Professional Documents

Culture Documents

ABB - Lubricants - and - Greases Manufacturing Plants - EN0711 - Light PDF

ABB - Lubricants - and - Greases Manufacturing Plants - EN0711 - Light PDF

Uploaded by

Syarif HidayatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ABB - Lubricants - and - Greases Manufacturing Plants - EN0711 - Light PDF

ABB - Lubricants - and - Greases Manufacturing Plants - EN0711 - Light PDF

Uploaded by

Syarif HidayatCopyright:

Available Formats

Lubricants & greases manufacturing plants

Optimize and improve your performance

International technology provider

Design, engineering and supply of lubricants and greases manufacturing plants

With over 50 years of blending experience, in both new Key equipment

and revamped plants all over the world, Cellier, as an State-of-the-art equipment has been developed and

Activity of ABB France, fully understands the complexity standardised by Cellier Activity to meet the specific requi-

of running a lubes or greases manufacturing plant and rements of the lubricants and greases markets:

in particular how to achieve inventory using Just In Time

(JIT) principles integrated with the production of many −− Automatic Batch Blender

finished products and packing combinations. −− Drum Decanting System

−− In-Line Blending system

Our services include: −− Simultaneous Metering Blending system

−− High-yield grease reactor and peripherals

−− Conceptual design −− Pigged pipe lines

−− Basic engineering −− Pigged manifold

−− Detail engineering

−− Equipment design and supply All the equipment can be skid mounted. In addition to the key

−− Installation and start-up by ABB’s own expert team equipment noted above, our capability includes the design and

−− Training and technical assistance delivery of raw material and finished product storage, transfer

−− Software telemaintenance services and distribution units as well as filling and packaging systems.

Design Process Control

Cellier Activity has developed specific software for the design Cellier Activity has developed Lubcel™, a specific process

of new plants or modernisation of existing ones. The design control software for lubricants and grease manufacturing

is optimised to give the shortest Return On Investment (ROI) plants helping you to achieve the compliance with quality

time and to guarantee the plant performance. procedures and a total traceability of operations.

3-D view of a grass-root plant

2 International technology provider | Lubricants and greases manufacturing plants

Process and know-how

Increasingly stringent product-quality requirements are the PORTFOLIO BLENDING UNITS SIZING

• Blending batch size

standard for today’s lube oil market. Formulations are forever ANALYSIS • Blending facilities design

• Cycle times / work load

increasing in number and complexity. In addition to these

production constraints, the Lube Oil Blending Plant (LOBP)

has to face up to the highly competitive lubricants market.

DESIGN

RAW MATERIALS BALANCE

• Bulk storage sizing FINISHED PRODUCTS STORAGE

• Unloading facilities design • Dedicated tank sizing

• Packaged additives storage • Holding tank sizing

Competitive cost is of primary importance as is customer and handling design

• Raw materials transfers

service especially for the industrial lubricants market. Ability to

guarantee, at short notice, delivery for the exact quantity re- FILLING FACILITIES SIZING FINISHED PRODUCTS TRANSFER

quired by the customer is the daily challenge of every modern • Balance per pack

• Filling orders numbers

• Transfers requirements

• Transfers system design

LOBP. • Change / rinsing over time

• Filling lines design

(lines / manifolds / pumps, etc.)

In this environment, only an optimised LOBP design can

ensure customer satisfaction and supplier profitability. ENGINEERING PROCESS DOCUMENTS OTHER ENGINEERING DOCUMENTS

• PFS • Layouts

• Equipment list

A blending plant typically includes five main areas: • Process description

• Typical PID's

−− Raw materials storage ORGANISATION / ECONOMICS

−− Blending units • Plant organisation CONCEPTUAL

• Manning level

−− Finished-product storage (bulk) • Operational cost DESIGN BOOK

−− Filling and loading

−− Packed finished products warehouse and dispatch

These areas are closely interconnected and as such an The design methodology specifically developed by Cellier

optimised design needs to cover the complete plant. Design Activity for complex batch production plants, and supported

is based on the actual customer production requirements and by specific design tools, can be applied at the different steps

constraints which include: of the project from feasibilty study up to turn-key unit design.

− − Production portofolio (product slate, required production, Dynamic simulation of production portofolio can be imple-

formulas, grade/ pack distribution) mented which is of special interest to further optimise areas

− − Batch size distribution (Economic Order Quantity or with great load variations such as truck loading gantries.

Customer Order based)

− − Product compatibility This know-how applies also to the manufacture of greases.

− − Raw material characteristics and delivery mode

− − Products Lead time and peak demand.

Lubricants and greases manufacturing plants | Process and know-how 3

Lube Oil Blending Plant

Cellier has developed specific processing equipment to meet the lubricant market

requirements and quality constraints.

Automatic Batch Blending Simultaneous Metering

The Cellier Automatic Batch Blender represents a techno- Blending

logically advanced blending option especially adapted to

complex formulations, extended products slate and blend-to- Simultaneous Metering Blending (SMB) is similar to the ILB

order policies which are part of modern lubricants production but coupled with a sequential control and mode of operation.

requirements. It combines the advantage of the ILB in terms of production

capacity but also the advantage of the sequential control

The principal advantages of Automatic Batch Blending related to flexibility and contamination.

systems as compared to conventional batch blending are :

Advantages:

−− High level of blending accuracy and repeatability

−− High RFTI (Right First Time Index ), no re-blend − − High throughput capability

−− Reduced manpower requirements − − Low inter-contamination through rinsing being part of

−− Enhanced blending flexibility the blend

−− Quick blend turnaround − − Reduced number of dosing modules compared to conven-

−− Low contamination tionnal ILB (typically 4 vs. 9) meaning reduced investment

−− Minimum (virtually zero) slop generation. − − Simpler control

− − Possible batch interruption enabling direct drum decanting

Flexibility in batch size, product formulation, raw material or manual additions.

handling and process sequences yield to a powerfull

blending tool in the fields of lubricants, lubricant additives or

fuel additives. Drum Decanting System

Cellier Drum Decanting System (DDS) is designed to pump

In Line Blending liquid products (even viscous) stored in drums or small

containers and to incorporate them in formulation processes

In Line Blending (ILB) is especially adapted to large through- (chemical industry, lubricants, etc.).

put production with a limited number of products and

compatibility groups and when immediate product availability The DDS perfoms the following functions:

is required or intermediate storage is difficult (such as ship

loading). −− empties a drum or mini-container

−− doses a quantity of product

Advantages: −− rinses the emptied drum and

−− recycles the rinsing product.

−− Product immediately available (on spec)

−− Large throughput

−− High level of blending accuracy and repeatability

−− Low manpower requirements.

4 Lube Oil Blending Plant | Lubricants and greases manufacturing plants

1 2

3 4

1 Simultaneous Metering Blending systems with pigged lines | 2 In-Line Blending systems | 3 Drum Decanting System | 4 Automatic piggable manifold

Pigging systems Pigging Manifold

Used for many years in certain industries, pipe pigging Interconnecting the large number of source tanks with

technology can be used where a large variety of products different possible destinations (filling, loading, etc.) has

are transfered. always been a major problem of Lube Oil Blending Plants.

The unsafe and unpractical old “snake-pit” can now be

Advantages: replaced by a closed and compact piggable manifold ensuring

safe interconnection without cross-contamination or product

− − Optimisation of installation costs by reducing the number loss.

of lines

− − Operating and cleaning costs reduced by a significant Advantages:

decrease of rinsing liquid quantities

− − Line flexibility increased, simultaneous multi-connections, − − Automatic operation

reduction of cleaning time between two batches − − Compactness and optimized space requirement

− − Quick, automatic and safe pipe cleaning system − − Flexibility: multidirectional connections, bidirectional

− − Completely closed system pigging, dedicated/pigged lines, different diameters)

− − No more dead zones, complete line cleaning −− Fast cycle time

− − No waste generation. −− Equipment availability and cleanliness, easy maintenance.

Lubricants and greases manufacturing plants | Lube Oil Blending Plant 5

Greases manufacturing plant

Cellier provides expertise and in-house technologies to optimize your greases

manufacturing process.

ABB designs greases manufacturing units meeting your In-line manufacturing process

specific needs. These units integrate saponification In the in-line greases manufacturing process, the saponifi-

reactors offering excellent performance in terms of cation, dehydration and finishing phases are completed

mixing, thermal transfer, easy cleaning and maintenance. continuously. The in-line process offers:

They also include satellite solutions conferring flexibility

and modularity to your plant: in-line dosing (flowmeters, − − flexibility,

loss-in-weight), transfers of finished products using − − reduced cycle time,

pigged lines and production monitoring systems. − − improved process control.

Application Heating/cooling

All types of grease - simple, complex or mixed - lithium, The key to the process control, productivity and quality lies

lithium/calcium, aluminium, etc. with or without additives. in the mastering of thermal exchange systems. An accurate

heating/cooling system for the heating of oil and chemical

Batch manufacturing process components and the cooling of the finished product enables:

The batch greases manufacturing process includes the

following phases: − − reduced heating/cooling times,

− − fine product temperature regulation with +/- 1°C accuracy,

− − metering and addition of reactants (fatty acids, base oils, − − high pressures and high velocities of the heating/cooling

water, alkali), medium,

− − saponification run in a reactor/kettle operating at atmos- − − elimination of thermal shocks,

pheric pressure or as a pressurized kettle to convert the − − reduced operational costs.

fatty acid to soap and disperse the soap throughout the

mixture, Process control

− − dehydration to remove the reaction water, The module of the Lubcel™ software developped for grease

− − homogenisation or milling to break agglomerated process control is perfectly adapted to the requirements of

particles, adjust the grease consistency and produce a greases manufacturers. It is based on:

smooth and stable product,

− − cooling − − ABB expertise in the control of continuous and batch

− − in-line deaeration to remove air entrapped prior to filling. processes,

− − choice of reliable and accurate measurement, control and

To add special properties to the grease, other ingredients may regulation instruments,

be introduced, such as oxidation inhibitors, anti-corrosion − − customization of the control system according to the

and anti-wear agents. This additivation step is completed in process needs.

a finishing kettle where the deaeration of the product may be

completed. and provides common control tools for both greases and

lubricants manufacturing processes.

6 Greases manufacturing plant | Lubricants and greases manufacturing plants

1 2

3 4

1 Grease reactors | 2 Dosing hopper with bag emptying | 3 Filling line | 4 Control room with production monitoring

Benefits Cellier Activity delivers complete units from the storage and

− − High dispersion and thermal yields delivery systems of raw materials to the filling and packaging

− − Easy cleaning systems, including utilities production.

− − Reduced investments costs

− − Minimised operational costs The units can be delivered as skidded units, fully assembled

− − Flexible and multipurpose units for the production of and ready for operation, including valves, fittings, control

current greases. instruments, utilities and thermal insulation, for ease of instal-

− − Excellent process repeatability and quality control. lation and to meet customer layout constraints.

Lubricants and greases manufacturing plants | Greases manufacturing plant 7

Extended process control

Lubcel™: Process control and plant scheduling software

Lubcel™ Syncel graphics module

Lubcel™ is a powerful control system for batch production Syncel graphics module is a SCADA system sharing common

monitoring and management which perfectly fits the require- database with the Lubcel™ solution. It includes a complete

ments of lube oils or grease manufacturers. Lubcel™ ensures integrated synoptic screen maker.

the entire management of raw materials, product formulation,

sub-recipes and recipes, resources, inventories, production Workshop capabilities

batches and cleaning sequences. Parameter setting enables Lubcel™ enables the management of manual operations

Lubcel™ to optimize the production. through deported industrial PC, WIFI tablets PC.

Lubcel™ can be extended to encompass the control and Warehouse module

supervision of all the operations within the plant, from raw Lubcel™ enables the management of packed additives, IBC

material reception and storage to product dispatch (blending, containers including bar coding scanner and printer solutions.

intermediate storage, transfers, filling and warehouse). It is a

plant-wide control system integrating sub-systems such as Advanced short-term scheduling module

graphics, workshop capabilities, warehouse management, Lubcel™ indicates the daily load for each blending or filling

advanced schedule features. It has no limits in communicating resource (ABB, SMB, ILB…) or workshop (reception, blen-

with other systems such as lab or business systems (ERP). ding, filling). This short-term scheduling module is a powerful

tool for smoothing the load.

Lubcel™ is able to be integrated with the majority of PLCs

or controllers. With Lubcel™ you will achieve the total process Histcel historics module

control and plant scheduling software integration of your Lubcel™ enables information from the previous year’s pro-

production system. duction data records to be retrieved for data tracking purpose

and to perform analysis or to get some trends. The results of

multi-criteria searches can be exported in Excel format files in

order to manipulate the records with standard tools.

1 Synoptic screen for the monitoring of a piggable manifold | 2 Synoptic screen for the monitoring of raw materials transfer through pigged lines

1 2

8 Extended process control | Lubricants and greases manufacturing plants

Typical Lubcel™ architecture

Lubricants and greases manufacturing plants | Extended process control 9

Modernisation of existing plants

Stock

Why modernise and improve performance ?

− − To comply with highest international quality standards.

− − To enhance productivity and lower production costs.

− − To increase production capacity.

50 %

− − To enlarge product portfolio.

Additive

−− To ensure a better customer service. Saving Reblend

95 %

− − To increase control and interface by automation and plant- 2%

wide process control system.

Improvement factors

The technologies developped and implemented by Cellier

Activity improve the efficiency of existing plants. 50 %

75 %

Modern blending tools

− − Variable batch size.

Operators Slop

− − Dosing accuracy.

− − Reduced and repeatable cycle time. Typical savings resulting from an LOBP upgrade

Pigging technology / contamination control during transfers

− − Quick product change without slop generation. Key Performance Indicators (KPIs) improve by the reduction of

− − Minimisation of cross-contamination. minimum batch volume and reblend index.

High-connectivity control system A better productivity is obtained by an optimal resource

− − Elimination of human errors. allocation. It results in time savings by efficient, reliable and

− − Operation traceability. automated rinsing and transfer (pigging) procedures as well as

− − Connectivity to corporate network (ERP). in raw material savings (additives and base oils).

Results and capabilities Additional benefits are a laboratory workload reduction and

Major benefits of a plant upgrade are product and process a drastic slop reduction (virtually zero at blending stage) and

flexibility. Your plant becomes market responsive allowing: product loss.

− − high quality products,

−− inventory reduction,

− − Just-In-Time operations.

1 Automatic Batch Blenders as skidded units before shipment | 2 Tank farm

1 2

10 Modernisation of existing plants | Lubricants and greases manufacturing plants

Worldwide references

Through our capability to meet the real needs of the lubricants industry and

our unique position as specialist in the supply of turnkey production units,

Cellier Activity enjoys a leading position in this market.

The major international petroleum companies have chosen Cellier Activity.

AMOC Egypt

AGIP Italy

BP Castrol Australia, Belgium, China, India, Iran, Iran, Singapour, South Africa

CHEVRON USA

COPEC Chile

ENGEN RSA

ENOC UAE

EXXON MOBIL China, Egypt, France, Hong Kong, Japan, Singapour, Tunisia, UK

GALP Portugal

IDEMITSU Japan

INDIAN OIL India

INFINEUM Italy, Singapore

LUBRIFIN Romania

LUKOIL Romania

Q8 Belgium

LUBRIZOL France, India, UK

NAFTEC Algeria

NIPPON OIL Japan

PERTAMINA Indonesia

PSO Pakistan

RAK OIL UAE

REPSOL Spain

SHELL Belgium, Canada, France, Japan, Philippines, Russia, Singapore, Trinidad

SINOPEC China

TOTAL Belgium, China, France, India, Saoudi Arabia, Spain, Vietnam

Lubricants and greases manufacturing plants | Worldwide references 11

Contact us

ABB France Note:

FRABB_PA_CE036-V032011EN

We reserve the right to make technical changes or

Process Automation Division

modify the contents of this document without prior

Cellier Activity notice. With regard to purchase orders, the agreed

700 bd. Jean-Jules Herbert particulars shall prevail. ABB does not accept any

P.A. des Combaruches responsibility whatsoever for potential errors or

possible lack of information in this document.

73100 Aix-Les-Bains, France

Phone: +33 (0)479 35 05 65 We reserve all rights in this document and in the

Fax: +33 (0)479 88 37 71 subject matter and illustrations contained therein.

E-Mail: info.cellier@fr.abb.com Any reproduction, disclosure to third parties or

utilization of its contents – in whole or in parts – is

www.abb.com/industries forbidden without prior written consent of ABB.

All copyrights and trademarks are the property of

their rightful owners.

Copyright© 2011 ABB

All rights reserved

You might also like

- Synthetic Gear Oil SelectionDocument9 pagesSynthetic Gear Oil Selectionsmallik3No ratings yet

- Automatic Grease Lubricators White PaperDocument5 pagesAutomatic Grease Lubricators White PaperPaul RuckNo ratings yet

- Lubricants MarketDocument27 pagesLubricants MarketBhagyesh DokeNo ratings yet

- Lubimax Pib 2400sa - TDSDocument1 pageLubimax Pib 2400sa - TDSkarthibenNo ratings yet

- CetvelDocument17 pagesCetvelmehmetaliozgur100% (1)

- How Hybrid Car WorksDocument11 pagesHow Hybrid Car WorksVivek SharmaNo ratings yet

- Speciality Lubricants For Machine ToolsDocument15 pagesSpeciality Lubricants For Machine ToolsDarmawan PutrantoNo ratings yet

- LubricantsDocument26 pagesLubricantshoseinNo ratings yet

- 3 - Syntetic Pocket GuideDocument9 pages3 - Syntetic Pocket GuideRay Cepeda MenaNo ratings yet

- Lubrication Management: An Overview of Best PracticesDocument39 pagesLubrication Management: An Overview of Best Practicesdungga1100% (1)

- Lubrication Oils and AdditivesDocument12 pagesLubrication Oils and AdditivesavciayNo ratings yet

- 03 BPA Bakery IndustryDocument12 pages03 BPA Bakery IndustryMAYANK AGARWALNo ratings yet

- Gear OilsDocument3 pagesGear OilsPurchase ZenoilNo ratings yet

- Global Industrial Gear Oil MarketDocument16 pagesGlobal Industrial Gear Oil MarketSanjay MatthewsNo ratings yet

- Foodgrade Lubricants PDFDocument3 pagesFoodgrade Lubricants PDFSridhar ReddyNo ratings yet

- Automotive LubricantsDocument13 pagesAutomotive LubricantsArun Kumar67% (3)

- Base Stocks 基础油Document18 pagesBase Stocks 基础油Yesica RozoNo ratings yet

- GreaseDocument13 pagesGreaseParth Shah100% (2)

- Grease Construction and FunctionDocument7 pagesGrease Construction and FunctionProphx BliziceNo ratings yet

- OEM Engine Oil Lubricant Specifications: White PaperDocument4 pagesOEM Engine Oil Lubricant Specifications: White Papermohamed100% (1)

- Lubrication & Lubrication SystemsDocument21 pagesLubrication & Lubrication Systemss_mohankumarNo ratings yet

- 2 - SyntheticsDocument57 pages2 - SyntheticsRay Cepeda Mena100% (1)

- Correct LubricantDocument69 pagesCorrect LubricantZeshan Haydar100% (1)

- Base Oil Groups Manufacture Properties and PerformanceDocument4 pagesBase Oil Groups Manufacture Properties and Performanceiosalcido100% (1)

- PETROVOLL BROCHURE FINAL (May2016) PDFDocument50 pagesPETROVOLL BROCHURE FINAL (May2016) PDFAbir MazumderNo ratings yet

- Article - Lubrication at BHP SteelDocument5 pagesArticle - Lubrication at BHP SteelzuhdisulaemanNo ratings yet

- Approved List of Lubricants 23169revMAY2012Document2 pagesApproved List of Lubricants 23169revMAY2012Justin HendrixNo ratings yet

- H-1 Food Grade LubricantsDocument5 pagesH-1 Food Grade LubricantsmishraenggNo ratings yet

- Food Grade Brochure PDFDocument9 pagesFood Grade Brochure PDFMilena GonzalezNo ratings yet

- Shell Turbo T46 PDFDocument2 pagesShell Turbo T46 PDFdionisio emilio reyes jimenezNo ratings yet

- BROCHURE Premium Greases Guide TNRDocument7 pagesBROCHURE Premium Greases Guide TNRRezhaNo ratings yet

- What Are Metalworking FluidsDocument10 pagesWhat Are Metalworking FluidsDimas NevesNo ratings yet

- 5G Technology Training SeriesDocument6 pages5G Technology Training SeriesmirzaNo ratings yet

- LUBCON High Performance H1 Food Grade LubricantsDocument9 pagesLUBCON High Performance H1 Food Grade LubricantsNokiabhre WijayaNo ratings yet

- Lubricants For The Manufacturing IndustryDocument20 pagesLubricants For The Manufacturing IndustrynarenjiNo ratings yet

- Machinery Lubrication MagazineDocument82 pagesMachinery Lubrication Magazined_ansari26No ratings yet

- CASE STUDY 2 - SteelDocument19 pagesCASE STUDY 2 - SteelAnkit UjjwalNo ratings yet

- The Castrol Range of Industrial Lubricants High - 1Document40 pagesThe Castrol Range of Industrial Lubricants High - 1Shan Rana100% (1)

- Your Benefit: Optimised Lubrication Management: Enhanced Reliability and Efficiency in Your PlantDocument2 pagesYour Benefit: Optimised Lubrication Management: Enhanced Reliability and Efficiency in Your PlantVelibor Karanovic100% (1)

- X - Hydraulic Fluids Electronic HandoutDocument41 pagesX - Hydraulic Fluids Electronic HandoutRay Cepeda Mena100% (1)

- Reprot On TrainingDocument36 pagesReprot On TrainingMd.Mahbub MorshedNo ratings yet

- Industrial Brochure ISS 3 FEB11Document6 pagesIndustrial Brochure ISS 3 FEB11yorkshirewizardNo ratings yet

- Chemical Process Safety NotesDocument59 pagesChemical Process Safety NotesRishikesh AwaleNo ratings yet

- Special Lubricants For Textile MachineryDocument40 pagesSpecial Lubricants For Textile MachineryMarcos Silva100% (1)

- JM 105 SW 120 Ifu 9510905 enDocument124 pagesJM 105 SW 120 Ifu 9510905 enАлекса МирковићNo ratings yet

- Lubrizol Hydraulic FluidsDocument6 pagesLubrizol Hydraulic Fluidsrohit_12346No ratings yet

- Lubricants For Steel Industry: CondatDocument2 pagesLubricants For Steel Industry: CondatAlstome PowerNo ratings yet

- CNS Systems VDL 6000 AIS User ManualDocument47 pagesCNS Systems VDL 6000 AIS User ManualborisgolodenkoNo ratings yet

- Advantages of Zinc-Free Hydraulic OilsDocument2 pagesAdvantages of Zinc-Free Hydraulic OilsAnonymous F2TxS3YoaNo ratings yet

- Chemical Engg Basic IndiabixDocument123 pagesChemical Engg Basic IndiabixRishikesh Awale100% (3)

- Lubrizol360 Webinar PPT Template - v2 - Evaluation of Performance Properties of Slideway Lubricants - Z124Document58 pagesLubrizol360 Webinar PPT Template - v2 - Evaluation of Performance Properties of Slideway Lubricants - Z124tiến thử huỳnhNo ratings yet

- En Cement Industry Open Cast MiningDocument8 pagesEn Cement Industry Open Cast MiningArnaldo Macchi MillanNo ratings yet

- Kluber Bearing LubricationDocument9 pagesKluber Bearing Lubricationmotosega78100% (1)

- High Temperature Grease and Lubricants Market Size, Share and Forecast Upto 2021Document6 pagesHigh Temperature Grease and Lubricants Market Size, Share and Forecast Upto 2021Hari PurwadiNo ratings yet

- OCI Disaster Recovery & High Availability PDFDocument24 pagesOCI Disaster Recovery & High Availability PDFsudhirpatil15No ratings yet

- Chocolates CacepDocument4 pagesChocolates CacepMoisesNo ratings yet

- Biobased Lubricants and Greases: Technology and ProductsFrom EverandBiobased Lubricants and Greases: Technology and ProductsRating: 5 out of 5 stars5/5 (1)

- Chemical cleaning 1 رائعة PDFDocument16 pagesChemical cleaning 1 رائعة PDFmohamed karem100% (1)

- HP Lubes GuideDocument196 pagesHP Lubes GuideJen Ekx100% (1)

- Rolling TechnologyDocument4 pagesRolling TechnologyFrancis Erwin Bernard100% (1)

- Adding Motor Oil in An EngineDocument22 pagesAdding Motor Oil in An EngineBEN EMEKANo ratings yet

- Viscosidades KluberDocument23 pagesViscosidades KluberRCMNo ratings yet

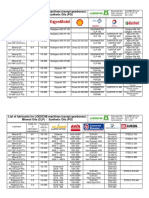

- List of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)Document8 pagesList of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)MossaabSelaimiaNo ratings yet

- Seaworthy.: A Selection of Lubricants For Marine and Offshore ApplicationsDocument20 pagesSeaworthy.: A Selection of Lubricants For Marine and Offshore ApplicationsEduardo CastilloNo ratings yet

- Shell Turbo T PDFDocument3 pagesShell Turbo T PDFrehmanNo ratings yet

- Hydraulic Oil ApplicationDocument3 pagesHydraulic Oil ApplicationRohit Ramamurthy TevnanNo ratings yet

- Rimula R3 MV 15W40Document2 pagesRimula R3 MV 15W40AdiWijayaNo ratings yet

- Shrewd Debate TacticsDocument25 pagesShrewd Debate TacticsRishikesh AwaleNo ratings yet

- Chemical ProcessesDocument150 pagesChemical ProcessesRishikesh AwaleNo ratings yet

- Exact Calculation Procedures For Multicomponent DistillationDocument21 pagesExact Calculation Procedures For Multicomponent DistillationRishikesh AwaleNo ratings yet

- Caustic Scrubber-Indirect Hydration IPA ProductionDocument1 pageCaustic Scrubber-Indirect Hydration IPA ProductionRishikesh AwaleNo ratings yet

- Ammonia Process InformationDocument4 pagesAmmonia Process InformationRishikesh AwaleNo ratings yet

- FS 2 Ep. 7Document5 pagesFS 2 Ep. 7John Garry BofillNo ratings yet

- Lab3 - SWT301Document72 pagesLab3 - SWT301Le Ngoc Tuan Minh (K16HL)No ratings yet

- Integrated Management Systems Manual Without Company RefDocument17 pagesIntegrated Management Systems Manual Without Company ReflkjhiuhNo ratings yet

- FluxMag54 Hydro Generator Skin EffectDocument3 pagesFluxMag54 Hydro Generator Skin EffectSrinivas KamarsuNo ratings yet

- Dissertation Adoption of Enterprise Resource Planning Erp in VietnamDocument30 pagesDissertation Adoption of Enterprise Resource Planning Erp in VietnamAr Puneet AroraNo ratings yet

- Electricity Billing System Report FileDocument99 pagesElectricity Billing System Report FileHell boyNo ratings yet

- Python Scripting Syllabus - by Murali P N, Besant TechnologiesDocument11 pagesPython Scripting Syllabus - by Murali P N, Besant TechnologiesRishi RockyNo ratings yet

- DriversDocument26 pagesDriversHN100% (1)

- Release Notes: Dell Emc NetworkerDocument34 pagesRelease Notes: Dell Emc NetworkerAhmed Gaber HaibaNo ratings yet

- CAMA2014 Des13Document16 pagesCAMA2014 Des13bibbi20% (1)

- Guitar Tuner With An Arduino: by EE421ACDCDocument9 pagesGuitar Tuner With An Arduino: by EE421ACDCKerem AydınNo ratings yet

- Panasonic SA AK52Document171 pagesPanasonic SA AK52Mario Lozano SNo ratings yet

- Design and Development of Low Cost IR Based Home Automation SystemDocument5 pagesDesign and Development of Low Cost IR Based Home Automation Systemp41005679No ratings yet

- ENGL 307T Introduction To Digital Writing Syllabus, S14Document6 pagesENGL 307T Introduction To Digital Writing Syllabus, S14Dan RichardsNo ratings yet

- (Registration Wing) Form For Capturing Details of Parent's Name & Communication DetailsDocument1 page(Registration Wing) Form For Capturing Details of Parent's Name & Communication DetailsVinesh NairNo ratings yet

- Edu Datasheet Srmicm V6 1Document3 pagesEdu Datasheet Srmicm V6 1vcp vcloudxpertsNo ratings yet

- AP0138 Pin and Part Swapping With Dynamic Net AssignmentDocument8 pagesAP0138 Pin and Part Swapping With Dynamic Net AssignmentdrakenhavenNo ratings yet

- Update NS ServersDocument22 pagesUpdate NS Serversazucena.ubierna9698No ratings yet

- IP30 - ICAO AI.7 (3) - Rev. Handbook On Radio Frequency Vol. II PDFDocument135 pagesIP30 - ICAO AI.7 (3) - Rev. Handbook On Radio Frequency Vol. II PDFramchander harbhlaNo ratings yet

- ETP4860-B1A2 Embedded Power User ManualDocument93 pagesETP4860-B1A2 Embedded Power User ManualElisvan Jordan Guzman Espinoza100% (1)

- Staples Technology Solutions Network Services': 21 Century Office ProductsDocument22 pagesStaples Technology Solutions Network Services': 21 Century Office Productsboysen76No ratings yet

- Emfis PlusDocument24 pagesEmfis PlusPrabhu Natarajan100% (2)

- 06 - External MemoryDocument21 pages06 - External MemoryHighlights ManiaNo ratings yet

- MacLean Power System - 1Document250 pagesMacLean Power System - 1ransransNo ratings yet