Professional Documents

Culture Documents

RCC Pipe Weight PDF

Uploaded by

YAZER0 ratings0% found this document useful (0 votes)

21 views19 pagesOriginal Title

RCC pipe weight.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views19 pagesRCC Pipe Weight PDF

Uploaded by

YAZERCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 19

HISTORY.

eee Ca te

Gr et Meet ag

The Indian Hume Pipe Co. Ltd., as early as 1926

BU RC eee Ca ue TL

See CAR ea areal

Coe ee een ieee ni cals

Sateen rics

For 60 years, the pipes supplied through over 50

SOLE caM ete ect ha

Rees acme Mae ket ed

ete, etc. and are still giving trouble-free servi

Re eae Ia etary

centrifugal spinning process, discovered by Walter

Cuetec ce

Gea anu ee een

Se Un CUE en

Be ee el mee acl

Ree ec ur Roe)

Davalopment in order to improve the product and

production technology. Piant and product design

also play a leading role in maintaining the

Ce Reece mun oe ecu

Ce RU ee Cue ea tte tet)

me ee een i

CORA ec eer?

Se ae eee nae

aggressive service conditions,

eee aCe es

engaged in the development of these products

RRC TiS ea Cea cee ina

Ca au ean ey

eC once hate ae ety

BER Reem cance tery

Re neta seep ice)

Sr Seen es}

technique, togather with mix design, use of

welded cage and rigid quality control at every

Se ee eee anne

ureter hau erat ere

CRUC AULA Titties

SPECIAL FEATURES OF IHP PIPES

Density

IHP's method of manufacture

controlled spinning with

vibration produces concrete

Mui Nun cer oruea

eur ica

re cae

See e uted

Oe ee cea)

Greater density means longer,

more efficient working life.

Strength and

Tia

pest

ere eau Ruy

Niort

Pee c

eC MC eile

Deira ok

Precincts

ene iGy

ee Cut eed

Ere ient)

Welded cage

SiC ete aot CCR eeu melee ies ER Reo keh

Ream stn Tete etter nme ea tse

RN eel chad ce ke Me ML e MceRCOelOR RNC

era Le 3

Characteristics

mu Ce

cio eke

PRU Ree

Bae Re eeu!

of moisture.

‘* Autogenous healing of minor

cracks resulting from

Peres er et

Segre

ee Rees

Pee comet)

service life

Reinforced concrete

culvert and drainage

pipes:

These pipes are manufactured in

accordance with IS 458—1971 in

class NP2, NP3 and NP4.

NP2, NP3 and NP4 class pipes

upto 1200 mm dia.are normally

available in all the major factories.

Larger diameter pipes are made

for specific jobs.

These pipes are supplied with

collar joints or rubber ring joints,

Pipes required to withstand loads

in excess of NP4 class can also be

supplied. Enquiries may be directed

to the nearest IHP factory.

IHP design engineers are available

10 advise on all aspects of the safe

and economic use of appropriate

classes of pipes.

DIFFERENT TYPES OF IHP PIPES

Testing:

Reinforced concrete culvart and

drainage pipes are subject to load

and other tests at IHP factories

in accordance with the procedure

laid down in |.S. 3597, 1986, or

as specified by the purchasar or as

suggested by IHP

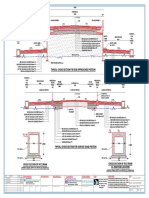

‘Space for Cement Mertar

INTERNAL FLUSH

EXTERNAL FLUSH

REINFORCED CONCRETE CULVERT

AND DRAINAGE PIPES

[ox [exam “Honan sor ae :

| NPS. APA Pa [NPS Nea

TALL PIPE WALL PIPE WAL. PIPE TALL [RE Mauer fae)

Hak [er [eae wr reve |e [rake | vee ak | er [a

da) cee ee a oe

jos |e aa eo] ret fea sf =a

Teo] 2000 se en eet

5 fre ee Z| Ho :

ca oso ea eee cd

[aso 32 [230] 76 | 620) 32 | 260 75 | 690| 76] 690

8 a see! re [77 se [aso] 78 [aral_7s oto

oe 4. [aeo| an [nanal os [68) ao | evel eo [pesados isso

a 4] se0| a0 [isto|ox [zac] 0 | cool oo [rail as [soo]

ea GE [ao] 30 [isco] se [re00] as ete) ao [rose es [rss

a so] 0 el ce aye sie eas Eg

vant 6 finee| 02a) 15 [22a [rao roo [a0 116 [p20

1209 ‘65 fisso| 115 | 2eac] 129 | 2000] a [1760] 116] 2649) 120 [2900

1200 7 posi] 7c ea SED |e

rE] See a Se ee

aso] amo | a0 [asso] — 140 |asao] @0 farol — 146) [4800] Ney Se rear sie acini

“aL Oe | ee Patol | maa [eeaa| so orecl = | = reo | aszo| 2 hese

z000} 2500 | 100 [2863] — | — 5 oe — tied hy isn lay

Se RCO se = C7 Sf

AND DRAINAGE PIPE JOINTS

- (oe iy test Ring

SOCKET SPIGOT RR. JOINT

REINFORCED CONCRETE PRESSURE PIPES

General:

Reinforced concrete pressure

pipes with collar or hydraulic

rubber ring joints are used for

water supply lines, irrigation

schemes, sewer rising mains

and similar projects. Indian

Hume Pipe Co. Ltd., has over

‘0 years experience in the

design and manufacture of

reinforced concrete pressure

pipes. Thousands of kilometers

of reinforced concrete pressure

pipes with these joints are in

service throughout Australia,

Europe, India and overseas

countries. They testify to the

efficiency and economy of this

form of pressure pipeline.

Specifications:

Reinforced concrete pressure

pipes are designed and

manufactured in accordance

with one of the following,

as required =

e1S. 458-1971

* Clients’ spacification

* IHP recommendations for

specific jobs.

Nominal effective lengths :

Upto 250 mm diameter—2.0 M

300 mm diameter and above

=25M

Reinforced concrete pressure

pipes are designed to

withstand appropriate external

loads, as well as internal

pressures.

Design:

Pipes can be designed and

manufactured to test pressures

upto and including the

maximum indicated in the

table, For test pressures

somewhat greater than shown,

‘wall thickness may be

increased with corresponding

reduction of bore. Allowable

test pressure for pipes over

600 mm diameter may be

reduced by external loads.

HP engineering staff are

available to assist with all

aspects of pressure pipe design.

Testing:

Alll pressure pipes are subjected

to a hydrostatic pressure test

at IHP factory. The test

pressure is directly related to

the required working pressure

for the pipe and in accordance

with the requirements of the

job. Pressure pipes also

‘subjected to other tests as

specified in the standard.

pte tite Mem) gic Moen

100 | 2000 | 25 |) 60 5 50

[400 (2500 32 26080 430 60 320.

aso_| 2500 | 35 | 30 so | a0 | 0 | ak

600 | 2500 | 40 | 480 85 10 90 1170

ee

a

[1000 | 2800 [55 tos | 100 | 2070 | — =

[1100 | zs00 co 10 - = a

Weights are approximate

ae Mh Cm Ol mee) NG aia 2 ae) by

General:

Rubber rings provide a quick, simple and

effective means of jointing concrete pipes.

When used with rigid concrete pipas :

the strength of the pipe combines with

‘the flexibility of the joint to onsure the

continusd effective operation ef the

pipeling, avan under adverse conditions:

caused by ground movement.

All rubber rings supplied with IHP pipes

‘ere manufactured in accordance with

1S, 5382-1969.

Nature! rubber has compression set

characteristics superior to synthetic rubber

and is normally used. Natural rubber,

however, has low resistance to

hydrocarbons, and in situations where

thoir presonoe is anticipatad,

polychloroprene (Neoprene) rubber rings

ere specified. Quality of rubber is not

affected when it is protected from sun and

light. In underground pipelines, in contact

with weter the life of rubber rings is as

much as that of pipes.

Roll-on Rubber

Ring Joint. ROLL ON JOINT

IMP manufactures socket and spigot

concrete pipas with a roll-on-'' ting j

in sizes from 100. mm to 1800 mm

diameter. This joint developed by

Cornilious in England, is in use for

concrete pipes for over 45 years, giving

satisfactory service

Confined ‘O’ Ring Joint:

Amore recent development by IHP is the

confined 'O' ring joint. The rubber ring

remains in a fixed position an the pipe

spigot. While jainting, the ring end

the pipe socket are lubricated, and the

joint is made

The confined

ing joint offer:

+ Eaciot closure in wet conditions.

‘* A more compact jeint in large diameter

pipes.

IHP flexibly jointed NP4 class pipes of

diamater 1000 mm and above have

confined ‘O' ting joints. Thi

@coammodated in the wall th

the pipes; hence there is no projection

of socket

CONFINED ‘0’ RING JOINT

Flow Chert for Concrete Pipe Lines

g

&

%

z

g

é

g

=

%

Loss of Head:

Structural

Design.

During the last decade the

designing of rigid underground

pipes, their joints and technique

of instellation have been

changing fundamentally from

empirical and traditional methods

to more rational methods

based on the scientific

principles of structural and soil

mechanics. A buried pipeline

is now recognised es « load

bearing structure, and within

the limits of present

knowledge, is designed

with growing confidence.

Condition of

installation.

The magnitude of loads

imposed upon a buried! pipe

by the overlying soil and by

any uniformly distributed

or concentrated surface

surcharge of large or infinite

extant, Gepends first on the

nature density and depti

of soil cover, the intensity of

surchargs, the nature of the

pipe—whather rigid or flexible

and on the conditions in

whieh it is installed—whether

trench or embankment,

Reference is often made to the

menufacturer’s tabuleted load

carrying capacities to select

the appropriate pipe class

when the service load

requirements are known.

This procedure is satisfactory

provided all factors are

considered. However, prior to

Seciding the class of pipe

required, the design engineer

should consider in detail, how

the pipe is to be laid, ie. the

depth of excavation, cover,

backfill material type, trench

width required for practical

installation, minimum density

of beckfill and possible

construction traffic loads.

Trench widths.

For pipes in trench cond

the fill and surcharge loads

depend upon the effective

trench width and whether it is

wide or narrow with respect

to the outsida diamotor of the

pipe and depth of soil covar

Whan installing a pipe, itis

‘essential that the trench width

be specified and excavated

uniformly and not be permitted

to “just happen” in a

haphazard manner

Back filling.

Another aspect of pipe

installation that is neglected is

backfilling. The ability of any

pipe to support an

embankment depends on

adequate side support, It is

essential thet side filling be

thoroughly compacted to at

least 90% of the maximum dry

density as assessed by the

modified ProctorTest Method.

If 90% compaction is not

attained, the ability of the pipe

to carty a given load is

reduced significantly.

Failure to provide side support

may cause failure of the

pipeline atless than the

designed loading and may also

induce difforential sattlement

when the fill above and beside

the conduit does not settle

uniformly.

Surcharge loads.

Pipes in service are subject to

loads generated by earth

pressures and superimposed

surcharges, such as traffic

loads for pipes under road

ways, The aetuel loads vary

according to the class of

foundetion material, depth of

cover, compaction procedure

and whether the pipe is

beneath an embankment or

ina trench.

A loading which is often

‘overlooked and which may

‘excaed the combinad loads is

traffic loading. The trend today

is for larger and consequently

heavy earthmoving equipment.

‘When this equipment is used

in conjunction with pipeline

installation it is often allowed.

10 pass over or alongside the

pipe during the backtilling

operation. Little concern is.

directed in the field to the

permanent effect such

transient traffic can have on

‘the pipe.

Installation of

Pipes.

The performance of the

pipeline in service depends not

only on the quality of pipe

and joint but also on

installation i, on the design

and execution of bedding,

jointing and backfilling. The

following notes will help to

design and execute installation

properly.

Trench

Preparation.

Trenches should be kept tothe

specified width since any

excessive increase in tranch

width will increase both the

load on the pipe, the quantity

of excavation, end will also

require more bedding material

under the pipe. A tronch

nerrower than that specified

may impede the proper placing

and consolidation af tho

bedding material and restrict

working conditions in the

trench during pipe laying.

Recommended trench widths

for various pipe diameters and

installation conditions are

indicated in tables enclosed

The foundation.

Uniform support along the

pipaline is important. All hard

spots and also soft zones

which can cause differential

settlement should be removed

from the foundation. Bouldars

and soft patches should be

dug out and replaced with well

tamped selected backfill.

isturbance by trampling of

ine soils or caarse grain

material in the tranch bottom

must be avoided. In water

bearing ground sufficient

waterstops should be provided

to provont passage af water

along the trench. Tha water

level should not be allowed to

rise before bavktilling is

completed. Rack ancuring in

TRENCH BEDDINGS

Concrete Cradle

Lre2 25034

300

DENSELY

COMPASTED:

BACKFILL

114.0 axa

PLAIN OR REINFORCED

CONCRETE M150

CONTINUOUS CONCRETE CREL!: OF MONOLITHIC CROSS

SECTION F UN«

FINE GRANULAR

FILL MATERIAL

—48.s6emi

SHAPED SUBGRACE WITH

GRANULAR FOUNCATION

Ordinary

iret

tak

150mm,

SHAPED SUSGRADE

Legend

Be=OUTSIDE DAMETER

BACKFILL COVER ASOVE TOP OF pire

INSIDE iaratitt

DEPTH OF SECOING MATERIAL ELOW PIPE

Note

FOR ROCK OR OTHER INCOMPRESSIOLE MATE nIALS,

DENSELY

BACKFILL,

Loose

BACKFILL,

DEPTH OF BEDDING

MAT, BELOW P.PE

3 goa

fea re

Teo a 1OG a je

[1600 mm & LARGER| 160m

THE TRENCH SHOULD

BE OVEREXSAVATED A MINIMUM OF 180mm 200) REFILLED WITH GRANULAR

MATERIAL,

tha foundation should be

generously overcut and

replaced by @ layer of granular

material,

Ground water should be kept

below the bottom of the trench

wherever possible during pipe

laying operations by the use

of temporary drains, sumps, or

ther suitable means. Peat

tor boggy material at formation

level should be removed and

replaced by sand or other

approves filling materials,

If the trench is excavated in

clay it is important to try to

maintain the water content of

the clay during construction,

‘Tha addition of water will

cause swelling whils excessive

Inying can Gauss shrinkage.

Either swelling or shrinkage

can cause an uneven trench

bottom

Where slips occur and the

trench wall ccllapses

immediate action should be

taken to inform the Resident

Engineer so that remedial work

may be put in hand to take

account of a trench width in

excess of that specified.

Care must be taken when

constructing a trench adjacent

to @ manhole, The trench

should be backfilled as soon es

possiole after the pipes are

laid to prevent eny movement

of the manhole causing an

pverload to the pipas,

Bedding

Materials.

The types of bedcing normally

usad With concrete pipes are

concrete cradle bedding,

‘Ist class bedding end ordinary

bedding

Concrete Cradle

Bedding:

(Reinforcs

This type of bedding using

good quality concrete,

carefully placed to ensure

adequate and uniform support

oas not unduly limit the

flexibility of the joints, provided

gaps—each not lass than

12 mm wide, are mace in the

cancrete at every second joint

position or at every 5 Meters

whichever is less. These

gaps should be ‘illed with

a soft compressible msterial

‘o prevent the entry of any

stonas, such other materials

liable to rastrict ‘lexibility of the

bed and consequently of the

pipeline itsalf

First Class

Bedding:

(Granular materiel)

Free draining gravels or

crushed stones, well graded

and evenly cor ted under

supervision will ensure good

joint performance. An excess

of fines in the material may

cause ‘bulking’ during progress:

of the work, with consequent

variations in ling, level and

compaction

4 or piain concrete)

Tho maximum particle size

should generally not exceed

20 mm. The presence of an

foceasional particle between

20 mm and 26 mm is

‘eplable provided the total

quantity of such particles is

only a very small ‘rection

‘ol the whole. If particles over

25 nin are prasent the

‘matorial should be rajerctad

The use of material obtained

rom the trench during

excavation should be permitted

only after a grading analysis

has been made end th

material approved as suitable

or the particular size of pipe

boing laid. When granular

bedding is used in trenches

dug in uniform coarse sands

or gravel it is important to

ensure that the bedeing

material is not compacted

lass than the natural trench

botiom

eo

Ordinary Bedding:

(natural soil of trench)

The bedding of concrete pipes

‘on natural soil of the tronch

bottom in these classes is

generally only suitable for

pipes up to 300 mm diameter.

Tha natural soil should be

uniform and fine grained:

conditions relatively dry.

Bedding

Procedure:

For concrete cradin bedding,

precast cradivs ar other

means of support for the pipes

‘et the correct height above

the trench bottom and which

can be safely left in place,

should be regularly placed by

means of a distance gauge and

then boned in to the correct

level and gradient. A layer

of compressible material

should be placed between the

pipe and credie to prevent

the creation of a hard spot at

the cradle

No supports should be used

in 1st class bedding, the top of

which should be trimmed to

the correct gradient, slightiy

above the fine! laval to allow

for e smal| settlement of heavy

pipes, as pre-determined by

‘ial. Timbering or sheeting

should, wherever possible, be

withdrawn as work proceeds

so that no voids are left in the

bedding. The bedding should

be properly compacted,

preferably by mechanical

‘maans.

Care should be exercised to

avoid disturbance of the

bedding bensath the pipe and

to make good any disturbance

which may occur accidentally.

‘The bedding must be dug out

under the pipa sockets so thet

the pipes are supported along

the whole length of their

barrels, and nat on their

sockets only.

The pipe should be suspended

during laying and jointing to

avoid disturbance of the

granular bed, and to prevent

tha whole weight of the pipe

from bearing on the rubber

ring during jointing for Rubber

Ring Joints and allow uniform

Caulking space in the casa of

collar joint. After completion

of jointing the sling should ba

carefully temioved to prevent

disturbance of the bedding.

Permissible depths of filling and types of bedding

for NP class pipes

Trench Condition

a DEPTH OF FILL OVER TOP OF PIPE

METHOD OF BEDDING

‘Gnomany | FIRSTCLASS | CONCRETE

BEDDING BEDDING ‘CRADLE

UNLIMITED | UNLIMITED.

SELECTED.

}-Comeacien

EARTH

Ordinary Bedding

LOAD FACTOR 15

sevecren,

compactes

GRANULAR

MATERIAL

‘0.8 Se min

First Class Bedding

LOAD FAGTOR 19

1 FILLING MATERIAL IS ORDINARY CLAY AS

PER 1, 783-1959 FIG. 1 (CURVE WITH

Ku 6 Ku'=130)

ft

2 FILL MATERIAL DENSITY=1750 KG/tas men

4/NO SUPERIMPOSED LOAD COMPACTED

EARTH

4. WIDTH OF TRENCH

UP TO 1200-0.0,+300 mm

BEYOND 1200-0.0.4450 mm.

concRETE

‘CRADLE

Concrete Cradle Bedding

Lap FACTOR @

Permissible depths of filling and types of bedding

for NP2 class pipes

Embankment (positive projection)condition

DEPTH TO INVERT OF THE PIPE

DIR.OF ‘METHOD OF BEDDING

pire [onsivary | rusrciass | concnere

= BEDDING BEDDING CRADLE

too | _ununareo | Unuiiree NLIAITED

074

zm

383M

377

305M

He -| 32% Ordinary Bedding

7 ¥ Loap FAcrON 1

00 340M egace

‘00 ase

800 780 t8 322M

000 on 355M Piste

wi ro ‘310M eee

7200 13M 235%

1400 135M 252M

; + seurcteo

‘600. | 267m | Eoweacteo

+800 235M EARTH

“900 265M sf

2000 257M

compacrer

oe Ba Seaton

MATERIAL

06 e min

First Class Bedding

LORE FACTOR 225

4) FILLING MATERIAL IS ORDINARY CLAY AB.

PER 3, 785-1989 FIG. 11

2) FILL MATERIAL DENSITY=17E0 KG/E

3) No SUF=AIMPOS:D LOAD

SELECTED.

NPAC TED

tae

ou

concrete:

rable

Concrete Cradle Bedding

Loap FacTOR 3.3

Permissible depths of filling and types of bedding

for NP4 class pipes

Embankment(positive projection)condition

DEPTH TO INVERT OF THE PIPE

PIPE

Da oF

METHOD OF BEDDING

GRoINARY | FIRSTCLASS

tL DDING. BeoUinG

CONCRETE

CRADLE

380

453M

aaa

400

00

12M

oom

7M

SEEM

520M

380M

5.09.M

49m

01M

a4eM |

510 M1

903 M

5.17 Ml

492 M4

375M

a5

499.

501M

Bad M

nl

Ordinary Bedding

LOAD FACTOR 188

5.25 M

8.86 M

Baa

2M

‘ont

ORDINARY

FILL

stLecTeD.

ING ShATERIAL I ORDINARY CLAY AS

7551959 FIG, 11

) Fill, MATERIAL SENSITY= 4750 Kotla

2) NO SUPERIMPOSED LOAD

ScMPAETED

EARTH

sL

comeacrs

GRANULAR

MATERIAL

06 Bemin.

First Class Bedding

LOAD FACTOR 236

_o20InaRY

FLL

sevecTen

COMPACTED

Fante

cu

concaete

CRADLE

Concrete Cradle Bedding

LOAD FACTOR 9:3,

SOME MAJOR WATER SUPPLY AND DRAINAGE

SCHEMES WHERE HUME PIPES ARE USED

Class or Test | Length

bape ote Sere Year | $e | pressure | in ms

1. | Quotta Water supply 1930 42" 2.00 Kqs.jom? | 16094

2, Hambantata water supply in Ceylon 1830 BY 2.00 ‘97000

3. Municipal Drainege, Karachi _ [asst 6-15" 45731

4, Jamshedpur Grainage 1931 4-27 Non pressuro_| 54000

5._| Warangal Water Supply 1938 457-26" [2.00 kas/em® | 31000

6 ‘Mithapur Chemicals; water supply 1939 ata" Non pressure 11000

3, Tata Iron & Steal Jamshedpur drainage: 1939 Vs Non pressure 11200,

| Delhi drainage i940 47-30" ‘Non pressure | 28000

8. Indus Water supply, Karachi 1941-42 | 33"-63" 2.00 Kgs/em? | 36000

70, | Tata Wron & Stesl, water supply & pereag |e a8" Non pressure | 33650

Jamshedpur Zz

11._|_ Water supply t Munirabad 1947 | 8" 6.00 62474

‘Aurangabad woter supply 1952-55 | 67-26" 1to2 72077

Hyderabed water supply i955 | 60-66" | 2t03 30570

‘Municipal drainage, Lucknow tees | 6-42" 81280 _|

Municipal drainege, Delhi 1959 78-90" Non pressure 17600,

Jabalpur water supply i859 ee 2.00 16764

‘Sabarmati water supply, Ahmedabad 7980 | 4%-18" ‘| 200 762017 |

Gorakpur drainage 1961-62, Non pressure 46310

2. _| Water supply to Gauheti 1981-62, 2.00 16800,

le ‘Nasik drainage 1964 Non pressure | 54075

21. Dharwar water supply 1965 4to6 46372

Madras water supply 1866 76.00. 16337

Improvement trust. Nagpur drainage 1907 Non pressure | 17728 |

Madurai water supply 1968 4.00 29300

Gulbarga water supply 1968 2.00, 42490

Jaipur water supply i969 | 24” 2.00 20120

Osman saagar water supply, Hyderabad 1971 700 mm: 4.00 14000

800 mm.

28, | Dharampur water supply, Madras i72«| 15". 460. | 4t06 "70000

600 mm.

28. | Rural water supply, Kanpur 1972 Bat Non prossuro | 12600

30, | Gandhigarh [itt irigation 1874 381-457 mm| Non pressure | 26000

| 31, | Augmentation to Yamuna Canal, Chandigarh. | 1978 | 450—600 mm | 2 kg/cm? 17250

| $2. | Bombay City end Suburbs Drainage” =| «1975 Saale Nee 25,000

* Projvctfinancva by the World Bark,

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- TCS (DRAIN) - Model PDFDocument1 pageTCS (DRAIN) - Model PDFYAZERNo ratings yet

- Latest BOQ - TranslatedDocument124 pagesLatest BOQ - TranslatedYAZERNo ratings yet

- Mss & WMMDocument6 pagesMss & WMMYAZERNo ratings yet

- Gs AssociatesDocument4 pagesGs AssociatesYAZERNo ratings yet