Professional Documents

Culture Documents

Solidworks Tutorial 11: Certified Solidworks Associate (Cswa)

Uploaded by

JoseEliasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solidworks Tutorial 11: Certified Solidworks Associate (Cswa)

Uploaded by

JoseEliasCopyright:

Available Formats

SolidWorks Tutorial 11

Certified SolidWorks Associate (CSWA)

Preparatory Vocational Training

and Advanced Vocational Training

Dassault Systèmes SolidWorks Corporation, Outside the U.S.: +1-781-810-5011

175 Wyman Street Fax: +1-781-810-3951

Waltham, Massachusetts 02451 USA Email: info@solidworks.com

Phone: +1-800-693-9000 Web: http://www.solidworks.com/education

© 1995-2013, Dassault Systèmes SolidWorks Corporation, a Copyright Notices for SolidWorks Standard, Premium,

Dassault Systèmes S.A. company, 175 Wyman Street, Waltham, Professional, and Education Products

Mass. 02451 USA. All Rights Reserved. Portions of this software © 1986-2013 Siemens Product Lifecycle

Management Software Inc. All rights reserved.

The information and the software discussed in this document are

subject to change without notice and are not commitments by This work contains the following software owned by Siemens

Dassault Systèmes SolidWorks Corporation (DS SolidWorks). Industry Software Limited:

D-Cubed™ 2D DCM © 2013. Siemens Industry Software

No material may be reproduced or transmitted in any form or by Limited. All Rights Reserved.

any means, electronically or manually, for any purpose without

the express written permission of DS SolidWorks. D-Cubed™ 3D DCM © 2013. Siemens Industry Software

Limited. All Rights Reserved.

The software discussed in this document is furnished under a

license and may be used or copied only in accordance with the D-Cubed™ PGM © 2013. Siemens Industry Software

terms of the license. All warranties given by DS SolidWorks as to Limited. All Rights Reserved.

the software and documentation are set forth in the license D-Cubed™ CDM © 2013. Siemens Industry Software

agreement, and nothing stated in, or implied by, this document or Limited. All Rights Reserved.

its contents shall be considered or deemed a modification or D-Cubed™ AEM © 2013. Siemens Industry Software

amendment of any terms, including warranties, in the license Limited. All Rights Reserved.

agreement.

Portions of this software © 1998-2013 Geometric Ltd.

Patent Notices Portions of this software incorporate PhysX™ by NVIDIA 2006-

SolidWorks® 3D mechanical CAD software is protected by U.S. 2010.

Patents 5,815,154; 6,219,049; 6,219,055; 6,611,725; 6,844,877; Portions of this software © 2001-2013 Luxology, LLC. All rights

6,898,560; 6,906,712; 7,079,990; 7,477,262; 7,558,705; reserved, patents pending.

7,571,079; 7,590,497; 7,643,027; 7,672,822; 7,688,318; Portions of this software © 2007-2013 DriveWorks Ltd.

7,694,238; 7,853,940, 8,305,376, and foreign patents,

(e.g., EP 1,116,190 B1 and JP 3,517,643). Copyright 1984-2010 Adobe Systems Inc. and its licensors. All

rights reserved. Protected by U.S. Patents 5,929,866; 5,943,063;

eDrawings® software is protected by U.S. Patent 7,184,044; U.S. 6,289,364; 6,563,502; 6,639,593; 6,754,382; Patents Pending.

Patent 7,502,027; and Canadian Patent 2,318,706.

Adobe, the Adobe logo, Acrobat, the Adobe PDF logo, Distiller

U.S. and foreign patents pending. and Reader are registered trademarks or trademarks of Adobe

Systems Inc. in the U.S. and other countries.

Trademarks and Product Names for SolidWorks Products For more DS SolidWorks copyright information, see Help >

and Services About SolidWorks.

SolidWorks, 3D ContentCentral, 3D PartStream.NET, eDrawings,

and the eDrawings logo are registered trademarks and Copyright Notices for SolidWorks Simulation Products

FeatureManager is a jointly owned registered trademark of DS Portions of this software © 2008 Solversoft Corporation.

SolidWorks.

PCGLSS © 1992-2013 Computational Applications and System

CircuitWorks, FloXpress, PhotoView 360, and TolAnalyst, are Integration, Inc. All rights reserved.

trademarks of DS SolidWorks. Copyright Notices for SolidWorks Enterprise PDM Product

FeatureWorks is a registered trademark of Geometric Ltd. Outside In® Viewer Technology, © 1992-2012 Oracle © 2011,

Microsoft Corporation. All rights reserved.

SolidWorks 2015, SolidWorks Enterprise PDM, SolidWorks

Workgroup PDM, SolidWorks Simulation, SolidWorks Copyright Notices for eDrawings Products

Flow Simulation, eDrawings, Portions of this software © 2000-2013 Tech Soft 3D.

eDrawings Professional, SolidWorks Sustainability, Portions of this software © 1995-1998 Jean-Loup Gailly and

SolidWorks Plastics, SolidWorks Electrical, and Mark Adler.

SolidWorks Composer are product names of DS SolidWorks.

Portions of this software © 1998-2001 3Dconnexion.

Other brand or product names are trademarks or registered Portions of this software © 1998-2013 Open Design Alliance. All

trademarks of their respective holders. rights reserved.

Portions of this software © 1995-2012 Spatial Corporation.

COMMERCIAL COMPUTER SOFTWARE - PROPRIETARY

The Software is a "commercial item" as that term is defined at 48 The eDrawings® for Windows® software is based in part on the

C.F.R. 2.101 (OCT 1995), consisting of "commercial computer work of the Independent JPEG Group.

software" and "commercial software documentation" as such

terms are used in 48 C.F.R. 12.212 (SEPT 1995) and is provided Portions of eDrawings® for iPad® copyright © 1996-1999 Silicon

to the U.S. Government (a) for acquisition by or on behalf of Graphics Systems, Inc.

civilian agencies, consistent with the policy set forth in 48 C.F.R. Portions of eDrawings® for iPad® copyright © 2003-2005 Apple

12.212; or (b) for acquisition by or on behalf of units of the Computer Inc.

department of Defense, consistent with the policies set forth in 48

C.F.R. 227.7202-1 (JUN 1995) and 227.7202-4 (JUN 1995).

In the event that you receive a request from any agency of the U.S.

government to provide Software with rights beyond those set forth

above, you will notify DS SolidWorks of the scope of the request

and DS SolidWorks will have five (5) business days to, in its sole

discretion, accept or reject such request. Contractor/Manufacturer:

Dassault Systèmes SolidWorks Corporation, 175 Wyman Street, Document Number:

Waltham, Massachusetts 02451 USA.

Tutorial 11: Certified SolidWorks Associate (CSWA)

The Certified SolidWorks Associate (CSWA) Program is a certification program that

certifies your SolidWorks skills. After you have trained yourself on how to work with

SolidWorks, you can take an exam and earn the CSWA. When you apply for a job in the

future, this certificate will prove your proficiency in using SolidWorks, thus the certificate

provides real value. If you want more information about how to get this certificate, please

ask your teacher.

If you have completed all of the tutorials in this array and have practiced some additional

exercises, you should be able to get the CSWA certificate. To become more acquainted

with the types of questions included on a CSWA exam, we will practice two exercises

from the CSWA test. You will not learn any new topics, but you will find out how to apply

what you have learned to pass the test and earn the certificate.

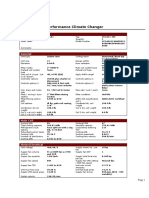

Assignment: Part 1

Available time: 45 minutes

We will show you how to complete an assignment as described on the test.

Build this part in SolidWorks. Your assignment is to build a part in

SolidWorks.

Unit system: MMGS (millimeter, gram, Although inches are often used in the

second). United States, we will work in

millimeters and grams, using the metric

system, which is the default unit system

in Europe, except for England.

Decimal places: 2. We will work with two decimals. This is

a default setting too.

SolidWorks Vocational/Technical Tutorial 1

Tutorial 11: Certified SolidWorks Associate (CSWA)

Part Origin: Arbitrary. The origin is at a random position,

although in some assignments the

position of the origin is determined.

A=63 mm, B=50 mm, C=100 mm Some dimensions are indicated in the

model with the letters A, B, or C. You

will replace them with the values given

on the left.

All holes through all, unless otherwise All holes with go through the whole

specified. model, unless otherwise specified (this is

often not visible in the drawing or

illustration.

Part material: Copper. The part is made out of copper in this

Density = 0.0089 g/mm^3 example.

The specific weight of copper is 0.0089

grams per mm^3.

What is the overall mass of the part in What is the total weight of the part? It is

grams? a multiple choice question with four

a) 1205 possible answers.

b) 1280

c) 144

d) 1108

2 SolidWorks Vocational/Technical Tutorial

Tutorial 11: Certified SolidWorks Associate (CSWA)

Work plan

Although the shape of this assignment looks fairly complicated at first glance, you will see

that it is built using boss-extrude and cut-extrude commands. The hardest part of the

assignment is making a work plan for it. Look at the shape very closely and try to divide it

into different features. It is very important to do this before you start modeling! Below you

will learn the steps we have used to build the model. Every step is a feature that we will

make. There are 10 features in total.

Once you have made your plan, the modeling is rather simple.

1 2 3 4 5

6 7 8 9 10

Of course, you can build your model in another way. There is no single correct way, but

complete it as simply as you can, using as few features as possible.

Let’s look at how to build the model from here.

1 Start SolidWorks and open a new part. Set the units to MMGS.

2 Select the Right Plane and

make a sketch as shown on

the right.

Can you make this sketch

yourself already? Very good.

Continue with step 8.

If you do not succeed doing it

yourself, try using the next

few steps.

SolidWorks Vocational/Technical Tutorial 3

Tutorial 11: Certified SolidWorks Associate (CSWA)

3 Draw the shape as you see

on the right.

Make sure the line from the

origin runs horizontally to

the right and has a length of

about 50 mm. With this as a

base the proportions will be

right.

4 Draw the arc now:

1 Click on Arc in the

CommandManager.

1

2 Click on Tangent Arc

in the

PropertyManager.

3 Click on the lower end

2

of the vertical line as

shown in the right. 3

4 Click on the upper end 4

of the vertical line as

shown on the right.

5 Put the midpoint of the

arc you have just drawn

exactly on the left vertical

line. By doing so you are 1

sure that the arc is always

90°.

1 Select the midpoint of

the arc.

2

2 Select (holding the

<Ctrl> key) the left 3

vertical line.

3 Click on Coincident in the PropertyManager.

4 SolidWorks Vocational/Technical Tutorial

Tutorial 11: Certified SolidWorks Associate (CSWA)

6 Make a fillet at the

bottom of the sketch:

1 Click on Sketch Fillet

in the

CommandManager.

2 Check to make sure 1

you have set a radius

of 10 mm in the

PropertyManager

(this is the default 3

value).

3 Click on the corner 2

you want to fillet in

the sketch.

7 Set the dimensions in the

sketch as shown on the right.

SolidWorks Vocational/Technical Tutorial 5

Tutorial 11: Certified SolidWorks Associate (CSWA)

8 Extrude the sketch to 50 mm.

9 Next, make a sketch, as

shown on the right.

1 Select the front surface of

the model to draw a new

sketch on it.

2 Click on the point where 2

the line converts to an arc. 1

Draw the circle and set the

dimension as shown in the

sketch.

10 Make an Extruded

Cut from the

sketch, setting the

depth to 13 mm.

6 SolidWorks Vocational/Technical Tutorial

Tutorial 11: Certified SolidWorks Associate (CSWA)

11 Make a sketch as shown on the right.

Can you do it yourself? Proceed to

step 15.

If this does not work out, follow the

next steps, which tell you how to

handle this.

12 Select the deeper plane

first. On this surface we

will make a new sketch.

Draw a circle and make

sure the midpoint is exactly 2

at the point where the

straight line converts to an

arc. 1

Set the size of the circle to

Ø20 mm.

13 Push the <Esc> key on

your keyboard to end

the Smart Dimension

command.

1,2 Select the line and

the arc as shown on 3

the right.

3 Click on Convert

Entities in the

CommandManager. 1

SolidWorks Vocational/Technical Tutorial 7

Tutorial 11: Certified SolidWorks Associate (CSWA)

14 Click on Trim

Entities in the

CommandManager.

Click Trim to

closest in the 3

3

PropertyManager.

Click on the three

parts of the sketch 3

that need to be

removed.

15 Extrude this

sketch to a depth

of 5 mm.

8 SolidWorks Vocational/Technical Tutorial

Tutorial 11: Certified SolidWorks Associate (CSWA)

16 Make the sketch as in the illustration

on the right.

1 Select the plane to draw a sketch on.

2 Draw a circle. Make sure the

midpoint is exactly on the point

where the straight line converts into

an arc.

3 Set the size of the circle to Ø10 mm.

17 Extrude the sketch to a

depth of 8 mm.

18 Make the sketch as drawn on the right.

Can you manage it yourself? If you can,

proceed to step 24.

If you cannot do it all by yourself, follow the

next steps.

SolidWorks Vocational/Technical Tutorial 9

Tutorial 11: Certified SolidWorks Associate (CSWA)

19 Select the plane you want

to make a sketch on.

Click on Sketch in the 2

CommandManager to

open the sketch.

Tip: In most cases when we want to make a sketch, we select a plane and start drawing a

line or circle. SolidWorks will automatically open then sketch then.

In the last step you opened the sketch explicitly, why? Because we will use the

Convert Entities command first and the sketch must be open to use this command.

That is the reason for this action.

20 Select the three edges in the model as

shown.

Click on Convert Entities in the

CommandManager.

10 SolidWorks Vocational/Technical Tutorial

Tutorial 11: Certified SolidWorks Associate (CSWA)

21 To offset sketch entities:

1 Select the edge as shown in

the illustration.

2 Click on Convert Entities in

the CommandManager.

3 Set the distance to 5 mm in

2

the PropertyManager.

6

4 Uncheck the option Select

Chain.

3

5 Check the option Reverse to

be sure the copy with be put 5

on the correct side. 1

4

6 Click on OK.

22 Click on Trim Entities

in the

CommandManager.

Select the option

Corner in the 1

PropertyManager.

Make the upper corners

by clicking as indicated

in the illustration.

5

6

4

SolidWorks Vocational/Technical Tutorial 11

Tutorial 11: Certified SolidWorks Associate (CSWA)

23 Next, make the bottom corners by clicking as

shown on the right. 1

4 2

24 Extrude this sketch over 8 mm.

Use Reverse Direction to

make sure the extrusion 3

extends in the correct

direction.

2

25 Make the sketch as shown.

Can you manage this by

yourself? Continue to

step 30. If not, follow the

next few steps.

12 SolidWorks Vocational/Technical Tutorial

Tutorial 11: Certified SolidWorks Associate (CSWA)

26 Select the plane on which

you want to make a sketch.

Draw three straight lines as

shown in the illustration. 2

3

1

27 Click on Tangent Arc in

the CommandManager.

Click at the bottom of

the left vertical line.

Click on the bottom end

of the right vertical line.

1

2

4

3

28 Select the midpoint of

the arc.

Hold the <Ctrl> key and

select the vertical line too. 2

Click on Coincident in the

PropertyManager.

SolidWorks Vocational/Technical Tutorial 13

Tutorial 11: Certified SolidWorks Associate (CSWA)

29 Add the two dimensions as

shown.

30 Make an Extruded Cut

from this sketch with a

depth of 9 mm. 2

31 Make the sketch as shown

and continue to step 35.

If you cannot manage this

yourself, follow the next few

steps.

14 SolidWorks Vocational/Technical Tutorial

Tutorial 11: Certified SolidWorks Associate (CSWA)

32 Select the plane to make the

next sketch as shown on the

right.

Draw a circle, just about the

size and position as in the

illustration.

33 Select the midpoint of the

circle.

Hold the <Ctrl> key and

click on the point as shown

on the right.

Click on Horizontal in the 2

1

PropertyManager.

34 Set the dimensions as shown

in the illustration.

SolidWorks Vocational/Technical Tutorial 15

Tutorial 11: Certified SolidWorks Associate (CSWA)

35 Make an Extruded Cut from

this sketch.

Select the option Through 2

All.

36 Make the sketch as shown on the right

and continue to step 40.

If you cannot manage this yourself,

follow the next few steps.

37 Select the upper surface from the model.

Click on Normal To in the pop-up menu.

1

2

16 SolidWorks Vocational/Technical Tutorial

Tutorial 11: Certified SolidWorks Associate (CSWA)

38 Click on Rectangle in the

CommandManager.

Draw the rectangle as shown in the

illustration on the right.

1

39 Set the two dimensions as shown.

40 Make an

Extruded Cut

from this sketch

and set the depth

to Through All.

SolidWorks Vocational/Technical Tutorial 17

Tutorial 11: Certified SolidWorks Associate (CSWA)

41 Make the sketch as shown.

42 Make an

Extruded Cut

from this sketch

2

and set the depth

to Through All.

43 Finally, make the sketch as

shown in the illustration on

the right.

18 SolidWorks Vocational/Technical Tutorial

Tutorial 11: Certified SolidWorks Associate (CSWA)

44 Make an Extruded Cut

from this sketch and set

the depth to Through 2

All.

45 The model is now ready. We have to select the kind

of material, and the assignments calls for copper.

1 Right-click on Material in the FeatureManager.

1

2 When Copper is in the list, you can click on it. If

not, click on Edit Material.

2

SolidWorks Vocational/Technical Tutorial 19

Tutorial 11: Certified SolidWorks Associate (CSWA)

46 Open the Copper Alloys list in the window that appears.

Select Copper.

Just to be sure: check the density under the properties. Is it the same as in the

assignment?

Click Apply and then Close.

4 5

47 We want to know the weight of this part.

1 Click on the tab Evaluate in the

CommandManager.

2 Click on Mass Properties.

2 1

20 SolidWorks Vocational/Technical Tutorial

Tutorial 11: Certified SolidWorks Associate (CSWA)

48 In the pop-up window you can read

the mass 1280.33 grams. This is

answer B from the assignment.

SolidWorks Vocational/Technical Tutorial 21

Tutorial 11: Certified SolidWorks Associate (CSWA)

Assignment: Part 2

Available time: 45 minutes

We will show you how to complete an assignment as described on the test.

Build this part in SolidWorks.

Unit system: MMGS (millimeter, gram, second).

Decimal places: 2.

Part Origin: Arbitrary.

All holes through all, unless otherwise specified.

Part material: 6061 Alloy.

Density = 0.0027 g/mm^3

What is the overall mass of the part in grams?

a) 2040.57

b) 2004.57

c) 102.63

d) 1561.23

22 SolidWorks Vocational/Technical Tutorial

Tutorial 11: Certified SolidWorks Associate (CSWA)

Work plan

Again, you have to think about the way you are going to build this model. Below are the

steps you should take. Every step is a feature.

1 2 3 4 5

6 7 8 9 10

49 Open a part and set the

units to MMGS. Make

the sketch on the Right

Plane as shown.

50 Extrude the sketch to

100 mm.

2

SolidWorks Vocational/Technical Tutorial 23

Tutorial 11: Certified SolidWorks Associate (CSWA)

51 We will create the first

auxiliary plane:

1 Select the edge shown. 3

2 Hold the <Ctrl> key

and select the plane as

shown in the 4

illustration.

3 Click on the arrow

beneath Reference

Geometry in the

CommandManager. 1

4 Click on Plane. 2

52 Set the angle of the new

plane to 30° in the

PropertyManager. 3

Check Flip.

Click on OK.

1

2

24 SolidWorks Vocational/Technical Tutorial

Tutorial 11: Certified SolidWorks Associate (CSWA)

53 Make the sketch as shown in the illustration

on the right and continue to step 58.

If you cannot make this sketch by yourself,

then follow the next few steps.

54 Select the auxiliary

plane you have just

created.

Click on Line in the 2

CommandManager.

Click as shown to get 5

the beginning of the

line. 4

Click as shown to get

the second point from

the line.

3

Move the cursor away

from the last point but

do NOT click!

55 Return to the end

point of the line with the cursor (do

NOT click). 1 2

SolidWorks starts drawing an arc

now.

Click as shown to get the second

point of the arc. Make sure to draw

half a circle.

SolidWorks Vocational/Technical Tutorial 25

Tutorial 11: Certified SolidWorks Associate (CSWA)

56 SolidWorks will automatically draw lines

again.

Draw the last two lines.

Tip: You saw an ‘automatic’ change of function between the Line and Arc command.

This is called Autotransitioning in SolidWorks and is very convenient if you want

to build a sketch from lines and tangent arcs.

57 Set the two dimensions as shown with

Smart Dimension.

58 Make an extrusion

from this sketch.

1 Click on Reverse 3

Direction in the

PropertyManager

to make sure that

the extrusion goes

2

downward and not

upwards. 1

2 Select Up to Next

to set the depth.

3 Click on OK.

26 SolidWorks Vocational/Technical Tutorial

Tutorial 11: Certified SolidWorks Associate (CSWA)

59 Make the sketch as shown

in the illustration on the

right and continue to

step 63.

If you cannot make this

sketch by yourself, then

follow the next few steps.

60 Create an arc:

1 Select the plane to

make a sketch on.

2

2 Click on Arc in the

CommandManager.

Click on 3 Point Arc

3

in the

PropertyManager. 4

3 1

4 Set the first arc point

at the corner as 5

shown.

5 Set the second point

on the edge. 6

6 Set the third point at a

random position.

61 Insert the two dimensions as shown.

SolidWorks Vocational/Technical Tutorial 27

Tutorial 11: Certified SolidWorks Associate (CSWA)

62 Draw two small lines

above the arc as shown.

3

4

63 Make an Extruded

Cut from this

sketch.

1 Select the option

Up to Surface to

set the depth.

2

2 Click on the

plane which

1

indicated the end

of the Extruded

Cut.

64 Make the sketch on the sloped

plane as shown in the illustration

on the right and continue to

step 71.

If you cannot make this sketch

by yourself, then follow the next

few steps.

28 SolidWorks Vocational/Technical Tutorial

Tutorial 11: Certified SolidWorks Associate (CSWA)

65 Select the sloped plane to

make a sketch on.

2

Click on Circle in the

CommandManager.

Keep the cursor still just above

the rounded edge at the top of

the plane. Do NOT click. 3

The midpoint of the edge

appears. Click on that to set

the middle of the circle. 4

66 Draw the circle and set the dimension.

SolidWorks Vocational/Technical Tutorial 29

Tutorial 11: Certified SolidWorks Associate (CSWA)

67 Draw two centerlines as shown on the

right.

Push the <Esc> key after you have drawn

the first centerline, and then draw the

second centerline.

68 To offset entities:

1,2 Select both centerlines (use

the <Ctrl> key).

3 Click on Offset Entities in

the CommandManager. 3

4 The distance is 5 mm.

8

5 Select the option Bi-

directional. 4

2

6 Select the option Cap ends.

7 Select the option Lines. 5

8 Click on OK. 1

6

7

30 SolidWorks Vocational/Technical Tutorial

Tutorial 11: Certified SolidWorks Associate (CSWA)

69 Click on Trim Entities

in the

CommandManager.

Click on the option

Trim away inside in 1

the PropertyManager.

Click on the Circle. 3

Click on all four lines

that run through the

circle. The pieces 4

inside of the circle will

be removed.

70 Click on Trim to closest

in the PropertyManager.

Click on the parts of the

circle that you want to be

removed.

2

SolidWorks Vocational/Technical Tutorial 31

Tutorial 11: Certified SolidWorks Associate (CSWA)

71 Did you trim

everything? Now

you can make an

2

Extruded Cut from

the sketch. Set the

depth to 5 mm.

72 Make the sketch as shown in the

illustration on the right.

73 Make an Extruded Cut

and set the depth to

Through All. 2

32 SolidWorks Vocational/Technical Tutorial

Tutorial 11: Certified SolidWorks Associate (CSWA)

74 We will now make the second

auxiliary plane.

1 Select the edge as shown. 3

2 Hold the <Ctrl> key and select the

plane as shown in the illustration.

3 Click on the arrow beneath 4

Reference Geometry in the

CommandManager.

4 Click on Plane.

2

75 Set the angle of the

new plane to 20° in

the 3

PropertyManager.

Click on Flip, so the

plane extends in the

right direction.

Click on OK.

1

2

SolidWorks Vocational/Technical Tutorial 33

Tutorial 11: Certified SolidWorks Associate (CSWA)

76 Make a sketch as shown on

the plane that you have just

created.

In steps 54 to 56 you have

already made a similar sketch.

If you want, you can check

these steps to see how it is

done.

Tip: Are the planes in the way while sketching? You can hide the planes. Click on Hide/

Show Items, and next on View Planes.

77 Make an extrusion from the

sketch.

1 First click on Reverse 3

Direction in the

PropertyManager to extend

the extrusion downwards.

2 Select the option Up to 2

Next.

1

3 Click on OK.

34 SolidWorks Vocational/Technical Tutorial

Tutorial 11: Certified SolidWorks Associate (CSWA)

78 Make the sketch as shown

on the right.

79 Extrude the sketch with a

height of 15 mm.

80 Make the sketch as shown on

the right.

SolidWorks Vocational/Technical Tutorial 35

Tutorial 11: Certified SolidWorks Associate (CSWA)

81 Make an

Extruded Cut

Through All from 2

this sketch.

82 The model is now finished. We will

select the material now.

1 Right-click on Material in the 1

FeatureManager.

2 Click on Edit Material.

2

36 SolidWorks Vocational/Technical Tutorial

Tutorial 11: Certified SolidWorks Associate (CSWA)

83 Open the Aluminum Alloys list in the window that appears.

Select 6061 Alloy.

Verify that the is the same as in the assignment.

Click Apply and then Close.

2

3

4 5

SolidWorks Vocational/Technical Tutorial 37

Tutorial 11: Certified SolidWorks Associate (CSWA)

84 Finally, we want to know the total

mass of this part.

Click on the tab Evaluate in the

CommandManager and next on

Mass Properties.

In the pop-up menu you can read a

mass of 2040.57 grams. So this is

answer A from the assignment.

You can also see the Center of mass.

This value is displayed in X-, Y-, Z- 1

coordinates in relation to the origin.

The center of mass is also indicated in

the model itself. 2

What are the main features you have learned in this tutorial?

As we have explained previously, you did not learn a lot of new features in this tutorial.

You have seen a few smart techniques, though, including:

Some of the options for the Offset command.

Some of the options for the Trim command.

The automatic change between a line and an arc while creating a sketch.

More importantly, you have practiced two examples from the CSWA exam. You have seen

how to make a plan when modeling a more complex part.

By practicing a lot with these kinds of assignments you can gain the necessary skills for

passing the CSWA exam and receiving a CSWA certificate.

38 SolidWorks Vocational/Technical Tutorial

You might also like

- Tacklife DM01M MultimeterDocument83 pagesTacklife DM01M MultimeterJoseEliasNo ratings yet

- Solidworks Tutorial 2: Picture HolderDocument22 pagesSolidworks Tutorial 2: Picture HolderJoseEliasNo ratings yet

- SolidWorks Tutorial07 GardenLightDocument60 pagesSolidWorks Tutorial07 GardenLightJoseEliasNo ratings yet

- SolidWorks Tutorial12 ClampDocument48 pagesSolidWorks Tutorial12 ClampJoseEliasNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CLI Basics: Laboratory ExerciseDocument5 pagesCLI Basics: Laboratory ExerciseJhalen Shaq CarrascoNo ratings yet

- 2 PassivetransportDocument8 pages2 PassivetransportFayeNo ratings yet

- Bimedtral Ing. 4 Y 3Document2 pagesBimedtral Ing. 4 Y 3Derly Garcia0% (1)

- Kernel One SBDocument140 pagesKernel One SBronanNo ratings yet

- First Quarter Examination in PracticalDocument2 pagesFirst Quarter Examination in PracticalMark Anthony B. AquinoNo ratings yet

- Study of Steam Generation Units With Their Accessories and MountingsDocument64 pagesStudy of Steam Generation Units With Their Accessories and MountingsMasudur RahmanNo ratings yet

- Input OutputcrwillDocument21 pagesInput OutputcrwillAbhishek SinghNo ratings yet

- Cut Pieces: From Flat Plates, Strips and Coil Stock. A. Shearing B. Bend Allowance C. Forming Dies D. Spring BackDocument100 pagesCut Pieces: From Flat Plates, Strips and Coil Stock. A. Shearing B. Bend Allowance C. Forming Dies D. Spring BackJade DigNo ratings yet

- Hadoop Course Content PDFDocument9 pagesHadoop Course Content PDFNaveen ElancersoftNo ratings yet

- Automatic Summarization of Youtube Video Transcription Text Using Term Frequency-Inverse Document FrequencyDocument9 pagesAutomatic Summarization of Youtube Video Transcription Text Using Term Frequency-Inverse Document FrequencyKarunya ChavanNo ratings yet

- Biosash Order Form Latest - 2019-9281576348996003Document3 pagesBiosash Order Form Latest - 2019-9281576348996003Amer Suhail ShareefNo ratings yet

- Synthesis of Sufanilic AcidDocument4 pagesSynthesis of Sufanilic AcidWinston Jake Gerolaga0% (1)

- Electrothermal Industries PDFDocument10 pagesElectrothermal Industries PDFAna Marie AllamNo ratings yet

- Dividido Trane 30 TonsDocument23 pagesDividido Trane 30 TonsairemexNo ratings yet

- Introduction To Water, Sanitation and Hygiene (WASH) : PosterDocument2 pagesIntroduction To Water, Sanitation and Hygiene (WASH) : PosterDanielNo ratings yet

- Practical Mix Design of Concrete2Document3 pagesPractical Mix Design of Concrete2Jiabin LiNo ratings yet

- Resume - Lifestyle Medicine RDDocument1 pageResume - Lifestyle Medicine RDapi-338995106No ratings yet

- Solutions Manual For Medical Imaging Signals and Systems 2e by Prince 0132145189Document38 pagesSolutions Manual For Medical Imaging Signals and Systems 2e by Prince 0132145189courbheadpan22xt100% (16)

- Suction Pile and FoundationDocument19 pagesSuction Pile and FoundationhaydarburedahNo ratings yet

- Holes by Louis Sachar: Guided Reading Questions, Vocabulary, and Task Sheets by Heather BlackburnDocument22 pagesHoles by Louis Sachar: Guided Reading Questions, Vocabulary, and Task Sheets by Heather BlackburnSonia ChowdhariNo ratings yet

- Carboxylic Acids and Their DerivativeDocument43 pagesCarboxylic Acids and Their DerivativenathasyaNo ratings yet

- Notes Physics 1Document668 pagesNotes Physics 1张书No ratings yet

- NITGEN USB Device Driver For Linux Installation Guide (Eng)Document7 pagesNITGEN USB Device Driver For Linux Installation Guide (Eng)fransm88No ratings yet

- Abu Ibrahim Al-Hashimi Al-Qurashi: Abū Ibrāhīm Al-Hāshimi Al-Qurashi Mawli Al-SalbiDocument12 pagesAbu Ibrahim Al-Hashimi Al-Qurashi: Abū Ibrāhīm Al-Hāshimi Al-Qurashi Mawli Al-SalbiJosué Barrón GonzálezNo ratings yet

- TOS BiologyDocument2 pagesTOS BiologyBea Noreen Ungab100% (3)

- On Campus BA - Consultant JDDocument2 pagesOn Campus BA - Consultant JDSivaramakrishna SobhaNo ratings yet

- Shattered Pixel Dungeon The Newb Adventurer's Guide: Chapter I: The BasicsDocument15 pagesShattered Pixel Dungeon The Newb Adventurer's Guide: Chapter I: The BasicsFishing ManiaNo ratings yet

- Learning Activity Sheet in General Mathematics 2nd QuarterDocument5 pagesLearning Activity Sheet in General Mathematics 2nd QuarterDominic Dalton CalingNo ratings yet

- Alxion: For Direct DriveDocument56 pagesAlxion: For Direct DriveAnselmo Aguado cortesNo ratings yet

- 118CP Selection of CP Systems For Reinforced Concrete StructuresDocument15 pages118CP Selection of CP Systems For Reinforced Concrete StructuresWill NashNo ratings yet