Professional Documents

Culture Documents

Corrosion Inhibitors PDF

Uploaded by

Sasa Djordjevic0 ratings0% found this document useful (0 votes)

20 views2 pagesOriginal Title

corrosion inhibitors.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views2 pagesCorrosion Inhibitors PDF

Uploaded by

Sasa DjordjevicCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Autolab Application Note COR05

Corrosion

Part 5 – Corrosion Inhibitors

Keywords that cause the formation of precipitates on the surface

blocking both anodic and cathodic sites indirectly.

Corrosion; Inhibitors

Hard water that is high in calcium and magnesium is less

Summary

corrosive than soft water because of the tendency of the

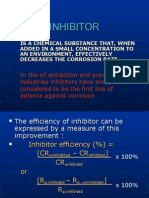

A corrosion inhibitor is a substance when added in a small salts in the hard water to precipitate on the surface of the

concentration to an environment reduces the corrosion rate metal forming a protective film.

of a metal exposed to that environment. Inhibitors often play

an important role in the oil extraction and processing

industries where they have always been considered to be The most common inhibitors of this category are the

the first line of defence against corrosion. silicates and the phosphates. Sodium silicate, for example,

is used in many domestic water softeners to prevent the

occurrence of rust water. In aerated hot water systems,

Types of corrosion inhibitors sodium silicate protects steel, copper and brass. However,

Anodic inhibitors protection is not always reliable and depends heavily on pH.

Anodic inhibitors usually act by forming a protective oxide Phosphates also require oxygen for effective inhibition.

film on the surface of the metal causing a large anodic shift Silicates and phosphates do not afford the degree of

of the corrosion potential. This shift forces the metallic protection provided by chromates and nitrites, however, they

surface into the passivation region. They are also are very useful in situations where non-toxic additives are

sometimes referred to as passivators. Chromates, nitrates, required.

tungstate, molybdates are some examples of anodic

inhibitors. Volatile Corrosion Inhibitors

Volatile Corrosion Inhibitors (VCI), also called Vapor Phase

Cathodic inhibitors Inhibitors (VPI), are compounds transported in a closed

Cathodic inhibitors act by either slowing the cathodic environment to the site of corrosion by volatilization from a

reaction itself or selectively precipitating on cathodic areas source. In boilers, volatile basic compounds, such as

to limit the diffusion of reducing species to the surface. morpholine or hydrazine, are transported with steam to

prevent corrosion in the condenser tubes by neutralizing

acidic carbon dioxide or by shifting surface pH towards less

The rates of the cathodic reactions can be reduced by the

acidic and corrosive values. In closed vapor spaces, such

use of cathodic poisons. However, cathodic poisons can

as shipping containers, volatile solids such as salts of

also increase the susceptibility of a metal to hydrogen

dicyclo-hexylamine, cyclohexylamine and hexamethylene-

induced cracking since hydrogen can also be absorbed by

amine are used.

the metal during aqueous corrosion or cathodic charging.

When these inhibitors come in contact with the metal

The corrosion rates can also be reduced by the use of

surface, the vapor of these salts condenses and is

oxygen scavengers that react with dissolved oxygen. Sulfite

hydrolyzed by any moisture to liberate protective ions. It is

and bisulfite ions are examples of oxygen scavengers that

desirable, for an efficient VCI, to provide inhibition rapidly

can combine with oxygen to form sulfate.

while lasting for long periods. Both qualities depend on the

volatility of these compounds; fast action wanting high

Mixed Inhibitors volatility while enduring protection requires low volatility.

Mixed inhibitors work by reducing both the cathodic and

anodic reactions. They are typically film forming compounds

Autolab Application Note COR05

Corrosion

Part 5 – Corrosion Inhibitors

Evaluation of Corrosion inhibitors

Electrochemical methods are used routinely routin for the

evaluation of the efficiency of corrosion inhibitors. The

advantages of electrochemical methods are short

measurement time and mechanistic information that they

provide which help not only in the design of corrosion

protection strategies but also

so in the design of new inhibitors.

Electrochemical Characterisation of anodic inhibitor

Benzoic acid was chosen as an example anodic inhibitor to

illustrate the use of electrochemical methods for the

characterization of inhibitors. A polished 3 mm diameter

diamet CK

45 steel rod embedded in epoxy was used as the working

Figure 1 – Linear polarization measurement in the absence and

electrode. The Autolab RDE (rotating disc electrode) system

presence of a corrosion inhibitor

was used to maintain a constant rpm of 800 for the

experiments. The experiments were conducted in the

AUTOLAB Corrosion Cell. The results shown in the figure illustrate when an anodic

inhibitor is added to the solution there is a shift of the

iciency of the inhibitor was studied by adding 0.5 M

The efficiency corrosion potential in the anodic direction and a reduction in

benzoic acid to 0.1 M Na2SO4 solution. The electrolyte was the anodic current. The corrosion inhibitor also results in the

deaerated for 30 minutes by N2 purging prior to the start of formation of the passive film evidenced by the appearance

the experiment. Reference measurements were done on 0.1 of the passivation plateau.

M Na2SO4 solution without inhibitor.

nhibitor. The pH of the solution

was adjusted to 6.5 with NaOH and H2SO4 prior to the start

References

of the experiment. A platinum sheet electrode (6.0305.100)

was used as the counter electrode and Ag/AgCl • P. Agarwal, D. Landolt, Corrosion Science, 260 (1998),

(6.0733.100) was used as the reference electrode. 673-691

The linear

ear sweep voltammetry (LSV) experiments were Date

conducted using an AUTOLAB PGSTAT302N controlled by

1 July 2011

the NOVA software. The potentials were scanned from -1.2

V to 0.6 V (vs. Ag/AgCl). Beginning the experiments at

cathodic potentials ensured that any oxide layer

laye present

prior to the start of the experiments was reduced. A 2.5 mV

potential step and a slow scan rate of 2 mV/s were used.

Figure 1 shows the polarization curves for solutions with and

without inhibitor are shown. The anodic part of the

polarization curve

urve without inhibitor is typical for active metal

dissolution.

Page 2 of 2

You might also like

- Effect of Nitrite - Chem Engi Research BulDocument5 pagesEffect of Nitrite - Chem Engi Research BulMei YeeNo ratings yet

- The Electrochemical Behavior of Mild Steel in Sulfide Polluted Nacl at Different VelocitiesDocument7 pagesThe Electrochemical Behavior of Mild Steel in Sulfide Polluted Nacl at Different VelocitiesShakeel MohmandNo ratings yet

- Inhibition of Mild Steel Corroin Cooling System - PHD - OK 1Document10 pagesInhibition of Mild Steel Corroin Cooling System - PHD - OK 1hadianatyaNo ratings yet

- Bahan Metlit1Document9 pagesBahan Metlit1valentinenorsNo ratings yet

- Performance of Some Thiophene Derivatives As Corrosion Inhibitors For 304 Stainless Steel in Aqueous SolutionsDocument21 pagesPerformance of Some Thiophene Derivatives As Corrosion Inhibitors For 304 Stainless Steel in Aqueous SolutionsNguyễn Minh ThôngNo ratings yet

- Electrochemical Comparisons of Corrosion Inhibitor Performance in Aluminum-Hydrogen Peroxide SystemsDocument5 pagesElectrochemical Comparisons of Corrosion Inhibitor Performance in Aluminum-Hydrogen Peroxide SystemsDarius MaximusNo ratings yet

- Corrosion ControlDocument24 pagesCorrosion ControlJane SmithNo ratings yet

- InhibitorDocument33 pagesInhibitorMohd SyazwanNo ratings yet

- Effect of Chloride Concentration On The Corrosion Rate in Carbon SteelDocument7 pagesEffect of Chloride Concentration On The Corrosion Rate in Carbon SteelAziz SaputraNo ratings yet

- Corrosion Science: Shuan Liu, Huyuan Sun, Lijuan Sun, Huiji FanDocument8 pagesCorrosion Science: Shuan Liu, Huyuan Sun, Lijuan Sun, Huiji FanVanessa Rios NolayaNo ratings yet

- Effect of Organic Acid Additions On The General and Localized Corrosion Susceptibility of Alloy 22 in Chloride SolutionsDocument10 pagesEffect of Organic Acid Additions On The General and Localized Corrosion Susceptibility of Alloy 22 in Chloride SolutionsjohnsopranaNo ratings yet

- Corrosion Prevention by Use of InhibitorsDocument19 pagesCorrosion Prevention by Use of InhibitorsSai PradeepNo ratings yet

- Passivation Treatment of Stainless Steel AcomDocument10 pagesPassivation Treatment of Stainless Steel Acomvijayarangam1984No ratings yet

- Corrosion Karbaschi2015Document10 pagesCorrosion Karbaschi2015carlosNo ratings yet

- Cifuentes L CorrosionDocument7 pagesCifuentes L CorrosionRenzo Pinto MuñozNo ratings yet

- Corrosion Inhibition of Mild Steel in Sulphuric Acid Solutions by Using Tetra Methyl Ammonium Bromide (TMAB)Document10 pagesCorrosion Inhibition of Mild Steel in Sulphuric Acid Solutions by Using Tetra Methyl Ammonium Bromide (TMAB)Basri GoeltomNo ratings yet

- Method To Prevent CorrosionDocument4 pagesMethod To Prevent CorrosionFaradilah Binti Ajma'inNo ratings yet

- Ascorbic Acid As Corrosion Inhibitor For Steel in Alkaline MediaDocument6 pagesAscorbic Acid As Corrosion Inhibitor For Steel in Alkaline MediaK S RamakrishnaNo ratings yet

- Corrosion Inhibition of Lysine As Basic Amino Acid On 316L Stainless Steel in 0.5 M H2SO4 Solution PDFDocument6 pagesCorrosion Inhibition of Lysine As Basic Amino Acid On 316L Stainless Steel in 0.5 M H2SO4 Solution PDFDartwin ShuNo ratings yet

- XPS Corrrev-2016-0016Document11 pagesXPS Corrrev-2016-0016chérifa boulechfarNo ratings yet

- Effect of Oxygen Concentration On Corrosion Rate of Carbon Steel in SeawaterDocument4 pagesEffect of Oxygen Concentration On Corrosion Rate of Carbon Steel in SeawaterAJER JOURNALNo ratings yet

- Unit 6 Corrosion Control by Inhibition - TeferiDocument40 pagesUnit 6 Corrosion Control by Inhibition - TeferiDESALEGN SHIBESHNo ratings yet

- Anodic ProtectionDocument30 pagesAnodic ProtectionChintoo GeeNo ratings yet

- Passivity - Design of Corrosion Resistant Alloys: Keywords: Alloy Design, Pitting Potential, OxidizersDocument5 pagesPassivity - Design of Corrosion Resistant Alloys: Keywords: Alloy Design, Pitting Potential, OxidizersrrameshsmitNo ratings yet

- Synergistic Effect of Halide Ions On The Corrosion Inhibition of Mild Steel in Sulphuric Acid Using Alkyl Substituted Piperidi-4 - One ThiosemicarbazonesDocument8 pagesSynergistic Effect of Halide Ions On The Corrosion Inhibition of Mild Steel in Sulphuric Acid Using Alkyl Substituted Piperidi-4 - One ThiosemicarbazonesInternational Journal of Research in Engineering and ScienceNo ratings yet

- Corrosion and Corrosion Inhibition of Pure Iron inDocument17 pagesCorrosion and Corrosion Inhibition of Pure Iron inKatNo ratings yet

- Abdel Gaber2006Document15 pagesAbdel Gaber2006Moisés AlvelaezNo ratings yet

- Extracto de Piper Longum Como Inhibidor de Corrosión Verde para Aluminio en Solución de NaOHDocument6 pagesExtracto de Piper Longum Como Inhibidor de Corrosión Verde para Aluminio en Solución de NaOHJessica AlejandraNo ratings yet

- Corrosion Science: Ramazan SolmazDocument10 pagesCorrosion Science: Ramazan SolmazkhalidNo ratings yet

- Group 4 CATHODIC INHIBITORDocument9 pagesGroup 4 CATHODIC INHIBITORfadelomar28_gmail_coNo ratings yet

- Corrosion Science: X. Liu, P.C. Okafor, Y.G. ZhengDocument8 pagesCorrosion Science: X. Liu, P.C. Okafor, Y.G. ZhengKArenNo ratings yet

- Copper Corrosion Inhibition by Azadirachta Indica Leaves Extract in 0.5 M Sulphuric AcidDocument4 pagesCopper Corrosion Inhibition by Azadirachta Indica Leaves Extract in 0.5 M Sulphuric AcidKArenNo ratings yet

- Control of CorrosionDocument12 pagesControl of CorrosionSyed ShahbazNo ratings yet

- Corrosion InhibitorDocument6 pagesCorrosion Inhibitorpadmesh awasthiNo ratings yet

- Corrosion Basic'sDocument58 pagesCorrosion Basic'sMayang Centya FebriaryNo ratings yet

- Amtec Consultants Expert Guide To Stainless Steel Corrosion Resistance ProblemsDocument4 pagesAmtec Consultants Expert Guide To Stainless Steel Corrosion Resistance ProblemssgttomasNo ratings yet

- Inhibitor CorrosionDocument21 pagesInhibitor CorrosionDiego Pabon100% (2)

- Advances in Gold Metallization at Motorola's Compound Semiconductor Fab (CS1) by Chad M. Becker, William Rummel, Dr. Paul OcanseyDocument4 pagesAdvances in Gold Metallization at Motorola's Compound Semiconductor Fab (CS1) by Chad M. Becker, William Rummel, Dr. Paul OcanseyPaidiu AndreiNo ratings yet

- CH.4. PP: Assivity AssivityDocument38 pagesCH.4. PP: Assivity Assivity이선엽100% (1)

- 07 - Chapter 1Document46 pages07 - Chapter 1jakinNo ratings yet

- Long-Term Propagation of PittingDocument4 pagesLong-Term Propagation of PittingPiranha TourniquetNo ratings yet

- Corrosion InhibitorsDocument38 pagesCorrosion Inhibitors20pcha122 20pcha122No ratings yet

- Anodic Dissolution of Pure Aluminum During Electrocoagulation Process - Influence of Supporting Electrolyte, Initial PH, and Current Density PDFDocument12 pagesAnodic Dissolution of Pure Aluminum During Electrocoagulation Process - Influence of Supporting Electrolyte, Initial PH, and Current Density PDFMicke Sandoval100% (1)

- DNP 8000 - Corrosion Inhibitor Series - InformationDocument27 pagesDNP 8000 - Corrosion Inhibitor Series - InformationMehman NasibovNo ratings yet

- 66 JMES 390 2013 LotoDocument12 pages66 JMES 390 2013 LotoAnonymous 1hOgJqwZuzNo ratings yet

- Experiment-10: Aim of The Experiment Organic InhibitorDocument3 pagesExperiment-10: Aim of The Experiment Organic InhibitorChayon MondalNo ratings yet

- Efect of Chloride On The Corrosion Rate in Carbon Steel 1668274137Document6 pagesEfect of Chloride On The Corrosion Rate in Carbon Steel 1668274137thakuryaNo ratings yet

- Met 04 Corrosion, SS Welding, DSWDocument27 pagesMet 04 Corrosion, SS Welding, DSWRaghu vamshiNo ratings yet

- AbstractDocument16 pagesAbstractShyam PahariNo ratings yet

- VOLTAMMETRY - Cathodic StrippingDocument10 pagesVOLTAMMETRY - Cathodic StrippingAndres Camilo Yasmo PerezNo ratings yet

- Acidcorrosion FlowingstreamDocument7 pagesAcidcorrosion FlowingstreamAMAN GUPTANo ratings yet

- Anodic ProtectionDocument30 pagesAnodic ProtectionLuis Eduardo PereiraNo ratings yet

- Introduction To The Chemistry of Pipes in SeawaterDocument18 pagesIntroduction To The Chemistry of Pipes in SeawaterNarvis RinconNo ratings yet

- Wet H S Corrosion and Inhibition: Technical PaperDocument9 pagesWet H S Corrosion and Inhibition: Technical Papershahramm_gh6062No ratings yet

- Ijciet: International Journal of Civil Engineering and Technology (Ijciet)Document11 pagesIjciet: International Journal of Civil Engineering and Technology (Ijciet)IAEME PublicationNo ratings yet

- Inorganic Anti-Corrosive PigmentsDocument14 pagesInorganic Anti-Corrosive Pigments이상현No ratings yet

- Corrosion: Corrosion ControlFrom EverandCorrosion: Corrosion ControlL L ShreirRating: 5 out of 5 stars5/5 (1)

- Amorphous and Nano Alloys Electroless Depositions: Technology, Composition, Structure and TheoryFrom EverandAmorphous and Nano Alloys Electroless Depositions: Technology, Composition, Structure and TheoryNo ratings yet

- Why Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksFrom EverandWhy Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksNo ratings yet

- 314 Monofinish GBDocument4 pages314 Monofinish GBdimitrios25No ratings yet

- Structural Bearings and Expansion Joints For BridgesDocument88 pagesStructural Bearings and Expansion Joints For BridgeswearplayNo ratings yet

- S3-9-Bridge Design W ECs Malakatas 20121001-IspraDocument92 pagesS3-9-Bridge Design W ECs Malakatas 20121001-IspraLuigiForgerone100% (1)

- 364-380 Adesilexpg1-Pg2 GBDocument4 pages364-380 Adesilexpg1-Pg2 GBdimitrios25No ratings yet

- DIN EN 1504-BasfDocument48 pagesDIN EN 1504-Basfcostinl100% (4)

- 06 Manus Sedlacek 1 Background Document To en 1991 Part 2 - Traffic Loads For Road BridgesDocument109 pages06 Manus Sedlacek 1 Background Document To en 1991 Part 2 - Traffic Loads For Road Bridgesdimitrios25100% (1)

- 1 - Introduction To UPV - Dave CorbettDocument42 pages1 - Introduction To UPV - Dave Corbettdimitrios25100% (3)

- Nitk RoukelaDocument91 pagesNitk RoukelaAtul GuptaNo ratings yet

- Sika Galvashield XP XPT XP2 XP4Document5 pagesSika Galvashield XP XPT XP2 XP4dimitrios25No ratings yet

- Chloride Threshold Values - State of The Art ReportDocument34 pagesChloride Threshold Values - State of The Art ReportOSE0597No ratings yet

- Ultrasound D1000 LF ENGDocument3 pagesUltrasound D1000 LF ENGdimitrios25No ratings yet

- Sentinel GLDocument2 pagesSentinel GLdimitrios25No ratings yet