Professional Documents

Culture Documents

Briquettes Episode Script

Uploaded by

Daniel Rugunya0 ratings0% found this document useful (0 votes)

7 views3 pagesBriquettes Episode Script

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBriquettes Episode Script

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views3 pagesBriquettes Episode Script

Uploaded by

Daniel RugunyaBriquettes Episode Script

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

Intro I

Back in the Stone Age when man discovered fire, there

were no such concerns as climatic change or a high cost

of living. Centuries later, it is now almost impossible

to light a fire without either or both of these factors

coming into play.

This week, we get to see two people who despite

unfavorable conditions and extremely limited resources,

are working to defy the odds and make it more convenient

to, well, light a fire.

This is Innovation Corner; my name is Purity Ndung’u.

Bumper

(V.O) Fredrick Omondi is a jua kali artisan who

specializes in the making of different types of charcoal,

biogas and solar stoves, popularly known as jikos.

Interview (00064, 00:12-00:39, 01:19-01:53)

(V.O) There is a wide variety of jikos that Fredrick

makes in his workshop. These range from the traditional

charcoal burning jikos to more modern versions which are

both cost efficient and more environmentally friendly.

Interview (00064, 02:02-03:03)

(V.O) The most widely consumed jiko is the conventional

clay stove. This is produced in different sizes, in order

to suit different customer needs.

Interview (00067, 00:02-01:28)

(V.O) Small-scale businesses, especially roadside vendors

of roasted or deep-fried foodstuffs will normally go for

the metal jikos, which are generally stronger and longer

lasting.

Interview (00067, 01:31-02:06)

(V.O) Another variety of jikos is one that is specially

made to utilize either charcoal or firewood.

Interview (00067, 02:30-03:28)

(V.O) Apart from this range of stoves, Fredrick has also

come up with a special jiko that is powered by solar. He,

however, could not divulge the process since he is yet to

patent his innovation.

Interview (00067, 04:43-04:51)

(V.O) He did, however, take us through the process of

making the ordinary jiko.

The process begins with a sheet of iron. Using a

standard, prior cutout, a pattern is drawn out on the

sheet. This provides the outline from which the outer,

metallic part of the stove will be made.

B-roll (00078, 00:01-00:52, 01:36-01:42)

(00079, 00:02-00:24, 00:42-01:01)

B-roll (00079, 01:02-01:28) (V.O) The two new cutouts

are hinged together at the joints created on the edges by

being hammered on the rail.

This creates a round sheet of iron, which will form the

upper part of the outer covering.

B-roll (00080, 01:26-02:25) (V.O) The process is then

repeated using a smaller cutout, which will form the

lower part of the outer covering.

This cutout is folded and a hole carved out at the

centre. This will eventually form the door used in

regulating ventilation of the stove.

B-roll (00080, 06:07-07:13) (V.O) Once the two round

sheets are ready, they are also merged at the joints to

come up with the now almost complete outer shell of the

stove.

B-roll (00083) (V.O) To complete the outer shell; a

circular sheet is used to cover the lower part of the

shell. Three stands are installed for supporting the

stove as it is in use. Two handles are also installed to

offer grip for portability of the jiko.

B-roll (00087, 00:22-01:44) (V.O) A ventilation door

is attached to the hole that was earlier carved out on

the lower part of the shell.

B-roll (00088, 00:01-02:00) (V.O) With the outer

structure now complete, all that is left is for the clay

to be mounted. This is done using mortar made out of

soil, cement and water.

(V.O) The structural process is now complete and all

the necessary parts of the jiko are in place. From here,

the stove will be put out in the sun for the mortar

holding the clay in place to dry. The outer shell is also

painted to paper over the possible rust on the sheet.

Link to Break

Most Kenyans are dependent on charcoal and firewood

cookers to light their fire. Through the different jikos

he makes, Fredrick Omondi is not only making it more

efficient to use these cookers, but also making a life

out of it.

We take a short break now and when we come back, we will

look at another innovator who is using not much more than

her two hands to make a difference. Don’t go too far.

Link from Break

Earlier on, we followed the process of making a charcoal-

burning stove. Now, we get to meet Caroline Akoth, who

uses coal dust and soil to make briquettes that are

cheaper than usual charcoal and emit less smoke.

Outro

One of the essential factors for an idea or a product to

be considered innovative is the problem that it comes to

solve. For most people, not least those who live in slum

areas, the primary concern is how to bring the cost of

living down. Caroline and Fredrick have proven that

through innovative thinking, you can not only help to

make life that little bit easier for yourself but also

for the community around you.

That’s it from us here at Innovation Corner. Please join

us again next week, same place and same time as we

explore more innovations in Africa. My name is Purity

Ndung’u; please keep watching KUTV.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Workshop On FAN Engineering For Hvac&R: Sushil K. ChoudhuryDocument85 pagesWorkshop On FAN Engineering For Hvac&R: Sushil K. ChoudhurySadique ShaikhNo ratings yet

- BUS6100 Mo1Document5 pagesBUS6100 Mo1Thelma AkpataNo ratings yet

- Gov - Ph-Proclamation No 739 S 1970Document2 pagesGov - Ph-Proclamation No 739 S 1970Jeffrey MendozaNo ratings yet

- Cussons Boiler Instructon ManualDocument32 pagesCussons Boiler Instructon Manualjakakolenk100% (1)

- Termeni Tehnici EnglezaDocument22 pagesTermeni Tehnici EnglezaCarmen Melisa Tanase100% (1)

- Tesla Leaks - Nicola Tesla Missing Patents & Inventions Not "Nikola Tesla"Document14 pagesTesla Leaks - Nicola Tesla Missing Patents & Inventions Not "Nikola Tesla"Ettore PellegriniNo ratings yet

- Setting A Quality Standard For Fuel EthanolDocument56 pagesSetting A Quality Standard For Fuel EthanolSuresh ChaluvadiNo ratings yet

- How Global Warming Affects Our PlanetDocument10 pagesHow Global Warming Affects Our Planetmalik bestNo ratings yet

- Saturn - Late BloomerDocument14 pagesSaturn - Late BloomerNina Elezovic Simunovic100% (1)

- Economic Assessment of Grid-Connected Residential Solar Photovoltaic Systems Introduced Under Romania's New RegulationDocument17 pagesEconomic Assessment of Grid-Connected Residential Solar Photovoltaic Systems Introduced Under Romania's New RegulationMinh Pháp VũNo ratings yet

- Gen2 Modernisation Brochure EN PDFDocument8 pagesGen2 Modernisation Brochure EN PDFMAYESTONNo ratings yet

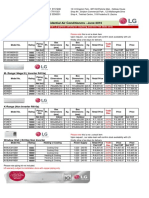

- LG Trade Price List June 2016Document2 pagesLG Trade Price List June 2016musturNo ratings yet

- BrochureDocument8 pagesBrochuredmoghaNo ratings yet

- BHEL Haridwar Summer TrainingDocument23 pagesBHEL Haridwar Summer TrainingNew CreationNo ratings yet

- 23 - Tabela para ConverterDocument23 pages23 - Tabela para ConverterflaviodellatorreNo ratings yet

- HomelcaDocument71 pagesHomelcashak10088596No ratings yet

- Fire Protection SystemDocument4 pagesFire Protection SystemAydaLeeNo ratings yet

- Ecp57vol12 035Document8 pagesEcp57vol12 035sumitrochakrabortiNo ratings yet

- Merlin XX EngineDocument6 pagesMerlin XX EngineIvan Kopić100% (2)

- 100ah - 12V - 6FM100 VISIONDocument2 pages100ah - 12V - 6FM100 VISIONBashar SalahNo ratings yet

- Annex B - Discussion On The Transaction Fee Rate For The Renewable Energy Market PDFDocument10 pagesAnnex B - Discussion On The Transaction Fee Rate For The Renewable Energy Market PDFRucheska SoNo ratings yet

- Insulation Coordination Studies For 400 KV Gis in A Hydroelectric Project in IndiaDocument6 pagesInsulation Coordination Studies For 400 KV Gis in A Hydroelectric Project in IndiaAchint KumarNo ratings yet

- Siemens Gamesa Wind Turbine 4 X Platform Brochure enDocument4 pagesSiemens Gamesa Wind Turbine 4 X Platform Brochure enMendes NetoNo ratings yet

- Clark GX 230Document108 pagesClark GX 230cornel_lupu100% (2)

- Resource Management: toxicity/IEQ:: Section 15800 - Air DistributionDocument5 pagesResource Management: toxicity/IEQ:: Section 15800 - Air DistributionAnonymous NMytbMiDNo ratings yet

- Brahmakumaris Solar Community KitchenDocument24 pagesBrahmakumaris Solar Community KitchenVijith SivanNo ratings yet

- Turbo Planetary Gear Technology OverviewDocument5 pagesTurbo Planetary Gear Technology Overviewsuna06m6403No ratings yet

- ResumeDocument9 pagesResumeAVES HUSAINYNo ratings yet

- JESR 2010 - 11 Final Report MEMDocument190 pagesJESR 2010 - 11 Final Report MEMHussein BoffuNo ratings yet

- Lab ManualDocument96 pagesLab ManualASWANI RAJAN50% (2)