Professional Documents

Culture Documents

Paper On Monpole

Uploaded by

Md Mohsin0 ratings0% found this document useful (0 votes)

14 views11 pagespaper on monopole

Original Title

Paper on Monpole

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentpaper on monopole

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views11 pagesPaper On Monpole

Uploaded by

Md Mohsinpaper on monopole

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 11

Publication No. 329

Cos

CIGRE- AORC TECHNICAL MEETING 2016

INTERNATIONAL CONFERENCE

GLOBAL TRENDS IN THE DEVELOPMENT OF

POWER TRANSMISSION & DISTRIBUTION SYSTEMS

INCLUDING SMART GRID

24" - 26" February 2016, New Delhi

PROCEEDINGS

Organised by Technical Partners

‘CIGRE Inca ete Beard of

iegation & Power

CIGRE-AORG Technical Meeting 2016 — Intemational Conference on Global Trends in the Development

of Power Transmission & Disinbution Systems incluaing Smart Grd, 24-28 Feb. 2018, New Dei, india

EMERGING SOLUTIONS FOR LINE COMPACTION

D. Prasad*, R. Kumaran, G. Agarwal, P.K. Reddy, Md. I, Khan

Supreme & Co. Pvt. Ltd.

(India)

SUMMARY

‘This paper presents various solutions for Tine compaction. The paper presents four

emerging technologies that support increased power transmission capacity for a given right of

way (RoW) and clearance level. Use of high temperature low sag (HTLS) conductor, which has

relatively low sag at high operating temperatures, is suggested to reduce the height of the tower:

Sag-tension calculations were made at different temperature levels and comparison was made

toindicate how the usage of HTLS can have an impact on line compaction. Insulated crossarms

can restrict the inward and outward swinging of the insulator. Since the insulators are directly

attached to the tower, a metallic crossarm is not required and thereby, the load on tower is

reduced. Monopole structures, which have a very small footprint are suggested instead of

“broader lattice tower. Monopoles are more flexible and have improved stability against wind

loads. Testing of monopole structure at different load conditions is also presented. Interphase

spacers are presented as an optional feature to prevent conductor galloping on EHV lines.

Different types of interphase spacers are discussed in brief, At the end, a comparison is made

between conventional towers with a monopole type structure with insulated crossarm,

KEYWORDS

RoW; Compact; HTLS; Monopole; Insulated crossarm; Interphase spacer.

1. Introduction

There is a continuous increase in electric power demand due to technological

advancement and rising living standards. This increase in power demand has resulted in an over

‘utilization of the transmission system. Growth in industrialization, increasing per- capita

income and rapid urbanization has led to s ~50% growth in the installed power generation

‘capacity over the last 5 years. However, transmission capacity has grown only by ~30%.

* engineeringteam@supreme.in, dharmbirprasad@yahoo,com:

261

‘New generating stations using conventional fuels such as coal, gas ete. and larges

renewable plants are being developed to mect the power demand, To accommodate the

demand and generation, it is imperative to cither upgrade their existing

infrastructure or provide new corridors for power transmis

several aspecis like RoW, environmental issues, cost of development must be taken j

account. Of all the issues, the most important impediment is securing RoW. High land pri

and difficulties in getting permission from landowners have enforced the power soto

explore an altemative solution to improve the power transmission capacity. These const

can be overcome with the new and innovative design concepts which led to the compatt

transmission line (CTL) formation,

2. Description of CTL and its’ components

The basic concept of power transmission using CTL is same as that of a convention

transmission line ie., to transmit power at higher voltage level to reduce losses dati

transmission. The most important hurdle in transmitting power at higher voltage is provid

the required electrical clearance along the line. This is because as the transmission line voltag

increases, the required clearance level also increases [1]. This increase results in a larger

requirement which can be minimized with the help of compact transmission line

Line compaction is the reduetion of tower dimension such that it leads to the redi

of RoW requirement compared to a conventional tower of same voltage level. The desi

stmeture, conductor materials and hardware accessories has evolved in CTL to reduce R

requirement [2]. ICuses basic components that are designed with the goal of tine compaction

‘may include certain concepts like usage of composite post insulators 2s crossarm to restitt

conductor swinging, interphase spacers to avoid conductor galloping, use of high performang

conductor and monopoles with less footprint [3]. The most important aspect of cor

transmission line is to design a structure which is compact, at an acceptable cost withol

compromising reliability and safety standards. Four components which contributes for

compaction is discussed in the following sections.

2.1, HTLS conductor

HITLS conductors are gaining more attention in

the field of transmission over the past few years. It

allows the thermal rating of the line has to be increased

[4]. Many of the HTLS conductors are made of strands

that are non-cylindrical (Ze, trapezoidal) as portrayed in

Fig. 1, which enables them to incorporate more

Aluminium thereby allowing the conductor to carry

more amount of current. HTLS conductor, not only carry

a large amount of current, they carry it ata sag very less

when compared with a conventional conductor. Another

unique feature of HTLS is that their core is made of glass ig, 1 Cross sectional view of

fibre composite material rather than steel as in ACER and HTLS conductor,

conventional conductor. Steel in ACSR conductors has

high coefficient of lincar expansion which makes them to sag mote at higher temperature. But

the composite core of HTLS does not expand easily and hence offers a less amount of sag wi

compared with an equivalent ACSR conductor.

262

2,

1g performance of ACSR and HTLS

Sag calculation will be the primary asset that need to be determined while designing a

_ transmission line. It is one of the most important factor which determines the height of the

tower. The catenary of a transmission line is usually considered to be a parabola and the sag

‘with respect to particular tensioning of the conductor is determined using Eq. (1).

S-WL8T oy

where

$_:Sag of the conductor,

W ; Weight of the total conductor load,

L_: Span of the conductor and

T : Working tension in the conductor.

Sag of the conductor depends upon the coefficient of linear expansion of the conductor

and modulus of elasticity [5]. These two parameters determine the conductor expansion and

allowable tension. Usually, worst case scenario (ie.. the maximum operating temperature) of

the conductor under no wind condition is considered for determining the height of the

conductor. It is under this condition the conductor tends to have maximum sag.

To verify the sag performance of ACSR and HTLS conductor, sag was calculated for

s operating temperature. For this purpose, an ACSR *Moose* which is traditionally used

400 KV line is compared with a HTLS of same diameter. Calculation is made for a span of

400 m with an average wind speed of 45 m/sec and terrain category of 2. ACSR ‘Moose’ has a

sximum operating temperature of 85°C whereas HTLS can be operated even about 200°C.

15

| 20 70 120 170 i

—®HTLS ——ACSR ‘Temperature (°C) 1 ,

Fig. 2 Comparison of sag between ACSR and HTLS,

When ACSR is subjected to its maximum temperature, the conductor sags are calculated

13.6 m. At the same temperature, HTLS sags only about 10.8 m and thereby give us

tion of tower height by almost 2.8 m (as presented in Fig. 2). Replacement of ACSR by

ives us a reduction of almost 20 % of the overall height of the tower.

ted crossarm

The freedom of movement provided to the insulator string determines the clearance that

e provided for the line, Clearance should be given to both inward and outward

a of the insulator. Instead of attaching the insulator from metallic crossarm, if we

directly to the tower, itis possible to restrict the insulator swinging and thereby the

ical clearance. This concept is known as insulated crossarm which was started

from 1960s [6]. Another factor that must be considered while designing a

‘transmission tower is the length of the insulator string, As the voltage rating increase, the

insulator chain length also increases. But in the case of insulated crossarm, the insulators are

strung in horizontal manner which greatly teduces the height of the tower. But for attaching.

insulators horizontally, they must have high bending strength and high ultimate strain [7]

‘Composite insulators made of silicone rubber are employed for this purpose. Insulated crossarm

consists of a brace made of long rod composite insulator which works under tension and a post

insulator that mostly works under compression caused by the horizontal load such as wind [8]

The vertical load such as the conductor (and ice load if present) are taken up by the brace,

Precaution must be taken so that the brace of the insulated crossarm is never been subjected to

a compression which will result in the contact of metallic fittings and thereby leading (0 radio

interference voltage (RIV) disturbances

*% RIGID

You might also like

- LoadsDocument2 pagesLoadsMd MohsinNo ratings yet

- Three-Way Switches Dimensional Data 115 - 230 KV, Type 3G and 3GLDocument4 pagesThree-Way Switches Dimensional Data 115 - 230 KV, Type 3G and 3GLbloodpointerNo ratings yet

- H-Frame ModelDocument1 pageH-Frame ModelMd MohsinNo ratings yet

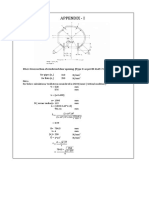

- Annexure 1-Monopole Design ParametersDocument1 pageAnnexure 1-Monopole Design ParametersMd MohsinNo ratings yet

- Design Basis Report For Lattice & Monopole TowerDocument5 pagesDesign Basis Report For Lattice & Monopole TowerMd MohsinNo ratings yet

- H Frame ModelDocument1 pageH Frame ModelMd MohsinNo ratings yet

- LoadsDocument2 pagesLoadsMd MohsinNo ratings yet

- Standard Swing Vang Design: 12" To 26" DropDocument3 pagesStandard Swing Vang Design: 12" To 26" DropMd MohsinNo ratings yet

- Bracket Bending CriteriaDocument1 pageBracket Bending CriteriaMd MohsinNo ratings yet

- LoadsDocument2 pagesLoadsMd MohsinNo ratings yet

- Minimum Clearance of Overhead PolesDocument3 pagesMinimum Clearance of Overhead PolesMd MohsinNo ratings yet

- 33s Monopole StaadDocument10 pages33s Monopole StaadMd MohsinNo ratings yet

- Technical Specification For ACSR Conductor, 24F OPGWDocument3 pagesTechnical Specification For ACSR Conductor, 24F OPGWMd MohsinNo ratings yet

- Buckling Observation of Door Openings For Wind Turbine TowersDocument9 pagesBuckling Observation of Door Openings For Wind Turbine TowersMd MohsinNo ratings yet

- SG000025 22SHM Reliance Industries LTD 44MPS FD HVR Structural Cal.Document22 pagesSG000025 22SHM Reliance Industries LTD 44MPS FD HVR Structural Cal.Md MohsinNo ratings yet

- MacLean Power System - 1Document250 pagesMacLean Power System - 1ransransNo ratings yet

- Bracket Bending CriteriaDocument1 pageBracket Bending CriteriaMd MohsinNo ratings yet

- SG000025 22SHM Reliance Industries LTD 33MPS FD HVR Structural Cal.Document22 pagesSG000025 22SHM Reliance Industries LTD 33MPS FD HVR Structural Cal.Md MohsinNo ratings yet

- SG000025 22SHM Reliance Industries LTD 44MPS FD HVR Wt.Document1 pageSG000025 22SHM Reliance Industries LTD 44MPS FD HVR Wt.Md MohsinNo ratings yet

- Door OpeningDocument8 pagesDoor OpeningMd MohsinNo ratings yet

- 33s Monopole StaadDocument10 pages33s Monopole StaadMd MohsinNo ratings yet

- 33s Monopole StaadDocument10 pages33s Monopole StaadMd MohsinNo ratings yet

- 33s Monopole StaadDocument10 pages33s Monopole StaadMd MohsinNo ratings yet

- Door Opening CalculationDocument2 pagesDoor Opening CalculationMd MohsinNo ratings yet

- Positive Design Pressure 36.4 PSF Negative Design Pressure - 40.5 PSFDocument3 pagesPositive Design Pressure 36.4 PSF Negative Design Pressure - 40.5 PSFRamachandra SahuNo ratings yet

- ANSI TIA EIA 222 G Wind Load CalculationsDocument2 pagesANSI TIA EIA 222 G Wind Load Calculationsasad_naqvi100% (5)

- Two Pile GroupDocument12 pagesTwo Pile GroupJammy KingNo ratings yet

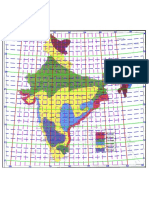

- Wind Map Grid IndiaDocument1 pageWind Map Grid IndiaMd MohsinNo ratings yet

- Is 4000 1992 PDFDocument18 pagesIs 4000 1992 PDFDarshit VejaniNo ratings yet

- A Pre Fertilization Benthic Survey of Ostrea Lake, N.SDocument27 pagesA Pre Fertilization Benthic Survey of Ostrea Lake, N.SMd MohsinNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)