Professional Documents

Culture Documents

Steel

Uploaded by

Sinhro018Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel

Uploaded by

Sinhro018Copyright:

Available Formats

HIGH-STRENGTH STEEL

The article describes the composition and m e c h a n i c a l properties of a heat-treated constructional steel with

200 kg/sq, m m tensile strength a n d r e a s o n a b l e d u c t i l i t y ( M e t a l T r e a t m e n t a n d Drop Forging, v. 27, No. 175, 1960).

The composition of the new steel ( % ) is: 0.40 C, 0.75 Mn, 1.60 Si, 1.80 Ni, 0.85 Cr, 0.30 Mo, 0.10 Ti and

0.003 B. The steel is b a s i c a l l y designed for making air frames. Since the frame represents about 10 % of the total

weight of a plane (without load), the new steel can significantly reduce the plane's weight and increase its l o a d -

carrying c a p a c i t y .

The n e w s t e e l is a modification of AISI 4340. Boron increases h a r d e n a b i l i t y and has an advantageous effect

on room and sub-zero i m p a c t toughness. In developing the new steel, over 40 various heats were produced. They

were forged and rolled into 15.9 X 22.3 X 31.6 turn bars which were then n o r m a l i z e d and annealed. The best c o m -

bination of strength and toughness had a steel based on the 4340 composition, modified with silicon and titanium;

the toughness and forgeability were even better in a v a c u u m - m e l t e d - s t e e l .

The o p t i m u m h e a t treatment was as follows: oil quenching from 900"C and double t e m p e r i n g at 200-260~

The m e c h a n i c a l properties were: RC = 53,0 b = 200 kg/sq, ram, a s = 165 kg/sq.mm, 5 (on 35.6 m m length) = 10 %,

~0= 35%, a k (Charpy specimen with V-notch) = 2.2 k g / s q . . c m at room temperature and at -40"C.

HOT-WORK TOOL STEEL

U. S. Patent No. 2,908,565 of 10.13.1959 (J. A. Nelson) covers a precipitation-hardening tool steel suitable

for work at up to 815"C. The steel can be used for pressure casting molds, forging dies, dies for extrusion and for

drawing shapes.

The m a i n alloying components are cobalt, copper and nickel, the total c o b a l t and copper content being 2-15 %

and their ratio, 3 : 1.

The nickel content is twice that of copper.

The steel has good m a c h i n a b i l i t y despite its high hardness and a high resistance to softening during heating,

which is especially important for parts operating at high temperatures. It has a high corrosion and wear resistance

and is r e l a t i v e l y i m m u n e to quench cracking. I t distorts during heating less than do martensitic steels; it is readily

ground and polished.

It was found that addition of 4 - 6 % ( m i n i m u m 2.5%) Co with and without copper, of Cr and W in amounts rep-

resenting 5 / 4 and 4/3, respectively, of the molybdenum content, and less than 1% Ni in a steel containing less than

0.15 % C and 3.5 % Mo enhances precipitation hardening and improves m a c h i n a b i l i t y .

S m a l l additions ( <-- 0.2 % each) of carbon, manganese, silicon and vanadium are very effective. The presence

of sulphur, lead, tellurium, selenium and silver is not permissible since they reduce the m e c h a n i c a l properties. The

following specific compositions are suggested (%) :

1) total Co and Cu = 2-15 (Cu/Co = 1 / 3 ) ; Ni = twice the Cu content;

2) 0.25 C, 1-6 Cr, ~ 3 W , -<5 Mo, M 0 / W = 5/4; 2-8 Co, 0 . 5 - 4 . 5 C u ( C u / C o = 1/3), ~ 3 N i ;

3) 0.25 C, 1-6 Cr, 2-8 Co, 0.5-4.5 Cu, 1-5 W, 1-5 Mo (Mo/W = 5/4);

4) 0 . 2 5 C , 1 - 6 C r , 2-8 Co, < 4 W , < 5 M o ( M o / W = 5/4), ~ 4 . 5 C u ( C u / C o = 1/3);

5) 0.25 C, 1-6 Cr, 2-8 Co, 0.5-4.5 Cu (Cu/Co = 1 / 3 ) , 1-5 W, 1-5 Mo (Mo/W = 5 / 4 ) ;

6) < 0 . 1 5 C , ~ 6 C r , < 1 Mn, < 1 S i , < 1 V , < 3.5 M o ( W / M o = 5 / 4 or 4 / 3 ) , 2.5-6 Co (copper only 0 . 2 5 -

0.5% of Co content).

Machining ofb/_11ets is r e c o m m e n d e d after air hardening from 1010*C. The hardness of the billets Rc = 40-45.

The finished products are aged at 538-566*C,which results in a hardness increase to Re = 50.

646

You might also like

- Maleable Cast IronsDocument0 pagesMaleable Cast IronsGilang Miky Pratama AlwianNo ratings yet

- Thermit Welding of Chromium Vanadium RailsteelDocument8 pagesThermit Welding of Chromium Vanadium Railsteelsantu_23No ratings yet

- Copper and Its AlloysDocument4 pagesCopper and Its AlloysneilNo ratings yet

- Roqtuf PDFDocument6 pagesRoqtuf PDFLeonidio CamposNo ratings yet

- Steel Material PropertiesDocument2 pagesSteel Material PropertiescadhoaNo ratings yet

- AISI Designation: Stainless Tool Steels Killed Carbon SteelsDocument14 pagesAISI Designation: Stainless Tool Steels Killed Carbon SteelsShankar JhaNo ratings yet

- Maraging Steel - WikipediaDocument5 pagesMaraging Steel - WikipediaVysakh VasudevanNo ratings yet

- FinkelShtein1963 Article HeatTreatmentOfLowCarbonSteelsDocument2 pagesFinkelShtein1963 Article HeatTreatmentOfLowCarbonSteelsSaleh SulimanNo ratings yet

- Weldab 13%CRDocument7 pagesWeldab 13%CRcawid100% (1)

- Art:10.1007/s11665 008 9336 Z PDFDocument7 pagesArt:10.1007/s11665 008 9336 Z PDFJosé AntonioNo ratings yet

- Metalurgia BásicaDocument30 pagesMetalurgia BásicaClever Ricardo ChinagliaNo ratings yet

- The Influence of Hot-Working Conditions On A Structure of High-Manganese SteelDocument10 pagesThe Influence of Hot-Working Conditions On A Structure of High-Manganese SteelPiranha TourniquetNo ratings yet

- Failure in Structural Steels and Overview of I 35W Bridge CollapseDocument24 pagesFailure in Structural Steels and Overview of I 35W Bridge CollapseopulitheNo ratings yet

- Failure in Structural Steels and Overview of I 35W Bridge Collapse PDFDocument24 pagesFailure in Structural Steels and Overview of I 35W Bridge Collapse PDFUnknownNo ratings yet

- Wire Rod of Boron-Bearing Low-Carbon Steel For Direct Deep DrawingDocument9 pagesWire Rod of Boron-Bearing Low-Carbon Steel For Direct Deep DrawingNicolas ValleNo ratings yet

- Lecture 9 - Ferrous AlloysDocument31 pagesLecture 9 - Ferrous Alloysmahmoud foudaNo ratings yet

- Steel Making PresentationDocument80 pagesSteel Making PresentationAlvin Garcia PalancaNo ratings yet

- Effect of Alloying Elements On Thermal Wear 2006 Journal of Iron and Steel RDocument7 pagesEffect of Alloying Elements On Thermal Wear 2006 Journal of Iron and Steel RJesus ZilchNo ratings yet

- Creep-Resistant Austenitic Cast SteelDocument6 pagesCreep-Resistant Austenitic Cast SteelKarna2504No ratings yet

- Advance Vanadium Modified Steels For High Pressure Hydrogen ReactorsDocument7 pagesAdvance Vanadium Modified Steels For High Pressure Hydrogen ReactorsMatthieuNo ratings yet

- Course Prepared by M.Jayaprasad Materials, Manufacturing and Testing of EngineDocument63 pagesCourse Prepared by M.Jayaprasad Materials, Manufacturing and Testing of EngineGopi GopinathNo ratings yet

- Stainless Steel AOD Operation and Slag OptimisationDocument41 pagesStainless Steel AOD Operation and Slag OptimisationRamiz Shaikh100% (1)

- Transition From Wood To SteelDocument24 pagesTransition From Wood To SteelNithin KannanNo ratings yet

- Metals: Sci 401 Lecture 8Document54 pagesMetals: Sci 401 Lecture 8Niña Viaña BinayNo ratings yet

- Influence of Tungsten and Carbon Addition On Electrochemical Behaviour of 9 % CR Creep-Resistant SteelDocument6 pagesInfluence of Tungsten and Carbon Addition On Electrochemical Behaviour of 9 % CR Creep-Resistant SteelElMacheteDelHuesoNo ratings yet

- Welding of Copper and Its AlloysDocument30 pagesWelding of Copper and Its Alloysaj87_goswami100% (2)

- Welding TMCP SteelsDocument7 pagesWelding TMCP SteelsElias Kapa100% (1)

- Engg. Materials DMEDocument11 pagesEngg. Materials DMESudhansubhusan PaniNo ratings yet

- 73 Ijmperdjun201973Document6 pages73 Ijmperdjun201973TJPRC PublicationsNo ratings yet

- Colour Metallography of Cast IronDocument13 pagesColour Metallography of Cast IronIjabiNo ratings yet

- Maraging Steel: Maraging Steels (A Portmanteau of "Martensitic" and "Aging") Are Steels (Iron Alloys) That Are KnownDocument5 pagesMaraging Steel: Maraging Steels (A Portmanteau of "Martensitic" and "Aging") Are Steels (Iron Alloys) That Are KnownVysakh VasudevanNo ratings yet

- Copper Alloys WroughtDocument47 pagesCopper Alloys WroughtPROBLEMSOLVERNo ratings yet

- Heat-Treatment of High Carbon Steel Wire - PatentingDocument4 pagesHeat-Treatment of High Carbon Steel Wire - Patentingعزت عبد المنعم100% (1)

- Steel DeoxidationDocument12 pagesSteel DeoxidationUlises Quintana CarhuanchoNo ratings yet

- FC-06-Engineering Material & Metallurgy PDFDocument431 pagesFC-06-Engineering Material & Metallurgy PDFsomnath ghosh100% (1)

- Metallurgy of MaterialsDocument15 pagesMetallurgy of Materialscal2_uniNo ratings yet

- TMCP Steels and Their Welding 12342Document16 pagesTMCP Steels and Their Welding 12342claude.bouillot3566100% (1)

- Maraging SteelDocument4 pagesMaraging SteelJayanthiANo ratings yet

- Review of Creep Resistant SteelsDocument4 pagesReview of Creep Resistant SteelsAleš NagodeNo ratings yet

- Unit 5 Non Ferrous Metal and Alloys: Visit For More Learning ResourcesDocument28 pagesUnit 5 Non Ferrous Metal and Alloys: Visit For More Learning ResourcesEXAM CELL AVS TECHNo ratings yet

- Presentation14 ALLOY STEELDocument41 pagesPresentation14 ALLOY STEELMahadi HasanNo ratings yet

- The Effect of Heat Treatment On Interface Properties of S45CDocument8 pagesThe Effect of Heat Treatment On Interface Properties of S45CRamon BrownNo ratings yet

- Structural SteelDocument6 pagesStructural SteelZaid HabibuNo ratings yet

- Carbides in High Chromium Cast IronsDocument8 pagesCarbides in High Chromium Cast IronsLewy HandleNo ratings yet

- Unit - Iii: Ferrous and Non Ferrous MetalsDocument101 pagesUnit - Iii: Ferrous and Non Ferrous Metalssenthilkumar tsNo ratings yet

- Sci 401pptDocument107 pagesSci 401pptNiña Viaña BinayNo ratings yet

- Processingand Applicationof IFGradesteeel Prospectsin SAIL3Document19 pagesProcessingand Applicationof IFGradesteeel Prospectsin SAIL3Chhatramani SinghNo ratings yet

- Alto CromoDocument10 pagesAlto CromoEduardo LavratiNo ratings yet

- Decarburization and Desulphurization of SteelDocument10 pagesDecarburization and Desulphurization of SteelHitesh KumarNo ratings yet

- 금속재료 중간고사 기출문제 (2006-2016)Document10 pages금속재료 중간고사 기출문제 (2006-2016)Li Ken LokNo ratings yet

- Lecture-1, Plain Carbon SteelsDocument40 pagesLecture-1, Plain Carbon Steelssatish chinthamNo ratings yet

- Material Science 1 Assignment 2Document4 pagesMaterial Science 1 Assignment 2Mehul BansalNo ratings yet

- P92 Paper IIW Conference GrazDocument13 pagesP92 Paper IIW Conference GrazzhangxingzydNo ratings yet

- Heat Treatment of NiHardDocument6 pagesHeat Treatment of NiHardbadelog5297No ratings yet

- Bainite in SteelDocument12 pagesBainite in Steelsathyadevi konnurNo ratings yet

- Nonferrous Teaching MatDocument31 pagesNonferrous Teaching MatAsyiqotul UlyaNo ratings yet

- Cu Ni FabricationDocument28 pagesCu Ni FabricationAli Varmazyar100% (1)

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- CorrespondenceDocument7 pagesCorrespondenceSinhro018No ratings yet

- Litx Oo :, Al/L .V'I 1 I/Lgd "1 L - JDocument6 pagesLitx Oo :, Al/L .V'I 1 I/Lgd "1 L - JSinhro018No ratings yet

- Stainless Steels: Corrosion-Resistant Steels For Force-Measuring Elastic MembersDocument5 pagesStainless Steels: Corrosion-Resistant Steels For Force-Measuring Elastic MembersSinhro018No ratings yet

- Designing of Manual Workstation Structure With Emphasis On ErgonomicsDocument6 pagesDesigning of Manual Workstation Structure With Emphasis On ErgonomicsSinhro018No ratings yet

- Cracking of Welded Joints of Cast and Deformed Titanium Alloy Vt5Document5 pagesCracking of Welded Joints of Cast and Deformed Titanium Alloy Vt5Sinhro018No ratings yet

- Methods of Testing: A Study of Coatings On High-Temperature Nickel Alloys by The Potentiodynamic MethodDocument5 pagesMethods of Testing: A Study of Coatings On High-Temperature Nickel Alloys by The Potentiodynamic MethodSinhro018No ratings yet

- Rapid Induction Heat Treatment of Articles From Plain and Low-Alloy Low-Carbon and Medium-Carbon SteelsDocument4 pagesRapid Induction Heat Treatment of Articles From Plain and Low-Alloy Low-Carbon and Medium-Carbon SteelsSinhro018No ratings yet

- Structure Formation in Ferrous Alloys. Nonequilibrium StructuresDocument9 pagesStructure Formation in Ferrous Alloys. Nonequilibrium StructuresSinhro018No ratings yet

- Mechanohydrogen Treatment of Titanium Alloys With Rough TurningDocument4 pagesMechanohydrogen Treatment of Titanium Alloys With Rough TurningSinhro018No ratings yet

- ObituaryDocument1 pageObituarySinhro018No ratings yet

- Z o KG/MM 2: - 2 2 3 I 2b E) Leo UDocument3 pagesZ o KG/MM 2: - 2 2 3 I 2b E) Leo USinhro018No ratings yet

- Corrosion-Resistant SteelsDocument5 pagesCorrosion-Resistant SteelsSinhro018No ratings yet

- Magnesium and Titanium Alloys: Special Features of The Structure and Phase Composition of Magnesium Alloy Ma20Document4 pagesMagnesium and Titanium Alloys: Special Features of The Structure and Phase Composition of Magnesium Alloy Ma20Sinhro018No ratings yet

- Chemicothermal Treatment: LimitDocument5 pagesChemicothermal Treatment: LimitSinhro018No ratings yet

- Strain and FractureDocument6 pagesStrain and FractureSinhro018No ratings yet

- f30OO - . - , A - .P .0,7'5-"Document3 pagesf30OO - . - , A - .P .0,7'5-"Sinhro018No ratings yet

- Fe ALDocument3 pagesFe ALSinhro018No ratings yet

- Theory: Ni 63. AllDocument2 pagesTheory: Ni 63. AllSinhro018No ratings yet

- Boriding OF DIE Steels: Occurs inDocument2 pagesBoriding OF DIE Steels: Occurs inSinhro018No ratings yet

- Thermomechanical Treatment:, o Zo .To Oo O o O00 00Document5 pagesThermomechanical Treatment:, o Zo .To Oo O o O00 00Sinhro018No ratings yet

- A Letter To The Editorial BoardDocument2 pagesA Letter To The Editorial BoardSinhro018No ratings yet

- + + K - E - J, (1) Where Fi Are Atomic Scatter Factors, Analysis of Eq. (1) Indicates That The StructuralDocument3 pages+ + K - E - J, (1) Where Fi Are Atomic Scatter Factors, Analysis of Eq. (1) Indicates That The StructuralSinhro018No ratings yet

- Model VH200: Whole Room Heater Owner'S GuideDocument14 pagesModel VH200: Whole Room Heater Owner'S GuideGaryNo ratings yet

- Classification of PolymersDocument11 pagesClassification of Polymerssayon.ghosh1001No ratings yet

- Water Supply Products: No. Products Standard Number Standard TitleDocument12 pagesWater Supply Products: No. Products Standard Number Standard TitleMohd Naim Bin KaramaNo ratings yet

- Threading Inserts and GradesDocument3 pagesThreading Inserts and GradeskarthikeyanNo ratings yet

- Design Ofcombined Footing - Pad TypeDocument75 pagesDesign Ofcombined Footing - Pad TypeChinmoy PalNo ratings yet

- Ex. 3 - Aeroelastic Static Stability 16-19/10/2018: Ex. 3a - Divergence Analysis With 1 DOFDocument2 pagesEx. 3 - Aeroelastic Static Stability 16-19/10/2018: Ex. 3a - Divergence Analysis With 1 DOFjacazio.brischettoNo ratings yet

- MEC3451 Problem Set 1Document4 pagesMEC3451 Problem Set 1Joshua MamouneyNo ratings yet

- C-CVD Pyrosil Coatings: Sura Instruments GMBHDocument22 pagesC-CVD Pyrosil Coatings: Sura Instruments GMBHThắm PhạmNo ratings yet

- Crystal DefectsDocument1 pageCrystal DefectsMATEO SEBASTIAN VARGAS HERNANDEZNo ratings yet

- Impact Test ReportDocument7 pagesImpact Test Reportgammoora92% (25)

- Introduction To Electrostrictive MaterialDocument21 pagesIntroduction To Electrostrictive MaterialAbhijeeth Nagaraj75% (4)

- Tajuk Eksperimen Ebb 325 0809Document1 pageTajuk Eksperimen Ebb 325 0809fred5181No ratings yet

- Design of T Girder JUNE 14THDocument71 pagesDesign of T Girder JUNE 14THEngineeri TadiyosNo ratings yet

- Effect of Temperature of Water Injection On Humidification ProcessDocument5 pagesEffect of Temperature of Water Injection On Humidification ProcessSayed ElSheikhNo ratings yet

- Lesson 10 - Construction - FieldworkDocument66 pagesLesson 10 - Construction - FieldworkJubillee MagsinoNo ratings yet

- PASCHAL Product OverviewDocument24 pagesPASCHAL Product OverviewKeyur PatelNo ratings yet

- HPLC Accessories: PEEK FittingsDocument9 pagesHPLC Accessories: PEEK FittingsJaycer AsbyssNo ratings yet

- Specifications For Lakhvir JiDocument2 pagesSpecifications For Lakhvir Jiankush7779No ratings yet

- Fes TBT HVAC Safety PDFDocument1 pageFes TBT HVAC Safety PDFsalem enwaiji100% (1)

- Chapter A DIN 931 ISO 4014 A2 STAINLESS PDFDocument5 pagesChapter A DIN 931 ISO 4014 A2 STAINLESS PDFJonathan DouglasNo ratings yet

- Aqua 1Document329 pagesAqua 1AshutoshAparajNo ratings yet

- Ice-Lined Refrigerator: Refrigeration SystemDocument2 pagesIce-Lined Refrigerator: Refrigeration SystemfranslalaNo ratings yet

- Ansi MSS SP-55-2011Document23 pagesAnsi MSS SP-55-2011SivaNo ratings yet

- Code of Practice For Temporary Works Procedures and The Permissible Stress Design of FalseworkDocument10 pagesCode of Practice For Temporary Works Procedures and The Permissible Stress Design of FalseworkHameed AfinnihNo ratings yet

- Literature Case Study: Row Housing On ContoursDocument20 pagesLiterature Case Study: Row Housing On ContoursLokesh Singh100% (1)

- Gewiss - Iec 309 Range Plug & Socket 1Document3 pagesGewiss - Iec 309 Range Plug & Socket 1Jhored SombillaNo ratings yet

- Design Checklist PLDocument3 pagesDesign Checklist PLSiva KumarNo ratings yet

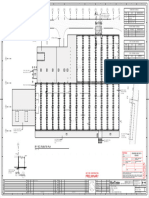

- P23008-St-Ti Tree Dry Mess-Rvt21-001 - Sheet - 7m-5650-S-00005 - Dry Mess Foundation PlanDocument1 pageP23008-St-Ti Tree Dry Mess-Rvt21-001 - Sheet - 7m-5650-S-00005 - Dry Mess Foundation Planmaodcb5No ratings yet

- Mill Housings Mangal SinghDocument5 pagesMill Housings Mangal SinghGun SmithNo ratings yet

- 10-Operation of Framo Cargo PumpsDocument2 pages10-Operation of Framo Cargo PumpsFlorin KaraNo ratings yet