Professional Documents

Culture Documents

IVT Network - 4 Indispensable Pre-Inspection Actions - 2014-02-27

Uploaded by

Mohammed YousffiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IVT Network - 4 Indispensable Pre-Inspection Actions - 2014-02-27

Uploaded by

Mohammed YousffiCopyright:

Available Formats

Published on IVT Network (http://www.ivtnetwork.

com)

4 Indispensable Pre-Inspection Actions

Nov 6, 2013 8:27 am PST

An FDA inspector is coming to your facility right now. They may not come tomorrow, but every pharmaceutical, biologic, and

medical device manufacturer will have to face and manage an FDA inspection. There are some vital pre-inspection activities,

given by Bill Hall at IVT’s 18th Annual Validation Week, that will guarantee not only confidence when confronting an FDA

inspection—but also compliance.

1. Internal/Mock Audits

The value of internal audits have been discussed here before. Internal audits should be performed using the same groups that

will host the actual FDA inspection (i.e., QA/QC, Regulatory Affairs, Production, Engineering). Mock audits give you the

chance to identify and fix problems. They also allow your facility continuous improvement in terms of handling the audit

process. An internal audit will also help you identify where there are gaps in documentation.

2. Review of Critical Documentation

Comprehensive documentation for validation and manufacturing procedures is cornerstone of audit readiness. The analysis of

the documentation can be divided into different document types.

Validation Master Plan

Make sure your validation plan is current and referencing a “lifecycle approach” to validation. Make sure it references statistics

being utilized when collecting, evaluating, and monitoring data.

Change Control Documentation

For any changes have been indicated to have impact on the validation status of processes, equipment, or critical utilities have

the appropriate follow-up activities (such as revalidation) been completed and signed off. Review “as built” drawings to ensure

they accurately reflect any changes made to equipment.

Register Download Brochure

Critical SOPs

Know what are your critical standard operating procedures (SOPs) in relation to your SOPs.

Training Program & Records

Keep your training programs and any record up to date. This should include laboratory personnel.

Equipment Qualification Documentation

Confirm you have appropriate documentation for design qualification, installation qualification, operational qualification, and

performance qualification.

Process Validation Documents

If there have been any failures or deviations during the execution of validation, review the findings, follow-ups, and corrective

and preventive actions.

Also guarantee summary reports and protocols are readily available.

3. Write an Inspection Procedure

Write a procedure that details the steps of the inspection and where resources will be allocated during the inspection. Namely,

who does what where and why.

4. Review Critical Quality Systems that interface with Validation

Procedures and corrective actions are the two biggest reasons for regulatory actions. Review the change control, recall,

annual product review, deviations/exceptions, and preventative maintenance procedure.

Source URL: http://www.ivtnetwork.com/article/4-indispensable-pre-inspection-actions

You might also like

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- Data Integrity and Compliance: A Primer for Medical Product ManufacturersFrom EverandData Integrity and Compliance: A Primer for Medical Product ManufacturersNo ratings yet

- IVT Network - Incorporate Domestic and International Regulations For Effective GMP Auditing - 2013-08-20Document3 pagesIVT Network - Incorporate Domestic and International Regulations For Effective GMP Auditing - 2013-08-20huykhiemNo ratings yet

- Cleaning Validation in Continuous Manufacturing - Pharmaceutical TechnologyDocument9 pagesCleaning Validation in Continuous Manufacturing - Pharmaceutical Technologyiyas utomoNo ratings yet

- Process Validation Ensuring Quality Through Lifecycle ApproachDocument1 pageProcess Validation Ensuring Quality Through Lifecycle ApproachMina Maher MikhailNo ratings yet

- Good Documentation Practices - 2014-09-30Document1 pageGood Documentation Practices - 2014-09-30ApoloTrevinoNo ratings yet

- WP Gmp-En AnshDocument12 pagesWP Gmp-En AnshFelix ShihNo ratings yet

- Data Integrity Background and FAQDocument4 pagesData Integrity Background and FAQMina Maher MikhailNo ratings yet

- Cleaning Validation Boot CampDocument7 pagesCleaning Validation Boot Campramin_47No ratings yet

- Simple strategies for improving qualitative quality risk managementDocument15 pagesSimple strategies for improving qualitative quality risk managementLuis Gustavo PachecoNo ratings yet

- 04JA BlackburnDocument7 pages04JA BlackburnFederico BrigatoNo ratings yet

- Pharmaceutical Quality Audits: A ReviewDocument9 pagesPharmaceutical Quality Audits: A ReviewHema PepakayalaNo ratings yet

- GMP For Facility Design References April06Document17 pagesGMP For Facility Design References April06madhubiochemNo ratings yet

- 05JA ChvaicerDocument11 pages05JA ChvaiceramgranadosvNo ratings yet

- IVT Network - Statistical Analysis in Analytical Method Validation - 2014-07-10Document11 pagesIVT Network - Statistical Analysis in Analytical Method Validation - 2014-07-10Jose Luis Huaman100% (1)

- IVT Network - Sanitization of Pharmaceutical Facilities - 2014-08-29Document7 pagesIVT Network - Sanitization of Pharmaceutical Facilities - 2014-08-29Bhagath VikasNo ratings yet

- Events Presentations Raci 121126Document22 pagesEvents Presentations Raci 121126mokhtari asmaNo ratings yet

- FDA Warning Letter For Inadequate Batch Record ReviewDocument1 pageFDA Warning Letter For Inadequate Batch Record ReviewMina Maher MikhailNo ratings yet

- SRS (Software Requirements Specification) SCLIMSDocument17 pagesSRS (Software Requirements Specification) SCLIMSMelvin Espuerta LotocNo ratings yet

- Understanding ISO 21501-4 12-2010 DGDocument4 pagesUnderstanding ISO 21501-4 12-2010 DGgirodadoNo ratings yet

- GMP Inspections enDocument56 pagesGMP Inspections ennaokijoe34No ratings yet

- Warning Letter - Deficiencies in Validation and OOS - ECA AcademyDocument2 pagesWarning Letter - Deficiencies in Validation and OOS - ECA AcademyDeepakNo ratings yet

- Risk Assessment of Aseptic Transfer Between Pharmaceutical FacilitiesDocument11 pagesRisk Assessment of Aseptic Transfer Between Pharmaceutical FacilitiesPiruzi MaghlakelidzeNo ratings yet

- Whythe10 ppmCriterionShouldBeAbandonedDocument5 pagesWhythe10 ppmCriterionShouldBeAbandonedMuhammad AsifNo ratings yet

- Avoiding Errors With The Batch Release ProcessDocument11 pagesAvoiding Errors With The Batch Release ProcessAnthony CollierNo ratings yet

- Measuring Cleaning Risk Using FMEAs and a Risk DashboardDocument13 pagesMeasuring Cleaning Risk Using FMEAs and a Risk DashboardBlueSagaNo ratings yet

- EMA - Reflection Paper For Laboratories That Perform The Analysis or Evaluation of Clinical Trial SamplesDocument19 pagesEMA - Reflection Paper For Laboratories That Perform The Analysis or Evaluation of Clinical Trial Samplesrpg1973No ratings yet

- Bioequivalence Its History Practice and FutureDocument8 pagesBioequivalence Its History Practice and FutureKumar GalipellyNo ratings yet

- Forced DegradationDocument8 pagesForced DegradationBiyaya San PedroNo ratings yet

- IVT Network - The FDA CGMP Inspection Is Coming - Make The Best of It - 2016-02-05Document18 pagesIVT Network - The FDA CGMP Inspection Is Coming - Make The Best of It - 2016-02-05marwaNo ratings yet

- Lecture 9 - QAQC PDFDocument37 pagesLecture 9 - QAQC PDFTMTNo ratings yet

- IVT Network - FAQ - Statistics in Validation - 2017-07-05Document2 pagesIVT Network - FAQ - Statistics in Validation - 2017-07-05ospina3andresNo ratings yet

- Application of Poisson Distribution in Establishing Control Limits for Discrete Quality AttributesDocument10 pagesApplication of Poisson Distribution in Establishing Control Limits for Discrete Quality AttributesJavier GalvanNo ratings yet

- Transport of CellsDocument20 pagesTransport of CellsshneetsNo ratings yet

- Pharmaceutical Regulatory InspectionsDocument2 pagesPharmaceutical Regulatory InspectionsTim SandleNo ratings yet

- Iupac Oos Oot PDFDocument33 pagesIupac Oos Oot PDFGATOMICONo ratings yet

- Who TRS 981 QRMDocument32 pagesWho TRS 981 QRMrdasarath100% (1)

- Generation and Validation of Standard Operating Procedure For Dissolution ApparatusDocument18 pagesGeneration and Validation of Standard Operating Procedure For Dissolution ApparatusAbhishek JhaNo ratings yet

- CalibrationDocument5 pagesCalibrationMonika KshNo ratings yet

- Handling Out of Specification ResultsDocument8 pagesHandling Out of Specification ResultsPavana KharwalNo ratings yet

- Environmental Monitoring Risk AssessmentDocument22 pagesEnvironmental Monitoring Risk AssessmentMarcelo CarvalhoNo ratings yet

- BPOG's ProtocolDocument11 pagesBPOG's ProtocolRadha Krishna B VNo ratings yet

- Bilgisayarlı SistemlerDocument14 pagesBilgisayarlı Sistemlerttugce29No ratings yet

- Dr. Reddy's Laboratories LTD CTO India 01-20 Through 28-2020 - 483 PDFDocument8 pagesDr. Reddy's Laboratories LTD CTO India 01-20 Through 28-2020 - 483 PDFBrian WilliamsNo ratings yet

- Sop of Disinfection, CoatingDocument27 pagesSop of Disinfection, CoatingAhmed Quadri0% (1)

- White Paper 10 Problems With Pharma Plant MaintenanceDocument9 pagesWhite Paper 10 Problems With Pharma Plant MaintenanceAlok Kumar SharmaNo ratings yet

- Defining criticality for pharmaceutical qualityDocument10 pagesDefining criticality for pharmaceutical qualitypakdekroNo ratings yet

- EU GMP Guidelines 2013Document3 pagesEU GMP Guidelines 2013alexpharmNo ratings yet

- Cleaning Validation: JANUARY 2013Document11 pagesCleaning Validation: JANUARY 2013dhimas06No ratings yet

- Change Control for Functionally Equivalent "Like-For-LikeDocument5 pagesChange Control for Functionally Equivalent "Like-For-Likedm_alvesNo ratings yet

- 41 (1) In-Process Revision - 1790 - Visual Inspection of InjectionsDocument10 pages41 (1) In-Process Revision - 1790 - Visual Inspection of InjectionsBudy WijiyantoNo ratings yet

- Cleaning Sanitisation Disinfection Annex1 PDFDocument4 pagesCleaning Sanitisation Disinfection Annex1 PDFAbhiNo ratings yet

- Documentation: Cleaning Validation Seminar Surabaya, 20 August 2015Document32 pagesDocumentation: Cleaning Validation Seminar Surabaya, 20 August 2015itung23No ratings yet

- Introduction To CGMP Compliance CourseDocument111 pagesIntroduction To CGMP Compliance CourseHend maarofNo ratings yet

- Risk Assessment On Temperature and Relative Humidity Deviation During On-Going Stability StudiesDocument2 pagesRisk Assessment On Temperature and Relative Humidity Deviation During On-Going Stability StudiesAAAAAAAAAAAAAAAAAAAA ANo ratings yet

- FDA - Level 2 Guidance - Records and ReportsDocument9 pagesFDA - Level 2 Guidance - Records and ReportsaabbNo ratings yet

- VP-08-107 - Protocol For Hold Time of Softgel EquipmentsDocument7 pagesVP-08-107 - Protocol For Hold Time of Softgel EquipmentsprakashNo ratings yet

- Microbiological Pharmaceutical Quality Control Labs GuideDocument8 pagesMicrobiological Pharmaceutical Quality Control Labs GuideArmando SaldañaNo ratings yet

- Pharmaceutical excipients auditing SOPDocument55 pagesPharmaceutical excipients auditing SOPFarheen FurqanNo ratings yet

- Sampling in Cleaning Validation in Pharmaceutical Industry - Pharmaceutical GuidelinesDocument2 pagesSampling in Cleaning Validation in Pharmaceutical Industry - Pharmaceutical GuidelinesASHOK KUMAR LENKANo ratings yet

- Day 2 5 - Drug Inspection Overview - UInokonDocument65 pagesDay 2 5 - Drug Inspection Overview - UInokonWaqas AhmedNo ratings yet

- MDSAP QMS Training Review ChecklistDocument6 pagesMDSAP QMS Training Review ChecklistMohammed YousffiNo ratings yet

- MDSAP QMS F0014.2.001 Training Evaluation FormDocument2 pagesMDSAP QMS F0014.2.001 Training Evaluation FormMohammed YousffiNo ratings yet

- MDSAP QMS Training ProcedureDocument7 pagesMDSAP QMS Training ProcedureMohammed YousffiNo ratings yet

- 11.1 200+ Interview QuestionsDocument13 pages11.1 200+ Interview QuestionsMuhammad AbdelalemNo ratings yet

- The GCP Audit - How To ConductDocument4 pagesThe GCP Audit - How To ConductMohammed Yousffi100% (1)

- Ich E6 CGP Essential Documents For The Conduct of A Clinical Trial PDFDocument9 pagesIch E6 CGP Essential Documents For The Conduct of A Clinical Trial PDFMohammed YousffiNo ratings yet

- Ich E6 CGP Essential Documents For The Conduct of A Clinical Trial PDFDocument9 pagesIch E6 CGP Essential Documents For The Conduct of A Clinical Trial PDFMohammed YousffiNo ratings yet

- Complete Windows Server AdministrationDocument2 pagesComplete Windows Server AdministrationMohammed YousffiNo ratings yet

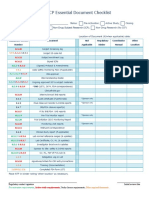

- ICH GCP Essential Document ChecklistDocument2 pagesICH GCP Essential Document ChecklistMohammed Yousffi50% (2)

- Checklist For GCP 2005 PDFDocument20 pagesChecklist For GCP 2005 PDFMohammed YousffiNo ratings yet

- Checklist For GCP 2005 PDFDocument20 pagesChecklist For GCP 2005 PDFMohammed YousffiNo ratings yet

- Ejemplo Cadena Fria AbbottDocument17 pagesEjemplo Cadena Fria AbbottMario Vazquez BNo ratings yet

- Checklist For GCP 2005 PDFDocument20 pagesChecklist For GCP 2005 PDFMohammed YousffiNo ratings yet

- SterileDocument11 pagesSterilepiyusharora19640% (2)

- ISO 9001 Internal Audit Tips Hi-Res MEADocument12 pagesISO 9001 Internal Audit Tips Hi-Res MEAneeraj00715925No ratings yet

- Validation ProcessDocument4 pagesValidation ProcessMohammed YousffiNo ratings yet

- 3-3 Risk ManagementDocument56 pages3-3 Risk ManagementMohammed YousffiNo ratings yet

- CFR Part 11 ComplianceDocument16 pagesCFR Part 11 ComplianceMohammed YousffiNo ratings yet

- Iso 11137 Testing RequirementsDocument2 pagesIso 11137 Testing RequirementsMohammed YousffiNo ratings yet

- ICRIN Internal Audit SOPDocument8 pagesICRIN Internal Audit SOPMohammed YousffiNo ratings yet

- Microbiology Qualification ProgramDocument5 pagesMicrobiology Qualification ProgramShady AbdelraoufNo ratings yet

- Tajweed UL Quran in EnglishDocument28 pagesTajweed UL Quran in EnglishKhan MohammadNo ratings yet

- Learn Arabic Letters Step-by-StepDocument64 pagesLearn Arabic Letters Step-by-StepPakololo Biol100% (1)

- Cleaning and Sanitization GuidelinesDocument27 pagesCleaning and Sanitization Guidelinesadutaka100% (2)

- Corrective and Preventive Actions A Five Step ApproachDocument35 pagesCorrective and Preventive Actions A Five Step ApproachMohammed YousffiNo ratings yet

- Noorani Qaida With Tajweed EnglishDocument17 pagesNoorani Qaida With Tajweed EnglishMohammed YousffiNo ratings yet

- Auditing The Microbiology LaboratoryDocument68 pagesAuditing The Microbiology LaboratoryMohammed Yousffi94% (18)

- Basics of sterilization methodsDocument9 pagesBasics of sterilization methodsMohammed YousffiNo ratings yet

- Emc VNX - Fast CacheDocument5 pagesEmc VNX - Fast CacheRajNo ratings yet

- Cubot X9 CeDocument4 pagesCubot X9 CeSaqib HussainNo ratings yet

- Air - Density, Specific Weight and Thermal Expansion Coefficient vs. Temperature and PressureDocument8 pagesAir - Density, Specific Weight and Thermal Expansion Coefficient vs. Temperature and PressureSantosh JayasavalNo ratings yet

- 18 Quick Release Coupler Mod 5051 PDFDocument6 pages18 Quick Release Coupler Mod 5051 PDFmmkattaNo ratings yet

- Flex I TanksDocument19 pagesFlex I TanksDel Kumar del KumarNo ratings yet

- ABB Power Quality FiltersDocument16 pagesABB Power Quality FiltersHayanJanakatNo ratings yet

- Ec1008 QBDocument3 pagesEc1008 QBSomasundaram RamuNo ratings yet

- Product Datasheet: Miniature Circuit Breaker - xC60 - 1 Pole - 6 A - C CurveDocument3 pagesProduct Datasheet: Miniature Circuit Breaker - xC60 - 1 Pole - 6 A - C CurveAroke TitusNo ratings yet

- Method of Estimating Percentage of Material Within Specification Limits (PWL)Document6 pagesMethod of Estimating Percentage of Material Within Specification Limits (PWL)Devrim GürselNo ratings yet

- Barfield User Manual - 1811H-1811G-101-00165 168 169Document77 pagesBarfield User Manual - 1811H-1811G-101-00165 168 169benjadonnadieuNo ratings yet

- 02-HSE Enginer - Amrish Kumar CVDocument5 pages02-HSE Enginer - Amrish Kumar CVsugunNo ratings yet

- Nukkad Natak Script in Hindi On Child Labour PDF Download PDFDocument4 pagesNukkad Natak Script in Hindi On Child Labour PDF Download PDFS SERIES MUSICNo ratings yet

- Form Tech-3D Description of The Methodology and Work PlanDocument16 pagesForm Tech-3D Description of The Methodology and Work PlanSurendra MaharjanNo ratings yet

- New Features in Oracle Essbase 11.1.2.4 vs Earlier VersionsDocument11 pagesNew Features in Oracle Essbase 11.1.2.4 vs Earlier VersionsSathish BalaNo ratings yet

- BRC Storage and DistributionDocument92 pagesBRC Storage and DistributionIhor MayNo ratings yet

- 1012cei Handpiece Rev9 PDFDocument15 pages1012cei Handpiece Rev9 PDFNicku LozovanuNo ratings yet

- Product Data Sheet: Micom P121 - Overcurrent and Earth Fault Protection Relay-20 Te-Standard DisplayDocument1 pageProduct Data Sheet: Micom P121 - Overcurrent and Earth Fault Protection Relay-20 Te-Standard DisplayRamanathpura Venkannachar KiranNo ratings yet

- Info Iec62055-31 (Ed1.0) enDocument8 pagesInfo Iec62055-31 (Ed1.0) enDaysi Ivonne Ortega MonteroNo ratings yet

- YALE (C878) GP135VX LIFT TRUCK Service Repair Manual PDFDocument20 pagesYALE (C878) GP135VX LIFT TRUCK Service Repair Manual PDFfjskekdmmemNo ratings yet

- WP Schneider Electric Renewable Energies CatalogDocument72 pagesWP Schneider Electric Renewable Energies CatalognaveedfndNo ratings yet

- Cellupdate Less RLC 'Unrecoverable' Error Recovery Via SCRI in 25Document4 pagesCellupdate Less RLC 'Unrecoverable' Error Recovery Via SCRI in 25Biswajit MohantyNo ratings yet

- PVC SpecificationDocument17 pagesPVC SpecificationDavid Ruelas50% (2)

- Wireless PregtuFINAL 2018Document7 pagesWireless PregtuFINAL 2018Tej SarvaiyaNo ratings yet

- Gn190 - 410 EnginesDocument72 pagesGn190 - 410 EnginesEdward Tucholski100% (1)

- 2X 3 00 PDFDocument74 pages2X 3 00 PDFRaby AbidiNo ratings yet

- Ford Diesel 3-Cylinder Liquid-Cooled 201 Ci: (3.3 L) (112 X 112 MM)Document8 pagesFord Diesel 3-Cylinder Liquid-Cooled 201 Ci: (3.3 L) (112 X 112 MM)Alex CastilloNo ratings yet

- GCC 5241PDocument16 pagesGCC 5241Pboating1997No ratings yet

- Rule Xviii - Glass & Glazing (Book Format)Document2 pagesRule Xviii - Glass & Glazing (Book Format)Ardino Anilao100% (1)

- Delta Valves Tech TipsDocument20 pagesDelta Valves Tech TipsmujeebtalibNo ratings yet

- E - Lawyer Desktop Application PDFDocument46 pagesE - Lawyer Desktop Application PDFFUNMAZIANo ratings yet