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(16)100% found this document useful (16 votes)

4K views503 pagesKawasaki 65ZV-2

Uploaded by

Nguyen NgocKawasaki 65ZV-2 workshop manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 503

Kawasaki 93207-00771

n= ‘August 2014

SHOP MANUAL

WHEEL LOADER

65ZV-2

General Information

Standard Measurement Values for

Performance Check

Function & Structure

Check & Adjustment

Powored by luzu 4HKX Engine

Serial No. 6544-9001 and up

8207-00774

‘gust 2011

Foreword

“To ensure good machine performance, reduce atures or problems, an prolong the Senice Meo each component,

licnacessary o operate the machine as drat in the Operate and Mantenance Manual.

‘o-flecvely diagnose and repr the machin, iis important io fotow te guidlines ai out nhs Shop Manu

General information

Funetion and structure

Forthe engine refer to he engine Shop Manual provided bythe engine manufacturer,

“The purpose ofthis ranual so provide information onthe product athe coe malserance and repair math

‘cs, Plese read mis manvalo ensure cones toublchooting and good pai sevice.

“Tis manual wil te gevodeally reviews and vevsed fr ore saisectry conten. you have any epiion or

equess pleas Inform us

Safety Symbols

‘0 accident may occur ifyou daregard safety res

In tis manual, several expressions are used according o levels of dange: for nepecon ad repair work ae shou

below. Read the work procedures and cautions deserbed in his manual, and take provenive meacures egainst

poset prebions balote staring serves wok,

“Tis danger symbol Wenites special warnings or |

procecues which, If not sty observed, il fest

fr death o seni nary

‘This warning symbol idenifes special wamings or

procedures which, Ino stl odsorveo, ould est

Fdeath or seous jury.

PST

This cauton symbol erties spec! inerucions or

procedures whieh, If net stil observed, may res

Ir minor or macerate nun.

IMPORTANT

or procedures whch, i not correctly flowed, may

tesutin serous machine damage ‘|

We canrot presi all posible zccens or inccens tht ay occur during service werk. Therefore, an aceidet that

isnot special mertoned in is manus may eccu To potctyoursell Fem all accents, be caret wen dong

CONTENTS,

(6520-2 Genera Information

How o Use Manual

Satety precautions

‘Symtols

Outing

Layout of main components

Inspection and maintenance table

Recommended Lubicans

Coolant

Lubrication chart

‘Weight of main components

Bot tottering torque

ese band ightoningtoreue

Liguid gasket ana sere ok agent

‘Cautions regarding welding repair sevice

(652-2 Measurement for Perfomance Check

‘cots on Satety

‘Standard Measurement Valves for Perfomance Check

(6520-2 Function & Structure Chasse Group

Front Chases

Lessing tnkage

Loading kage pi

Reor Chesle -

Fuel tank (SIN 9001-8012)

Fuel ank (SIN 9018-),

Foor board mount.

Center Pin

Upper cote in

Lower eente in

Dust sea!

{8520-2 Check & Adjustment Chasis Grup

kage Pin -

nee

‘center Pe

‘sting stim

002

02

Bfe222

00.10

oo

oot

00.16

oo

cote

oa

032

sea

122

122

124

126

125

126

127

128

128

128

26

1

132

132

14

104

{652V-2 Function & Sivcure Power Group

Power tine

Engine / Transmssion

Engine /transssion meunt

Racer

lator mount

Propetor Shah

‘Second proper shat assembly

‘Thi propeller shat assembly

ale Assembly 7

Ale Sopport

Diller Gear :

Function f 12D

Operation of PD

(6520-2 Check & Adjustment Power Gus

Engine

Measuring engine speed

Messung engine ol pressure

Propeter Sra

Propeller shat phase

‘Secor prope sh asgrment

Tightening torque -

'852V-2 Function & Stuchire Torque Converter and Transmission Group

Torque Converter

‘Terque converter sructre

Power Bow path

Torque mutipication

‘Torque Converter Gear Pump

Pump spaciicasons

2a

222

224

28

226

226

La

a

233

324

22

322

322

32.2

324

328

‘Tansmision -

Ccuch combination

‘Shitove poston

Dowrsit beton operation

CGesrtrin and number fteeth

Yate locaton

Ctch specications

Ccuteh Pac, os

Forw and reverse euten -

‘stand 2nd speed ctch

‘516 an ath speed cteh

Power Flow Path inthe Transmission

yeu Systm Olga

drut Grout Oagram

oiFtow

(Ot fow inthe torque converter ine

Ot ow tthe euteros

TiC 298 TM Ot Creviation

Cconttal Vale

itport yout

Modulation Mecham

(Catch contol a pressure curve

Mogtéaton mechanism operation

Accumulator

Accumulator for et and 2nd speed oktch

‘Chtch Solenoid Vave

Fer fowardreverse and speed utes

£652V-2 Check & Adjustment Torque Converter and Transmission Group

teh OF PHS ~

Mosung ch ol pressure

(952V-2 Functon & Stueture HyerauleGroup

Flushing Hyerauie Creu

Purpose of fusing

Coons on Hydaule Pants Replacement

24

224

a

28

32.28

2220

3229

3230

200

S841

392

232

an

«22

422

223

yorouieGreut Symbols...

Hyd

Pumps & motors

fscers

(Operation mettods

Presture con! vale

Flow contol vaive

Deconal contol vane

heck valve

Mscetenecus hyerauc synbos.

Hyareute System Operation

Hydaulc systor operation tine

Layout of crave Unis

drat Tank

Hyerauitank specications

Hyereulc ol level check

yore tant (SmI 8001-8700)

yout tank (SM 9101-)

Hyerautic Pum -

Hydrate pump specications

ydrause pump precip

Hycraute pump wear pate

Hydrate pump bushing lbricaton

ysrate yin

Boom cylinder

Steering ovine

Bucket cinder

Hydraulic yinderspecfestins

Leading System

Fescing Vv (or Po rossure)

Pot Vave (SIM 9001-9050)

ot vive funcon

Pot valve operation (modulated poston)

Pre-detnt and detent magnet solic

aoa

424

424

424

228

28

428

226

126

420

228

428

4240

aan

sat

aot

4292

4284

4246

4216

4207

4248

4248

22.49

aat9

aoe

42.20

aon

4222

422

e228

2226

42.26

42.28

Plot Vaio (SIN 9051=)

Pilot valve function

Pilot valve eperton (modulated poston)

Presdatent and cent magnet solenois

"Mutite Cotol Valve (KN.2227)

tiple contol vaive spcieations

Nutiple convo vate main reli valve

tiple cota vate overload ral vale (with maka function)

ple contol valve make valve

tiple conto vate bucket spool

Nustiple contol valve boom spo!

‘dap (Dice)

Fide Conta (OPT) oon

Fie conto hydrate cult

ise contol function

ie contol operation -

Ride contol valie azcembly

Accumulator fre cone)

Sterng System

Prorty Valve

Priory vate operation

roto

Valve System

to atte

tuo specication

‘opto operstin

‘ofive® fed back mechanism operation

String sped and fow ate conta

Hydauls pump ol amount and steering fence

Ci fow change when OrAmp. Is operated

rt rotor operation pineple

Emergency check vahe

Inet check ve

Aecumetsor

4220

4231

4291

4238

4238

42395

4296

4238

4240

424i

4249

4246

4248

ary

22.49

4251

42.66

2287

4269

4260

4269

4269

4263

4208

4265

4267

4268

42688

4269

4270

aon

273

ears

aaa

ficient Losing System (OPT)

ficient oading system outine

ourtng ofthe ELS vate

Mouming of the variable kickouteonscr

Eficint eading system operation

Fen Motor System

Mounting of on motor -

Fan Notor Line

Hydrate drut an moter normal ation)

Reversing Fan Moto Line (OFT).

Reversing fan moter function

Hydra cout (Reverse rotation) :

‘Secondary Steering

‘Seconds steering operation

Secondary steering motor and pump

{65ZV.2 Check &Adjuctmont Hysauie GIOUP nn

Loading Steting Creult Role VatvalRive Conta Ciel Reducing Vive (OPT)

‘Lesaing cut el valve setingprsvces

Fide cortl circuiting vale setting pressures (OPT)

‘Seerng cel ele valve sting pressures

Hydautie Clinger

de natural et

(652V-2 Function & Stucture Brake Group

Brake System Outing

Senses broke

Pathing rake

‘Adjustment of ade intemal pressure

‘Brake Units Layout

Unioader Valve

nose valve operation

ave Unt

Accumulator

nine Fier

4276

42.76

aor

4278

4278

4280

42.40

eat

4204

42.90

4298

42.05

42.96

4297

404

432

432

47

439

4512

412

24

22

22

22

22

23

24

525

26

228

29

rake vane

Brake valve performance chat

Brake valve outine

Senco Brake

Service brake cperation

Service brake Win plate

Service brake soe plate

Brake cheat alrbieding procacure

Passing Brake

Patking brake operation

Pething brake sclenoi valve

Parking Brake Nanval Release

Parking Brake Sering Chamber

Brake Crout Check Valve

Pressure Sensor (or stop amp and deck)

Pressure sensor fr decuch)

Preseure sensor (lr sop tame)

652V.2 Chock & Adjstment Brake Group :

rake Cout Ol Pressure

‘Unioaer vate seting pressure

Brake vave il prosure

Service Broke

‘Service brake performance ceck

‘Serve brake feton pate wear measucoment

Pathing Brake -

asking brake performance check

rking brake learance ajusiment

(652V-2 Function & Stuctue Eletreal Group

How to Use Elecical Wing Diagram

Uilsaton des schémas des cSbages lecques (FRANCAIS)

‘Verwendung ds elekischen Scnalpans DEUTSCH)

Modal utsz20 dete schema dei colegament lt (TALIANO)

Como uitzar un Diagrams de Alamtxade Eléctico(ESPAROL)

Como Ubizar 0 Diagrams de Ligagtes Eléctreas (PORTUGUES)

Electreal Cable Color Coves

8

se

0

et

622

ea

eo

es

26

7

28

lectical Creu Symboss - 9

‘Sensor Mount 6210

Fuse cott

Fuse bor ett

Fuse nk 6243

Engine Sart Circuit - cata

Engine str cout lagram cata

Nout! starer 6-15

‘Stare sith e216

ater ay cn e217

‘terrae tein ire a7

Diode unit : 0248

Neva eay e219

Safety relay 220

Power GeneratingCharging Circuit 221

‘Aerator e221

ECM (Engine Contr) : e272

uncon of CM eon

CConnactoneagram e222

Monto tam est

Diagnosis toute code (OTC) information .

Accelerator pedal

‘Transmission Convo Cues and Mero Cee

‘Machine contol unit MCU)

Machine cortrl uit (MCL) connection degram

Machine corr unit (MCU) uncon

Adjstatie doce preset etch

Montring syste

Instument Panel and Suen

Inseument pel -

Instrument pant rer surace

Gauge creat

Fuel lovel sensor 62.60

Moom

MOON fancoR

Monier Changeover

Information Monitor

‘Replacement Montor -

Fault Log Monitor os

InpuvOutput Merit

Parameter Seng Mortar

‘Speciation Sting Monitor

Electrical Detent Creat

‘Bucket eveler

Detect slene

Lit kickout lower Keka

Sensor assy

Detent sien

Prose eight exjstmant

Died

Diode check method

CCeution for aod check method

‘Surge votoge and suae suopession diodes

1652V-2 Function & Stucture Operate Station Group

cabin

ass

Weer meu.

Weer moter

Operator Seat

‘Steering and Transmission Shit Lever

Tixcase

Cohn shat

it ever

‘Ae Condtoner

Denso ai concstione components

Denso air conctoner structure

Function of cootng mechanism

cooing cet.

lect coat

[Ax condone unctons of components -

charge ofetigrant -

‘condone troubleshooting

1652V-2 Check & Adkistment Operatr Staion Group

‘ie Conditioner

Adjustment of ube ol quently wien components of a condone ar replaced

Adjustment os gop (betwoon hub and rot) compressor magnetic ditch

Compressor Vibe adusiment....

Paris tobe replaced paodeally

{52V-2 Drawing & Disgrams

‘nee Assembly

“Terque Converter and Transmission

Hydraulic & Brake Cxcult

Brake Cat

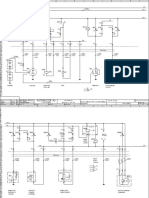

Elctical Wing Diagram (1/4) (SN 9001-2050)

ctl Wing Dsgram (24) (SN 8001-2050)

tectical Wing Diagram (34) (SIN 3001-9050) :

tetra Wing Diagram (ve) (SIN 9001-8050)

tect Wing Disrem (14) (SIN 8051~) -

"teeta Wing Diagram (24) (SIN 9051~)

lectical Wring Diagram (34) (SIN 8051~)

tetra Wing Diagram (44) (SIN SO51-)

Electra! Wing Diagram

lay ofookng at connectors

Electea wing aagram abbreviation chart

Electca Wing Diagram (CAB)...

Electrcat Comection Diagram (12) (SN 8001-5050)

Electical Connection Diagram (272) (SN 8001-8080)

Electcal Connection Diagram (12) (SiN S051)

re13

re19

r14

72-19

m2

72.28

72.28

7.82

7268

m2

132

738

136

sat

2

925

26

‘tects! Connection Diagram (212) (SIN 8051)

‘ecto Circuit Diagram (Cabin Ni Condkoner)

Seca Wiking Diagram (Cabin Ai Gondioner)

Equipment Operation Table (Cin Ar Contenes)

Eleccal Equipment Layout

(tne of MOOK (Machine Operation Diagnostic Module) Operation

[MODI InpulOutput Monitor InpwOutput Sra Correspondence Table

9228

92.28

92.28

92.28

s227

92.38

27

MEMO

1652v-2 General Information

65ZV-2 General Information

Hom to Use Maru 002

Outine. oo

02

582-2 General nfrmation

ow t Use Manat

How to Use Manual

Safety precautions

‘Toe mest important port in providing repair service is

satel To encore saely,cbeerve the genera coun

‘escrbed below.

This manoal is intended for propery tse and

eloped servic echnicians

‘Any wor: onthe machine mast be performes by he

trained personnel ony.

= Catfuly read tis manual thorohly understand

the operation mathod before you operate of repair

the machine

Be sure to wear appropriate ches and protectors,

‘such as stay bots, hard Hat and goggles

Place the machine on level and slid ground, ana

place chocks against the wheels fo prevent move:

Remove the cable from the battery belere stating

the sevice work, and attach a DONOT OPERATE

tag ee stein wheel

Be aur to eles the intemal pressure before you

remave @ pipe, such as the hyerale l,i oF

‘engine coolant pe

Be sure o apply the ariclaton stopper before siat-

ing wore,

+ While supporting the botiom af the chasis using 2

Jack, be sur lo Suppor the chasis using the blocks,

whan he boom or buckets ated or when 2 unt e

lites by 2 rara, be aur to place stand or 0-

{quate ring under the unt to revert imexpected

‘roping.

1 net stato workin an enclosed area acequate

venation set proviced,

+ To remove a heavy ust (20 kg (40 bs) or ere), be

sure 0 use 9 rane oroter ing devi,

est ater slopping operation, be caretul not 10

‘ect tucn aot eomponent. You may get burned.

Contact tie manutocuer' eel dealer fo tee ser

‘ing snd enanging,

Always store the tools In good condion, and use

thom propery.

+ Keep the work area clan. Clan up spls nme

siey,

+ Avoid he use of fammatie sents and cleaners,

= When working ouldore keep work ares, ladders

saps, dcks and work plats clear of sn. ce,

nd mad

+ Use safe work platiorms to reach higher areas of he

machine,

Any teria that operates a refigerant recovery

and rcyeing mactine must iret be cated hgh

[an EPA approved losing program,

Nore infoeration avaiable at tobawepa cou

‘soefiie®/A08tectniciansGdecers ns.

os

6520-2 General ntrmaton

How to Use Manual

‘Symbols.

For safe and effective service work, the folloving sym

bo ore used for notes ang ute informaton in is

manual

‘Symbor | tee Besaipton

[shows the condition 6 procedure hat wil bo useful

lorefciet in ding service work

(Shows te weigh of a pat oan, The wet

Ishould be consiereasoecting we rope ar cable

forging work or determing he worn poe~

Wiight

Ightering| Shows th ightning trae of ssn that should

Yorquo [be careful Ughtoned during assenbly wor

[snows te typ of coating or achesve anc the coat

coating |S te

Ob or

water

spy

[Shows the lo water supply port sn the ref

lout.

‘snows the oo water dain por and he rain

[amour |

Ee) of

IMPORTANT

Tike spcfied condi are rol saaied or he spaced posers wah

ocerved, are stor posbiy al he produ wr be dared the po

{ermaner fhe peut be roaute,

“he'mescage Shows be revarve measures.

‘Abbreviation

‘Te eaveepace, abbreviatons are used in sentences, To understand the contents of this manual, eer othe flow

Ing atorevition ie. Adetonalsbbreviatone are sted on page 9217

FIG son Engine RE ocoRighthandside Sd ono Spee

THe“ erue converter et nang side a at speed

“tne oS ranemision H igh gene

SOL 1 Soenois va L tow rnin Re

SW Stes Gxoceouna ELS 77 Ecent ding eyter

F Frontor Forward OPT. -Opton MOD “Machine operation dag:

a patent Assy Aasembly nostic made

B Batery ist ‘st speod MCU Machine contl unit

R RearorReverse hd 2nd peed

i]

(852V-2 Genera Information

Outing

Outline

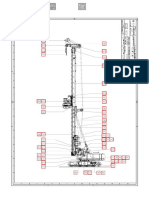

Layout of main components

pats oor-one)

(sitios

a

I

on on)

‘a(n 0-205) a

1. Engine ascorby (euzu HKTX) 10, Patking bake 49, Tranamiesioncootrel vive

2. TransmissonvTorque converter assy 11. Arcleaner 20. Bucket cylinder

5. Radiator sscomby tt Mute 21. Moist eyineor

4 Hyoraute ot cote Fen moter 22. Steering yi

5 Veateooer Hyeraute pump 23. Accumulator (or scoring)

dna propel sha 15. Mutipie (bade) contol vale 24. Pump unt (or secondary

1 18, Orbit” steering) (OPT)

a 17, Prony vale 25, ELS (OPT)

8. Rear ile eesembiy 18. Pit valve (er loading)

Inspection and maintenance table

(652V-2 General rfrmation

‘Outing

IMPORTANT.

Refer 1o Operation & Meintenanoe Manual for maints- tion require tore frequent mainis-

ee One Severe appteaton reo ‘requent maine

‘Severe conditions include heavy dust. extremely

sbrasive material, causic chemicals, extremely wet

‘conditions or abnormally hot or colt ambient temper-

4: Fat time replacement o clesing only

renga when

Ses feces WW] | 20 | 510 [www] zon] Revers

[eneacErin Gi ert ° I

[checctngneCoatretewst o

[eve Waring amas °

oor o

bran wins wat Sorat tam Ful Far ©

ee Fel me o

es nd ct Bove Bete oO

[heck irae Sm oO

hese Coole Fan °

Dron Wher ee Sow Ha Foe Tk o

Repsce Erg er OF Feria °

rae | Repos Fil Fir Cenens ©

ian Erna Fl Pun Fer °

han Fest Food Pup Sraner ©

Check Ergre Compression Presure oO

(Cesk oa ht ave tas Crane °

ian Fontan o

Regine Ectanaget Ful Pup ts Evert o

ian e Reo Caner Eat i

Chan Raat A oa pol csi Fos °

ae Reo A Clana lt ‘Riera cesringe oasce =" O

Fence Cott Evey ayers ra0Hb Fos ©)

Soo o

"gnenbsen | Ress Terese Ov Fier Coae ale |

cores [Regace Wansmesen Or o

[Gan Resace Tivo rear °

os.

52-2 General information

Outi

Firat time replacement or daring only

Serargroom

reais

eget

So

[raha Or

o

°

Garon as

sig ow Bec ra

rk anes of het ae

lofo/o|

[esha (dPepoter SS)

Felsen Gear OF

rear nc Prope Se)

rosea Repeat)

‘eng sen

[Crs eer Oooo

Grong (Seema Cae

[Sn Secs Bake Comat

"aa Psi ake ring

ek Sei rata

jolofo

tenet

Sack ye

[Sere

Repase aac Or Reon Far

Reto Wyre Ok Gran Fer

ferns Faw re Tok CopeEN-OTHD)

Repos Fieri aie Tnk eaters NOT)

ofo]o|

Fens Bat Tm on)

esis Cua Ee

ac an he Re Vewr

[ROP al Ow Proce Sm

oo

[Greaang Center Pr)

os Goer car on

(Grane Repo et at

oor

(652-2 General Information

‘Outing

2: Fst ime repiacomentor leaning only

‘ton wen eh —= vn,

Sanaa itor ©

[Seerton Gen °

ria) [CO nen OI ©

e 3

[ to

o

ea ad ai A lo aE o

Gan Crain Fer owen o

se cry [TRA Ce RE oe

ite Ts he tie Fe oe o

ev Cron Cod 7 °

eps Ar ir Rae D9 Bayar iii O

has [hacia cin o

owe

{65ZV.2 General Information

ating

Recommended Lubricants

Rett apacty | ey ‘Aeet Tempera 0) Change nova

(Approximate) WOFOH | gy Gene 0 to 29.30 40 | Grows)

Engine oil ae

Engine tether ee | shah 500

Tenuisin | some | Eranegiiemrer| | = 1000

trsrotetork | roiter | tyatacar | FP et leolau! || 20m

aren | Fo 25 tr Sa

aiwerdols [Fone 25186 | Engine (CO) 2060

nd ee

‘Nol: + shows "Hyeraul tank ol capacly at evel gauge cantar”

Engine

‘Transmission

Hydraulic System

itera &

Pranetary

Lutvestng Grease

Use ol thal meets engine ol classification API CFS

se engin ol casscation API CD or ATF (to Transmission Fd)

‘Never mix engine llana AT.

Use incustiatyee tyatoule ls which are ceifod by supple having antswear, an

foam, antnust and antroxiationaddtve properties for heavy duty use. Use ofthe wrong

vcosty ofl can cause improper apeaton of hyaic nctions or premature Pur a

3. Ina case that fro-esistnt ld is used in he hyeraute eu, some hyeraie up:

‘meni such as pumps andor fan mtr, must be relscedperodely,

Warning: When operating in col amber tomperaures (15 °C cr elder) ISO VE%2 or

{aulvalentnycrulc of use is recarimended. When changing ovr Yo cold cate

Fysraute of. hom Wicker ISO VEE to thine 160 VG22), Bake system bieodng

{1 each wee! hub wit be required fo remove thicker ol and prevent daly reaction

Of brake aplication and release,

Use cass API CD engine of wih 6% “Anche” adetive oration moder

Use motipupose-ypo EPIMOLY grease for most appliations,

LG! NO? grease fr suitable for most temperatres,

NLG! NO 1 er NO O gress fr exams law temperate.

Use isn base grease for universal janis ane a propel shat spine

08

1652V-2 General Infomation

Outi

‘ies Fuel Fegan

and Senet ek ra oe

Coolant Recommended mixture of antifreeze

Coolant specification

‘The machine fs orginal led wit Long Lite Cootant

(ron-amin type stisione jel) which nee not be

‘placed forthe Ws two yests or S000 hours.

‘Do ct use Amin type Long Life Coolant in cooling sys-

tem. may cause a coresion agaist rater or neater

It standad anieoze (ot Long Life Cooan)is used for

tho replacement, should be replaced every six

‘ont.

ror gare | 96 | 0 | 8

‘eovinw [ ot [124 | 188 | 74 | ves | BO

macro [oe |e | | | ®

Teo much anteeze in the coolant mixture may

cause engine overneating

Keep 39% antheeze mixture (same athe mare

fora mitmum ambient temperture of 19°C) he

‘engine overheats ina igh ambient erperatue

= Do not use hare water or water with high levels of

calcu end magnesium lon asthe coolant water.

IMPORTANT

‘Do not mk dierent brands of antvesze because

they each conain speci adctives

(Careless muing olen aminishos the ofc of hese

ecahves and causes packing damage oF water leak

202.

oot0

(8520-2 Genera information

Outing

Lubrication chart

6

° 6 Ho.

(Grease pote Msiparpose grease Hyrule ot

a so. To

‘Chock and adit recessary erat Engine i

o £0

Otreplacerent Engine ol

oot

(652-2 General Information

‘tine

Weight of main components

ee Tee] a

‘or | Ser ens

tirana oo pote es

iow ios atte

aioe tne ope |e

Erie oon a7 70 [S30 [racing bow

see 7 [Batnas

‘ao Rosh ic)

ne Trip re

Fine J

= J

Gear woah co |

Rada sro =

“on saa To 2

Powers Taco ep ak = [7

Tesi st [=

Frentane ror 3S [arpa

Rear sera 570] 0 |e an og

Taps eracave =f

i ae ee

recent are wpa

Beer ee Bpe_| one ahaa

That rer spe] He eharo a

Seog ara 2s | 546 | onarg at

ow = aie | oe [nn TN

oo-t2

520-2 General Information

Outine

Bolt tightening torque

Hexagon bolt

1. Thread ype

Mote tread, Unified trese

2. Bot suengin

acer) 109 (117)

8. Thread pn

etic tread: Coarse itch tread (C), foo pitch head

nied tireac: Coarse pth tvead (UNC), fe pitch Evosd (UNF)

vs

F oo oo

doe [Ses [Pe en act

eer a a

me Pe Be = =

nas = 5

wee = =

ae pw eee ca =

OE = =

we [rw CER i =

| oe a a

see a 7

oye = a

wenerene |e} gL ir oe

THE a 3

we a a a

we = oy

ewe ee a ii

we ee em

cn a

we pw ee aa

a —[ to sa

Tae a Ea

Noe: Tighten the bots according te he above st, unis cnerse spect,

oo-13

(652V-2 General nfrmation

‘Outing

tn)

ro ia aa

woe eT Ree [ion oo eo)

we Poe Ee 78

we 58 a

we pow Ls 32 35

wi 38 ca

me bow Be ry HD

ots oy Bs

ew L828, 0 =D

we ais ao =r

ae bow BPE spas

"Pas eo ae

wewemmee [2] Laer Be ee

is eo ws

mw bom Lose oro Bo

a ae as

we Poe Lee Bs co

we tow passe 5a 7580,

rz 50 1

we pw LS a8 Bie

ce pw Le ‘388, 200

a 700 30

fe [ane as TE

"Noe: Tighten he tots accortng tothe above et uns ohernse specie,

oo.te

82-2 General nfermation

Cuties

on

aa eR

we eee ee a ‘ean

pe are 7 =

wo | woes % =

Hi * =

we Pw Ee 7 =

ons He ie

we Pw ES we =

ors 1s ae

m=) we foes at m=

ens 2 a

warernee [yp Le 5 7

a a co

we) es a co

ms a oo

] ow ae se 7

we i ss 0

we | wee 73 a0

eae, w= 0

wa | we 8S To Te

129 a Tr

we a Lee ia 230

ca Te 20

Noto: Tighten th tls according tthe above st, unless otherwise spect.

Flanged hexagon bolt

1. Bott ype: Metre teas

2. Bot strength: 8.8 (67)

3. Threas pitch: Coase piten tweed (C)

so

ee i

ee ee Pach ean

oan

or Sameer

tes ae Pach ear)

Memeoness wiz 18 oe

om

te seen)

ro fess

cots

(652V-2 General Irfrmaton

urine

006

{852V-2 Genera Inornaton

Outies

Hose band tightening torque

retin any esonene | Tegpaeron | Tempter | Toherg ome

Ter fn Ome J Ged on

ma 3a | aR

a a | a ‘ « 2

Ta snes Nosema | Teheingiane | Tomsnngionn | Tate

Tere fn | a ian ton ‘on

To connect he hose tthe pipe, tahien the hese bande ang Domain,

the falowing poston

Liquid gasket and screw lock

agent

‘To reassemble the disassembled pas, be sure to use

the specied que gasket or seow lock agent or the

‘equivalent sccordng fo the fotoning Hts:

ss | tee | caer | tems

sere | exe | omens | retest

Cautions regarding parts removal

{9 acter or shat tobe removed hae been locked by

tne of the above agents, remove the str or shat

Using a general tool, seen 2s wrench or plo.

Ais eitfut to remove the sxe or aha, et ne bat

to soln the agent (200-260°C) sing Saering eon

orgae tore,

Caution

‘thee is a set near the sero” shat tobe roves,

catty use the heating method for removal, to avec

amage io he sea

‘neat nas been used to remove the bolt a new bo

shouldbe used during reassembly.

oT

(6520-2 Genera infomation

‘outine

Cautions regarding reassembly

‘To reassemble a screw

Completely cerove the hardened lock agent fem the

Seren and the teased nola before reassembling the

Note

‘A pace of hardened lock agant may be pected off and

ramain In the component. The rtraring piece may

‘couse matiuneton urng fasion: saat

‘To bond a plane orto fit a shaft

Remove the hardaned loc

ent using wire brush or

‘he ike, ad pos the curses using ean paper Use of

‘a Locte® primer ite Looqui® Primer prepares mela)

urface ofthe treads and speeds curing tm.

Anticeize Agent

| tees 767

peor \oce|

(tego)

oo.t8

52-2 General Irfrmation

ute

Screw lock agent application procedure

‘Through-hole

‘apy sew lock agent one oF two Ines on the male

i

How to wind a seal tape

[As the screw f tightened by tuning clockwise, seal

{ape must be wound up dckwse drecton as shown

ove. noth ape lbs loosened or eroved wie

lightning to srom suiting in lescage

‘Toavoida pecs of sea! tape ein the cut. fave tor

2 czrews fom te end ofthe toad ard a hrasdog

IRoodose,

Slgny steteh the ape when cuting it out an press

‘te tape oro the sere teas.

Cautions regarding welding repair

service

I woling is needed to repair th chassis, observe the

{ofowing precautions to protact he hysraulic eyinders,

Iyer units, ger eel, and eleccal wits Worn pas.

bie camage

Cautions,

4 Tum he eater ewiteh OFF,

2. Romove the balley terminals both postive snd

negate sides rom te boty

8. Disconnaet the eannecor fo MCU (machine con

tole), ECM (engine contol snd Se condone.

4, Ground the welser near the seton tobe welded.

Example t

‘cores eure

Example?

(movant co

009

652-2 GoneralIrformaton

‘uti

5, Toground the welder, checkthat he eect erent

wil rot Row though the ender.

‘indore covers for seme models havea ow

‘conduve mel hat wa cause spark the welding

‘arent flows. The spark may eamage the cylinder

onet eon heen,

(regreasinces )

0.20

652V-2 GaneralInformtion

Outing

6. The weld spatered on the hyerauteeyinders and

lon he pated secons of pins wil damage the yin

{ers pin. There are other pata tet may

‘tragedy the spatter, hyerauke unis, har

rotsee, hydrate hoses, anc nylon tubes,

Be sure to mask these unis and pars before wee

Tiand oe one cen)

Jn acon unin

aan neta

EE

Pate seen en scien) ,

(@) Plated section

Cove he pled sections wih hestreseant ct,

such a lass woo! er eas,

Note

“The wed spattered onthe pated sections causes core:

; ce ‘Sold

— |

(0) Cover the mydraute unis, leces! unis, har

nesses, hycreulle hoses, nylon tutes, et. wth

earroastnt lh (lass woo or canvas) or scrap

atfal io prtoe them rom spat.

= _—

sera} 2 tebe

eer” ce

(2) Hycraulc hoses, nylon tubes, or hamesses are

‘easly camaged by the hea ding welding. To po

{act them fom ne neat, remove them from he 390-

tion obo wold to ck enough clearance,

ot

(652V-2 Measurement for Performance Check

65ZV-2 Measurement for

Performance Check

Ccoutons on Safety oo

Standerd Measurement Vales for Perlomance Check

03

a2

(652-2 Measuroment or Performance Check

Cavs on Satay

Cautions on Safety

PRG

‘Unexpected movement ofthe machine may cause an

codon resin nny or ces.

‘Theretore o prove reple sence win the engine

‘runing, Be sure to observe the flowing ea

atk te machine on loval grou

‘opr the park brake,

loathe hes with ctocks to prevent thea fom

‘movng,

Determine the signate between the service man.

Prost ary parson frm walong into Sanporous

* ost anioulston areas of he machine

Under he machine

‘cu the engine

Intont of ortehind the machine

‘Operation under he boom or the Bockel may leas 0

Make sue to apoly be sateylxk of he boom and

the buckot cane ever povided in the eb, remove

the starr key, nd stech @ "00 NOT OPERATE

tag to the ab,

Pe

Be cael not to be bunt By busting Ngh pressure

Release th pressure remaining inside the ct and

open the cap of tha hyaraule tank beter rereng

the plug forthe pressure measurement pt o that

{ho nema presetre ofthe hyarale tank released

an burt ofthe high presi ol can be preven

Entering the arbulaon ara of the machine body

wale the engine is runing may cause severe sect

Make suo to stop the engine, pus out the starter kay,

fand etiach 2 "DO NOT OPERATE tag 16 tho cab

bore entering the ariculation area,

Touching the fn arin V bat of he engine or he hot

fea wie the engi fe running mey cause Severe

Setoons.

Make sure to stop the engine before opening the

| stoneteam acre paa

033,

(652V-2 Mesaurement for Performance Check

‘Standard Measurement Values for Performan Check

Standard Measurement Values for Performance Check

Measurement conditions

Tomporaureoftergue converter oi: 50-80°C (120-100"F}

Tomporature of hyeraulic of: 60-B0°C (120-100"F)

“Temporaine of engine cola 30-60°C(120~160°F)

= eenmese|

a sana

bcos ea

EES, [imimminenmub aaa ena | astern | Sar

sapaesiegremme stamens eng | aw

iia oT nas |

ro oR Hae a

se toionaoainoge omer antma | Faso | ree

araratanr rete mt | vm | tom

7 een, |e fae Tae

i wea nate ipat [EBM PE mum E21 (98-2) 86-206)

E [ames fromnromnieeene a sicasnanne

£ ies Eee

034

{65ZV-2 Measurement fx Performance Cneck

Slanard Measurement Value for Perfomance Check

seas

Espresso

eae a Joccanar sires

seam lvceroma 1602)

mace fama vase

ses eoescens [Fo AT tara

Faro Ba

as eninonnes _[ratorar F03

arn 303

; ning tn ah atten a) age

i Loang re ove ee restr) a apt oe

Fleece ang ent nse manson

Kesar eo o omer

wig seed epee aang? figebtonerae

lane reduc prose 0) ago0 oer teed le

Fenmawran [Ira arowatre ae ts) oe

Sea” rem eeemeesee mary

soe

"Eh |e at get Re), 298

the dung force ofthe ok whee! fe smal. Ae 8

resul re tipping can be ecuces

‘men te diving Tore ofthe let whee! reduced

{slpping occurs), he cing ore of he right west

val be nveased To mit te Feducien in he Wott

‘Smunt of heaving oe

‘Assuming that he crn orque of he fh wheels Ta,

fps that of tn let wheel eT. the relation between Ty

land Tycan be expressed as flows:

Tee Bt

TR

‘The valve obtalnes trom the above formula eleres

to asthe bas fat. The kml of to ies alo 1.4 In

‘ther werd, ul the aference In he surges vease

tance between the ight and le thes Is incase fo

40%, the prion gear wll le propery engeged wa he

shifted se gears, ana driving force wil be properly

‘applied fo both he side gears to provant the es fom

spp

2. Ifthe surface resistance of the sight wh

‘ecuoed, he engagerent poston between the pe~

ton are se gears willbe shifted as show nae

{6} sve. n't case he gh ans eh ees are

‘overs compared vith the ebave description,

SZV-2 Function & Swveure Power Gru

MEMO

a

Powee Group

65ZV-2 Check & Adjustment

Power Group

Engine 202

Proper Shan 233

eszv-201

Engine

1 Adjustment Power Group

Engine

[Unexpected movernat of the machine may cause an

‘acedent resuting nin of death

‘Therefor, to prvce reper Serice wih the gine

runming, be swe observe the faowing tome!

Fark he machine on lov! ground

‘py the parking broke,

Block ie res wih chocks to prevent he thes ftom

Determine the signals betwoon the sovice men

roti any person fom wating info dangerous

Near rtcwation tea ofthe machine

Under the machine

Pound he engi

In font for behind the machine

Do not ouch he fan or V-be ofthe engine ohh

“ampertutesecton the engin unning,

Be cure to stop tne engine Bolore you open the se

cover ef tha engine roe.

Keep a guards in pice.

‘Avot high temperature components even when the

feng stopped

Use a pote tachometer when checking engin revo-

Measuring engine speed

Measurement instrument

Standard measurement value

Low tte (on) a0050

Hg ie (i: 2450850 (8190019060)

2.410450 [9 905"

Measuring engine oil pressure

Measurement instrument

= Pressure gauge

Inst

position

2. Messuring pot §10x1.00,

3. Oll pressure gouge: .0 MPa (10 Ke) (150g)

Standard measurement value

233

{652V.2 Check & Adjustment Power Gioup

Propet Stat

Propeller Shaft

Propeller shaft phase

[Aust th yokes ofthe secon an thr poplar shafts

fo the same crecton phase)

= The. propeller shaft ataches to the transmission

shat"The shat from tho Fort ceerenalf tho reat

‘Mirena is refered to 2s tho propel shat. The

proper shat srolates ae machine une,

‘nen the proposer shan fe artested duet

mmadine nena, teens me yore panes

(eecsians} wil otuse unbalance between the ans:

Iissin torque apd the reacion farce. As a rosu,

the propel cha wil extremely bat, and

‘oe le of he snot wil be shortened

Second propeller shaft al

As misalignment may preduce an ebrormal eis,

be cure to aign pons (A). (), and (Ch of he yokes

when reassembling the propeller shat

wa

{520-2 check & Aajesment Power Gove

Propeter Sat

Tightening torque

nee tS neo

IMPORTANT

Never reuse universal ant ordain bot orks

‘Aways use new bats and secue wih loctte™ 262

and primer,

os

1.2.8. 78.9Nem 6.19 kg) (59 0-1)

£7 230 Ne 25.5 gn) (170108)

5 TIN (78m) (57 th

8304 Nim (31 Kat) (225 bt)

TTR (1B gh) (13)

<~

1.2.5: Screw lock agont (Thyoe Bond 1327)

4: Seren lock aport Locte® 202)

(652-2 Function & Structure Torque Converter and Transmission Group

65ZV-2 Function & Structure

Torque Converter and Transmission Group

Torave Converter. 322

Torave Convertor Gear Pum. 323

Transmssion 224

Ccktch Pack. 32.10

Hydraulic System Diagram. aate

Hydraulic Grout Diagram s218

Few 3220

TC and TIM OH Ceulaton 322

Conal Vale

‘Accurate.

(oktch Seno Valve

22

{852V-2 Funcion & Sieur Torque Converter and Transmission Group

“Torque Converter

Torque Converter

Torque converter structure

“Tho torque converter is between the engine and re

rricson, and consists of hae impale as shown inthe

Tue. The tree impolers are pump (P), une (1),

‘ad stator (3) empois.

Power flow path

‘The pump ie connected to the engine Awe, ane

rotates together with the engine

“The turbine fs connects othe torque cavern out

‘The stator § fked to the tore convener ae, The

trae of ne Inpators fe hed wih oi When the engine is

Sate, the pump impeter rotates, hereto te Owl

Croat ote the tute peter (cretion cer

pump-sturine etter »pump) Ola redvectes by the

fred stator impr Bact Te the pump impel. When

= impor rotstes the power wl be rans

utat shat

Torque multiplication

Lo ~

It the engine speedipump impeller spead stays the

sare but ihe wine impeller speed i reduced du fo

‘he wansmissin oae-oulpu torque s nereacod. Tha

erque rutpleaten" Hea i iso genersted

“Tsbine implies spe08 (min) om

Speed rat

a Pump inpeter speed (in "(pm

2a

152V-2 Function & Structure Torque Converter and Transmssion Group

Torque Converter Gear Pump

Torque Converter Gear Pump

Pump specifications

Teor aoa va acon

ee

es pone pd S000 am)

Sure 1250 nom)

fee | one

Siena?

oii ore ot 0860)

etal busting

Oring

Oil seat

8. Pin

10! Bat

“1 Snap ng

4

2

a

é

5. Side plate

8

é

24

(652V-2 Function & Stuctue Torque Conveder end Transmssion Group

Sancricsin

Transmission

Clutch combination Downshift button operation

cea eae “Tis este pais quick up and down shiteg when n

ese adore auonate "

a Woperte om 2nd ot ad st to nd

a a

‘Te transmissions eauipped wih six duchos:

Forward range, reverse, and tet 2nd, 3 and 4th

speeds. Combining ne cuiches as shown inthe lable

ere provide four forward spoods, and four reveree

Speeds for & toll of eight speeds. Two eles must

be engaged atthe sare tie to move the machine.

Shift lever position

1 |SatierdSomann ton epecen

‘Auiomate of manual speed change ie avaiable

— LL |

Porat =

seo — voeniere |

sere? a Flow control valve

ca | onl ee=| Sf

26

52V-2 Function & Stvture Hysrais Group

Hyeraule ret Symbols

Directional control valve Check valve

pean C over

-

45+

a7

652-2 Function & Stuctre Hyrauc Group

yoreuse reut Symbols

Miscellaneous hydraulic symbols

w

(ence

(epoca |

@/-o]gl¢/0 C

bo}2))> 1

228

652V-2 Funcon & Stucture Hydraulic Group

yaraule System Operation

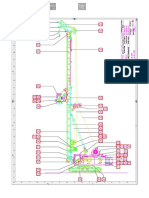

Hydraulic System Operation

Hydraulic system operation out-

line

“Te hydraulic system consis of th floning systema:

~ Looding system

= Seetng system

~ Fan motor systam

Ride conta system (OPT)

Secondary steering

Loading system

“Te loading system consists ofthe following compe:

ents Al numbers base on page 926.

= Hygroute pump (1)

Unis vate (22)

Line ter (29).

(Check vate (22)

+= Reducing valve (38)

Pot vave (16)

+ Multiple conto vate (3)

oom ender (5)

+ Bucket cyiner (6)

Ol fom pur (1) fows 10 plot valve (16) tou

Uunloaer valve 22), tine iter (38), check vane (32) an6

reducing valve (8), Ot plot vate (16) is reduced 0

$5.5 MPa (6 kale) (512 Bs by recucing vate (38).

nen the plot contol lover is operated, te pil ave

line opened, and the ol pressure fs generated

‘depending onthe poston ofthe plot conto ver.

‘The plot pressure eneg he ol pack to muse con

‘tl valve (2} moves the spool agsnat ts retum spn.

“The spool pross.in distance (csplacement) depends on

tho pot valve pressure.

(Ot fom the easer pump is ten ciocid through mut

fle cantl valve (3) © boom cyindes (5) ane bucket,

eyander 6

Return ll fom the cyedors ows through the waive to

{Me al cooler, elu ster (12) and into the hyraulc

ven if no nyaulic pune suppies ol © the leading

‘ara plot conta ckcuts due fo rouble, er te engine

Is shut of the boom can be lowered to the ground by

the pressure In accumulator (33) he ake cet

c2eo ofan omergoncy

Steering system

“The stowrng system consis ofthe fosouing conpo-

nts

+ Hyrule pump (1)

roy ale (5)

2 orate? (8)

‘Accurnsatr (24)

+ Seeting einer (8)

(8 rom pump 1) fows to Oil? (14) trough the pe

ony eae (9)

‘When the stoerng wheels ture, an ameunt of pro-

portona othe taming speed ts cent om pump (1) 12

Ssteeting oytnder (8) rough prionty valve (18) 3nd

rear),

nen the steering whee snot operated, soe al of

the nyrauti of ctcherged fom pump (2) s supped

the ing eat

Prony valve (15) detects he resistance of the hyeraulc

‘al passing Evosgh Orito!® (14), namely the specs of

the stating wheels ett ane he amount fo and

‘hen datibutes ot othe loading ans stoerng create

‘Accumulate (4) is provided to prevent shock atthe

‘ine of siartng ane sopping tne steering whew,

ilo the stooring wheel is not tuned, slnost alt

‘hydraulic of fom steering pump (1) s sen othe oad

Ing tne bythe etn of he fw conto 00! nity

vave is}

(ret trom steering eyinsors (8) tows trough

tive (14) ard retums fo the fora lank

Finay totus othe an tough eu ier (12)

Fan motor system

‘The fan motor system consis ofthe folowing compo-

~ Hyaraute pump (1)

= Untsder vate (22)

1 Fan mate (1)

The cooing fn is even by hyekaule meter (72). The

pressure ol fem unloacer valve (22) ows tothe poe

Profan motor assy, enor fan motor (71) and ow co

trol vate, and then, tans fan meter 71).

“Tvge Kinds of signa son om the ECM, torque con

ver temperate seneor, nc hyaukoltompar

lure sensor, e inp ino tre MCU 38 iforsation fo

‘regulate the minimum fan even,

‘Te fan rovouton Is regulated by the of amount sup

pled fn meter (71) Ot areunt supped ofan motor

{71s changed In proporion se the engine revoluson

‘nd the opening area of the flow contal valve of far

motor (7)

Ride control system (OPT)

Fler to "Ride Contol(OPTY" page 42-47 forthe infor.

‘Secondary steering

ter o "Secondary Sterng" page £2.95 fr the nor.

ration,

29

(82V.2 Function & Stucture Hydraulic Group

Hyataute System Operation

42.10

{52V-2 Function & Stucture Hyraulic Group

Layout of Hyerautc Units

Layout of Hydraulic Units

6. Fanmetor 12. Seconsary steetirg pump

Hydraulic Tank

Hydraulic tank specifications

aon

(682V-2 Function & Shuctre Hysravic Group

‘yore Tark

Gacy a eal aa LST

[tn sen

— ope se.

(hPa) baton oat

a av anges a ta)

eoanearenoay(aa)

suton anion | miratrate [un se on

Suen [toto ee som)

Sion he tig resus (3) t= a

THOM

Deshage vevesorg ear WP) len oa)

on),

eaber ate ol son) [Raion se fe

‘amie

kan pcs 5a

Patil ring a RGR GAS OS,

‘oe artigos

SHE6n ae ein pres (5) ET a

saeeneT

robe we eg gon

Tike waste rane BP) HFENT DT

Oaa)

‘onstoe Fate fe

rater

Hydraulic oil level check

lore checking the hydrate ol level, observe he ok

‘owing ites

+ Cheek hat he machine I 0 level grou.

‘Check he hyeroule ol laval before oparaion (when

‘ligt wan),

Lower the boom to the lowest lint, and set the

ket love on he groan.

Check that te of levels atthe center of the ol vet

‘ight gouge,

‘amount: 701 (18.8 US ga

Note

Trine os at oporating temperature 60°C ~ 90°C (10°F

~ 200°F) the alovel may be at or roar tho topo the of

evel sight gauge

Pua

ore sam ge

ES)

a

a2

(652V-2 Function & Sucure Hysaule Group

yore Tank

Hydraulic tank (S/N 9001~9100)

Hyaraute tank

love sight gouge

‘Breather vatve (ak cap)

Fite

‘Suton strainer

Retr iter element

Rete vate

Serna

Cover

10

2

13

16

18

"

Drain pug

Inspocton hole cover

FReturn pipe (or raha)

eturm pipe (or pit)

Vent pipe (o axe using)

Temperate sonsor

Ot ove sensor

Lock bt (i 9003+)

Hydraulic tank breather valve (tank cap)

(SIN 9001-9100)

Spring (or exhaust vate)

Valve assem

(@) Exhaust vate

(0) Socton vate

{@)Airbleeder vane

Spring for sucon valve)

Key (gare as ster key)

-mtacring bts (3 pes) socket head

4219

652V-2 Function & Sucre Hyoute Group

yeraute Tonk

‘wien the pressue inside the tyeroule tank crops

holow tho ouside air pressure, the outside ir ows

tough liter element 2) ane to vale sesembty (4).

Sueton vale () then opened lt the al How no

the tanks

Wen hear pressure inside the hye tank ss to

8 certain port 29 xPs (03 kfc) (4.3 ps), Exhoust

ave (} Rod (opened) so thal te can fw ut of

the tank throug tor element 2)

ne cc ou aa po he Dom ape reste

‘Therefore 29 kPa (0.3 Kalam?) (4.3 pal) pressure Is

always appied othe inside of he yea ark.

“The pressure appli tothe inside ofthe hyraulic tan

provoke th dust and cet rom being sean inthe

tank and improves performance of he pum

‘he postive pressure puses the lio he pup redue-

Ing the poss of pump cava.

“Torelease the intemal pressure fom the hyaul tank,

press downward on cover (1). lr Bieder vale (c)

be were to releaae the internal prssute,

“Too pressures aso appt the axes.

Installing eap

“Too cap can be insted in any boom or bucket post.

tn,

a8

652V-2 Furcion & Sructure Hyereulie Group

yeraute Tank

Hydraulic tank (SIN 9101~)

1. Hyer ark 10. Dron plug

2. Of oval sign gauge {1 Inspoction hole cover

3. Broathor valve irk cap) 12. Retum pipe for brake)

a 13. Ratu ppe (for pt)

5. Suction stainer 14. Vent pipe (fo ale housing)

6 element 25. Tomporatue sensor

z 36. Ollevel sensor

e 7 Lock bat

8

Hydraulic tank breather valve (tank cap)

{SIN 9101~)

‘cap

Filer element

‘Spring (or exhaust vave)

vole assembiy

(e) Exhaue vale

(©) Suction valve (Ar bleeser valve)

Spring (or suction vale)

22.15

(652V-2 Function & Stucture Hysraule Group

Hyerule Tank

‘wien the pressure inside the hycrauie tank crops

below the cuside ai prossure, Te ovtsice air ows

rough fier cement (2) and to valve assoméhy (4.

Seton valve (9) then opened othe 3 fw nto

the tne

‘men the ak pressure inside the hyraule tank #368 to

‘2 corain pat 29 Pa (03 kar) (4.3 pal, Exhaust

‘ate (a) fed (opened) so nat he sr can How out of

the tank theugh Mer element (2

‘One cyclo (down and up ofthe boom apples pressure

totheinsie of he tan

‘Therefore 29 KPa (03 tale?) (4.3 ps) proseue fe

always app othe inside ofthe hycraute tank.

‘Te pressure applied to the inside of he hyd tank

‘events tne dust and drt for being cram iro the

{ank ond improves perfrmarceof he pump.

‘Ta postive pressure pushes the ol othe pump reduc-

ing the possibly of pump cavitation,

Toreleave the intemal pressure rom the hye nk,

prose down cap (1) Ae bloser ave) wll lowered

{oveease the nernal pressure.

‘The pressure Is also applet the axes

Installing cap

The cn cn bette ney boo or bake pa

4246

(6520-2 Furcton & Stuctue Hydraulic Group

Hydraule Pump

Hydraulic Pump

4, Dive gear & Ot seal

2, briven gear 8. Snap eng

5. Breck 10. Pn

4 Goat case 14, Oring

5. Caner 12. Stud bt rut

6 Cover 43. Bott

7. Wear piste 14, Bushing

Hydraulic pump specifications

[esis ceeoe Taser Foros Faroe eae

PERRET geteah| (0s 287) «ove 25601) ares 7

ax a no 3008

‘The tiple gear pump Is used forthe steering, leasing,

brake ar pot

4aar

(82V-2 Function & Shucture Hysol Group

yerauic Pump

Hydraulic pump principle

‘The cl the ret area Is token in he cavites between

‘he gear ect ight fir csengagemert and vansered

‘wards the ulet ares encosed In betwaen the fest

‘and the gear easing

when the gear teeth mesh again, the ois exruted out

‘ofthe ton caves an forvarded othe oll,

42.18

{52V-2 Function & Stucture Hyraule Group

yore Pum

Hydraulic pump wear plate

Oy

‘hia ean

Bath stas ofthe gear consis of floating ype presse

Plates having balancing function. The pressure pates

‘mamain optimum clearance on both sles ofthe gear

(pressure balance mechanism) 50 tat the high vor

‘ot effcency is ensure,

Rotaing gears fod the pressurized ol along the ie

‘cumference ofthe case tthe oulet por. The press

{apd oli also sent the high-pressure area inthe ear

“The posure plate posted

7 dlerance between the gree

hd he side suace of he gears kept very

7 pressing foe tothe plat is adjusted wo an

‘poropiate valve by seting the opium high-pressure

‘rea ofthe pat,

‘The High-pressure area inthe rear af the pressure plate

is eclosed bythe pate sea, tack sea, and ena

‘ion late

To provent he gasr-seaing area tom extemely high

proseure due to conned ol, thee i @ conned ol

bypass groove athe ger-soaing area of the presse

plate

Hydraulic pump bushing lubrica-

tion

“Tne lubcaton system uses nee fom the pressur-

Pat of he oiled fom tha inlt gon is set tothe bush-

ings to ubista tem. Afar tat, the als etumed 10

the inet side and then sent othe discharge side.

‘Bushings roqutelubrction to maintain slong service

le. Avoid busting damage due loa lacs of breton

ley

‘Staring up new pump wit ol supe tot

~ Atow new pump oll (aw rpmino load for in

ee

~ Uso the proper vscosty for the colbes possible stat

‘up fempeature. Change viscosty seasonal ten

perature cxanges ae groat mere han 20°C (8"F),

4249

(652V-2 Function & Siucture Hydra Group

yaraule Cylinder

Hydraulic Cylinder

Boom cylinder

Pon rut (2.601 Nem 285 Agen) (1.0458)

Bon (7 481 Nim Sgn (89 8)

Steering cylinder

)

(Potent (600890 Nem (129 gen) 441222 4)

Fd cover 8: 300580 Nem (3128 kg) (2242 I)

1. oytnder ve 10. Square tng 18, puter ang

2. Paton ros 11. Stoner tng 20. Org

3. Paton 12 Owe 2 Weertng

4. Beton nut 13. One 2

5 Roseover 16. Backup ring 2

©. Bushing 18. Upacing 28, Bushing

7 bot 18. Backap rg 25, Dust seal

a= 17. Dust seal 26. Piston packing

8. Wear tna 18. Seong

42.20

{652V-2 Funcon & Suucture Hyraulie Group

Hyeraule Cyercor

Bucket cylinder

(in 8001-2060)

jal Wn

4 yA

(Cooma pr) fiw

(snva0st=)

1 T

(Coa omneriey eer

= Pton mu 46008290 Non 69 kgm (2.2008170 bt)

Bot (7)'880290 Nn (88.7 Kaen) 648207 DR)

4. Cynder ube 10. 19. Butersing

2 Peston od no 2

5 Peto 2 21. Wear rng

4 Piston not 13. fing 22 Pag

5. Rod cover 14. Backup ring 23. Omg

8. Beshing 15. Upockng, 2a. Bushing

7 pot 16. Backup ing 25. Dut seat

a 47, Dust cea! 25. Piston packing

a= 18. Sip ng

Hydraulic cylinder specifications

4221

(652V-2 Function & Stuctre Hyrouto Group

vera Cynder

rn

‘ror dowersveddavawrnaais | gaTES De

nine

ote inne a enrsen

(vowed se) ao

z ress)

ee

Since Pane Pats eiorsen

(ovr drat) | a ae

z aire,

ie caneersosauncursas | gitirtieg

Sinad . a pereion

(ereroaect ewan) ose

42.22

(652V-2 Function & Souctue Hydraube Goup

Loading System

Loading System

Tay

oa

‘The plot operation system uses the plot valve pressure

te canta the poo! of tee mile conta vale and

‘move the boom eylnder(s} ana buck evnderts).

When the cont ever operated, the pot valve tn is

‘pened. and he ol prestue is generated depending on

‘he poston of te cnr eve.

‘The pilot pressure entering th ol pack to the mate

conta valve moves the specl against ts eum Sang.

‘The spool pessin distance (isplacemont cepends on

the plot wae gronaure

CO fom the lad pump is then decd trough the

valve to te cyinder

Feet ol fom the oylndors Rows trough the vave to

the of color retum Ror ane it he tank

(toe plot va is supe fom the brake Sine whe

being reduced > 35 HP (35 ale) (512 ps by he

reducing vave.

Even if no hyraulc pump supplies tothe loading

and plot conte eicuts cue te rouble, or ifne engine

is shut of, the boom can be loworea tothe grouna by

‘he pressure in the atzumsltor inthe bake crcuk

‘eae of en emergency.

2223

(652V-2 Function & Stuctre Hyeraule Group

Reducing Valve (or Pt Pressure)

Reducing Valve (for Pilot Pressure)

ve prove lato pressure te operate the park

leader plot va uncons.

‘The olf rom the brake accumulator oct fs into

2 pio ol cout by way of passage Z. Theol pressure

in the pot ol crus appeg also on chamber C by

way oftee 1

nen the ail pressure i the pile ait cea fat oF

above the set pressure, the of chamber C unseats

the bal by way of ofce 2. and escapes 10th tank by

way of passage ¥. As a rsul the pressure m chamber

(C-decresses, then the plunger moves up and closes

rescue on the plo! oll eu

he set pressure

rae ces apa

When the ll pressure on the pit of chou sie

Becomes ess than te sel pressure, the bal moves

‘down andthe pressure a snarber © becomes equiv

pressure orth pt ol ort side (8) As a

2 punger moves down by a seg, oper the

reage 2, en nrodices te accumulator restr 0

Dot oi aut side 20 fat the poseure is main

‘aod at he specified vale.

‘This ressurzod ols supped to the multiple conta

valve ol pack tough the plot valve and reves the

‘mutigieconvot valve spect

Set pressure

35 MPa (38 ken?) (512 ps)

42.28

{352V-2 Functon & Suucure Hysaule Group

Flot Vat (SIN 9001-2050)

Pilot Valve (S/N 9001~9050)

a r 1

eucomg~-—

From Top

—

ee

a od

eon ea

Oo ® ° @Fo

Cc @ ° © O

From Botom,

(eee

4225

652V-2 Function & Stuctre Hydra Group

Plo: Vate (SIN 9001-3050)

BSbay den) xem

Lear

wo POp—~ so WO a

alt MW) aT (f Fore

Et ot

Hl Oo ‘al A *

Tro Tree Tre Teo

Tec uevasea Tam tov tsa

a “sein 88) —

1 Lover 14, ong

2 Peano 45 Song

3 Paan red 8 Sg

4 Peat rod 47, Speak

£ eten elena ol (20m down ost) 18 Dotentbushng

Daten son col (B00m as) 4a. Sng

4 Daten een ol (oct eve) 20. Geert eng

Pang ase 21. Sel at (pices per poo)

5 Fang ec ening mar) 22. Sona sot

10. Pushed 2. Sng cont

Mt Song 28, Casing

12. Pg 25. Sing

18. Spang set

42.28

(652V-2 Funcon & Siucture Hydrate Group

Pot Vale (SIN 9001~9050)

Pilot valve function

‘The pct vale apples ol pressure in proportion tothe

cpecating angle of the lever thereby caning. out

remete contol ofthe spool inthe mulpla contol valve

Pilot valve operation

(modulated position)

Or, ma)

ey saree,

on mm

Lear ise naa pata

‘The plot vake hes hols of lengthwise drecton in

lahich the vesucing waive & but The rediong vale

Secton consists of spool (17), spring for secondary

pressure (15),16), retin sring (14) and spring seat

(22)23). eng insertec in pag (12), pushrod (1) can

be moved smenthy to change te bending qantty of

secondary pressure epg (76H).

Retr spring (1) contacts casing (24) ar sping seat

(2223). Ths spring works on returing push od (10) 29

Fs osginal positon whut relation to econday pres.

Sure, theretore ensures reluring the spool 9 ria

‘oot has the elle 9 reacve force sping o give the

‘modulation feeling to operator,

When lover (1 & inthe neutral poston, the fore of

Secondary pressure spring (15K16) isnot workes on

p00 (7) and spools pushed up fo push oa (10) by

return spring (14). As spect (17) eloces the pump por

and be tank port és opened, the ol pressures not

‘pple othe utile conta! valve ol pack. The spool

‘of matte contol vate is held iy reuval by ts carer:

Ing spnlgs. There no a flow othe cyte.

ar

| iva

nen leva (1)¢ shit rn the neta, pushrod (10)

‘and sping seat (29) are pushed down at the same time,

2 value of secendary pressure sping i chenges

‘post (17) foreed down by secondary pressure spring

(10), are ten, ne ark port i cosed ane pump port

Ieepaned,

‘As aresul he pressurize ol tom the pump ws into

the mulpie contol valve ol pack. The spool of the rut

te corrl valve moves allowing ol rm the lading

pump to owt the vines

\Wnen the olf pressure Inthe multiple contol valve of

pack reaches. over the. Gesred pressure, spool (17)

roves up. AS 2 result th tank pot is opened and ine

Purp pois cose. This acton also conrouies oft

Ing ot meculaton,

Spool camer at tank sido is greater than spoot

darmetor at pump sie.

4227

(6520-2 Function & Structure Hysoule Group

Pil: Vata (SIN 9001-8050)

‘Accordingly e ol pressure in the ruple conta valve

‘i pack ie recced below the dested pressure, Spool

(17) moves down again by spring (16) and doses the

{ane por. The pump pote opened. rats the oll

Bressure in the mage contel vive oll pack again

‘Tis eyeing scion provides pressure reduction to only

have suicrt pt pressure poss to he rile contol

valve to aca tn normal moculsles manner and

maintains 2 constant pressure tothe mule control

vive.

“The ol pressure tothe multiple corrl valve is propor:

tional © fever (1) angle, anc is balanced with the lever

angle. This rsuts in the muliple contol valve spool

boing moved the deirod smount. Oi ow rom the lead

ing pump to te eyinder i alse proportenal. Cyecer

Specs eal cooled

men over (1) moves tly forward o ack he mal

pl conta valve ezoachoul also be moves hal stroke,

‘This allows maximum ol flow ta the eylindrs forthe

lastest eynder movement.

Indio, spring seat (18) and sing (25) are instalod

‘nei of pus od (10) in the "Boor Float or "Bucket

‘Dump Wen lever (1) 6 shited more than a desi

‘angle, sping (25) makes contact wit the botlom of

push od 10} nade chameter. The ncnation of second

bressurechangad bys sping force. Then, i De sure

{ha multiple convo valve spect Is uly suohed, sping

(25) and sping seat (13) are usec. This abows spool

(7) fo be tly sroked and tl pct pressure il be

‘ected it the ol pak, tus uy stoking the musta

conta valve poe

«28

652-2 Function & Sxucture Hydraulic Group

Pilot Vaive (SIN 9001-2050)

Pre-detent and detent magnet

solenoid

‘The pce-tent function insted inthe “Suchet Rol

Back’ or "Boom Fla” position hat extends the change

fetng to operator ust before electomognetic detent

‘The prodetent section conse of detent busing (18),

ing (79), dotting (20) and soo bal 21).

Push fod (3) insted in the “Bucket Rall Back” oF

"Boom Fost positon has the notch hat tel bal i

tein

Wen push rod (3) shied and steethal un upon the

Stop, cperation laa Increases big by facie free

‘ping, bacouse the spring fs shortened

‘This extends the change of feeling to operator just

Delors electomagneti detent

Tye fie ating

oes

26ton, the detent magnet works to has the Iver a

Ite poation, when the lover is shite to “Oucket Rot

‘Beck or “Boom Raise” or"Soom Fat poston

Detent magnet secon consis of deretsclenks coi

(2), ising cise (88) and push rod 2).

men the cut forthe bucket level or the boom Kk

‘ut ption tuned on, detent solenoid cal (7s ene

‘ized ard magnetized so that fing de (6 forced up

‘82 (oppose sie) Is held by magnet force of detent

‘sdenod col (7),

Fer tis reason, lover (1) 6 nel at that sostion Ht you

esp the hard away tem lever (1),

“Therefore displacement cf pushrod (10) is malnsined,

‘nd tse suc tat coninues generating the 2

‘ond pressure constant.

men the clout is tuned of, getent solenoid cl (7)

Gesnorazed and devmagtelized. and lever (1)

‘turned othe nour poston,

In adation, the dotont magnet canbe cancetes the

lover is operated toward the neu! ection ‘wth

‘enough free fo overcome the power of deters,

4229

1552V.2 Function 8 Stuehire Hyer Group

Pot Vai (SIN 8051=)

Pilot Valve (S/N 9051~)

ie Fen)

(Seaton)

Te- Fotbck Ow

vw

Tare cy

ao

From Boom | sam

42.90

6520-2 Function & Stucture Hyraulic Group

Plot aie (SIN 8051=),

tune (Deter) (alg Cow (eten

fat «La

= i 1 »

@ ie if ae i Me

* a wt tu eee

Leovcranel Montrail

‘soonne ae =

Love

ried

ised

nine

Bete str cod bom dow Ros)

Bateson ot rn)

Beet sla a set we) 2. Saati

Fang ae Et St at ee per soc

Fr ae (erty ma) Bo Songs

Ranad % Saco

Sn & came

fe 25 Soma

Spring seat

Pilot valve function

‘The pilot vave apples ol pressure in propoton to the

‘operating anle of the lever, thereby caring out

‘era contol af he spoel inthe multe corr vave,

Pilot valve operation

{modulated position)

ast

(6520-2 Function & Stuctre Hysroulc Group

Pilot Vatve (SI 8051)

‘The plot valve has holes of enghise drecton in

which he reducing valve is bull. The reducing waive

Section ate consist of spool (17). sping fr secondry

pressure (15(),retum spring (14) and spring seat

(2x22) Beng insried in pg (12), push od (10) ean

be moved smootniy to change the bending quan of

secondary pressure seg (15X16).

FRelura spring (4) contacts casing (24) ans spring seat

(22423). Ths soring warks on etsring push fed (10)

Fs oveinal positon ioc! relation fo secondary pros

Sure, therefor t ensures reluring he spd 6 rows

‘saith the elects teacve force spring 0 ge the

‘modulate felng o operator,

Wen lover (1 Is inthe neural positon, the force of

secondary pressure epring (18) 16) ls not worked on

Spool (17) and spool pusted up to push ra (10) by

ratum sping (14). AS spool (17) cose the pum port

‘nd the tank pot is aponed, the oi pressure fs not

‘gp othe matte corte valve ol pack, The ep00!

‘of maple contol valve els in novia by ke center

Ing peings Thee sno o few tothe cinder

42.02

(8520-2 Function & Sucre Hydraue Group

Pot Va (SIN S0S1-)

w J

c

r 0

ts Ci»

When lever (1s shied rm he neta, push rd (10)

2d sring seat (23) ste push gown at ie sare te,

the value of secondary pressure spring is changed

‘Spocl (77) foreas dawn oy the secondary pressure

sping (16) ard then the tank por is closed and the

pomp ports opened,

{As a result he pressurized il rom the pump fows ito

the muliple conta valve ol pack. The spoof he mut

tiple contol valve moves allowing of fom the leading

par ow fo the cyan,

\Wnen the cil pressure in the rutile conta vale ot

pack reaches over he desved presse, spool (17)

roves up. As 2 recut, he fark pr Is opened and the

ump pois lose. This econ aso contibes tea

Ing o!modation

+ Spock diameter at tank side grater than spool

Glameter a pump #88

‘Accordingly he ol pressure in the multiple conta valve

‘pack is reduces below the dosed pressure. Spool

(17) moves doun again by seg (8) ane cosee the

{ank por. The pump port cpened, I res the of

rescue inthe mutipte contal valve il pack aga

‘This cyeling econ proses pressure redueson to only

have sufcen pl pressure pase tothe matte conte

valve o actuate tin @rormal mediates manner ang

maintains 2 constant pressure "othe rutile contol

valve

“The ol pressure to the multiple conta valve is popoe-

tonal a lever (1) ange, an i balanced th te ever

‘angle. This fess Inthe mutpe corel valve spool

boing moved ne deszed aroun. Ol ow fom tha ac

Ing pur to the ender ie elzo proportion, Cylinder

speedis easly contated

hin lover (1 moved fly fora or back the rt

‘le contol valve epoo shoul also be moves stroke,

‘This tows maximum of ow tothe cylndere forthe

fastest eyinder movement

In atten, sping ses (18) and sping (26) a0 real

inside of push roa (10) i te "Boom Fea” or "Bucket

Dump" When lover (1 6 shied move hans desred

‘angie, sping (25) mates contact with fhe boton of

push fod (10 insice ameter. The nanan of second

Bressore changed by his sping fore. Then, to be sue

fe mutile conte valve spodl i hy stroked, epeng

(25) and spring eat (13) ae used. Ths alow spool (17)

{be fly Suoked ane fl pot posture wl be cectad

Ino the o pack, ts fly stoking the rulple contol

valve spo

Pre-detent and detent magnet

solenoid

4299

(852V.2 Function & Stuctue Hysaute Group

Pilot Vave (SM 8051)

stants

‘The pro-etent function i instal inthe "Bucket Rol

Back’ or "Boom Float poston hat extends the change

featng to operator us before electromagnetic detent

‘The predotent secon consists of detent bush (18),

sing (18), detent ing (20) sna ste! bal 21),

Push rod (8) netted in tho “Bucket Rall Beck" or

"acon Fat” postion has the notch that set bal

won

Won push rd (3) is shifted ae steel all ran upon the

stop, operation torque grows big by reacve frce of

sping, bocause the spring fe shorted.

This extonds the change of feeting to operator just

before electomagneti detent

In ston, he detent magnet wes to ld the lover at

Its poston, when the lever is shed to “Bucket Rol

‘eck 1 Beam Rae” of "oom Flt postion,

‘Octont magnet section consists of detnt solenoid sub

(hong se (BNE) and push rs (21).

en the crcuk forthe bucket levee rte boom Kck-

(04 (opin) ured an detent scent sb (7) er

(zed and magnetized 0 thal fang ase (8) otfrcee up

Sie (pposie side) is held by magne fre of tert

Solent col)

For this reason, lover (1) shel at thet poston i you

kegp the hand away tom lever (1)

“Therefore dlplecomant cf push ro (1) maine

nd tis tho siicure hat continues gaerating the o8c-

(ne pressure constantly.

men he proxy switch tuned of, detent solenoid

call 7)is devenergled ond demagnetzed ar tver (1)

‘Svelized othe neal postion.

In action, the detent magnet canbe cancetes Mf the

lover is operated toward the neural dvecton wih

‘Snough free to avetome tha pero tenis.

652V-2 Function & Stucture Hydrate Group

‘utile Conrot Vai RAL222T)

Multiple Control Valve (KML22/2T)

9, Cover

10, Gauge por (14)

“The bucket pity line is used forthe mutiple contol

vave, ond corsets ofthe folowing uns:

1. Main ral vaio

Relieves the pressure when the working pressure

frceeds the reel setting pressure

2, Bucket spel

Used fr bucket oparatin, such as ot back, holt

Inga titenge. ard curping

3. Boom spe

Used for he boom operation, suchas raising, hol

‘ng hight lowering, an eating,

4, Overid ait valve

‘Win make-up uncon, onthe bucket ise)

Relves the high pressure fram the csr i

[rescure is extoraty Fgh Poses the cylinders

from a vacuum (negate pressure)

5. Mako-up valve (On the boom sie)

Prolels the oyinders from vacuum (negative

reste

6, Load check valve

reverts the revereee al fow or momentary “oad

cop

42.98

652V-2 Function & Seuchre Hysraute Group

‘Mutiple Conta Valve (KRL227)

Multiple control valve specifica-

tions

voreetaeeesmeen | ease

comeraaeemorman | elige

gees |e Feta} ee

Mave | =" aot se | ister

22.08

{82V-2 Function & Swucure Hydraulic Group

Matte Contal Vatve (ML2227)

Multiple control valve main relief

valve

‘The mein veil vv is isles betweon the pump and

‘na contol spel. When the eyensor comes tothe stoke

nd, or the press s above the set pressure, the of

fed fom the sump wil be decrarged ito te tank

through this valve (main reef vale) to revert pump

‘216 pipe damage.

‘Main relief valve operation

Secor ree

mae

ve ‘Seon Purge Odea

Show"? Pexpet Fier chamber

1. When he ol pressure fal hese pit or below

Tho pressurized ol rom the pump fows Into the

chamber A trough the exfce 1, and the plunges

Dresses agains! the sleeve bythe pressure aaa -

ference oe plunger and the peng free. Als ne

Sloave comsletely does Ie pump po byte pres

‘sue ars iterencs ofthe slowvn batwoon the pump

portside ane chamber Aside,

2. When theo pressure exceeds the So pont

\wmon the ot pressure inthe cyan iss above

the preseure tel by he spring, the poppet fs moves

to the let and opens the por. Then the alin the

chamber A ows To the Tonk though clearance

Delween he pody and sieeve.

[AS a result he prossre inthe chamber A rapialy

‘owers arin purgeris moved tothe le, Then he

plunger opens the porto te tank port snd the pres-

Surzed olin the pump pot escapes tothe ark por,

ote

Clogging ofthe oice i plunger wi cause low pees-

nother possible cause of low pressue it contamina.

ton in of damage 1a, he ato ele pope, plunge,

‘or clogging of the ite.

‘Aways cosn the fer dung overtau of the reset

22s?

(652-2 Funcon & Stuctre Hyraule Group

Mutple onto Vale (xML22227)

Adjusting set pressure

Loosen the lock nut and adust the pressure by the

‘suing sere. Torn Skee the adjusting screw to

32 set pressure, or tum counircocrwise the

‘sgsing sere to lower the sat pressure.

‘for adjustment, bo sure fo hen the ack nt

Set pressure

20820 54a (21086 kal) (2966871 pi)

IMPORTANT

“Anvays be cotan © ghton ok nul won tished

vith austen.

‘Oni sot presinesin ccordarce wih seting speci.

eats,

a8

{522 Function & Stuctire Hyde Group

tiple Cantal Valve (KML2227)

Multiple control valve overload

valve (with make-up func-

(tnstaled on both the rod and botom sides of the

bucket eeu)

Each overload ral valve (with make-up funn) is

instaed in he creat between the cyder ana the con:

ol valve spool. Whon the spool In the NEUTRAL

poston, external force on the cylinder Becomes 120

high end te of pressure wil be greatly creased, the

‘era tel va rl the oto he tank protect

the cylinders and pipes for breakage.

Overload relief valve operation

1. As vetoed rie vane

fal

Preece Post BY soncas

lumen the ol presses athe set port or blow:

The pressures of tom tne cyngor sont tothe

‘cramer B tough the how Aol he piston, a he

plunger s pressed against the sleeve by he srng

foxce

‘Also the sleeve completely coses the cyinder pot

by the preseu area afrence of the sleeve

Detween the exinder por ise andthe chamber &

oun aoa

ote | r= €

hoon Plnger CberB.Papst