Professional Documents

Culture Documents

Wear

Uploaded by

ZihCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wear

Uploaded by

ZihCopyright:

Available Formats

Crater Wear:

The wear taking place on the rake face of a single point cutting tool like crater is

called crater wear.

The crater wear is mainly caused due to

▪ The presence of friction between the chip-tool interface,

▪ The abrasion action of microchips present at the chip-tool interface.

▪ The abrasive action of fragments of Built Up Edge (BUE) at the chip-tool

interface and diffusion wear.

▪ The diffusion wears, due to the atomic attraction between the tool and work

the atoms of the tool material will get diffused and deposited over the

workpiece called diffusion wear.

Diagram of worn cutting tool, showing the principal locations where crater wear

and flank wear occur

Flank Wear:

The wear taking place on the flank face of a single point cutting tool is called flank

wear.

The reasons for flank wear are:

▪ The presence of friction at the tool work interface.

▪ The abrasive action of microchips or powdered particles present at the tool

work interface and diffusion wear.

▪ The diffusion wears, due to the atomic attraction between the tool and work

the atoms of the tool material will get diffused and deposited over the

workpiece called as diffusion wear.

You might also like

- Rock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesFrom EverandRock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesNo ratings yet

- Chip Formation and Tool LifeDocument37 pagesChip Formation and Tool Lifeneelesh singh100% (10)

- ACMV TrainingDocument227 pagesACMV Traininghbitho100% (3)

- 072 DEW Werkstoffauswahl Kaltarbeit GBDocument40 pages072 DEW Werkstoffauswahl Kaltarbeit GBFebrian JhaNo ratings yet

- Tool Wear & Tool LifeDocument49 pagesTool Wear & Tool LifeMessi LionelNo ratings yet

- Failure Analysis in Engineering ApplicationsFrom EverandFailure Analysis in Engineering ApplicationsRating: 1 out of 5 stars1/5 (1)

- Distinguish Between Crater Wear and Flank Wear of A Single Point Cutting ToolDocument2 pagesDistinguish Between Crater Wear and Flank Wear of A Single Point Cutting ToolBHAVESH JOSHINo ratings yet

- Tool WearDocument11 pagesTool WearRam27092003 GermanNo ratings yet

- Theory of Tool Wear and Surface RoughnessDocument12 pagesTheory of Tool Wear and Surface RoughnessjssrikantamurthyNo ratings yet

- Tool Wear: Manufacturing Technology - IIDocument31 pagesTool Wear: Manufacturing Technology - IIKhalil RazaNo ratings yet

- Machine Tool-Economic of MTDocument29 pagesMachine Tool-Economic of MTjssrikantamurthyNo ratings yet

- Unit 3Document16 pagesUnit 3Vishal JangirNo ratings yet

- 4.1 and 4.2 Tool Wear Mechanism and Types of Tool DamageDocument35 pages4.1 and 4.2 Tool Wear Mechanism and Types of Tool DamageTAMILARASAN MNo ratings yet

- Machinabilitytool Life & Tool Wear 4 in 1Document9 pagesMachinabilitytool Life & Tool Wear 4 in 1dsdvdNo ratings yet

- Manufacturing Chapter 3Document57 pagesManufacturing Chapter 3Jibril JundiNo ratings yet

- CF AsDocument12 pagesCF AsarulsivagiriNo ratings yet

- Tool WearDocument12 pagesTool WearSharath Kumar Bm100% (1)

- Modelling and Analysis of Micro Drill BitDocument4 pagesModelling and Analysis of Micro Drill BitMr. S. Thiyagu Asst Prof MECHNo ratings yet

- Electrochemical DeburringDocument8 pagesElectrochemical DeburringBARANINo ratings yet

- 2 Machining Operations and Machine ToolsDocument57 pages2 Machining Operations and Machine Toolssakali aliNo ratings yet

- Ch3 - Metal CuttingDocument30 pagesCh3 - Metal Cutting03 ABHISHEKNo ratings yet

- Machining MechAnalysis CHPT 4Document81 pagesMachining MechAnalysis CHPT 4Brahim MouchaneNo ratings yet

- Tool Life, Tool Wear Machinability PDFDocument9 pagesTool Life, Tool Wear Machinability PDFshivaNo ratings yet

- Lecture 10 (Cutting Tool Technology)Document18 pagesLecture 10 (Cutting Tool Technology)hashir siddiquiNo ratings yet

- Up Vs Dowm MillingDocument1 pageUp Vs Dowm MillingZahraa SayedNo ratings yet

- Tool Wear and Tool LifeDocument16 pagesTool Wear and Tool Lifedraco555No ratings yet

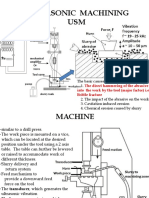

- Ultrasonic Machining USM: The Basic Causes of Material Removal 1Document13 pagesUltrasonic Machining USM: The Basic Causes of Material Removal 1Saswat KhataiNo ratings yet

- L7. Tool Wear and Tool LifeDocument34 pagesL7. Tool Wear and Tool LifeFasil GetachewNo ratings yet

- Wear On Cutting Edges - SandvikDocument5 pagesWear On Cutting Edges - SandvikJo MarbeNo ratings yet

- Metal Cutting Basics-MinDocument104 pagesMetal Cutting Basics-MinmuthukumaranNo ratings yet

- l2.104 Ecture-02-Part-2-Tool Wear and Tool LifeDocument24 pagesl2.104 Ecture-02-Part-2-Tool Wear and Tool LifeNexhat QehajaNo ratings yet

- THEORY of METAL CUTTING-Cutting Tool, Cutting Fluid & Machining EconomicsDocument17 pagesTHEORY of METAL CUTTING-Cutting Tool, Cutting Fluid & Machining EconomicsIzi75% (4)

- Unit-3 (Broaching, Lathe, Planer, Boring Machines)Document74 pagesUnit-3 (Broaching, Lathe, Planer, Boring Machines)KrupalPawarNo ratings yet

- 2-Tool Wear, Tool Life, and Economics of Metal CuttingDocument13 pages2-Tool Wear, Tool Life, and Economics of Metal CuttingOKELLO JOB LAZARUSNo ratings yet

- May 2015Document20 pagesMay 2015ManojKumar MNo ratings yet

- 004 U1 Cutting ToolDocument10 pages004 U1 Cutting ToolGaruda Sastha ArunNo ratings yet

- Experiment No.2 PDFDocument6 pagesExperiment No.2 PDFGest Account 08No ratings yet

- Tool Wear MechanismDocument9 pagesTool Wear MechanismDevansh AgrawalNo ratings yet

- Traditional and Non Traditoinal Lab 1Document8 pagesTraditional and Non Traditoinal Lab 1Ahmad ZrngNo ratings yet

- 1Document44 pages1mohammadmaleki91172No ratings yet

- Cutting Forces in Hard Turning Comprising Tool Flank Wear and Its Implication For The Friction Between Tool and WorkpieceDocument7 pagesCutting Forces in Hard Turning Comprising Tool Flank Wear and Its Implication For The Friction Between Tool and Workpiecematic91No ratings yet

- Practical1 BSC 2020Document3 pagesPractical1 BSC 2020Suchetana DasNo ratings yet

- Tool AnglesDocument9 pagesTool AnglesatwaattallaNo ratings yet

- 01 Dujv UE Presentation 2018 PDFDocument69 pages01 Dujv UE Presentation 2018 PDFelias attalahNo ratings yet

- Module-5: Tool Wear & Tool LifeDocument10 pagesModule-5: Tool Wear & Tool LifeYashas KattemaneNo ratings yet

- Unit PPTDocument81 pagesUnit PPTGayatri KanwadeNo ratings yet

- Metal Machining and Automation (ME 3201)Document19 pagesMetal Machining and Automation (ME 3201)kasam santhosh prathikNo ratings yet

- Tool Chapter - 2Document43 pagesTool Chapter - 2Tamirat NemomsaNo ratings yet

- 815-Press Tools: Part A 1. List Out Three Stages of CuttingDocument20 pages815-Press Tools: Part A 1. List Out Three Stages of CuttingRajendra MurthyNo ratings yet

- TDD-Metal Cutting & Special ToolsDocument27 pagesTDD-Metal Cutting & Special ToolsGS RathoreNo ratings yet

- A Review of The Degradation Mechanisms of The Hot Forging ToolsDocument12 pagesA Review of The Degradation Mechanisms of The Hot Forging ToolsNatalino FonsecaNo ratings yet

- Materials For Forming ToolsDocument40 pagesMaterials For Forming Toolssav33No ratings yet

- Manufacturing Tech. IIDocument13 pagesManufacturing Tech. IIanon_376852568No ratings yet

- Study of Chip Formation & Classification of ChipsDocument22 pagesStudy of Chip Formation & Classification of ChipsAmin RafiqNo ratings yet

- Damage Detection Using AnsysDocument82 pagesDamage Detection Using AnsysAHMAD GHARABLINo ratings yet

- Theory of Metal CuttingDocument38 pagesTheory of Metal CuttingcrazynupNo ratings yet

- Chip Formation and Tool LifeDocument37 pagesChip Formation and Tool LifeSquakx BescilNo ratings yet

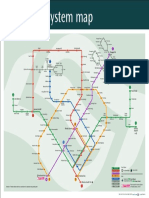

- Nus Kent Ridge MapDocument1 pageNus Kent Ridge MapShawn SimNo ratings yet

- BEng ME Timetable Sem2Document7 pagesBEng ME Timetable Sem2ZihNo ratings yet

- UGCPE ModRegScheduleDocument1 pageUGCPE ModRegScheduleZihNo ratings yet

- ME TEs - 20180508Document16 pagesME TEs - 20180508ZihNo ratings yet

- Singapore Train System Map 2016Document1 pageSingapore Train System Map 2016Pinky KimNo ratings yet

- ME4102 Briefing Slides (Sem 2 AY1920)Document10 pagesME4102 Briefing Slides (Sem 2 AY1920)ZihNo ratings yet

- EMA (1) (1) - Unlocked PDFDocument222 pagesEMA (1) (1) - Unlocked PDFZihNo ratings yet

- Lesson PlansDocument1 pageLesson PlansZihNo ratings yet

- 191002officeworking SBPPTDocument23 pages191002officeworking SBPPTZihNo ratings yet

- Nus Academic Calendar AY2019-2020Document2 pagesNus Academic Calendar AY2019-2020Meiqi GuoNo ratings yet

- Cutting Tools Page 33 34 35Document90 pagesCutting Tools Page 33 34 35ZihNo ratings yet

- ISO 50001 UK I Overview Webinar SGDocument27 pagesISO 50001 UK I Overview Webinar SGZihNo ratings yet

- Laboratory Timetable For Semester 6, 2pm - 5 PM: Monday Monday SubgroupsDocument1 pageLaboratory Timetable For Semester 6, 2pm - 5 PM: Monday Monday SubgroupsZihNo ratings yet

- Cdio Design Build Project:: Pee Suat Hoon - Helene Leong - Dennis SaleDocument48 pagesCdio Design Build Project:: Pee Suat Hoon - Helene Leong - Dennis SaleHilal AhmadNo ratings yet

- 301 Tutorial 6 (Week 9) SolutionsDocument2 pages301 Tutorial 6 (Week 9) SolutionsZihNo ratings yet

- 16 - Properties and Applications of Materials PDFDocument65 pages16 - Properties and Applications of Materials PDFmpcd07No ratings yet

- Rake Angle PDFDocument9 pagesRake Angle PDFZihNo ratings yet

- High Speed MachiningDocument8 pagesHigh Speed MachiningVignesh WaranNo ratings yet

- 301 Tutorial 5 With AnswersDocument4 pages301 Tutorial 5 With AnswersZihNo ratings yet

- HW Solutions For Period 3Document10 pagesHW Solutions For Period 3dellibabu509No ratings yet

- Lab Me2142Document1 pageLab Me2142ZihNo ratings yet

- Tutorial 1 PDFDocument41 pagesTutorial 1 PDFZihNo ratings yet

- ME2151 Tut1Soln PDFDocument5 pagesME2151 Tut1Soln PDFZihNo ratings yet

- Tutorial 2Document17 pagesTutorial 2ZihNo ratings yet

- Lab ME2121 ME3112Document1 pageLab ME2121 ME3112ZihNo ratings yet

- Tutorial 1 PDFDocument41 pagesTutorial 1 PDFZihNo ratings yet