Professional Documents

Culture Documents

Amb Training Yokogawa PDF

Uploaded by

ambranjaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Amb Training Yokogawa PDF

Uploaded by

ambranjaCopyright:

Available Formats

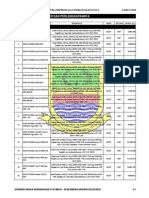

TRAINING CENTRE

(SINGAPORE)

STUDENT TRAINING TEXTBOOK

Name :

Company :

Course Period :

Document No: CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

Document No: CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

COURSE : CS 1000 & CS 3000 ENGINEERING (Vnet/IP)

NAME OF COURSE MATERIAL USED : CS 1000 & CS 3000 ENGINEERING (Vnet/IP)

Edition Date Revised Item Rev. No.* Author

0 September 2001 - R3.01 Jessie Chong

1 December 2004 Contents (Page 1) R3.04 Jessie Chong

Add F3, FFCS (Page 1-10)

2 March 2006 Revised Materials to Vnet/IP R3.06 Jessie Chong

3 September 2007 Revision R3.07 Ivan Choo

This document is maintained by : Wendy Kok Initial: Wendy Kok Date: September 2007

Note: Instruction Manual is updated/controlled by YHQ.

* - Denotes the release no. of the software corresponding to the contents of this instruction

manual. The revised contents are valid until the next edition is issued.

WELCOME TO YOKOGAWA TRAINING CENTRE

WELCOME TO YOKOGAWA TRAINING CENTRE

Yokogawa Training Centre in Singapore commenced operation in 1986. For the past

years, we have been actively involved in training customers in area of

instrumentation and control. To date, we have trained a total of more than 10,000

participants from over 480 organisations based in Asia, Middle East, Africa, Europe

and America.

We welcome you to attend this course and trust that you will benefit from the training

session. Feel free to approach the staff or instructors should you need any

assistance.

The following information may be helpful to you during this course period.

General Information

Address : 5 Bedok South Road, Singapore 469270

Telephone No.: 62493654

Fax No. : 62419537

Schedule

Session : 0900 – 1630

Tea break : 1000 – 1015

1445 – 1500

Lunch : 1130 – 1245

General Rules & Regulation

• Be punctual for all sessions.

• Avoid entering restricted premises – Factory Acceptance Test area & staff offices

• Smoking is strictly confined to smoking areas only.

• No consumption of beverages and food in the classroom to ensure cleanliness of

the training environment.

Others

Trainees can bring along a jacket to keep themselves warm as the training

environment may be cold.

YOKOGAWA SINGAPORE TRAINING CENTRE

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

WELCOME TO YOKOGAWA TRAINING CENTRE

YOKOGAWA SINGAPORE TRAINING CENTRE

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

COURSE OUTLIINE

COURSE OUTLINE

OBJECTIVE : This course enables participants to learn to perform

generation of CENTUM CS 1000/3000 regulatory control

functions, sequence control functions and Human Interface

Station.

DURATION : 5 days

PARTICIPANTS : For engineers involved in software generation or modification

on the CENTUM CS 1000/3000 system.

PREREQUISITE : Participants should have attended CENTUM CS 1000/3000

Operation course.

COURSE CONTENTS :

DAY 1

Centum CS 1000/3000 system specification

Project creation and attribute utility

Project common definition

DAY 2

FCS configuration

I/O module configuration

Software switches configuration

Message definition

Control drawing builder

DAY 3

Regulatory Control Function Definition

Sequence Control Function Definition

DAY 4

HIS configuration

Windows configuration

DAY 5

Graphics builder

YOKOGAWA SINGAPORE TRAINING CENTRE

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

COURSE OUTLIINE

YOKOGAWA SINGAPORE TRAINING CENTRE

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

TABLE OF CONTENTS

TABLE OF CONTENTS

A. SYSTEM OVERVIEW A1

A1. System Components A1

A1.1 Types of HIS A3

A1.2 Types of FCS A5

A2. FCS Hardware Description A15

A3. Network A20

A4. System Specifications A22

A5. Hardware Configuration A25

A6. System Components of Vnet/IP Network A27

A7. Field Control Station [Vnet/IP] A30

A7.1 FFCS-L Hardware Description A31

A8. Transmission Path Specification [VnetIP] A32

A9. Questions A33

A10. Exercises A33

B. ENGINEERING ENVIRONMENT B1

B1. Test Function B1

B1.1 Virtual Test B1

B1.2 Target Test B2

B2. Concurrent Engineering B3

B3. Engineering Work Flow B4

B4. Questions B5

C. PROJECT CREATION C1

C1. Types of Project C1

C2. Creating a Default Project C2

C3. Project Attribute Utility C6

C3.1 Start Project Attribute Utility C6

C3.2 Start Project Attribute Utility C8

C3.3 Changing the Attribute of a Project C9

C3.4 Deleting a Project C10

C4. Questions C11

C5. Exercise C12

YOKOGAWA SINGAPORE TRAINING CENTRE Page 1 of 15

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

TABLE OF CONTENTS

D. PROJECT COMMON ITEMS D1

D1. Alarm Builder D1

D1.1 System-Fixed Alarm Status Character String D3

D1.2 User-Defined Alarm Status Character String D4

D1.3 Alarm Processing D5

D1.4 Alarm Priority D6 D2.

Plant Hierarchy Builder D10

D3. Engineering Unit Symbol Builder D12

D4. Switch Position Label Builder D13

D5. Multiple Projects Connection Builder D15

D6. Operation Mark Builder D17

D7. Station Configuration Viewer D20

D8. Status Change Command Character String Builder D21

D9. Security Builder D22

D9.1 User Definition D22

D9.2 Advanced Security Settings D25

D9.3 Security Level D31

D10. Exercise D36

E1. FIO SYSTEM OVERVIEW E1-1

E1.1 ESB and ER Bus E1-3

E1.2 System Configuration E1-4

E1.3 Network Specifications E1-5

E2. FIO SYSTEM OVERVIEW (Vnet/IP) E2-1

E2.1 Network Specifications E2-2

E2.2 Connection With Other Control Bus Domains E2-3

E2.2.1 Connection Between Vnet/IP and Vnet Domains E2-3

E2.2.2 Connection Between Vnet/IP and VLnet Domains E2-3

E2.2.3 Connection with HF Bus/RL Bus Domains E2-4

E2.2.4 Connection with Vnet Domains of Revisions R3.04 E2-4

or Earlier

YOKOGAWA SINGAPORE TRAINING CENTRE Page 2 of 15

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

TABLE OF CONTENTS

F1. LFCS CONFIGURATION F1-1

F1.1 LFCS Property - Constant F1-1

F1.1.1 Fast Scan/Medium-Speed Scan Period F1-1

F1.1.2 Pulse Width and Serial Startup Interval for F1-2

MC Instrument Block

F1.1.3 MLD-SW Block AUT/CAS F1-2

F1.1.4 SEBOL Statement F1-2

F1.1.5 User-Defined block F1-3

F1.1.6 IOM Online Updating F1-3

F1.1.7 Options F1-3

F1.1.8 PID Pulse Width Output F1-4

F1.1.9 PI-HLD Action after Hold F1-4

F1.1.10 Sequence Table Algorithm F1-4

F1.1.11 dPV/dCPV Output from SUB Becomes F1-5

Zero Right After IOP

F1.112 Accept Batch-End during EMST F1-6

F1.2 LFCS Property - Constant 2 F1-9

F1.2.1 SS-DUAL PV Update during Deviation F1-9

Alarm

F1.2.2 Alarm Notify Action when All AOF Released F1-10

F1.2.3 Specify Reference Station for Tag List F1-10

F1.2.4 Annunciator Message with Data F1-10

F1.2.5 Increase Number of System Common F1-11

Switches

F1.2.6 Preset MV Valid Immediately F1-11

F1.3 LFCS Property – State Transition F1-12

F1.3.1 State Transition Matrix F1-12

F1.4 LFCS Property – Line 1 F1-13

F1.4.1 Make RIO Bus Dual Redundant F1-13

F1.4.2 Repeater Connection F1-13

F1.5 LFCS Property - Network F1-14

F1.5.1 VLnet TCP/IP Settings, Vnet TCP/IP F1-15

Settings

F1.6 LFCS Station Definition F1-15

F1.6.1 Definitions F1-15

F1.6.2 Scan Transmission F1-19

F1.6.3 Detailed Settings F1-20

YOKOGAWA SINGAPORE TRAINING CENTRE Page 3 of 15

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

TABLE OF CONTENTS

F2. KFCS CONFIGURATION F2-1

F2.1 KFCS Property - Constant F2-1

F2.1.1 Fast Scan/Medium-Speed Scan Period F2-1

F2.1.2 Pulse Width and Serial Startup Interval F2-2

for MC Instrument Block

F2.1.3 MLD-SW Block AUT/CAS F2-2

F2.1.4 SEBOL Statement F2-2

F2.1.5 User-Defined block F2-3

F2.1.6 IOM Online Updating F2-3

F2.1.7 Options F2-3

F2.1.8 PID Pulse Width Output F2-4

F2.1.9 PI-HLD Action after Hold F2-4

F2.1.10 Sequence Table Algorithm F2-4

F2.1.11 dPV/dCPV Output from SUB Becomes Zero F2-5

Right After IOP

F2.1.12 Accept Batch-End during EMST F2-6

F2.2 KFCS Property – Constant 2 F2-9

F2.2.1 SS-DUAL PV Update during Deviation Alarm F2-9

F2.2.2 Alarm Notify Action when All AOF Released F2-10

F2.2.3 Specify Reference Station for Tag List F2-10

F2.2.4 Annunciator Message with Data F2-10

F2.2.5 Increase Number of System Common Switches F2-11

F2.2.6 Preset MV Valid Immediately F2-11

F2.3 KFCS Property – State Transition F2-12

F2.3.1 State Transition Matrix F2-12

F2.4 KFCS Property – KFCS Property – Line 1 F2-13

F2.4.1 Make I/O Bus Dual Redundant F2-13

F2.4.2 Interface Card Type F2-13

F2.5 KFCS Property - Network F2-14

F2.5.1 VLnet TCP/IP Settings, Vnet TCP/IP Settings F2-15

F2.6 KFCS Station Definition F2-15

F2.6.1 Definitions F2-15

F2.6.2 Scan Transmission F2-19

F2.6.3 Detailed Settings F2-20

F3. Field Control Unit for FIO (Rack Mountable) F3-1

- FFCS (FFCS Compact FCS)

F3.1 Configuraton of Field Control Unit F3-2

F3.2 Duplexed Structure of the FFCD F3-3

F3.3 Create a New FFCS F3-7

F3.4 Input/Output F3-8

F3.4.1 Creating a New Node: FFCS F3-9

F3.4.2 Creating a New I/O Module: FFCS F3-10

YOKOGAWA SINGAPORE TRAINING CENTRE Page 4 of 15

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

TABLE OF CONTENTS

F4. Field Control Unit for Vnet/IP for FIO F4-1

(19” Rack Mountable) – FFCS-L

F4.1 Configuraton of Field Control Unit F4-2

F4.2 Hardware Configuration of FFCS-L F4-3

F4.3 Create a new FFCS-L F4-4

F4.4 Input/Output F4-5

F4.4.1 Creating a New Node: FFCS-L F4-6

F4.4.2 Creating a New I/O Module: FFCS-L F4-7

G1. INPUT/OUTPUT FUNCTIONS(LFCS) G1-1

G1.1 FCS Input and Output Interfaces G1-1

G1.2 Process Input/Output G1-2

G1.2A Creating a New Node: LFCS G1-2

G1.2.1 Type Tab – Node Number G1-3

G1.2.2 Dual Redundant Power Supply G1-3

G1.2.3 HKU Set G1-3

G1.2.4 Installation Pattern G1-3

G1.2.5 Component Number G1-3

G1.2.6 Node Comment G1-3

G1.2.7 Unit Tab – Start Mode G1-3

G1.2.8 High Speed Read G1-3

G1.3 Creating a New I/O Module : LFCS G1-4

G1.3.1 IOM Type G1-5

G1.3.2 Installation Position G1-7

G1.3.3 Duplicate Next Card G1-8

G1.3.4 High Speed Read G1-8

G1.3.5 IOM Comment G1-8

G1.4 IOM Builder G1-9

G1.4A Analog I/O Module Nest (AMN11) Configuration G1-9

G1.4.1 Terminal G1-9

G1.4.2 Signal G1-10

G1.4.3 Conversion G1-10

G1.4.4 Service Comment G1-11

G1.4.5 Low Limit/High Limit G1-11

G1.4.6 Unit G1-11

G1.4.7 Set Details G1-12

G1.4.8 Dual G1-12

G1.4.9 P&ID Tag Name G1-13

G1.4.10 Label (User-defined label) G1-13

G1.4B Detailed Setting of Analog I/O Module G1-13

G1.4.1 Detect IOP G1-14

G1.4.2 IOP Detection Level G1-14

G1.4.3 Square Root G1-15

G1.4.4 OOP Clear G1-15

G1.4.5 Detect OOP G1-15

G1.4.6 Fallback, Maintain Current Value G1-16

G1.4.7 Pulse Input G1-16

G1.4.8 Resistance G1-16

YOKOGAWA SINGAPORE TRAINING CENTRE Page 5 of 15

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

TABLE OF CONTENTS

G1.4.9 Cold Junction Compensation G1-16

G1.4.10 Command G1-17

G1.4C Digital I/O Module (ADM51T) Configuration G1-18

G1.4.1 Terminal G1-18

G1.4.2 Mode G1-19

G1.4.3 P&ID Tag Name G1-19

G1.4.4 Tag Name G1-19

G1.4.5 Tag Comment G1-19

G1.4.6 Switch Position Label G1-20

G1.4.7 Label G1-20

G1.4.8 Button1, Button 2 G1-20

G1.4.9 Level G1-20

G1.4.10 Tag Mark G1-21

G1.4.11 Upper Window G1-21

G1.4.12 Help G1-21

G1.5 Exercise G1-22

G2. INPUT/OUTPUT FUNCTIONS (KFCS) G2-1

G2.1 FCS Input/Output Interfaces G2-1

G2.2 Process Input/Output G2-2

G2.2A Creating a New Node: KFCS G2-2

G2.2.1 Type G2-3

G2.2.2 Node G2-3

G2.2.3 Master G2-3

G2.2.4 Power Supply Unit G2-4

G2.2.5 Component Number G2-4

G2.2.6 Node Comment G2-4

G2.3 Creating a New I/O Module: KFCS G2-5

G2.3.1 IOM Type G2-6

G2.3.2 Installation Position G2-8

G2.3.3 Duplicate Next Card G2-9

G2.3.4 Output Type G2-9

G2.3.5 High Speed Read G2-9

G2.3.6 IOM Comment G2-9

G2.4 IOM Builder G2-10

G2.4A Analog I/O Module (AAI141-S) Configuration G2-10

G2.4.1 Terminal G2-10

G2.4.2 Conversion G2-11

G2.4.3 Service Comment G2-12

G2.4.4 Low Limit/High Limit G2-12

G2.4.5 Unit G2-13

G2.4.6 Set Details G2-15

G2.4.7 P&ID Tag Name G2-15

G2.4.8 Label G2-16

G2.4B Detailed Setting of Analog I/O Module G2-16

G2.4.1 Detect IOP G2-17

G2.4.2 IOP Detection Level G2-18

G2.4.3 Cold Junction Compensation G2-19

G2.4.4 Fallback G2-20

YOKOGAWA SINGAPORE TRAINING CENTRE Page 6 of 15

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

TABLE OF CONTENTS

G2.4.5 Pulse Input G2-20

G2.4C Digital I/O Module (ADV551-P) Configuration G2-22

G2.4.1 Terminal G2-22

G2.4.2 Mode G2-22

G2.4.3 P&ID Tag N ame G2-23

G2.4.4 Tag Name G2-23

G2.4.5 Tag Comment G2-23

G2.4.6 Switch Position Label G2-23

G2.4.7 Label G2-23

G2.4.8 Tag Comment G2-23

G2.4.9 Button1, Button2 G2-24

G2.4.10 Level G2-24

G2.4.11 Tag Mark G2-24

G2.4.12 Upper Window G2-24

G2.4.13 Help G2-25

G3. INPUT/OUTPUT FUNCTIONS (FFCS) G3-1

G3.1 FCS Input/Output Interfaces G3-1

G3.2 Process Input/Output (FFCS) G3-2

G3.3 Creating a New Node: FFCS G3-3

G3.3.1 Type G3-4

G3.3.2 Node G3-4

G3.3.3 Remote Node G3-4

G3.3.4 Power Supply Unit – Dual-Redundant Power Supply G3-4

G3.3.5 Power Supply Capacity – Power Supply G3-5

G3.3.6 Component Number G3-5

G3.3.7 Node Number G3-5

G3.4 Creating a New I/O Module: FFCS G3-6

G3.4.1 Installation Position – Slot, High Speed Read, G3-6

IOM Comment

G3.4.2 Duplicate Next Card G3-8

G3.4.3 Output Type G3-9

G3.4.4 High Speed Type G3-9

G3.4.5 IOM Comment G3-10

G3.5 Creating a New EB 401 (ER Bus Interface Master G3-10

Module: FFCS)

G3.5.1 IOM Type (Type and Position Tab) G3-10

G3.5.2 Installation Position (Type and Position Tab) G3-10

G3.5.3 Duplicate Next Card – Remote Node G3-11

Communication

G3.5.4 Maximum Number of Nodes (Set Details Tab) G3-11

G3.5.5 Communication Protocol (Set Details Tab) G3-12

G3.5.6 Communication Base Period (Set Details Tab) G3-12

G3.5.7 Node Response Timeout (Set Details Tab) G3-12

G3.5.8 Number of Retries Upon Node Response Timeout G3-12

(Set Details Tab)

YOKOGAWA SINGAPORE TRAINING CENTRE Page 7 of 15

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

TABLE OF CONTENTS

H. SOFTWARE INPUT/OUTPUT FUNCTIONS H1

H1. Identification of Software Input/Output H3

H2. Internal Switches H4

H2.1 Common Switches (%SW) H4

H2.1.1 Condition Testing and Status Operation H5

H2.1.2 Common Switch Builder H6

H2.2 Global Switches (%GS) H9

H2.2.1 Condition Testing and Status Operation H11

H2.2.2 Global Switch Builder H12

H3. Message Output Functions H15

H3.1 Annunciator Messages (%AN) H15

H3.1.1 Condition Testing and Status H15

H3.1.2 Annunciator Builder H16

H3.2 Operator Guide Messages H20

H3.2.1 Operator Guide Builder H20

H3.3 Printout Messages H22

H3.3.1 Printout Builder H22

H3.4 Sequence Message Request H24

H3.4.1 Sequence Message Request Builder H25

H3.5 Help Messages H27

H4. Message Types H29

H4.1 System Alarm Messages H29

H4.2 Process Alarm Messages H30

H5. Questions H31

H6. Exercises H32

I. CONTROL DRAWING BUILDER I1

I1. Control Drawing Environment I2

I1.1 Function Block I2

I1.2 Text I3

I1.3 Wiring I3

I1.4 Data Link Block I3

I2. Toolbar Buttons I4

I3. File Import and Export I10

I3.1 Text File Import and Export I10

I3.2 CS Source File Import I10

I4. Exercise I11

YOKOGAWA SINGAPORE TRAINING CENTRE Page 8 of 15

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

TABLE OF CONTENTS

J. REGULATORY CONTROL FUNCTION J1

J1. Function Block Processing Functions J3

J2. Detail Specifications of PID Block J5

J2.1 Basic J5

J2.2 Tag J10

J2.3 Input J12

J2.4 Alarm J14

J2.5 Control Calculation J20

J2.6 Output J30

J2.7 Connection J33

J2.8 Others J34

J3. Other Function Blocks J36

J4. Question J37

K. SEQUENCE CONTROL FUNCTION K1

K1.1 Sequence Table Block K1

K1.2 Sequence Table Configuration K2

K1.2.1 Number of Signals K3

K1.2.2 Sequence Table Elements K4

K2.1 Step Sequence Table K7

K2.2 Non-Step Sequence Table K10

K3. Logic Chart K12

K3.1 Logic Chart Configuration K13

K3.1.1 Logic Chart Elements K13

K3.1.2 Input Element Symbol K15

K3.1.3 Output Element Symbol K15

K3.1.4 Logic Operation Element Symbol K16

K4. Exercise K21

L. HIS FUNCTION L1

L1.1 HIS Properties - Type L1

L1.1.1 Station Type L1

L1.1.2 Station Address L2

L1.1.3 Component L2

L1.2 HIS Properties - Constant L3

L1.3 HIS Properties - Network L4

L1.3.1 Control Bus TCP/IP Settings L5

L1.3.2 Setting Ethernet TCP/IP Settings L5

L1.3.3 Setting Vnet/IP Network L6

YOKOGAWA SINGAPORE TRAINING CENTRE Page 9 of 15

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

TABLE OF CONTENTS

M. HIS CONFIGURATION M1

M1.1 HIS Constants M1

M1.1.1 Station Type M1

M1.1.2 Closing Process M2

M1.1.3 Long Term Data Save M4

M1.1.4 Message Print Wait Time M5

M1.1.5 Instrument Diagram Operation M5

M1.1.6 Security M6

M1.1.7 Multiple Projects M7

N. FUNCTION KEYS N1

N1. Function Keys Assignment N2

N1.1 Function N2

N1.1.1 Assigning Window Call to a Function Key N3

N1.1.2 Assigning a System Function to a Function N3

Key

N1.1.3 Assigning Trend Data Acquisition Function N6

To a Function Key

N1.1.4 Assigning LED to a Function Key N7

N1.1.5 Assigning a Program Executing to a N7

Function Key

N1.1.6 Assigning a Multimedia to a Function Key N8

N1.1.7 Assigning Panel Set Call Function to a N8

Function Key

N1.1.8 Assigning the Function of Calling up a N9

Window from a Different Station to a

Function Key

N1.1.9 Assigning the Function of Calling up a N10

Remote Window by Window Name to a

Function Key

N1.1.10 Assigning the Function of Copying a N11

Currently Displayed Window Set to a

Function Key

N1.1.11 Assigning the Function of Clearing a N11

Window on the Remote CRT to a

Function Key

N1.2 LED N12

N1.3 Change Privilege/Change Authorization over the N13

Functions Assigned to the Function Keys

N2. Emulate Function Keys in Operation and Monitoring N14

N2.1 Enabling Shortcut Keys N14

N2.2 Shortcut Actions N15

N2.3 Cautions on Using Shortcut Keys N15

N2.4 Reserved Shortcut Functions N16

YOKOGAWA SINGAPORE TRAINING CENTRE Page 10 of 15

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

TABLE OF CONTENTS

O. SCHEDULER O1

O1. Scheduler Builder O1

O1.1 Function O1

O1.2 Start Method, Start Month, Start Date, Period, O2

Times of Repeat

O1.3 Comment O2

O2. Exercise O3

P. SEQUENCE MESSAGE REQUEST P1

P1. Sequence Message Request Builder P1

P1.1 Function P1

P1.2 Station Name P1

P2. Exercise P3

Q. PANEL SET Q1

Q1. Panel Set Builder Q1

Q1.1 Panel Set Q1

Q1.2 Display Window Q1

Q1.3 Calling up the Panel Set Q2

Q1.4 HIS Notification Q2

R. TREND ACQUISITION PEN ASSIGNMENT R1

R1. Structure of Trend R1

R2. Sampling Period and Recording Span of Trend Data R3

R3. Trend Acquisition Pen Assignment Builder R4

R3.1 Trend Format R5

R3.2 Long Term Data Save R7

R4. Trend Group Definition R8

R4.1 Acquisition Data, Data Axis Span Change, R8

Low/High Limit Value

R4.2 Data Type R8

R5. Export Trend Data to CSV File R9

S. HIS WINDOW CREATION S1

S1. HIS Window Creation S1

S1.1 Window Types S2

S1.2 Window Name S3

S1.3 Help Message Number S3

S1.4 Window Comment S3

S2. Set Details Tab S4

S2.1 Window Operation and Monitoring Authority S4

S2.2 Disable Scaling S5

YOKOGAWA SINGAPORE TRAINING CENTRE Page 11 of 15

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

TABLE OF CONTENTS

T. CONTROL GROUP WINDOW DEFINITION T1

T1. HIS Window Creation T1

T1.1 Control Group (8-loop) T2

T1.2 Control Group (16-loop) T3

T1.3 Console Control (8-loop) T3

T2. Instrument Diagram Definition T4

T2.1 General Tab T4

T2.2 Instrument Diagram Tab T5

T2.3 Data Bind T6

U. OVERVIEW WINDOW DEFINITION U

U1. HIS Window Creation U1

U1.1 Overview U2

U2. Overview Window Definition U3

U2.1 General Tab U3

U2.2 Overview Tab U4

U2.3 Function Tab U6

U2.4 Data Bind Tab U8

V. HELP MESSAGE WINDOW V

V1. System Alarm Help V1

V2. User-Defined Help V1

V3. System Window Help V1

V4. Help Window Creation V2

V4.1 Help Message Number V3

V4.2 Help Message Comment V3

V5. Help Window Definition V3

W. GRAPHICS BUILDER W

W1. Graphics Builder Environment W1

W1.1 Graphics W2

W2. Toolbars W3

W2.1 Standard Toolbar W3

W2.2 Draw Toolbar W4

W2.3 HIS Functions Toolbar W5

W2.3.1 Process Data - Character W6

W2.3.1A General Tab W6

W2.3.1B Text Tab W8

W2.3.1C Graphic Modify Tab W9

W2.3.1D Modify Coordinates Tab W13

W2.3.1E Process Data - Character Tab W15

W2.3.1F Data Bind Tab W18

W2.3.2 Process Data - Bar W21

W2.3.2A General Tab W21

W2.3.2B Fill Tab W22

W2.3.2C Graphic Modify Tab W23

W2.3.2D Modify Coordinates Tab W24

YOKOGAWA SINGAPORE TRAINING CENTRE Page 12 of 15

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

TABLE OF CONTENTS

W2.3.2E Process Data - Bar Tab W25

W2.3.2F Data Bind Tab W26

W2.3.3 Process Data - Arrow W27

W2.3.3A General Tab W28

W2.3.3B Fill Tab W29

W2.3.3C Graphic Modify Tab W30

W2.3.3D Modify Coordinates Tab W31

W2.3.3E Process Data - Arrow Tab W31

W2.3.3F Data Bind Tab W33

W2.3.4 Process Data - Circle W34

W2.3.4A General Tab W34

W2.3.4B Fill Tab W35

W2.3.4C Graphic Modify Tab W36

W2.3.4D Modify Coordinates Tab W37

W2.3.4E Process Data - Circle Tab W38

W2.3.4F Data Bind Tab W39

W2.3.5 Touch Target W40

W2.3.5A General Tab W40

W2.3.5B Function Tab W41

W2.3.5C Data Bind Tab W42

W2.3.6 Push Button W43

W2.3.6A General Tab W43

W2.3.6B Text Tab W44

W2.3.6C Label Tab W45

W2.3.6D Function Tab W46

W2.3.6E Graphic Modify Tab W47

W2.3.6F Data Bind Tab W48

W2.3.7 Faceplate W49

W2.3.7A General Tab W49

W2.3.7B Faceplate Block Button Tab W50

W2.3.7C Data Bind Tab W51

W2.3.8 Instrument Diagram W52

W2.3.8A General Tab W53

W2.3.8B Instrument Diagram Tab W54

W2.3.8C Data Bind Tab W55

W2.3.9 Window W56

W2.3.9A General Tab W57

W2.3.9B Window Tab W58

W2.3.9C Data Bind Tab W59

W2.3.10 Message W60

W2.3.10A General Tab W61

W2.3.10B Text Tab W62

W2.3.10C Message Tab W63

W2.3.10D Data Bind Tab W64

W2.3.11 Dialog Name W65

W2.3.10A General Tab W66

W2.3.10B Text Tab W67

W2.3.10C Dialog Name Tab W68

W2.3.10D Data Bind Tab W69

YOKOGAWA SINGAPORE TRAINING CENTRE Page 13 of 15

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

TABLE OF CONTENTS

W2.3.12 Trend W70

W2.3.12A General Tab W71

W2.3.12B Trend Tab W72

W2.3.12C Data Bind Tab W73

W2.3.13 Overview W74

W2.3.13A General Tab W75

W2.3.13B Text Tab W76

W2.3.13C Function Tab W78

W2.3.13D Data Bind Tab W79

W2.3.14 Control W80

W2.3.14A General Tab W81

W2.3.14B Control Tab W82

W2.4 Format Toolbar W83

W2.5 Edit Object Toolbar W84

W2.6 Parts Toolbar W85

W2.6.1 Parts W85

W2.6.2 Linked Part W87

W2.7 Background Screen Bitmap and Soft Key W91

W2.7.1 Background Screen Bitmap W91

W2.7.2 Soft Key W91

W2.7.2A Soft Key Tab W91

W2.7.2B Text Tab W93

W2.7.2C Function Tab W94

W3. Graphic Builder Operation Mode W95

W4. File Properties W96

W5. Setting the Options W101

W6.1 Debug Function on the Graphic Builder W103

W6.2 Debug Dialog W104

X. TEST FUNCTION X

X1. Types Of Test X1

X2. Operating EnXironment X3

X3. Test Procedures X6

X4. Function Of Test Function Main Menu Window X7

X5. I/O Disconnect/Connect X7

X5.1 I/O Disconnect Setup Dialog Box: PFCS/SFCS X8

X5.2 I/O Disconnect Setup Dialog Box: LFCS X8

X5.3 I/O Disconnect Setup Dialog Box: KFCS X9

X6. Wiring Function X10

X6.1 Wiring Edit Functions X10

X6.1.1A Types of Wiring X11

X6.1.1B Wiring Definition Items X13

X6.1.1C Automatic Data Wiring Creation X15

X6.1.1D Wiring Data Storage X15

X6.1.1E Wiring Data Downloading X16

X6.2 Wiring Operation Functions X17

X6.2.1A Display Cycle Change X18

X6.2.1B Wiring On/Off X18

X6.2.1C Wiring Execution X18

YOKOGAWA SINGAPORE TRAINING CENTRE Page 14 of 15

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

TABLE OF CONTENTS

X6.2.1D Wiring Continuous Execution X18

X6.2.1E Wiring Stop X18

X6.2.1F Wiring Pause X18

X6.2.1G Suspend X18

X6.2.1H Wiring Change X18

X7. Test Target Station Operation Functions X21

X8. Step Execution Function X21

X9. Breakpoint X22

X9.1 Breakpoint Setting X22

X9.2 Breakpoint Setup X22

X9.3 Breakpoint Operation and Monitoring X24

X9.3.1A Display Cycle Change X24

X9.3.1B Breakpoint Monitoring X25

X10. One-Shot Execution Function X26

X10.1 Function Blocks to which One-Shot Execution X26

may be applied

X10.2 Message One-Shot Output X27

X10.2.1 One-Shot Output Messages X28

X11. Profiler X30

X11.1 CPU Load Display X31

X11.2 All Blocks Completion Times X32

X11.3 Function Blocks Profile Data Display X33

X12. I/O Error Test X35

YOKOGAWA SINGAPORE TRAINING CENTRE Page 15 of 15

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

TABLE OF CONTENTS

YOKOGAWA SINGAPORE TRAINING CENTRE Page 16 of 15

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

A. SYSTEM OVERVIEW

A1. System Components

This chapter describes each of the CENTUM CS 1000/3000 system components.

Human Interface Stations (HIS)

The HIS is mainly used for operation and monitoring – it displays process variables, control

parameters, and alarms necessary for users to quickly grasp the operating status of the plant.

It also incorporates open interfaces so that supervisory computers can access trend data,

messages, and process data.

Hardware Requirements

PC model: A recommended personal computer

Main Memory: Varies according to the software to be installed:

YOKOGAWA SINGAPORE TRAINING CENTRE Page A1 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

Peripherals: CD-ROM drive and 3.5-inch FDD. An MO drive, a DAT drive, or a backup hard

disk should also be made available for the backup of the system, databases, and engineering

data. In order to connect the PC with peripherals, SCSI card may be required to be installed

in the PC.

Software Environment

Operating system:

Windows 2000, Service Pack4 (recommended),

Windows XP, Service Pack1, Service Pack2,

Windows Server 2003 or

Windows 2000 Server, Service Pack4

Color pallet:

Above High color (65536). With at least 8MB of VRAM, 16000000 colors can be specified.

Virtual memory paging size: 300 MB. (Not to use System Builders)

400 MB. (To use System Builders)

Software Compatibility

The CS 3000 software is compatible with the commercial software listed below, with which

the compatibility has been confirmed:

YOKOGAWA SINGAPORE TRAINING CENTRE Page A2 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

Compatibility cannot be guaranteed for any commercial software other than those listed

above.

Revision Numbers of Report Package and Microsoft Excel

When using the report package in the release R3.03 or later, inconsistency with the

Microsoft products service releases may occur.

A1.1 Types of HIS

Two types of HIS:

• Desktop Type

Uses a general purpose PC.

• Console Type

Consists of a console assembly and a general purpose PC. Two types of console

type HISs:

YOKOGAWA SINGAPORE TRAINING CENTRE Page A3 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

YOKOGAWA SINGAPORE TRAINING CENTRE Page A4 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

Engineering PC (ENG)

The PC with engineering functions used to perform CENTUM CS 3000 system generation

and maintenance management.

A1.2 Types of FCS

Field Control Station (FCS)

FCS performs process control, and manages communication with subsystems such as

PLCs. The control station is used to generate the control function where the process

variables are read and control calculation is carried out in the processor cards to

determine the control output to be sent to the field.

• FCS for FIO

This FCS uses the Fieldnetwork I/O (FIO) modules, which are compact and

consist of various lineups such as the connector types and so forth. According to

the application capacity, there are the standard model and the enhanced model.

• Compact FCS for FIO

This is a compact FCS with I/O modules integrated into the Field Control Unit.

• FCS for RIO

This FCS uses the Remote I/O (RIO) modules, which have many installation

bases and M4 screw terminals to connect signal cables. According to the

application capacity, there are the standard model and the enhanced model.

• Compact FCS for RIO

This controller is usually installed near the equipment or process it controls, and

is ideal for communicating with subsystems.

YOKOGAWA SINGAPORE TRAINING CENTRE Page A5 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

Standard FCS (Main Memory 16 MB)

Model Type

AFS10S Field Control Station (19” rack mountable type)

AFS10D Duplexed Field Control Station (19” rack mountable type)

AFS20S Field Control Station (with cabinet)

AFS20D Duplexed Field Control Station (with cabinet)

AFS30S Field Control Station (for FIO, 19” rack mountable type)

AFS30D Duplexed Field Control Station (for FIO, 19” rack

mountable type)

AFS40S Field Control Station (for FIO, with cabinet)

AFS40D Duplexed Field Control Station (for FIO, with cabinet)

Enhanced FCS (Main Memory 32 MB)

Model Type

AFG10S Field Control Station (19” rack mountable type)

AFG10D Duplexed Field Control Station (19” rack mountable type)

AFG20S Field Control Station (with cabinet)

AFG20D Duplexed Field Control Station (with cabinet)

AFG30S Field Control Station (for FIO, 19” rack mountable type)

AFG30D Duplexed Field Control Station (for FIO, 19” rack

mountable type)

AFG40S Field Control Station (for FIO, with cabinet)

AFG40D Duplexed Field Control Station (for FIO, with cabinet)

Compact type FCS (SFCS) – Available in both CS1000 and CS3000 Systems.

A compact type FCS model (SFCS) connects to RIO directly, not via RIO bus.

Compact FCS (PFC : Main Memory 8 MB/16 MB,

AFF 0 : Main Memory 32 MB)

Standard type PFCS in the CS 3000

Model Type

PFCS-H Field Control Station (compact type)

PFCD-H Duplexed Field Control Station (compact type)

AFF50S Field Control Unit (for FIO, 1” Rack Mountable)

AFF50D Duplexed Field Control Unit (for FIO, 19: Rack Mountable)

Standard type PFCS in the CS 1000

Model Type

PFCS-S Field Control Station (standard type)

PFCD-S Duplexed Field Control Station (standard type)

PFCS-E Field Control Station (enhanced type)

PFCD-E Duplexed Field Control Station (enhanced type)

Configuration of a Control System with different types of FCSs:

YOKOGAWA SINGAPORE TRAINING CENTRE Page A6 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

YOKOGAWA SINGAPORE TRAINING CENTRE Page A7 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

YOKOGAWA SINGAPORE TRAINING CENTRE Page A8 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

• Cabinet Type LFCS2/LFCS

YOKOGAWA SINGAPORE TRAINING CENTRE Page A9 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

• Rack Mountable LFCS2/LFCS

YOKOGAWA SINGAPORE TRAINING CENTRE Page A10 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

• Cabinet type KFCS2/KFCS

YOKOGAWA SINGAPORE TRAINING CENTRE Page A11 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

• Rack Mountable KFCS2/KFCS

YOKOGAWA SINGAPORE TRAINING CENTRE Page A12 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

• Compact type FCS (PFCS/SFCS)

YOKOGAWA SINGAPORE TRAINING CENTRE Page A13 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

• Compact type FCS (FFCS)

YOKOGAWA SINGAPORE TRAINING CENTRE Page A14 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

A2. FCS Hardware Description

Power Supply Unit

For the LFCS, the main power distribution board receives a specified power supply and

distributes it to the power distribution boards in the front and two node power distribution

boards in the rear.

Nest power distribution boards distribute the power to the power supply unit(s) of the

FCU and nodes on the front side of the cabinet.

FCU power distribution boards distribute the power to the power supply unit(s) of the FCU.

Node power distribution boards distribute the power to the nodes on the rear side of the

cabinet.

The power unit in an FCU receives power supply from the power distribution

Board, converts it to an isolated direct-current voltage, and supplies that DC power to each

unit and card in the FCU.

The KFCS node power distribution boards are used to distribute the power from the main

power distribution board to node and FCU power distribution board.

This unit supplies power to the common part of the PFCS/SFCS.

A power supply module is connected to a 100 to 120V AC or 220 to 240V AC or 24V

DC main source and supplies insulated +5V and +24V to each installed I/O module through

the back board. The +5V and +24V outputs support dual-redundant insulated output

operation. - FFCS

Battery Unit in FCU

Back-up period: 72 hours maximum

Backs up the memory in the processor card during a power failure.

Battery life Temperature

3 years 30° C or less

1.5 years 40° C or less

9 months 50° C or less

Control Bus Coupler Unit

The coupler is where the Vnet or VLnet cable is installed into the FCS. It performs signal

isolation and signal level conversion.

RIO Bus Distribution Unit (LFCS)

RIO bus distribution units are provided in the front and rear sides of an LFCS with cabinet.

Each RIO bus distribution unit connects up to three nodes to the same RIO bus.

The standard RIO bus distribution unit can be used for either a single or dual RIO Bus.

RIO Bus Interface Card (LFCS)

The RIO bus interface card performs data communication via the RIO bus coupler unit

between multiple nodes connected on the RIO bus.

RIO Bus Coupler Unit (LFCS)

The RIO bus coupler unit couples the RIO bus interface card installed in the FCU to the RIO

bus by modulating and demodulating the signals.

YOKOGAWA SINGAPORE TRAINING CENTRE Page A15 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

ESB Bus Interface Card (KFCS)

The ESB bus interface card (SB301) performs data communication via the SB401 on node

unit for FIO between I/O modules.

ESB Bus Coupler Unit (KFCS)

The ESB bus coupler unit couples the ESB bus interface card installed in the FCU to the ESB

bus by modulating and demodulating the signals.

ESB Bus Coupler Unit (FFCS)

ESB bus coupler module (Model: EC401) is installed in field control unit and used for

communicating with the ESB bus interface module (Model: SB401) of local node.

This module has one ESB bus port. Dual-redundant bus schemes can be configured with the

two modules.

Fan Units

Used to suppress an increase of the temperature inside the cabinet and prevent a

temperature increase from causing malfunctions and faster deterioration of the parts in the

FCU and nodes.

Node Interface Unit

The NIU offers an interface function to send analog and contact I/O signals from the field to

the Field Control Unit via a RIO bus, and it offers the function to supply power to the

input/output units.

Node

Signal processing devices that convert process input/output signals to or from the field

equipment and transmits them to the field control unit (FCU).

Process Input/Output

Used to exchange signals between field devices and FCSs.

An FCS can receive signals from process detectors and output signals to process control

signals to process control elements.

Processor Card in FCU

The processor card performs control calculations as well as monitors its own CPU and power

supply.

External Interface Unit

The external interface unit outputs the result of the self-diagnostics by the processor card to

the contact output terminals on the power distribution board.

YOKOGAWA SINGAPORE TRAINING CENTRE Page A16 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

Dual-Redundant Architecture of FCU: KFCS

• Each processor card unit has two CPUs, which perform the same control

computation. The computation results are compared by a collator during each

computation cycle. If the computation results from the two CPUs match, the collator

determines that the computation is normal and sends data to main memory and bus

interface unit.

• Because the main memory has an ECC (Error-Correcting Code), transient bit

inversion errors occurring in the main memory can be repaired.

• If computation results from CPU1 and CPU2 do not match, the collator decides that

a computation error has occurred, and the control right is transferred to the standby

card.

• The standby processor unit card performs the same computation as the control one,

even though it is in the standby state. Therefore, it can immediately resume the

output of control computation data to the bus interface when it takes over the control

right.

• Self-diagnostics will be executed on the processor unit in which an error has

occurred. If no CPU error is detected as a result of diagnostics, the error will be

taken as a transient computation error, and the unit returns from error state to

standby. The processor unit on standby performs the same computation

concurrently with the control side.

Therefore, CPUs within the same unit collate each other’s computation data, being

sure to detect any computation errors. Because the unit on standby performs the

same control computation concurrently with the control unit, it can take over the

control computation at any point without interruption, even for a very short time.

**NOTE: LFCS same as above except that ESB Bus Interface

(SB301) is replaced by RIO Bus Interface (RB301).

YOKOGAWA SINGAPORE TRAINING CENTRE Page A17 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

Dual-Redundant Architecture of FCU: SFCS

• At the Vnet interface, a communication interface supporting dual-redundancy is

mounted on the CPU and connected to the dual-redundant control bus.

• At the processor unit, control side and standby side CPUs synchronize each other to

perform the same control computation. If an error occurs at the control side CPU,

the synchronous execution hot standby system will transfer the control right to the

standby side CPU without interruption.

• If an invalid access is detected against the main memory or the standby side in the

control side processor unit, processing on the control side will stop immediately and

the control right will be transferred to the standby side. This prevents the destruction

of data inside the local system, as well as at the destination site due to CPU

malfunctions.

• There is a WDT (Watch Dog Timer) in the processor unit to supervise the execution

of control function. Whenever the abnormality in control function is detected, the

control right is switched from control side to the standby side, as if the abnormality is

in the control side processor.

• In the main memory, error-correction coding (ECC) function is provided so that the

transient bit inversion error in the main memory may be repaired.

• The PI/O bus interface has the function to run the PI/O executions on control side

and to diagnostic the PI/O performance by itself. The same diagnostic function is

also running in standby side PI/O bus interface.

When an abnormality occurs in the control side PI/O bus, the control right is

immediately switched to the standby side PI/O, thus the PI/O executions may be

continued.

**NOTE: PFCS same as above except that Vnet Interface is

replaced by VL Net Interface.

YOKOGAWA SINGAPORE TRAINING CENTRE Page A18 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

Dual-Redundant Architecture of FCU: FFCS

• There are two processors on each processor module. Each CPU performs the same

control computations, and the results are compared each calculation. If the results

agree, then the module is assumed to be normal and the results are transmitted to

memory and bus interface module. The main memory uses ECC (error-correcting

code) which can correct transient reversed-bit errors.

• If the results from CPU1 and CPU2 do not agree, then the comparator takes this as

“CPU abnormal”, and switches to the standby processor module.

• A Watch Dog Timer is used to detect if the active processor module is abnormal,

which results in a switch from active to standby processor module.

• The standby processor module is performing the same computations as the active

module, and when it is switched to active status then the results it has just computed

are transferred to the bus interface there is no interruption in control.

• If a “CPU abnormal” error is detected in a CPU module, a self-diagnostic check is

performed on the module; if the hardware is not abnormal, then the error is treated as

a transient error and the module reverts from “abnormal” to “standby” status.

• The V net and V net interface are dual redundant.

YOKOGAWA SINGAPORE TRAINING CENTRE Page A19 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

A3. Network

Network Vnet VL Net

Transmission Speed 10 Mbps (real-time control bus) 10 Mbps (real –time control bus)

Cable Types 10 Base 2 ( for HIS) 10 Base 2 cable ( for stations)

10 Base 5 (for FCS, CGW, etc)

Transmission 185 m/segment (for 10 Base 2) 185 m/segment (for 10 Base 2)

distance 500 m/segment (for 10 Base 5)

Access Method Token Passing Token Passing

Repeater Max. 1.6 km, 8 repeaters Max. 1.6 km, 8 repeaters

- Coaxial Cable Max. 20 km, 4 repeaters Max. 20 km, 4 repeaters

- Optical Fiber

Ethernet

HIS and ENG, HIS and supervisory systems can be connected by an Ethernet LAN;

supervisory computers and personal computers on the Ethernet LAN can access messages

and trend data in the CENTUM CS 3000 system. The Ethernet can also be used for sending

trend data files from the HIS to supervisory computers, for equalizing HIS databases and for

acquiring trend date for other stations, eliminating the load on the V net.

YOKOGAWA SINGAPORE TRAINING CENTRE Page A20 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

Vnet/VLnet versus Ethernet

A system with only a single HIS, with engineering functions installed, does not need Ethernet

but in general Ethernet (and corresponding network engineering) is required.

Also, instead of equalizing HIS databases and acquiring trend date for other stations via the

VL net, these can be performed via Ethernet, reducing the load on the VL net. (Installing

Ethernet requires optional network engineering).

YOKOGAWA SINGAPORE TRAINING CENTRE Page A21 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

A4. System Specifications

System CS 1000 CS 3000 CS 3000 with

Vnet/IP

Maximum number of 8000 100 000 100 000

monitoring tags (When using LHS4000, (When using LHS4000,

up to 1,000,000 per up to 1,000,000 per

system) system)

Total number of stations in - 256 -

multi-domain systems

Total number of 1 16 16 (Vnet/IP domains +

interconnected domains Vnet domains)

Total number of stations per HIS (8) 64 (HIS (16) , FCS, 64 (HIS, FCS, APCS,

domain FCS (16) BCV, CGW) GSGW, Exaopc, PRM ,

Vnet Router)

**Note : No limit on

number of HIS stations

HIS: Human Interface Station

BCV: Bus Converter

CGW: Communication Gateway Unit

FCS: Field Control Station

APCS: Advanced Process Control Station

GSGW: Generic Subsystem Gateway Package

Exaopc: OPC Interface Package

PRM: Field Communications Server for Plant Resource Manager

AVR10D: Vnet Router

● Bus Converter (BCV)

With the CS 1000 system, the bus converter (BCV) connects the station on the VL

net and the µXL control unit on the RL bus.

YOKOGAWA SINGAPORE TRAINING CENTRE Page A22 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

With the CS 3000 system, the BCV connects the station on the V net and station(s)

on other domain(s).

A domain is a logical V net bus segment. You can use a Bus Converter to link

CENTUM CS 3000 domains, or link to previous systems (CENTUM CS, CENTUM-

XL, CENTUM CS 1000, etc).

When you reach the maximum of 64 stations in a domain, you can start a new

domain and link the two domains using a Bus Converter.

Functional Overview - Bus Converter for V net

The Bus Converter for V net is used to connect one domain V net to a CS 3000 system or a

system with CS 3000 and CENTUM CS constructed on other domain V net. It acts as an

intermediary in communication between the two, upper level and lower level, V nets. It

facilitates communication with a hierarchical structure so that all stations connected to the

lower level V net can be put under the integrated supervision of the stations of the upper level

V net. When CS 3000 is connecting to a CENTUM CS system, CS 3000 will be in upper level

and CENTUM CS will be in lower level.

● Communication Gateway Unit (CGW)

The communication gateway unit is a gateway that connects the supervisory

computer with the VL net or V net, which are the control communication networks for

the CS 1000 system and CS 3000 system, respectively.

YOKOGAWA SINGAPORE TRAINING CENTRE Page A23 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

YOKOGAWA SINGAPORE TRAINING CENTRE Page A24 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

A5. Hardware Configuration

Setting the Domain Number: LFCS/KFCS/PFCS/SFCS/FFCS/FFCS-L

A domain stands for a range of stations connected by a single train of the V net.

Set the domain number to a value from 1 to 16.

To set a domain number, set the dip switches as follows.

Bits 2 and 3 must always be zeros (0s).

YOKOGAWA SINGAPORE TRAINING CENTRE Page A25 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

Setting the Station Number: LFCS/KFCS/PFCS/SFCS/FFCS

Set station number specified following range.

• Within the range of 1 to 24 (*1)

• Within the range of 1 to 64 (*2)

To set a station number, set the dip switches as follows.

YOKOGAWA SINGAPORE TRAINING CENTRE Page A26 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

A6. System Components of Vnet/IP Network

The specification when connecting devices in a Vnet/IP domain is as follows:

• Number of Vnet/IP stations connected: Max. 64 units

Vnet/IP stations including V net router

• Other general-purpose Ethernet communication devices

(PCs, routers, switches etc.): Max. 124 units

• Levels of layer 2 switches: Max. 7 levels

The specification of connection between Vnet/IP domains is as follows:

• Multi-level connection of Vnet/IP domains: Max. 15 levels (16 layers)

• Transmission delay between any domains: 250 msec or less

● Vnet/IP Domain

A Vnet/IP domain consists of two independent subnets of bus 1 and bus 2. In the

CENTUM CS 3000, combining Vnet/IP and V net/VL net domains, up to 16 domains can

be set. To each domain, up to 64 Vnet/IP stations and up to 124 other general-purpose

Ethernet communication devices (PCs, routers, etc.) can be connected.

YOKOGAWA SINGAPORE TRAINING CENTRE Page A27 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

● Vnet/IP Station

A Vnet/IP station in a domain is connected to a layer 2 switch in each bus. The following

table shows a list of Vnet/IP stations.

● Human Interface Station (HIS)

An HIS serves as a human interface for operation, monitoring, and engineering. For

connections to the Vnet/IP, a VI701 Control Bus Interface Card is used.

● FFCS-L

The FCS performs process control and manages communications with subsystems such

as PLCs. Two types of field control stations for Vnet/IP and FIO are available:

AFV10S: Field Control Unit (for Vnet/IP, FIO, rackmounted)

AFV10D: Duplexed Field Control Unit (for Vnet/IP, FIO, rack-mounted)

The FFCS-L can connect up to 3 FIO type I/O nodes as standard. In this case, the total

number of nodes is 4 including an FCU. Furthermore, by adding the Application Capacity

Expansion Package, up to 15 I/O nodes can be connected including an FCU.

Only the FFCS-L can be connected to Vnet/IP as a control station.

● Layer 2 Switch

This is a device to connect equipment within the Vnet/IP domain.

● Advanced Process Control Station (APCS)

An APCS advanced process control station implements control functions with a general-

purpose PC connected to a Vnet/IP, aimed at improving advanced control and plant

efficiency. Use VI701 Control Bus Interface Card for connection to Vnet/IP.

● Generic Subsystem Gateway Package (GSGW)

With a general-purpose PC connected to a Vnet/IP, GSGW packages can collect and set

data of various types of subsystems using an OPC DA server. They can easily collect and

set subsystem data without creating dedicated communications programs.

Use VI701 Control Bus Interface Card for connections to Vnet/IP.

YOKOGAWA SINGAPORE TRAINING CENTRE Page A28 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

● V net Router

The V net router is the hardware dedicated to connect a Vnet/IP domain and a V net/ VL

net domain. It can also connect the V net domain of the CENTUM CS. It performs the

frame conversion and filtering between Vnet/IP and V net/VL net.

A Vnet router is a device to connect a Vnet/IP domain and a Vnet domain for relaying

control communications. This router realizes operation and monitoring of a control station

in one domain from another domain by connecting the Vnet/IP and Vnet domains. The

following product is available:

AVR10D: Duplexed Vnet Router (for redundant use of communications and power supply

modules)

● Layer 3 Switch

A general-purpose layer 3 switch is used to connect between Vnet/IP domains in each

bus.

● Router

A router with Security function to ensure the security of a Vnet/IP network is used to

connect the bus 2 side with an external network such as Intranet.

YOKOGAWA SINGAPORE TRAINING CENTRE Page A29 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

A7. Field Control Station (Vnet/IP)

The FFCS-L is a control station that can only be connected to Vnet/IP. The types of function

blocks and I/O cards that can be connected are the same as those of the FFCS.

The FFCS-L is available in the following station types:

• AFV10S Field Control Unit (for Vnet/IP, for FIO, 19-inch rack mountable)

• AFV10D Duplexed Field Control Unit (for Vnet/IP, for FIO, 19-inch rack mountable)

Next, specify the database type. The following database types are available:

• General-purpose type

• Expanded type (To use an expanded type database, the following package is

required: LFS1530 Application Capacity Expansion Package (for AFV10 )

When a new FFCS-L is created, the control bus type of that domain will automatically

be Vnet/IP.

YOKOGAWA SINGAPORE TRAINING CENTRE Page A30 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

A7.1 FFCS-L Hardware Description

Power Supply Module

A power supply module is connected to a 100 to 120V AC or 220 to 240V AC or 24V

DC main source and supplies isolated +5V and +24V to installed I/O modules through the

back board. The +5V and +24V outputs support dual-redundant isolated output operation.

Battery Pack

Back-up period: 72 hours maximum

The battery unit is used for backing up the main memory of the processor module when

power failure occurs.

Battery life Temperature

3 years 30° C or less

1.5 years 40° C or less

9 months 50° C or less

Processor Module

Control algorithm calculations are performed in the processor module.

The processor module has diagnostic capability, when the CPU or power supply

encounters abnormalities, a signal can be output through external interface unit.

ESB Bus Coupler Module (EC401)

ESB bus coupler module (Model: EC401) is installed in field control unit and used for

communicating with the ESB bus interface module (Model: SB401) of local node.

This module has one ESB bus port. Dual-redundant bus schemes can be configured with

the two modules.

External Interface Unit

The external interface unit has terminals for connecting the specified power supply, and

distributes the power through the output connectors.

YOKOGAWA SINGAPORE TRAINING CENTRE Page A31 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

A8. Transmission Path Specification (Vnet/IP)

Network Topology: Star formation

Transmission Path Redundancy: Available (control bus communications only)

Transmission Cable: Unshielded twisted pair (UTP) at enhanced category 5 or greater.

YOKOGAWA SINGAPORE TRAINING CENTRE Page A32 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

A9. Questions

Q1. Which station does the necessary calculation and processes the input/output

electrical signal from the field?

Q2. Which station is used for monitoring and operation of the field tags and

Instrument, displaying the necessary process variable, output variable?

Q3. What is the network cable for signal transmission between FCS and HIS for CS3000

and CS1000?

Q4. What software platform is CS 1000 and CS 3000 installed in the HIS and ENG?

Q5. What will happen to the FCS memory when there is power failure to the FCS?

Q6. What is a node in LFCS?

Q7. What is the maximum of HIS stations in a CS 1000/CS 3000?

Q8. What is the difference between an ENG and a HIS?

A10. Exercises

1. Configure the following FCS dip switches for station FCS0305.

YOKOGAWA SINGAPORE TRAINING CENTRE Page A33 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

A. SYSTEM OVERVIEW

YOKOGAWA SINGAPORE TRAINING CENTRE Page A34 of A33

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

B. ENGINEERING ENVIRONMENT

B. ENGINEERING ENVIRONMENT

The CENTUM CS 1000/CS 3000 engineering functions are used for system generation – for

creating the databases necessary for monitoring, operation and control – and for

maintenance.

The Test Functions allow combinations of monitoring/operation and control functions to be

tested before being put into operation. There are two types of test functions:

. Virtual tests

. Target tests

Test Function Virtual test

Target test I/O disconnection (Use virtual I/O)

Use real I/O

B1. Test Function

B1.1 Virtual test

Virtual test uses an FCS simulator instead of an actual FCS. The FCS simulator simulates

the functions and operation of the FCS and runs under an HIS.

It uses FCS simulation (virtual FCS) to test the system configuration on a single Personal

Computer. You can operate several virtual FCS at the same time.

YOKOGAWA SINGAPORE TRAINING CENTRE Page B1 of B5

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

B. ENGINEERING ENVIRONMENT

B1.2 Target test

Target test uses an actual FCS. When there are no I/O modules and I/O test devices, an

FCS input and output can be simulated by using the I/O Disconnect and Wiring Functions.

These use actual HIS and FCS for the test. Actual field wiring is not required, or – if it

exists

– you can specify that it be ignored (I/O switching).

YOKOGAWA SINGAPORE TRAINING CENTRE Page B2 of B5

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

B. ENGINEERING ENVIRONMENT

B2. Concurrent Engineering

Using Windows NT File sharing, several people can share an Engineering database on a

network; concurrent engineering is possible.

YOKOGAWA SINGAPORE TRAINING CENTRE Page B3 of B5

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

B. ENGINEERING ENVIRONMENT

B3. Engineering Work Flow

The engineering work flow for this course is as shown:

Start

Start System View

Step 1: Project Creation

. Create necessary folders for target system.

Step 2: Defining Project Common Items

. Define security function.

. Define operation marks.

Step 3: Defining FCS Control Functions

. Define FCS station configuration.

. Define Process I/O modules.

. Define Software I/O.

. Define Messages.

. Define Regulatory Control Functions.

. Define Sequence Control Functions.

Step 4: Defining HIS Functions

. Define HIS station configuration.

. Define HIS constants.

. Define Function Keys assignment.

. Define Scheduler Function.

. Define Trend Recording Functions.

. Define Sequence Message.

. Define User-defined windows.

. Define Help Dialog.

Step 5: Conducting Test Function

. Run a Virtual Test Function.

YOKOGAWA SINGAPORE TRAINING CENTRE Page B4 of B5

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

B. ENGINEERING ENVIRONMENT

B4. Questions

Q1. What is the difference between a virtual test and target test?

Q2. How is concurrent engineering done?

YOKOGAWA SINGAPORE TRAINING CENTRE Page B5 of B5

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

B. ENGINEERING ENVIRONMENT

YOKOGAWA SINGAPORE TRAINING CENTRE Page B6 of B5

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

C. PROJECT CREATION

C. PROJECT CREATION

Create a project, which is the basic unit of the engineering database management.

A project is a unit manages the database of the FCS and the HIS created by the user. All

builder files defined by various builders are managed under the project.

C1. Types of Project

There are three types of project; the default project, the current project and the user-defined

project.

The project attribute (default, current, and user-defined) may be changed using the Project

Attribute Change Utility.

. Default Project

The project created the first time when the System View starts is referred to as the default

project.

The characteristics of the default project are as follows:

. This project is downloadable to the FCS.

. The virtual test with the FCS simulator can be performed for this project.

. This project is downloadable to the HIS.

. This project is downloadable off-line to the FCS of the target system.

. Current Project

When any one of the FCS’s created in a default project is successfully downloaded, the

attribute of the project changes from the default project to a current project.

Online engineering becomes enabled.

The current project can perform the target test using the Test Function.

The characteristics of the current project are as follows:

. Multiple current projects cannot be created.

. The target test can be performed for this project.

. This project is downloadable to the HIS.

. This project is downloadable to the FCS of the target system.

. User-Defined Project

A project copied either from the default project or from the current project is referred to as

a user-defined project.

This project cannot be loaded to the HIS. This project is used when engineering using

virtual tests or making a backup copy of the current project.

The characteristics of the user-defined project are as follows:

. Multiple user-defined projects can be created in System View.

. The virtual test with the FCS simulator can be performed for this project.

. This project is not downloadable to the FCS or HIS of the target system.

YOKOGAWA SINGAPORE TRAINING CENTRE Page C1 of C14

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

C. PROJECT CREATION

C2. Creating a Default Project

A project is created when System View is executed for the first time after the builders are

installed. The project created has the attribute of “the default project” at this stage. Once this

project is downloaded to the FCS of the target system, the project’s attribute is changed from

“the default project” to the current project.

1. Start System View

Start

Programs

YOKOGAWA CENTUM

System View

2. Start Default Project Creation

When the System View could not identify an existing current or default project, it will

prompt the user to create a default project with the dialog box as shown below. Click

[YES] to create the default project.

3. Project Outline

YOKOGAWA SINGAPORE TRAINING CENTRE Page C2 of C14

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

C. PROJECT CREATION

The project information area allows the project creator to enter arbitrary characters.

Enter information on the process and the person in charge of DCS to manage the

project.

4. Project Property

Project name is an alphanumeric character string less than 8 characters.

The comment within 32 alphanumeric characters or 16 double-byte characters may

be entered as the project description.

Moreover, an alias can be created for a project. An alias of project can be defined

with 8 alphanumeric characters.

The project position is the project folder’s location in the hard disk. The default

location in which to store the project is shown below. If more than one hard disk

exists, the storage drive may be specified accordingly such as D:\.

Default location in CS 3000: C:\CS3000\ENG\BkProject\

5. Creating an FCS folder

A folder for the first FCS database files is created when the default project is created.

YOKOGAWA SINGAPORE TRAINING CENTRE Page C3 of C14

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

C. PROJECT CREATION

Assign the correct station type and station address as they cannot be modified upon

confirmation. Additional FCS can be created in future for more FCSs.

6. Creating a HIS folder

A folder for the first HIS database files is created when the default project is created.

YOKOGAWA SINGAPORE TRAINING CENTRE Page C4 of C14

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

C. PROJECT CREATION

Assign the correct station type and station address as they cannot be modified upon

confirmation. Additional HIS can be created in furture for more HISs.

7. Project folders

The project consists of 3 basic folders – Common, FCS and HIS.

Additional FCS, HIS or other stations can be created under the pull down menu.

Select project

Right click on project

Create New

HIS or FCS

YOKOGAWA SINGAPORE TRAINING CENTRE Page C5 of C14

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

C. PROJECT CREATION

C3. Project Attribute Utility

The Project’s Attribution Utility is an engineering tool that makes it convenient to register a

project created from other PC, to change a project’s properties or to remove the registration of

a project.

Before using the Project Attribute Change Utility, check that System View is not running. If it

is running, the Project Attribute Change Utility cannot run.

Only one project can exist as the default project or current project in System

View.

C3.1 Start Project Attribute Utility

Start Project’s Attribution Utility

Start

Programs

YOKOGAWA CENTUM

Project’s Attribution Utility

YOKOGAWA SINGAPORE TRAINING CENTRE Page C6 of C14

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

C. PROJECT CREATION

Click

Click

YOKOGAWA SINGAPORE TRAINING CENTRE Page C7 of C14

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

C. PROJECT CREATION

C3.2 Registering a Project

To register a new project in the System View, select [Register] in the Project’s Attribution

Utility.

Click

YOKOGAWA SINGAPORE TRAINING CENTRE Page C8 of C14

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

C. PROJECT CREATION

C3.3 Changing the Attribute of a Project

To change the attribute of a project, select [Change] in the Project’s Attribution Utility.

Click

C3.4 Deleting a Project

YOKOGAWA SINGAPORE TRAINING CENTRE Page C9 of C14

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

C. PROJECT CREATION

To delete a project, select [Delete] in the Project’s Attribution Utility.

Click

YOKOGAWA SINGAPORE TRAINING CENTRE Page C10 of C14

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

C. PROJECT CREATION

C4. Questions

1. Describe the major difference between

. Default Project

. Current Project

. User-defined Project

YOKOGAWA SINGAPORE TRAINING CENTRE Page C11 of C14

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

C. PROJECT CREATION

C5. Exercise

1. Create a project name [TESTPJT] with the following folders:

. FCS0101 (AFS40D /AFV10D)

. HIS0164 [Based on the installed Vnet/ Vnet/IP card (VF701/VI701)

configuration.]

2. Change the project [TESTPJT] attribute to Current.

3. Change the project [TESTPJT] attribute back to User-defined.

4. Delete the project [TESTPJT] without deleting it from the hard disk.

5. Restore the project [TESTPJT] back to System View window.

6. Remove the project [TESTPJT] from the hard disk in the System View window.

7. Before proceeding to the next chapter, do the following:

. Change project [TRAIN3] back as Default project.

. Delete any other projects from the System View window.

8. Start a Virtual Test Function of Project TRAIN3/VNETIP based on the following steps:

Click Start

Programs

YOKOGAWA CENTUM

System View

In System View, select FCS0101 from TRAIN3 / VNETIP.

From the pull-down menu, choose Test Function.

Select the HIS station for emulation.

YOKOGAWA SINGAPORE TRAINING CENTRE Page C12 of C14

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

C. PROJECT CREATION

At this stage, the FCS simulation will start based on the chosen FCS and HIS station.

The FCS simulation box called Test Function will appear. Minimise the box without

closing it.

Minimise the System View window and the Virtual Test Function HIS monitoring and

operation window is ready to be used for testing.

YOKOGAWA SINGAPORE TRAINING CENTRE Page C13 of C14

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

C. PROJECT CREATION

YOKOGAWA SINGAPORE TRAINING CENTRE Page C14 of C14

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

D. PROJECT COMMON ITEMS

D. PROJECT COMMON ITEMS

The items to be commonly used in the project are defined. If the [COMMON] folder under the

project folder is selected in System View, a listing of builder/ viewer file names will be

displayed in List View. Each of the builders/viewers can be started by double-clicking the

builder/viewer file name.

In this chapter, the definitions of the following common items are explained:

• Alarm Builders

- Alarm Priority Builder

- Alarm Processing Table Builder

- System-fixed Status Character String Viewer

- User Defined Status Character String Builder

• Plant Hierarchy Builder

• Engineering Unit Symbol Builder

• Switch Position Label Builder

• Multiple Projects Connection Function Builder

• Operation Mark Builder

• Station Configuration Viewer

• Status Change Command Character String Builder

• Security Builder

D1. Alarm Builder

Upon occurrence of the alarm, the color of the tag mark for the function block corresponding

to the alarm changes to the alarm color. The alarm status is displayed in a character string,

and the alarm is processed in a predetermined manner.

The alarm status character string can be either a system-fixed character string or a

user defined character string.

Designating the Alarm Status

To engineer the alarm status, designate the following:

1. Alarm status character string (alarm name) or System-fixed Status Character String Viewer

Designate the alarm status character string in the User-Defined Status Character String

Builder.

The alarm status character strings available for each function block are in the system-fixed

character string viewer.

2. Alarm priority

Designate alarm priorities one by one in the Alarm Priority Builder. Multiple alarm priorities at

the same level cannot be designated for each function block simultaneously

3. Alarm processing table

Designate the alarm processing table in the Alarm Processing Table Builder.

4. Alarm processing level for each function block

Designate the alarm processing level in the Function Block Overview Builder, the

Function Block Detail Builder, the Control Drawing Builder, the Annunciator Builder, and the

Tag List Builder.

YOKOGAWA SINGAPORE TRAINING CENTRE Page D1 of D36

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

D. PROJECT COMMON ITEMS

YOKOGAWA SINGAPORE TRAINING CENTRE Page D2 of D36

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

D. PROJECT COMMON ITEMS

D1.1 System-Fixed Alarm Status Character String

The alarm status character strings that are output upon occurrence of the alarm are

available for each type of function block. The character string can be confirmed with the

system fixed status character string viewer.

The table below shows the alarm status character strings available for each function

block:

YOKOGAWA SINGAPORE TRAINING CENTRE Page D3 of D36

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

D. PROJECT COMMON ITEMS

D1.2 User-Defined Alarm Status Character String

USER9 (Faceplate Block), USER10 (SFC Block), USER11 to 16 (Unit Instrument)

There are eight tables (USER9 to USER16) for alarm status character strings that the

user can designate in the User-Defined Status Character String Builder for user-defined

blocks.

The function blocks that can use the alarm status character strings designated here are

faceplate blocks, SFC blocks, and unit instruments. There is a table reserved for each of

these function blocks, used for designating the alarm status character strings. The figure

below shows the relationship between the alarm status character string and the bit

position (default) for each function block:

YOKOGAWA SINGAPORE TRAINING CENTRE Page D4 of D36

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

D. PROJECT COMMON ITEMS

D1.3 Alarm Processing

The user can designate the alarm display color and priority to process each alarm of

function blocks in the Alarm Processing Table Builder.

The alarm status conforms to the designation performed in the Alarm Processing Table

Builder and the User-Defined Status Character String Builder.

The alarm status bit positions in the Alarm Processing Table Builder correspond to the

character string Nos. in the User-Defined Status Character String Builder.

Alarm status bit positions 1 to 6 are not displayed in a window because they are system

fixed.

Alarm processing levels Nos. 1 to 4 are also system-fixed.

The user can designate the color and the priority for alarm processing level Nos. 5 to 16

for alarm status bit positions 7 to 32. The user can change alarm status bit positions 7

and 8 that are for existing control stations.

YOKOGAWA SINGAPORE TRAINING CENTRE Page D5 of D36

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

D. PROJECT COMMON ITEMS

D1.4 Alarm Priority

The alarm processing level is defined for each function block. The output operation for

each alarm priority can be selected.

The HIS performs alarm output action according to the alarm processing level.

The Operation and Monitoring executes the following alarm processing according to the

alarm priority:

¾ Display in a window (CRT)

Designate in the Alarm Priority Builder, whether or not the status change is to be

displayed in a window upon occurrence of the alarm or upon recovery of the system.

YOKOGAWA SINGAPORE TRAINING CENTRE Page D6 of D36

CKEG_R3_Vnet/IP_TB Ed. 3 September 2007

D. PROJECT COMMON ITEMS

¾ Printout to a Printer (PRT)

Designate in the Alarm Priority Builder, whether or not the status change is to be printed

out to a printer upon occurrence of the alarm or upon recovery of the system.

¾ Log to a File (Historical File)

Designate in the Alarm Priority Builder, whether or not the status change is to be logged

in a historical message save file upon occurrence of the alarm or upon recovery of the

system.

A message logged in a historical message save file can be displayed in a Historical

Message Report window.

¾ Alarm Action

The alarm output actions by the HIS include messages output on the window screen and

the LED flashing.

Basically, the alarm flashing action starts upon receiving a message that indicates

occurrence of an alarm. The action stops upon receiving a message that indicates

returning to a normal status, or when acknowledgment operation is performed by the

operator.

The alarm actions are classified into the following types based on the flashing actions that

correspond to alarm occurrence, returning to a normal status and acknowledgment

operation: