Professional Documents

Culture Documents

570 Inspección de Pipas

Uploaded by

jorge gbCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

570 Inspección de Pipas

Uploaded by

jorge gbCopyright:

Available Formats

570 inspección de pipas

API Publication 510, Pressure Vessel Inspection Code: Maintenance Inspection, Rating, Repair,

and Alteration

API Recommended Practice 571, Damage Mechanisms Affecting Fixed Equipment in the

Refining Industry

API Recommended Practice 574, Inspection Practices for Piping System Components

API Recommended Practice 576, Inspection of Pressure-relieving Devices

API Recommended Practice 577, Welding Inspection and Metallurgy

API Recommended Practice 578, Material Verification Program for New and Existing Piping

Systems

API Standard 579-1/ASME FFS-1, Fitness-for-service

API Recommended Practice 580, Risk-based Inspection

API Recommended Practice 581, Risk-based Inspection Technology

API Standard 598, Valve Inspection and Testing

API Recommended Practice 651, Cathodic Protection of Aboveground Petroleum StorageTanks

API Recommended Practice 750, Management of Process Hazards

API Publication 2201, Safe Hot Tapping Practices in the Petroleum and Petrochemical

Industries

ASME B16.34 1, Valves—Flanged, Threaded, and Welding End

ASME B31.3, Process Piping

ASME B31G, Manual for Determining the Remaining Strength of Corroded Pipelines

ASME B31, Code Case 179/181

ASME Boiler and Pressure Vessel Code (BPVC), Section V, Nondestructive Examination

ASME BPVC, Section VIII, Divisions 1 and 2

ASME BPVC, Section IX, Welding and Brazing Qualifications

ASME PCC-1, Guidelines for Pressure Boundary Bolted Flange Joint Assembly

ASME PCC-2, Repair of Pressure Equipment and Piping

ASNT SNT-TC-1 2, A Personnel Qualification and Certification in Nondestructive Testing

ASNT CP-189, Standard for Qualification and Certification of Nondestructive Testing Personnel

ASTM G57 3, Method for Field Measurement of Soil Resistivity Using the Wenner Four-

Electrode Method

MTI 129 4, A Practical Guide to Field Inspection of FRP Equipment and Piping

NACE RP 0169 5, Control of External Corrosion on Underground or Submerged Metallic Piping

Systems

NACE RP 0170, Protection of Austenitic Stainless Steels and Other Austenitic Alloys from

Polythionic Acid Stress Corrosion Cracking During Shutdown of Refinery Equipment

NACE RP 0274, High-voltage Electrical Inspection of Pipeline Coatings Prior to Installation

NACE RP 0275, Application of Organic Coatings to the External Surface of Steel Pipe for

Underground Service

NACE Pub 34101, Refinery Injection and Process Mixing Points

NFPA 704 6, Standard System for the Identification of the Hazards of Materials for Emergency

Response

ASME B31.3

A shortened form of ASME B31.3, Process Piping, published by the American Society of

Mechanical Engineers

fitting

Piping component usually associated with a change in direction or diameter.

6 Interval/Frequency and Extent of Inspection

all piping systems and pressure-relieving devices shall be inspected at the intervals/

frequencies provided in this section.

Scheduled inspections shall be conducted on or before their due date or be

considered overdue for inspection

6.2 Inspection During Installation and Service Changes

6.2.1 Instalacion de pipas

Verificar que la instalacion como estructura , juntas , conexiones de la instalacion de la

pipa sea la correcta y apropiada. Deberá de ser segura y limpia para operación.

La inspeccion deberá ser documentada con sus mediciones de espesores nominal y

minimas . lo cual servirá para hacer un calculo de corrosión después.

6.2.2. servicio de cambios de pipas

Al ser realizado el cambio de pipas, La nueva instalación deberá ser inspeccionada antes de

usarse , establecidno asi nuevos intervalos de inspección para las condiciones nuevas del

servicio.

6.3 Piping Inspection Planning

6.3.1 General

La frecuencia de la inspección es con respecto al grado de degradación que tenga el circuito de

pipas ya sea por debajo o encima del suelo.

Tipos de degradación en tabla 1 de api 571.

6.3.2 RBI for Inspection Planning

Una evaluacion rbi debera ser utilizada para aumentar o disminuir los limites de inspección

descritas en la table 2. Si el grado de inspección aumenta o disminuye vea la tble 3.

Esta evaluación rbi deberá ser revisada y aprobada por un eg en pipa o un authorized piping

inspector.

6.3.3 Inspection Intervals

Si no se usa rbi , se le da inspección a la pipa y mantenimiento usando los siguientes criterios

a- Rango de corrosión, y cálculos de vida remanente

b- Clasificación de pipas en servicio

c- Requerimientos de jurisdicción

d- Juicio del inspecor, especialistas en pipa o materiales . inspecciones previas, actuales.

6.3.4 Piping Service Classes

6.3.4.1 General

Clasificacion de pipas debido a posibles peligros poteniales

6.3.4.2 Class 1

Acidos,quimicos, etc. un problema en estos es de mucho cuidado.

6.3.4.3 Class 2

Hirogeno,hidrocarburos

Gasolina, gas natural, acidos fuertes

6.3.4.4 Class 3

You might also like

- MSDS (Ar 16)Document3 pagesMSDS (Ar 16)Irfan Ali100% (1)

- Study Sheets Based On API 653 Exam InformationDocument7 pagesStudy Sheets Based On API 653 Exam InformationDevin Hardy100% (1)

- PCC Plant Inspection: Basil MirandaDocument31 pagesPCC Plant Inspection: Basil MirandaHector Alberto Garcia Lopez100% (1)

- API 653 Exam Study Sheet QuestionsDocument0 pagesAPI 653 Exam Study Sheet QuestionsYasser Abd El Fattah100% (1)

- Asphalt Core BrochureDocument6 pagesAsphalt Core BrochurenderinozNo ratings yet

- NYC Building Rules & Regulations GuideDocument166 pagesNYC Building Rules & Regulations Guidelandmark58No ratings yet

- Osha 29 CFR 1910.134Document50 pagesOsha 29 CFR 1910.134Ellis HowardNo ratings yet

- API 571 Damage Mechanism Affecting Fixed Refining EquipmentsDocument4 pagesAPI 571 Damage Mechanism Affecting Fixed Refining EquipmentsKmt_AeNo ratings yet

- Rbi Q&a 5Document6 pagesRbi Q&a 5eslam_el_dinNo ratings yet

- ASME Sec VIII d1 Ma App 8Document2 pagesASME Sec VIII d1 Ma App 8fuihiufhNo ratings yet

- Quality Lifting Equipment Inspection StandardsDocument21 pagesQuality Lifting Equipment Inspection StandardsikponmwonsaNo ratings yet

- Oregon OSHA's Excavation Safety PresentationDocument46 pagesOregon OSHA's Excavation Safety PresentationgzapasNo ratings yet

- Trico Bond EpDocument2 pagesTrico Bond EpBrandon TrocNo ratings yet

- Prepared By: Engr. B. A. Benito/Rubbie Gay de ClaroDocument83 pagesPrepared By: Engr. B. A. Benito/Rubbie Gay de ClaroChristine SeletariaNo ratings yet

- Part Number: - Part Title: - Subpart: - Subpart Title: - Standard Number: - TitleDocument1 pagePart Number: - Part Title: - Subpart: - Subpart Title: - Standard Number: - TitleDuy HaNo ratings yet

- Welding Symbol Modul 1Document52 pagesWelding Symbol Modul 1bheghe100% (1)

- Assessment 1 API 570Document5 pagesAssessment 1 API 570Mohamed ZainNo ratings yet

- PDF Api 570 Awareness Coursepdf DDDocument23 pagesPDF Api 570 Awareness Coursepdf DDkareemNo ratings yet

- The Imo Performance Standard For ProtectDocument34 pagesThe Imo Performance Standard For ProtectBranko Brezec100% (1)

- Sigma C200a Coaltar Epoxy BaseDocument1 pageSigma C200a Coaltar Epoxy BaseBilal Ghazanfar100% (1)

- B-GAS-GRADE - 2-Theory GoodDocument34 pagesB-GAS-GRADE - 2-Theory GoodCERTS100% (1)

- BLADDER TANK PROPORTIONING SYSTEMDocument12 pagesBLADDER TANK PROPORTIONING SYSTEMakshay MahajanNo ratings yet

- 3m & Fischer Firestop Material For Curtain Wall JointsDocument110 pages3m & Fischer Firestop Material For Curtain Wall JointsRenjith RaveendranNo ratings yet

- Vacuum Box Test Procedure: PurposeDocument4 pagesVacuum Box Test Procedure: Purposesaravan1891No ratings yet

- 750 Joule Charpy Impact Testing MachineDocument1 page750 Joule Charpy Impact Testing MachineSyed AbudhakirNo ratings yet

- 1113 Maintenance of PRVDocument63 pages1113 Maintenance of PRVhardito sussatrioNo ratings yet

- Flange & Bolting Info ASME B16 - 5 & BS1560 Flanges - 2Document1 pageFlange & Bolting Info ASME B16 - 5 & BS1560 Flanges - 2Caleb IsukuruNo ratings yet

- OLD BGAS Grade-1 - Revision Questions - 2007Document11 pagesOLD BGAS Grade-1 - Revision Questions - 2007Alex joseph alexNo ratings yet

- Excavations QuizDocument12 pagesExcavations QuizMax McguireNo ratings yet

- Installation and Operating Manual FMTB 5000 Test Bench: 0.5 - 5000 m3 / HDocument36 pagesInstallation and Operating Manual FMTB 5000 Test Bench: 0.5 - 5000 m3 / HDaniel Oscar100% (1)

- Thies - Safety Valves 356 - 357Document4 pagesThies - Safety Valves 356 - 357Piero Graffigna Pruzzo100% (2)

- Compressed Gas Safety HSE Presentation HSE FormatsDocument45 pagesCompressed Gas Safety HSE Presentation HSE FormatsasepNo ratings yet

- Ansi 107 VS 207 (2009)Document13 pagesAnsi 107 VS 207 (2009)RobVajko100% (1)

- Mercer Valve 9500 Series Pilot Operated Relief Valve Sizing ProgramDocument6 pagesMercer Valve 9500 Series Pilot Operated Relief Valve Sizing Programdilema_pgNo ratings yet

- Sample Questions For API 570 EDocument14 pagesSample Questions For API 570 Eمبشر أحمدNo ratings yet

- API 653 Certification Data Sheets DimensionsDocument12 pagesAPI 653 Certification Data Sheets DimensionsBrian CaseNo ratings yet

- Osha 1910.178 Industrial Trucks RegulationsDocument49 pagesOsha 1910.178 Industrial Trucks RegulationsAngel Noriega CanoNo ratings yet

- Advanced Leak Testing MethodsDocument6 pagesAdvanced Leak Testing MethodsRanendraNo ratings yet

- Flanged Basket Strainers IOMDocument4 pagesFlanged Basket Strainers IOMSteve NewmanNo ratings yet

- Astm-E1209 - 99Document6 pagesAstm-E1209 - 99DESTINY SIMONNo ratings yet

- Instruction Manual KED150Document36 pagesInstruction Manual KED150Muhammad Asyraf100% (1)

- WIWA Airless Spray GunsDocument52 pagesWIWA Airless Spray Gunsosvaldo lopezNo ratings yet

- ABRASIVE BLASTING SM PRESENTATION 2017.ppsxDocument18 pagesABRASIVE BLASTING SM PRESENTATION 2017.ppsxIsaac SamuelNo ratings yet

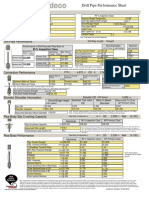

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 pagesDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNo ratings yet

- Detection and Evaluation of Discontinuities by Contact Pulse-Echo Straight-Beam Ultrasonic MethodsDocument7 pagesDetection and Evaluation of Discontinuities by Contact Pulse-Echo Straight-Beam Ultrasonic MethodsEric GozzerNo ratings yet

- Saep 1102Document6 pagesSaep 1102Francis ReyesNo ratings yet

- An Overview of Pipeline Leak Detection TechnologiesDocument9 pagesAn Overview of Pipeline Leak Detection TechnologiesharmlesdragonNo ratings yet

- 4505 DiaphragmValves RWDocument49 pages4505 DiaphragmValves RWdbmingoNo ratings yet

- API 653 PREPARATION/ REPONSES N°06 close bookDocument3 pagesAPI 653 PREPARATION/ REPONSES N°06 close bookkorichiNo ratings yet

- Special Inspections and Tests: @seismicisolationDocument3 pagesSpecial Inspections and Tests: @seismicisolationpriya giriNo ratings yet

- Article - Heat Treatment of Landing GearDocument4 pagesArticle - Heat Treatment of Landing GearLuis Gustavo PachecoNo ratings yet

- Api 577Document1 pageApi 577HIIOJGFNo ratings yet

- 40-Hr SSM Student Manual DD 10-20-21 Full With AppendixDocument171 pages40-Hr SSM Student Manual DD 10-20-21 Full With AppendixHamonaesdrasNo ratings yet

- S1202 Confined Space Plan TemplateDocument22 pagesS1202 Confined Space Plan TemplateMonirul Islam Badal100% (1)

- Hydrogen Sulfide ProtocolDocument32 pagesHydrogen Sulfide Protocolmashangh100% (1)

- Program New Glidermatic GRD HandsetDocument1 pageProgram New Glidermatic GRD HandsetJames100% (1)

- 26-2-2018 Closed and Open Book Exam: 1-Included Fluid ServicesDocument22 pages26-2-2018 Closed and Open Book Exam: 1-Included Fluid ServicesAshish Patel100% (5)

- Piping InspectionDocument6 pagesPiping InspectionFs100% (1)

- Api 510 2017Document1 pageApi 510 2017Santiago Cordova Alva0% (2)

- API 570 Piping Inspection Code GuideDocument57 pagesAPI 570 Piping Inspection Code GuideSakthi Pk100% (3)

- Futuro Continuo Afirmativo y NegativoDocument4 pagesFuturo Continuo Afirmativo y NegativoSkoNo ratings yet

- CH 3 Gas Refrigeration CycleDocument20 pagesCH 3 Gas Refrigeration CycleMeleseNo ratings yet

- 10 MW Unit 214.00 709 55.83 1972Document1 page10 MW Unit 214.00 709 55.83 1972Gangadhara P.K.No ratings yet

- MANUAL Vdocuments - Site FG Wilson P88e1Document287 pagesMANUAL Vdocuments - Site FG Wilson P88e1eletronica55100% (2)

- New Tutorial 2 Solution On ThermodynamicsDocument7 pagesNew Tutorial 2 Solution On ThermodynamicsNaveed AhmadNo ratings yet

- R6.3 TR-XXL Parameter Settings ReleaseDocument493 pagesR6.3 TR-XXL Parameter Settings Releasemishu35No ratings yet

- Chapter 2 Structure of AtomsDocument16 pagesChapter 2 Structure of AtomsCherry T CYNo ratings yet

- Microcontroller-Based Power Monitoring for COE RoomsDocument8 pagesMicrocontroller-Based Power Monitoring for COE Roomskenneth_molenilla1475No ratings yet

- MeasurementDocument4 pagesMeasurementJemason100% (1)

- Esite Bauer Poseidon Edition VE 300 850 Hengitysilmakompressori enDocument4 pagesEsite Bauer Poseidon Edition VE 300 850 Hengitysilmakompressori enrolandoNo ratings yet

- Checklist Water Audit v1Document19 pagesChecklist Water Audit v1hammad.phistreamNo ratings yet

- Bomba Electrica 1500gpm 300HP (Medidas)Document1 pageBomba Electrica 1500gpm 300HP (Medidas)Fire ChileNo ratings yet

- B23 B24 User Manual PDFDocument168 pagesB23 B24 User Manual PDFAurel BodenmannNo ratings yet

- FMC Smith Meter 01 - Mesurement Product & SystemDocument70 pagesFMC Smith Meter 01 - Mesurement Product & SystemDucVikingNo ratings yet

- DBB ValveDocument6 pagesDBB ValveshyamNo ratings yet

- JIMMA UNIVERSITY INTERNS' MANUFACTURING EXPERIENCEDocument41 pagesJIMMA UNIVERSITY INTERNS' MANUFACTURING EXPERIENCEAmanuelNo ratings yet

- Thermal Shock Resistant Neoceram Glass-CeramicDocument2 pagesThermal Shock Resistant Neoceram Glass-CeramicAmândio PintoNo ratings yet

- TriPac EVOLUTION 55711-19-OPDocument52 pagesTriPac EVOLUTION 55711-19-OPRodrigo Hernandez100% (1)

- SGP Chapter-1Document81 pagesSGP Chapter-1Shashank ReddyNo ratings yet

- Repair and RehabilitationDocument22 pagesRepair and RehabilitationConstro FacilitatorNo ratings yet

- MCQ 140Document14 pagesMCQ 140Aawez AkhterNo ratings yet

- Optical Properties of MaterialDocument63 pagesOptical Properties of MaterialNoviNo ratings yet

- Unu GTP SC 26 14Document30 pagesUnu GTP SC 26 14Ernesto RomeroNo ratings yet

- Genie GTH 4013Document202 pagesGenie GTH 4013Sam Manutenção100% (2)

- Pump Mechanical Seals GuideDocument41 pagesPump Mechanical Seals GuideArief Hidayat100% (1)

- Caterpillar Product Line 13Document7 pagesCaterpillar Product Line 13GenneraalNo ratings yet

- ECU Mount-On-Engine Vibration StudyDocument6 pagesECU Mount-On-Engine Vibration StudyElroy LeeNo ratings yet

- Corrosion RingsDocument1 pageCorrosion RingsRichard More LeonNo ratings yet

- Principle Design Solenoid ValvesDocument28 pagesPrinciple Design Solenoid Valveshassan alrokabNo ratings yet

- Seller'S Disclosure and Condition of Property Addendum (Residential)Document8 pagesSeller'S Disclosure and Condition of Property Addendum (Residential)Barbara BishopNo ratings yet