Professional Documents

Culture Documents

Boiler Comments PDF

Uploaded by

adnan0 ratings0% found this document useful (0 votes)

10 views2 pagesOriginal Title

Boiler Comments.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views2 pagesBoiler Comments PDF

Uploaded by

adnanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

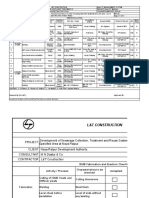

BOILER

S.NO REF # COMMENT

1 Drawing Boilers, CT & Vessel are in basement 2 as per attached drawing. So pls add

attached “P location column in your material schedule and attach a copy in location

3001 section of submittal.

2 1.04 Submittals portion related to you needs to be provided like O&M manuals

etc. why is it N/A?

3 1.05,A Manufacturer experience?. Why N/A.

4 1.06 Certifications related to your product needs to be provided & complied.

How is tank & heaters N/A?

5 1.07 Temporary caps for protection? Pls comply.

6 1.08 Warranty section needs to be complied & highlighted in the warranty

specs.

7 2.05,B,1 Ps justify your answer as per your product in the specification compliance

why draft inverter & coil relief valve is not applicable?. Rest of the specs

which you are complying in the same clause, pls highlight it in catalogue &

refer to page number in compliance.

8 2.05,B,2 Specification is asking for ASME certification & stamping alongwith heat

exchanger. Warranty mentioned in the clause is for heat exchanger. Pls

elaborate your reply in detail wherever u r complying or giving alternative.

This reply is not to the point.

9 2.05,B,3 Specs is asking for C.S.A, ANSI, ASHRAE, AHRI compliance along with

efficiency needs to be complied at the RETURN AIR TEMPERATURE OF 90F.

As per your graphs, you are not complying to efficiency at full fire mode.

10 2.05,B,4 Pls refer to respective page of the catalogue & highlighted for the features

which you are complying. Pls comply to the specification features which are

asked like two observation points, Gas valves, direct spark ignition & flame

sensor etc.

11 2.05,B,5 Pls comply point wise with compliance or alternatives along with catalogue

highlighting. All types of Sensors and switches needs to be complied or

alternative needs to be proposed. “ As per Manufacturer standard”, is not

acceptable as you are manufacturer representative & you have to explain

what is being offered.

12 2.05,B,6 Same as above.

13 2.05,B,8 Pls attached one manufacturer standard testing method for boiler & refer

to it.

14 2.05,B,9 Turn down ration needs to be complied . Specs is asking for 25:1

15 2.05,B,10 Pls highlight manufacturing standard for valves & connection in catalogue

or mention in the specification.

16 2.05,B,11,b Your thermal efficiency at the temperature of 70C is 88C so pls rectify in

the compliance & write comply. 99% is incorrect.

17 2.05,B,11,d Why is second main gas valve not applicable? Pls justify as per your product

construction/make.

18 2.05,B,11 Pls elaborate manufacturer’s standard what is being offered. It is not

acceptable like that.

19 2.05,C,1,2 Pls provide details of your coating RC851 against epoxy coating. Sacrificial

anodes are not acceptable as per specs for protection.

20 2.05,C,3 How is DIP tube not applicable for water tank? Temperature & pressure

relief valve?. Thermal efficiency of the tank as it has insulation so how

much efficient will be your tank in heat conservation, you have to specify

in your reply & catalogue. Your tank has u tube type stainless steel tubes

yet you wrote “N/A” why?

21 2.05,c,3,h,3 “As per manufacturer standard” not acceptable. Pls specify what you are

offering.

22 2.05,c,3,h,6 Pls specify “which standards”? This is not acceptable at all.

23 2.05,c,3,h,7 Manufacturer standard?

24 2.05,c,3,h,I,3 Specs is asking for remote heat exchanger connection inlet/outlets not the

heat exchanger itself so pls comply.

25 2.05,c,4 Specs is asking for 25 bar pressure while your proposed is 7 bar only.

26 2.05,c,5,6 Manufacturer standard?. Insulation thickness requirement is 75 mm “Fiber

glass”. Thickness should match.

27 2.05,D,E Pls write N/A.

28 2.06,A Comply to specs standards i.e ASME etc.

29 2.09 Pls write N/A

You might also like

- 18.02.22 Facade Lighting-Layout3Document1 page18.02.22 Facade Lighting-Layout3adnanNo ratings yet

- Eli Howard Fire Smoke and Radiation DampersDocument1 pageEli Howard Fire Smoke and Radiation DampersadnanNo ratings yet

- PMT A 237 Mezzanaine Floor Containment Layout CN 02Document1 pagePMT A 237 Mezzanaine Floor Containment Layout CN 02adnanNo ratings yet

- Eli Howard Fire Smoke and Radiation DampersDocument25 pagesEli Howard Fire Smoke and Radiation DampersAhmed OmarNo ratings yet

- Etag 029 April 2013Document37 pagesEtag 029 April 2013adnanNo ratings yet

- 17.09.07 - (Transmittal) AP-307-33 - Arch & Struct DD Report - P15Document1 page17.09.07 - (Transmittal) AP-307-33 - Arch & Struct DD Report - P15adnanNo ratings yet

- Order Online: All Prices Are Including VATDocument16 pagesOrder Online: All Prices Are Including VATadnanNo ratings yet

- PMT A 237 Ground Floor Containment Layout CN 01Document1 pagePMT A 237 Ground Floor Containment Layout CN 01adnanNo ratings yet

- DM-P16-0001-Drainage Site Setting Out Plan PDFDocument1 pageDM-P16-0001-Drainage Site Setting Out Plan PDFadnanNo ratings yet

- As Approved: Business BayDocument1 pageAs Approved: Business BayadnanNo ratings yet

- E 6400 01Document1 pageE 6400 01adnanNo ratings yet

- As Approved: Business BayDocument1 pageAs Approved: Business BayadnanNo ratings yet

- Revised: Power Distribution & Wiring Installation DetailsDocument1 pageRevised: Power Distribution & Wiring Installation DetailsadnanNo ratings yet

- As Approved: Business BayDocument1 pageAs Approved: Business BayadnanNo ratings yet

- Freeze ExampleDocument553 pagesFreeze ExampleadnanNo ratings yet

- As Approved: Business BayDocument1 pageAs Approved: Business BayadnanNo ratings yet

- Plot 15 ElectDocument50 pagesPlot 15 ElectadnanNo ratings yet

- Hello World! This Is A Second Paragraph. This Text Is Being Added To The Second Paragraph. This Is A Yet Another ParagraphDocument1 pageHello World! This Is A Second Paragraph. This Text Is Being Added To The Second Paragraph. This Is A Yet Another ParagraphadnanNo ratings yet

- Census Pop DataDocument1,551 pagesCensus Pop DataadnanNo ratings yet

- As Approved: Business BayDocument1 pageAs Approved: Business BayadnanNo ratings yet

- Freeze ExampleDocument553 pagesFreeze ExampleadnanNo ratings yet

- Member Email Jan 2014 Feb 2014 Mar 2014 Apr 2014 May 2014 Jun 2014Document1 pageMember Email Jan 2014 Feb 2014 Mar 2014 Apr 2014 May 2014 Jun 2014adnanNo ratings yet

- Twelve Cells Merged Together. Two Merged CellsDocument1 pageTwelve Cells Merged Together. Two Merged CellsadnanNo ratings yet

- Sample ChartDocument1 pageSample ChartadnanNo ratings yet

- CatnamesDocument1 pageCatnamesadnanNo ratings yet

- Combined MinutesDocument40 pagesCombined MinutesadnanNo ratings yet

- Freeze ExampleDocument553 pagesFreeze ExampleadnanNo ratings yet

- This Is On The First Page!Document2 pagesThis Is On The First Page!adnanNo ratings yet

- Member Email Jan 2014 Feb 2014 Mar 2014 Apr 2014 May 2014 Jun 2014Document1 pageMember Email Jan 2014 Feb 2014 Mar 2014 Apr 2014 May 2014 Jun 2014adnanNo ratings yet

- Freeze ExampleDocument553 pagesFreeze ExampleadnanNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Classification of Books Using Python and FlaskDocument5 pagesClassification of Books Using Python and FlaskIJRASETPublicationsNo ratings yet

- Iec Codes PDFDocument257 pagesIec Codes PDFAkhil AnumandlaNo ratings yet

- June 2017 (IAL) MS - Unit 1 Edexcel Physics A-LevelDocument16 pagesJune 2017 (IAL) MS - Unit 1 Edexcel Physics A-LevelNyraStardollNo ratings yet

- Paul Spicker - The Welfare State A General TheoryDocument162 pagesPaul Spicker - The Welfare State A General TheoryTista ArumNo ratings yet

- Bubble Test Direct Pressure InserviceDocument3 pagesBubble Test Direct Pressure InserviceEdAlmNo ratings yet

- Stucor Qp-Ec8095Document16 pagesStucor Qp-Ec8095JohnsondassNo ratings yet

- A Teachers' Journey: Phenomenological Study On The Puritive Behavioral Standards of Students With Broken FamilyDocument11 pagesA Teachers' Journey: Phenomenological Study On The Puritive Behavioral Standards of Students With Broken FamilyNova Ariston100% (2)

- Web-Based Attendance Management System Using Bimodal Authentication TechniquesDocument61 pagesWeb-Based Attendance Management System Using Bimodal Authentication TechniquesajextopeNo ratings yet

- Natural Cataclysms and Global ProblemsDocument622 pagesNatural Cataclysms and Global ProblemsphphdNo ratings yet

- Paper 1 AnalysisDocument2 pagesPaper 1 AnalysisNamanNo ratings yet

- Procter and Gamble - MarketingDocument10 pagesProcter and Gamble - MarketingIvana Panovska100% (5)

- March For Our LivesDocument22 pagesMarch For Our LivesLucy HanNo ratings yet

- IOT Questions and Answers - SolutionDocument8 pagesIOT Questions and Answers - SolutionOmar CheikhrouhouNo ratings yet

- B. Inggris X - 7Document8 pagesB. Inggris X - 7KabardiantoNo ratings yet

- KMKT Pra PSPM ANS SCHEMEDocument16 pagesKMKT Pra PSPM ANS SCHEMEElda AldaNo ratings yet

- The Comma Rules Conversion 15 SlidesDocument15 pagesThe Comma Rules Conversion 15 SlidesToh Choon HongNo ratings yet

- Ismb ItpDocument3 pagesIsmb ItpKumar AbhishekNo ratings yet

- Truss-Design 18mDocument6 pagesTruss-Design 18mARSENo ratings yet

- Low Speed Aerators PDFDocument13 pagesLow Speed Aerators PDFDgk RajuNo ratings yet

- Multimedia System DesignDocument95 pagesMultimedia System DesignRishi Aeri100% (1)

- Rishika Reddy Art Integrated ActivityDocument11 pagesRishika Reddy Art Integrated ActivityRishika ReddyNo ratings yet

- Riqas Ri RQ9142 11aDocument6 pagesRiqas Ri RQ9142 11aGrescia Ramos VegaNo ratings yet

- Strategic Marketing: The University of Lahore (Islamabad Campus)Document3 pagesStrategic Marketing: The University of Lahore (Islamabad Campus)Sumaira IrshadNo ratings yet

- Inventions Over The Last 100 YearsDocument3 pagesInventions Over The Last 100 YearsHombreMorado GamerYTNo ratings yet

- Homeopatija I KancerDocument1 pageHomeopatija I KancermafkoNo ratings yet

- BÀI TẬP LESSON 7. CÂU BỊ ĐỘNG 1Document4 pagesBÀI TẬP LESSON 7. CÂU BỊ ĐỘNG 1Yến Vy TrầnNo ratings yet

- SOCIAL MEDIA DEBATE ScriptDocument3 pagesSOCIAL MEDIA DEBATE Scriptchristine baraNo ratings yet

- Ti05001 PDFDocument1 pageTi05001 PDFanggieNo ratings yet

- Lesson 1 Q3 Figure Life DrawingDocument10 pagesLesson 1 Q3 Figure Life DrawingCAHAPNo ratings yet

- SecurityFund PPT 1.1Document13 pagesSecurityFund PPT 1.1Fmunoz MunozNo ratings yet