Professional Documents

Culture Documents

Centum VP 6 ENG Project Global PDF

Centum VP 6 ENG Project Global PDF

Uploaded by

priyasha123Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Centum VP 6 ENG Project Global PDF

Centum VP 6 ENG Project Global PDF

Uploaded by

priyasha123Copyright:

Available Formats

CENTUM VP COURSE PROJECT LESSON 6

OBJECTIVE OF THIS LESSON

This project will allow the student to construct feedback and sequence control function blocks to

manipulate a predefined batch application. The project will be built and tested in the “Test Function”, then

anytime during the three parts, you can load the project to the FCS.

This project is made up of three parts, each built on the preceding part. Information in the previous tabs

will come into play, plus you will need to refer to the FCS on-line Function Manual.

Create a New Project.

• Make your FCS an AFV10D and use the “General Purpose” database type.

• Make your HIS address HIS0164.

Create the I/O. NOTE: You will need to create a NODE #1.

• Make IOM #1 an analog input/output module AAI841-H (8 input/8 output)

• Create IOM #2 a 32-point digital input module ADV151.

• Create IOM #3 a 32-point digital output module ADV551.

• Create the function blocks, and sequence controls defined in each part.

Points to Note for the Project:

• On the “Detail Page” for the BSETUs and PIDs make the “Fully-open, Tightly-shut” = “No”.

• Remember to setup the totalization of the BSETUs for MIN.

• In the CALCU tuning panel, for the tank level, make P01 = 0.01 and P02 = 0.5.

• You can, at any point in this lab, make the project “Current” and load it to the FCS and HIS.

• After you have completed part 1 of this exercise create a graphic to control the process. Add to the

graphic as you complete the remaining parts.

CENTUM VP Engineering 1 TE 33M80N10-10EN-A

CENTUM VP COURSE PROJECT LESSON 6

Ingredient 1

Ingredient 2

Ingredient 3

MIXER COOKING

PROFILE

(PG-L13)

LEVEL

TEMP

STEAM

DRAIN

PUMP

Item Instrument Scale BSET Input Output

INGR-1 BSETU-2 0-1000 GPM 500 %Z011101 %Z011109

INGR-2 BSETU-2 0-1000 GPM 500 %Z011102 %Z011110

INGR-3 BSETU-2 0-100 GPM 50 %Z011103 %Z011111

Item Instrument Scale Output

Cooking Profile PG-L13 480 Seconds (Quick return) TEMP.SET

X02=60, X03=120, X04=180, X05=240, X06=300, X07=360, X08=420

Y01=120, Y02=290, Y03=290, Y04=150, Y05=150, Y06=70, Y07=50

Item Instrument Scale Input Output

TEMP PID 50-300 DEGF %Z011107 STEAM.SET

STEAM PID 0-200 LB/H (SQRT) %Z011108 %Z011112

LEVEL PVI 0-100 % CALC.CPV

CALC CALCU 0-100 LEVEL.PV

DRAIN SIO-11 %Z012101 %Z013101

PUMP SIO-11 %Z012102 %Z013102

MIXER SIO-11 %Z012103 %Z013103

COMP RL

CENTUM VP Engineering 2 TE 33M80N10-10EN-A

CENTUM VP COURSE PROJECT LESSON 6

PART 1

Create the instruments on the previous page, defining them as described. At the bottom of the page is the

calculation to be put into the CALCU to simulate the level filling or draining in the tank. You will need to

refer to the FCS Function Manual for specific details on these instruments. After they have been created,

test them on a control group before you build the sequence table that will control the process.

Process Steps:

1. When the process starts, add ingredients 1 & 2. When the level in the tank reaches 30%, turn on the

agitator and start the temperature profile.

2. When the profile gets to zone 3 add ingredient 3.

3. When the profile finishes, open the drain and turn on the pump.

4. When the level in the tank drops to 30% turn off the agitator.

5. When the tank is empty, turn off the pump and close the drain valve. Return the table to step #1.

Instruments:

• Make all of the fill and drain valves plus agitators to be SIO-11s

• Use this calculation in the CALCU feeding the reactors PVI for your level simulation.

1 program

2 alias D drain.MV *NOTE: Substitute the names shown in italics with the block names you

3 alias E ingr-1.MV created on the previous page.

4 alias F ingr-2.MV

5 alias G ingr-3.MV

6 H=P01*(E+F+G)

7 FI=RV+H-P02*D

8 IF (FI<0) THEN

9 FI=0

10 ELSE IF (FI>100) THEN

11 FI=100

12 END IF

13 CPV=FI

14 END

Calculation and

PV IN

PVI connection LEVEL CALC

for level simulation

IN CPV

PVI CALCU

CENTUM VP Engineering 3 TE 33M80N10-10EN-A

CENTUM VP COURSE PROJECT LESSON 6

MIX-A MIX-B MIX-C

Ingredient

Ingredient

Ingredient

MIXER COOKING

PROFILE

(PG-L13)

LEVEL

TEMP

STEAM

DRAIN

PUMP

Item Instrument Registers to change

MIX-A BDSET-1L INGR-1.BSET (500)

INGR-2.BSET (500)

INGR-3.BSET (50)

Profile: Y01=120, Y02=290, Y03=290, Y04=150, Y05=150, Y06=70,

Y07=50

MIX-B BDSET-1L INGR-1.BSET (500)

INGR-2.BSET (450)

INGR-3.BSET (80)

Profile: Y01=120, Y02=275, Y03=260, Y04=190, Y05=170, Y06=100,

Y07=50

MIX-C BDSET-1L INGR-1.BSET (250)

INGR-2.BSET (600)

INGR-3.BSET (40)

Profile: Y01=120, Y02=250, Y03=290, Y04=265, Y05=165, Y06=90,

Y07=50

CENTUM VP Engineering 4 TE 33M80N10-10EN-A

CENTUM VP COURSE PROJECT LESSON 6

PART 2

Part 2 allows the operator to make a pre-selected grade mix of the product. Listed on the previous page

are the instrument types and the specifications to use, use the FCS On-Line Builder manual (or use this

course manual) to look up specifics for what a BDSET-1 does.

What is the “BSET” register in a BSETU used for?

The process steps are the same except that the operator must select the desired mix first, and then start

the process.

New Process Step:

1. When the operator starts the process, he must then select a mix, which is down loaded to the INGR

and to the PROFILE from the BDSET-1.

CENTUM VP Engineering 5 TE 33M80N10-10EN-A

CENTUM VP COURSE PROJECT LESSON 6

MIX-A MIX-B MIX-C

Ingredient

Ingredient

Ingredient 3

MIXER COOKING

PROFILE

(PG-L13)

LEVEL

TEMP

STEAM

DRAIN

PUMP

FILL_A FILL_B FILL_C

LI Store LI Store LI Store

MIX-A MIX-B MIX-C

DRAIN_A DRAIN _B DRAIN _C

CENTUM VP Engineering 6 TE 33M80N10-10EN-A

CENTUM VP COURSE PROJECT LESSON 6

PART 3

Part 3 adds storage tanks for the different mixes. Make these tanks in a new control drawing. This will

require reading the Reactor’s drain status in a new sequence table in the control drawing.

• Use the PVI and calculation configuration shown on page 3 of the lab for these new tanks.

Add these Process Steps:

1. When a mix is selected, create a new sequence table that will open the appropriate storage tank fill

valve when the reactors drain opens after the batch completes. Close the storage fill valve when the

reactor drain closes.

2. If a storage tank is above 70% full don’t allow the associated mix to start and output an “Operator

Guide Message” stating which storage tank is too full.

Instruments:

1. Make all of the fill and drain valves SIO-11s

• Do not connect these to the I/O, instead put the SIMM=1 on the instrument’s tuning panel.

2. Make 3 storage tank PVIs with CALCUs for the simulation.

• Modify the following calculation to fit each of the CALCUs depending upon the mix. As a starting

point, make P01 and P02 = .5.

1 program

2 alias D fill-x.MV (This is the storage tank’s fill valve!)

3 alias E drain-x.MV (This is the storage tank’s drain valve!)

4 F=P01*D

5 FI=RV+F-P02*E

6 IF (FI<0) THEN

7 FI=0

8 ELSE

9 CPV=FI

10 END IF

11 END

CENTUM VP Engineering 7 TE 33M80N10-10EN-A

CENTUM VP COURSE PROJECT LESSON 6

Empty page.

CENTUM VP Engineering 8 TE 33M80N10-10EN-A

You might also like

- Python Programming & SQLDocument152 pagesPython Programming & SQLVinay Patel100% (1)

- Math Prime FactorizationDocument2 pagesMath Prime FactorizationSarah Bea JolcanainNo ratings yet

- SmartPlant InstrumentationDocument319 pagesSmartPlant Instrumentationmatrixtn100% (2)

- T315-02 System Architecture - RevCDocument20 pagesT315-02 System Architecture - RevCNikhilesh MuraleedharanNo ratings yet

- Maxplant: Step by Step Tutorial Centum VPDocument10 pagesMaxplant: Step by Step Tutorial Centum VPAhmed KhairyNo ratings yet

- HSBC Fund Transfer FORMDocument1 pageHSBC Fund Transfer FORMPinzariuSimona100% (1)

- Prosafe-Rs Vnet/Ip: User'S ManualDocument50 pagesProsafe-Rs Vnet/Ip: User'S Manualsaeed moradpourNo ratings yet

- Interview Qa CobolDocument145 pagesInterview Qa CobolVema Venkatesh GangodiNo ratings yet

- CENTUM - VP Function Blocks Reference Vol1 PDFDocument440 pagesCENTUM - VP Function Blocks Reference Vol1 PDFnubblerNo ratings yet

- Centum VP 7 ENG Advanced Labs - GlobalDocument6 pagesCentum VP 7 ENG Advanced Labs - GlobalNikhilesh Muraleedharan100% (1)

- Pump Simulation in Aspen PlusDocument47 pagesPump Simulation in Aspen Plusahmed elhamy mohamed100% (1)

- HIS Operation Centum VPDocument99 pagesHIS Operation Centum VPatif010100% (3)

- Yokogawa Giza PDFDocument187 pagesYokogawa Giza PDFWalid AissaNo ratings yet

- CS3000 R3 Engineering Course Day 4: Yokogawa Engineering Asia Singapore Training CentreDocument50 pagesCS3000 R3 Engineering Course Day 4: Yokogawa Engineering Asia Singapore Training CentreNumanNo ratings yet

- Huawei Cell Reselection ParametersDocument3 pagesHuawei Cell Reselection ParametersMohammad SelimNo ratings yet

- Function Blocks Overview CENTUM VP PDFDocument286 pagesFunction Blocks Overview CENTUM VP PDFrameshNo ratings yet

- VPEG Project Creation IOMDocument37 pagesVPEG Project Creation IOMdgfggfhghgdfhtNo ratings yet

- PPRS Training ManualDocument145 pagesPPRS Training ManualMahesh M P NairNo ratings yet

- Day2 - Control Drawing BuilderDocument19 pagesDay2 - Control Drawing BuilderNiyi Adetunji100% (1)

- Engineering Training Manual: Education Center Yokogawa Electric Corporation TE 33M80N10-10EN-ADocument1 pageEngineering Training Manual: Education Center Yokogawa Electric Corporation TE 33M80N10-10EN-ANikhilesh MuraleedharanNo ratings yet

- Centum VP Engneering Course Training Day 1Document80 pagesCentum VP Engneering Course Training Day 1Son Trieu100% (7)

- Workbook CENTUM VP PDFDocument160 pagesWorkbook CENTUM VP PDFSyed Mian Fahim Kakakhail50% (2)

- VPEG System OverviewDocument26 pagesVPEG System OverviewdgfggfhghgdfhtNo ratings yet

- Centum VP 3 ENG FCS Config - GlobalDocument16 pagesCentum VP 3 ENG FCS Config - GlobalNikhilesh MuraleedharanNo ratings yet

- Centum VP 3 ENG FCS Config - GlobalDocument16 pagesCentum VP 3 ENG FCS Config - GlobalNikhilesh MuraleedharanNo ratings yet

- Yokogawa DCS System Maintenance Procedures - Inst ToolsDocument31 pagesYokogawa DCS System Maintenance Procedures - Inst ToolsCarlos Jimenez100% (1)

- Schem SPI Installation GuideDocument129 pagesSchem SPI Installation GuideNikhilesh Muraleedharan100% (1)

- Microsoft Office Excel 2003 Intermediate III: Formulas and WorksheetsDocument8 pagesMicrosoft Office Excel 2003 Intermediate III: Formulas and Worksheetssantosha00No ratings yet

- 02.centum VP InstallationDocument541 pages02.centum VP InstallationHAMZA BENNo ratings yet

- HIS Configuration: Day 4 - Engineering CourseDocument81 pagesHIS Configuration: Day 4 - Engineering CoursechoirulNo ratings yet

- Certified Automation Professional A Complete Guide - 2020 EditionFrom EverandCertified Automation Professional A Complete Guide - 2020 EditionNo ratings yet

- Computer Application in Business Multiple Choice QuestionsDocument4 pagesComputer Application in Business Multiple Choice QuestionsAJOY KONERNo ratings yet

- S6 Regulatory ControlDocument22 pagesS6 Regulatory Controlplim5ollNo ratings yet

- Amb Training Yokogawa PDFDocument574 pagesAmb Training Yokogawa PDFambranja100% (1)

- S611-021501e - Cams For His Engineering GuideDocument89 pagesS611-021501e - Cams For His Engineering GuideLinx Lux SteiphsNo ratings yet

- Centum VP 1B30 - 01Document314 pagesCentum VP 1B30 - 01atif010100% (2)

- Centum VP His Builders Lesson 2: Objectives of This LessonDocument22 pagesCentum VP His Builders Lesson 2: Objectives of This LessonhalifNo ratings yet

- WritingYourFirstObjectARX PDFDocument11 pagesWritingYourFirstObjectARX PDFJavier RamosNo ratings yet

- S4 HIS FunctionsDocument41 pagesS4 HIS Functionsplim5oll100% (1)

- Day3 - Sequence Control FunctionDocument31 pagesDay3 - Sequence Control FunctionLê Bá Tấn0% (1)

- Centum VP 5 ENG Control Pgms - GlobalDocument36 pagesCentum VP 5 ENG Control Pgms - GlobalNikhilesh Muraleedharan100% (2)

- Centum VP 9 ENG GraphicsDocument28 pagesCentum VP 9 ENG GraphicsNikhilesh Muraleedharan100% (5)

- KPIs For Security Operations and Incident Response-2Document7 pagesKPIs For Security Operations and Incident Response-2siraj rahimNo ratings yet

- S10 ExercisesDocument101 pagesS10 Exercisesplim5ollNo ratings yet

- Introduction of CENTUM VP R6 RS R4 FullDocument98 pagesIntroduction of CENTUM VP R6 RS R4 FullmohamedfaizykaNo ratings yet

- CS3000 R3 Engineering Course Day 1: Yokogawa Engineering Asia Singapore Training CentreDocument60 pagesCS3000 R3 Engineering Course Day 1: Yokogawa Engineering Asia Singapore Training CentreNuman100% (1)

- Yokogawa Centum VP Hmi (Graphics) DesignDocument33 pagesYokogawa Centum VP Hmi (Graphics) Designswagat100% (2)

- Centum VP 8 ENG Backup - GlobalDocument4 pagesCentum VP 8 ENG Backup - GlobalNikhilesh MuraleedharanNo ratings yet

- Centum VP 8 ENG Backup - GlobalDocument4 pagesCentum VP 8 ENG Backup - GlobalNikhilesh MuraleedharanNo ratings yet

- CENTUM VP Fundamentals For Operation: Day 1 Training Module Code: VPOF Duration: 5 DaysDocument38 pagesCENTUM VP Fundamentals For Operation: Day 1 Training Module Code: VPOF Duration: 5 DaysJohn HowardNo ratings yet

- 6.CVP - E Day5Document54 pages6.CVP - E Day5João Paulo CostaNo ratings yet

- Sequence Control - LC64Document34 pagesSequence Control - LC64said_rahmansyah4750No ratings yet

- Cs3000 Operation With FfcsDocument106 pagesCs3000 Operation With FfcsNikhil S Pillai100% (3)

- Dcs CentumDocument36 pagesDcs Centumatif010100% (4)

- Centum VPDocument43 pagesCentum VPFachri AbdillaNo ratings yet

- CENTUM XL Engineering Function Manual-IM33G4Q10 11E 004Document65 pagesCENTUM XL Engineering Function Manual-IM33G4Q10 11E 004Ahmad Fadhil Reviansyah100% (2)

- DCS Presentation - Based Centum VPDocument77 pagesDCS Presentation - Based Centum VPrvicentclases100% (5)

- VPEG Software Input Output Functions PDFDocument21 pagesVPEG Software Input Output Functions PDFdgfggfhghgdfhtNo ratings yet

- Centum VP 2 ENG HIS Builder - GlobalDocument22 pagesCentum VP 2 ENG HIS Builder - GlobalNikhilesh Muraleedharan100% (1)

- Centum VP 1 ENG System Config - GlobalDocument18 pagesCentum VP 1 ENG System Config - GlobalNikhilesh Muraleedharan60% (5)

- Centum VP 1 ENG System Config - GlobalDocument18 pagesCentum VP 1 ENG System Config - GlobalNikhilesh Muraleedharan60% (5)

- Vpem PDFDocument174 pagesVpem PDFAMESH C PANDEY-INST-KURANGA100% (3)

- Centum VP Engneering Course Training Day 1 PDFDocument80 pagesCentum VP Engneering Course Training Day 1 PDFGanesh BhandaryNo ratings yet

- Centum VP HIS OperationDocument94 pagesCentum VP HIS OperationYana AbdurrahmanNo ratings yet

- Centum VP BatchDocument3 pagesCentum VP BatchYashwanth MnNo ratings yet

- Centum VP R6 EngineeringDocument3 pagesCentum VP R6 EngineeringMohammed Abd El Razek0% (1)

- Exaopc GS36J02A10-01E PDFDocument11 pagesExaopc GS36J02A10-01E PDFsina20795No ratings yet

- Centum VP MaintenanceDocument2 pagesCentum VP MaintenanceLaurence Malanum0% (1)

- PH SystemsDocument12 pagesPH Systemslux0008No ratings yet

- PLC Lab #4 Event SequencingDocument15 pagesPLC Lab #4 Event SequencingIan SpacekNo ratings yet

- Lab 1a Wind Tunnel Testing Principles & Drag Coefficients of Golf BallsDocument9 pagesLab 1a Wind Tunnel Testing Principles & Drag Coefficients of Golf BallsSaadNo ratings yet

- Lab 3 Integrated PLC Pneumatics Circuits 2015Document5 pagesLab 3 Integrated PLC Pneumatics Circuits 2015Aminullah MinNo ratings yet

- Lab Instruction Che 246Document21 pagesLab Instruction Che 246Faradilah Binti Ajma'inNo ratings yet

- 2 Dof Helicopter Courseware Sample For Matlab UsersDocument10 pages2 Dof Helicopter Courseware Sample For Matlab UsersAmine EL FERHANINo ratings yet

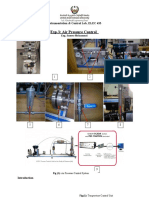

- Exp3 - Air Pressure ControlDocument8 pagesExp3 - Air Pressure ControlDon LawrenceNo ratings yet

- Record MechatronicsDocument46 pagesRecord MechatronicsSandeepakNo ratings yet

- Introduction To Data Science 5-13Document19 pagesIntroduction To Data Science 5-13Syed ZubairNo ratings yet

- Analysis of Road Accidents Using Data Mining TechniquesDocument3 pagesAnalysis of Road Accidents Using Data Mining Techniquesgunda prashanthNo ratings yet

- 2023-04-06-Acquisdata-India Information Technology Summary-101288422Document2 pages2023-04-06-Acquisdata-India Information Technology Summary-101288422Karan PatniNo ratings yet

- PATEL PALAK (ENROLLMENT NO: 130370702508) Supervisor: Mr. Yask Patel (Assistant Professor) Parul Institute of Engineering & Technology, Limda, VadodaraDocument1 pagePATEL PALAK (ENROLLMENT NO: 130370702508) Supervisor: Mr. Yask Patel (Assistant Professor) Parul Institute of Engineering & Technology, Limda, Vadodarapalak patelNo ratings yet

- Object Oriented Programming (OOP) : PPS UNIT-5Document48 pagesObject Oriented Programming (OOP) : PPS UNIT-5Kaushal KulkarniNo ratings yet

- Analytic Hierarchy ProcessDocument40 pagesAnalytic Hierarchy Processkuroko tetsuyaNo ratings yet

- CainterprtoolsDocument33 pagesCainterprtoolsapi-233997904No ratings yet

- MIDTERM EXAM (ICS 461 Artificial Intelligence)Document9 pagesMIDTERM EXAM (ICS 461 Artificial Intelligence)Aya AbdAllah AmmarNo ratings yet

- Print BusinessDocument5 pagesPrint BusinessEmz CelebreNo ratings yet

- C 65 HCDocument84 pagesC 65 HCChenna Vijay100% (1)

- Damage Analysis From A PictureDocument3 pagesDamage Analysis From A PictureSweety DarcyNo ratings yet

- Formulation LP 3423Document42 pagesFormulation LP 3423mazin9030% (1)

- Embedded Systems Engineer Interview PrepDocument7 pagesEmbedded Systems Engineer Interview Prepreema100% (1)

- MidtermDocument35 pagesMidtermDenisa BararNo ratings yet

- Investigation of Linux - Mirai Trojan FamilyDocument56 pagesInvestigation of Linux - Mirai Trojan FamilyWaqas AhmedNo ratings yet

- A Beginners Guide To Solaris Multipathing Software (MPxIO or STMS)Document10 pagesA Beginners Guide To Solaris Multipathing Software (MPxIO or STMS)marwanohag117No ratings yet

- User Account Information Technology SOPDocument16 pagesUser Account Information Technology SOPYuyu YcNo ratings yet

- Audit Layanan Teknologi Informasi Berbasis Information Technology Infrastructure Library (ITIL)Document12 pagesAudit Layanan Teknologi Informasi Berbasis Information Technology Infrastructure Library (ITIL)Alex MaryusNo ratings yet

- SIwave Training 2016 - Signal and Power Integrity Analysis For Complex PCBs and IC Packages PDFDocument268 pagesSIwave Training 2016 - Signal and Power Integrity Analysis For Complex PCBs and IC Packages PDFrey_hadesNo ratings yet

- Procure 2 MaintainDocument7 pagesProcure 2 MaintainfanoustNo ratings yet

- Pplus Logical Data ModelDocument7 pagesPplus Logical Data ModelHardip BhatiaNo ratings yet