Professional Documents

Culture Documents

Session 10B 1210PM PDF

Uploaded by

W N Nan Fajar0 ratings0% found this document useful (0 votes)

22 views15 pagesOriginal Title

SESSION_10B_1210PM.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views15 pagesSession 10B 1210PM PDF

Uploaded by

W N Nan FajarCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 15

MANAGING COAL LOSS USING BLAST

MODELS AND FIELD MEASUREMENT

August 2015

Murali Nagarajan, Specialist Engineer

Anthony Green Senior Blast Technician

Paul Brown Blast Technician

Peter Dare-Bryan Senior Mining Engineer

FRAGBLAST11

BACKGROUND

• Coal Loss was an issue with losses

from

– Coal roof

– Coal edge

• Reduced amount of coal being

uncovered

• Increased operating cost

• Developed a 5 step process:

– Develop a baseline and understand

the coal loss mechanisms

– Implement a QA/QC system

– Model the coal loss

– Develop a coal loss reduction

program

– Implement the program and

measure

2 © Orica Limited Group

BASELINE

• Correlate damage zones with drill

hole location

• Backfilling what is better drill

cuttings or gravel?

• What is touch coal?

• What is the true stand off?

• What is the variation between

design and actual?

• Need to implement a QA/QC

process

3 © Orica Limited Group

IMPLEMENT A QA/QC PROCESS

• Calibrate the touch coal holes by gamma

logging and give feedback to the drillers as to

their accuracy

• Update the coal model

• Use the new model for drill depth

• Tighten redrill variation limits

• Backfill with gravel Lost coal

Parting band

• Develop load sheets for each blasthole and

filled out with actual information. Damaged coal

• Audit the process and use continuous

improvement

• Losses – 11.5% edge loss and estimated 2%

required washing

4 © Orica Limited Group

MODELLING - BASELINE

Strip width – 60m

Bench height – 20-25m

Void – 12-18m

© Orica Limited Group

COAL LOSS REDUCTION

• Issues

– Coal edge buffering

– Environmental

• Risk Assessment

– Dynamic buffering

• Options to be evaluated

– 'Baby' deck

– Stratablast™

• Minimise complexity of in the drill & blast processes

• Minimise changes is the mining process

6 © Orica Limited Group

COAL LOSS – ‘BABY’ DECK

• Initial option due to minimise complexity and

changes to the mining process

• Initially used:

– 100ms between decks

– Main charge firing first

– 4 rows

• Variations occurred depending on the dip of

the coal

• Aim was to reduce the risk shearing of the

coal edge

• Need to evaluate:

– the extra time for drill and blast

– Mine plan changes

– Mine process changes

7 © Orica Limited Group

COAL LOSS – ‘BABY’ DECK

© Orica Limited Group

COAL LOSS – ‘BABY’ DECK

© Orica Limited Group

‘BABY’ DECK RESULTS

• A variety of options trialled

• Little variation in results

• Coal loss measured was 8.5%

• Reduced coal loss by 33% from

baseline

• Increase in loading time was small

• Minimal changes in mine plan or

the mining process.

10 © Orica Limited Group

COAL LOSS - STRATABLAST™

• Option of Stratablast™ implemented

to investigate further improvement in

coal loss

• Stratablast divides the horizon into

layers that are drilled, loaded and

blasted in one cycle.

• Each layer is treated separately with

different powder factors and

timing/movement

• Need to evaluate:

– the extra time for drill and blast

– Mine plan changes

– Mine process changes

11 © Orica Limited Group

COAL LOSS – STRATABLAST™

© Orica Limited Group

COAL LOSS – STRATABLAST™

© Orica Limited Group

STRATABLAST™ RESULTS

• Coal loss was reduced to less than 1%;

• Dig rates and dozer advance rates were

achieved;

• Design variations occurred:

– Dip of coal;

– Strata changes; and

– Product changes.

• The following changes in the mining process

were required:

– Drill preparation;

– Survey control;

– Drilling;

– Recording;

– Area to be blasted (mining block); and

– Extra 15% time taken for drill and blast;

14 © Orica Limited Group

CONCLUSIONS

• Drill and blast cost increased by 10% and it took 15% longer.

• 100,000 tne coal that was previously not recovered as bypass.

• Coal loss can be reduced by both methods but need to understand what

and why it is occurring.

• Important aspects were:

– Training of people;

– Feedback to people for good and the areas for improvement;

– Maintaining the equipment productivity; and

– Compromises along the whole mining process.

• Which method?

15 © Orica Limited Group

You might also like

- Slimhole Drilling Technology Final FinalDocument32 pagesSlimhole Drilling Technology Final FinalMohamed Sadek100% (1)

- AADE/Fluids Management Group: Advances in Deepwater FluidsDocument15 pagesAADE/Fluids Management Group: Advances in Deepwater FluidsBarry TrettNo ratings yet

- HPHT Solutions Drilling and EvaluationDocument41 pagesHPHT Solutions Drilling and EvaluationJohnSmithNo ratings yet

- Casing While DrillingDocument12 pagesCasing While Drillingkishansoni100% (9)

- Effects of Specific Charge and EDD:s On Fragmentation in An Aggregate Quarry, Building KCO Design CurvesDocument20 pagesEffects of Specific Charge and EDD:s On Fragmentation in An Aggregate Quarry, Building KCO Design CurvesKasse VarillasNo ratings yet

- Chapter 1 Introduction To Emergency Medical CareDocument19 pagesChapter 1 Introduction To Emergency Medical Carejmmos207064100% (1)

- Advertisement and Sponsorship-Price ListDocument4 pagesAdvertisement and Sponsorship-Price ListzulkiplyNo ratings yet

- Hatch Water PRM10Document17 pagesHatch Water PRM10guama21No ratings yet

- Re EntryDocument3 pagesRe EntryCHEKOUFI SaidNo ratings yet

- Surface Mine Planning and Design Unit5Document20 pagesSurface Mine Planning and Design Unit5AJAY KUMAR VNo ratings yet

- Underground MiningDocument191 pagesUnderground MiningrockyminNo ratings yet

- Ultra LiteCRETE Technology - Case Studies (EEG Client)Document20 pagesUltra LiteCRETE Technology - Case Studies (EEG Client)Priyaranjan Maral0% (1)

- Hardin WOCA2009 PlenaryDocument23 pagesHardin WOCA2009 PlenaryFauzia RizkyNo ratings yet

- COAL MINING TECHNOLOGY. A Presentation by MANOJ KUMAR SINGH Manager (IE), NCL-HQ, Singrauli (MP) - 486 889 E-Mail - Mks - Ie@nclhq - Nic.Document56 pagesCOAL MINING TECHNOLOGY. A Presentation by MANOJ KUMAR SINGH Manager (IE), NCL-HQ, Singrauli (MP) - 486 889 E-Mail - Mks - Ie@nclhq - Nic.Sidhartha sahu100% (1)

- Norsho PDF Norshore PublicDocument31 pagesNorsho PDF Norshore PublicjrladduNo ratings yet

- Well Plug AbandonmentDocument20 pagesWell Plug AbandonmentKenneth Tan100% (2)

- 13 - Baker Hughes - Kennedy enDocument36 pages13 - Baker Hughes - Kennedy enSpecule100% (1)

- A Pile DesignDocument23 pagesA Pile DesignSandeep KumarNo ratings yet

- Wind Power - Vattenfall Wind Assets: Onshore Capacity: 542 MW Offshore Capacity: 836 MW Production: 4.080 TWHDocument36 pagesWind Power - Vattenfall Wind Assets: Onshore Capacity: 542 MW Offshore Capacity: 836 MW Production: 4.080 TWHDavid Torres RodriguezNo ratings yet

- Introduction Drill Compl Intervention Fjelde 2012Document29 pagesIntroduction Drill Compl Intervention Fjelde 2012Qingming MaNo ratings yet

- Anchor Loss: Technical and Operational Challenges and RecommendationsDocument52 pagesAnchor Loss: Technical and Operational Challenges and Recommendationsigor teixeiraNo ratings yet

- Karara Mining EEO PresentationDocument28 pagesKarara Mining EEO PresentationFawad InamNo ratings yet

- Coiled TubingDocument31 pagesCoiled TubingMostafa KorttamNo ratings yet

- OPS SmallDocument56 pagesOPS SmallAlexander Daniel Gonzalez AguilarNo ratings yet

- 19 - Storvik - Subsea SeparationDocument19 pages19 - Storvik - Subsea SeparationMarco Andrés Guevara LunaNo ratings yet

- Chris RogersDocument35 pagesChris RogersjeaneemaxwellNo ratings yet

- Shree Cement - WHR PPT 15.6.16 - SCLDocument22 pagesShree Cement - WHR PPT 15.6.16 - SCLSivakumaran RajuNo ratings yet

- CFB Boiler Cethar NewFeb09Document21 pagesCFB Boiler Cethar NewFeb09mukthipatiNo ratings yet

- Effect of Surface MoistureDocument37 pagesEffect of Surface MoistureAnonymous W9VINoTzaNo ratings yet

- Connell Australia Activity1Document19 pagesConnell Australia Activity1tassili17No ratings yet

- A Hard Narrow Rock MiningDocument8 pagesA Hard Narrow Rock Miningaris goldieNo ratings yet

- Optitooth Jaw Plates - Customer Testimonial Data - 2017Document8 pagesOptitooth Jaw Plates - Customer Testimonial Data - 2017danielNo ratings yet

- FGD Design and Operating CriteriaDocument52 pagesFGD Design and Operating CriteriaTomek100% (1)

- SPE Optimization of Well Performance by Use of A Semi Permanent Dynamic Desander Ted Brueren Statoil1Document30 pagesSPE Optimization of Well Performance by Use of A Semi Permanent Dynamic Desander Ted Brueren Statoil1Tg TarroNo ratings yet

- JotHi RamanujamDocument58 pagesJotHi RamanujamLeonardo TejedorNo ratings yet

- T. Chatfield - Denbury's CO2 EOR ActivitiesDocument26 pagesT. Chatfield - Denbury's CO2 EOR Activitiesrecsco2No ratings yet

- 08 Prom Hill Mine Planning - Pheng Bounsombath & Larry NielsDocument57 pages08 Prom Hill Mine Planning - Pheng Bounsombath & Larry NielsDwik Thesoulof VillianoNo ratings yet

- Coal Quality Improvement ProjectDocument10 pagesCoal Quality Improvement Projectpowerman619No ratings yet

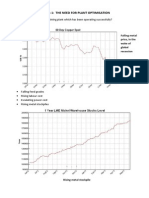

- Indonesian " Plant Optimisation" WorkshopDocument10 pagesIndonesian " Plant Optimisation" WorkshopRamoutar (Ken) SeecharranNo ratings yet

- Underground Coal Gasification - A Road Map For SuccessDocument28 pagesUnderground Coal Gasification - A Road Map For SuccessBISMI1No ratings yet

- Concerns and Measures During Part Load OperationDocument26 pagesConcerns and Measures During Part Load OperationkumargautamNo ratings yet

- RECONCILIATION (Modo de Compatibilidad)Document14 pagesRECONCILIATION (Modo de Compatibilidad)escaflowne4002No ratings yet

- P 19Document31 pagesP 19Debraj DattaNo ratings yet

- Canadian Crude Quality Technical Association Project Update: COQG MeetingDocument22 pagesCanadian Crude Quality Technical Association Project Update: COQG MeetingLindsey BondNo ratings yet

- IsaMill Carbon Presentation BHPB Nov 07Document56 pagesIsaMill Carbon Presentation BHPB Nov 07Manuel Leiva CerdaNo ratings yet

- RTIO Financial Community East Pilbara 110607Document16 pagesRTIO Financial Community East Pilbara 110607iflaminatorNo ratings yet

- 023 BP RefiningDocument27 pages023 BP Refiningpartho143No ratings yet

- Coal Mining: Ing. M.Sc. Marco Antonio Ardila BDocument15 pagesCoal Mining: Ing. M.Sc. Marco Antonio Ardila BLina Fernanda GómezNo ratings yet

- Well Control in Alaska Artic WatersDocument31 pagesWell Control in Alaska Artic Waterspaul.eastwood9991No ratings yet

- Mine Planning DesignDocument89 pagesMine Planning Designkhatonshughni83% (6)

- Bulk Sampling of Mineral ProyectsDocument40 pagesBulk Sampling of Mineral ProyectsDiana ReyNo ratings yet

- Casing Drilling Application WELL: MNIF-686Document6 pagesCasing Drilling Application WELL: MNIF-686Slim.BNo ratings yet

- Presentation in CSG DRLG 1Document6 pagesPresentation in CSG DRLG 1girlfriendmrvingNo ratings yet

- HPHTGaps-FinalReport 2006Document16 pagesHPHTGaps-FinalReport 2006Waleed Barakat MariaNo ratings yet

- ICARE - Engineering For RefineriesDocument16 pagesICARE - Engineering For RefineriesAnonymous ygQUvDKNo ratings yet

- 10 - Drilling Fluids Design and Selection - HandoutDocument18 pages10 - Drilling Fluids Design and Selection - HandoutFauzan Rahman HaqNo ratings yet

- Diseño y Desarrollo Del Proceso SARTDocument14 pagesDiseño y Desarrollo Del Proceso SARTFélix Vargas SantillánNo ratings yet

- Combined Ion Exchange - Solvent Extraction Process 1Document18 pagesCombined Ion Exchange - Solvent Extraction Process 1Georgi SavovNo ratings yet

- The Next Generation Melting SystemDocument19 pagesThe Next Generation Melting SystemkhladunNo ratings yet

- 7-Gullfaks IOR ScreeningDocument31 pages7-Gullfaks IOR ScreeningShakerMahmood100% (2)

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceFrom EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceNo ratings yet

- Plurigaussian ModelDocument38 pagesPlurigaussian ModelKasse VarillasNo ratings yet

- Domaining by Clustering Multivariate Geostatistical DataDocument12 pagesDomaining by Clustering Multivariate Geostatistical DataKasse VarillasNo ratings yet

- Session 8b 350pmDocument22 pagesSession 8b 350pmKasse VarillasNo ratings yet

- 2016G - Testing A Crisis Management System Via The Simulation of A Bulk Emulsion Truck Fire - Learning Through Collaboration 1 of 6Document6 pages2016G - Testing A Crisis Management System Via The Simulation of A Bulk Emulsion Truck Fire - Learning Through Collaboration 1 of 6Kasse VarillasNo ratings yet

- New Horizons in Blasting - The Innovation ImperativeDocument14 pagesNew Horizons in Blasting - The Innovation ImperativeKasse VarillasNo ratings yet

- Welcome To Fragblast11Document10 pagesWelcome To Fragblast11Kasse VarillasNo ratings yet

- Chap05 JOHN W. CRESWELLDocument27 pagesChap05 JOHN W. CRESWELLMuhammad Bilal100% (2)

- Guide SauvegardeDocument688 pagesGuide SauvegardemitrailleNo ratings yet

- Part 1 Hydraulic Design Calculation 473Document13 pagesPart 1 Hydraulic Design Calculation 473shashi rajhansNo ratings yet

- Heat ExchangersDocument29 pagesHeat ExchangerscooLkiD1412No ratings yet

- Concept MappingDocument26 pagesConcept Mappingdbryant0101100% (16)

- Aavit 5 ADocument113 pagesAavit 5 AAnonymous ok5UankNo ratings yet

- The Science of Bonding From First To Sixth GenerationDocument6 pagesThe Science of Bonding From First To Sixth GenerationRolzilah RohaniNo ratings yet

- BTS Lesson Preparation FormDocument1 pageBTS Lesson Preparation FormTsz Shing WONGNo ratings yet

- Resarch Paper - Google SearchDocument2 pagesResarch Paper - Google SearchhudNo ratings yet

- Semantics Course BookDocument67 pagesSemantics Course BookJosipa Blažević50% (2)

- Surface Tension Theory - EDocument11 pagesSurface Tension Theory - EthinkiitNo ratings yet

- Primate City & Rank Size Rule: O P A DDocument7 pagesPrimate City & Rank Size Rule: O P A DOmkar G. ParishwadNo ratings yet

- Blessings in DisguiseDocument238 pagesBlessings in DisguiseAJ HassanNo ratings yet

- Shell Paper Machine Oil S3 M 220Document3 pagesShell Paper Machine Oil S3 M 220DENNY BAYUAJINo ratings yet

- MGT602 Quiz 2 290411Document8 pagesMGT602 Quiz 2 290411sonutilkNo ratings yet

- If You Can Keep Your Head When All About YouDocument3 pagesIf You Can Keep Your Head When All About YouxabiersuarezNo ratings yet

- KSS 41 END enDocument702 pagesKSS 41 END enJavier Del Pozo Garcia100% (1)

- Karpagam College of EngineeringDocument6 pagesKarpagam College of EngineeringSuresh VpNo ratings yet

- Ellenberger - Psychiatry From Ancient To Modern TimesDocument76 pagesEllenberger - Psychiatry From Ancient To Modern TimesSiegfriedCristoforNo ratings yet

- Class IfDocument9 pagesClass IfDavidRavenMoonNo ratings yet

- Alfred Nobel and The Nobel PrizesDocument17 pagesAlfred Nobel and The Nobel PrizesElizabethDarcyNo ratings yet

- GulfSea HT Oil 32 PDFDocument1 pageGulfSea HT Oil 32 PDFObydur RahmanNo ratings yet

- Notes PCDocument35 pagesNotes PCSwapnil NanawareNo ratings yet

- Creating The Fusion EconomyDocument15 pagesCreating The Fusion Economyrocket_science3.0No ratings yet

- Return To Tranquility Ven - PunnajiDocument109 pagesReturn To Tranquility Ven - PunnajiNorah GravelleNo ratings yet

- 5 HPHT API 6x - FowlerDocument13 pages5 HPHT API 6x - Fowlerchau nguyenNo ratings yet

- Achieving Executive PresenceDocument7 pagesAchieving Executive PresenceSebastián LealNo ratings yet

- 11697415Document514 pages11697415Anonymous nC9gpUWPNo ratings yet