Professional Documents

Culture Documents

Hex Nylon Insert Locknuts (NE), Grade N5, Zinc: Page 1 of 2 REV-04 Date: April 28, 2017 NYLK - NE.N5.Z

Uploaded by

MarceloGonçalvesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hex Nylon Insert Locknuts (NE), Grade N5, Zinc: Page 1 of 2 REV-04 Date: April 28, 2017 NYLK - NE.N5.Z

Uploaded by

MarceloGonçalvesCopyright:

Available Formats

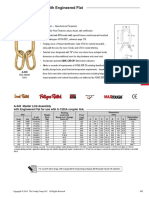

Page 1 of 2 Fastenal Product Standard REV-04

Date: April 28, 2017 NYLK.NE.N5.Z

Hex Nylon Insert Locknuts (NE), Grade N5, Zinc

The information below lists the required dimensional, chemical and physical characteristics of the products in this purchase order. If

the order received does not meet these requirements, it may result in a supplier corrective action request, which could jeopardize your

status as an approved vendor. Unless otherwise specified, all referenced consensus standards must be adhered to in their entirety.

C A D

Width Across Hex

Size Thickness

Flats Height

Max. Min. Max. Min. Min.

1/4 .328 .298 .439 .430 .225

5/16 .359 .329 .502 .489 .250

3/8 .468 .438 .564 .551 .335

7/16 .468 .438 .627 .616 .324

1/2 .609 .579 .752 .736 .464

9/16 .656 .626 .877 .861 .469

5/8 .765 .735 .940 .922 .593

NE

3/4 .890 .860 1.064 1.052 .742

7/8 .999 .969 1.252 1.239 .790

1 1.078 1.016 1.440 1.427 .825

1 1/8 1.203 1.141 1.627 1.614 .930

1 1/4 1.422 1.360 1.815 1.801 1.125

1 3/8 1.609 1.547 2.008 1.973 1.282

1 1/2 1.640 1.578 2.197 2.159 1.313

Specification Requirements:

• Dimensions: Per ASME B18.16.6

• Material, Performance

& Mechanical Properties: Nut Material: Carbon Steel, Grade N5 per ASME B18.16.6

Nylon 6/6 material shall be in compliance with

current RoHS European Union Directive

Prevailing torque per ASME B18.16.6

• Thread Requirements: ASME B1.1, UNC & UNF, Class 2B

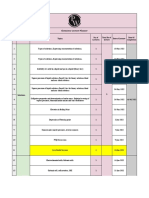

Page 2 of 2 Fastenal Product Standard REV-04

Date: April 28, 2017 NYLK.NE.N5.Z

• Product Marking: Grade N5 nuts shall be marked with three equally

spaced identical symbols on the top side of the nut,

alternatively, if made from bar stock, markings shall be

identified with one set of circumferential notches cut into the

corners of the nut.

• Manufacturer’s Marking: Manufacturer’s Identification (Nylon insert color may be used

to identify the manufacturer in addition to or an alteration of

the three grade marking symbols.)

• Finish: Fe/Zn 3AN per ASTM F1941/F1941M

• Material Test Reports: The MTR must have documented lot traceability, dimensional

results, full chemical test results and full mechanical test

results to the specification(s) above. In addition, the MTR

shall be in full compliance with Fastenal’s MTR

Requirements.

You might also like

- 5 ZDocument2 pages5 ZFernando TamayoNo ratings yet

- Top Lock Flange Nut, IFI 100/107, Grade F, Zinc Plated: Page 1 of 2 REV-05 Date: March 9, 2016 TPLK - FLG.GRF.ZDocument2 pagesTop Lock Flange Nut, IFI 100/107, Grade F, Zinc Plated: Page 1 of 2 REV-05 Date: March 9, 2016 TPLK - FLG.GRF.ZGuilherme Alexandre DelfitoNo ratings yet

- Hex Bolts, SAE J429Document2 pagesHex Bolts, SAE J429Luciano Salituri100% (1)

- Heavy Hex Nuts, ASTM A194/A194M and ASME SA194/SA194M, 2HM, PlainDocument2 pagesHeavy Hex Nuts, ASTM A194/A194M and ASME SA194/SA194M, 2HM, PlainSandip JawalkarNo ratings yet

- Tornillos Acero InoxDocument1 pageTornillos Acero InoxEduardo ArrietaNo ratings yet

- Proprietary Standard, Hex Cap Screw, Grade 9, Yellow Zinc: Page 1 of 2 REV-04 Date September 22, 2014 Hcs - Gr9.YzDocument2 pagesProprietary Standard, Hex Cap Screw, Grade 9, Yellow Zinc: Page 1 of 2 REV-04 Date September 22, 2014 Hcs - Gr9.YzYunlong GuNo ratings yet

- Direct Tension Indicating Washers, Type A325, Mechanical GalvanizedDocument1 pageDirect Tension Indicating Washers, Type A325, Mechanical GalvanizedtomaustinNo ratings yet

- Grandes Tuercas en PulgadasDocument2 pagesGrandes Tuercas en PulgadasDavid MejidoNo ratings yet

- Ficha Tecnica Tuerca Hex. Din 934 Clase 2Document2 pagesFicha Tecnica Tuerca Hex. Din 934 Clase 2FGA PRESUPUESTOSNo ratings yet

- HHN A194 8M 05Document2 pagesHHN A194 8M 05fernandoraiasaNo ratings yet

- HHSB A325 Asmbl PDocument3 pagesHHSB A325 Asmbl Palexayala5151No ratings yet

- Theaded Rod TyrenDocument3 pagesTheaded Rod TyrenanhnguyenhaiNo ratings yet

- Hex Cap Screw, 316 Stainless Steel: Page 1 of 2 REV-06 Date: November 28, 2018 HCS.316Document2 pagesHex Cap Screw, 316 Stainless Steel: Page 1 of 2 REV-06 Date: November 28, 2018 HCS.316fernandoraiasaNo ratings yet

- Heavy Hex Nut, ASTM A194/A194M and ASME SA194/SA194M, Grade 2H, ZincDocument2 pagesHeavy Hex Nut, ASTM A194/A194M and ASME SA194/SA194M, Grade 2H, ZincJ.GuerhardNo ratings yet

- CSI Spec Fiberglass PDFDocument5 pagesCSI Spec Fiberglass PDFSubash Bastola100% (1)

- Astm A563Document2 pagesAstm A563Carlos FloresNo ratings yet

- SSS FD BoDocument1 pageSSS FD BodbaldricaNo ratings yet

- Round Head Tension Control Structural Bolt Assembly, ASTM A325, Type 1, PlainDocument2 pagesRound Head Tension Control Structural Bolt Assembly, ASTM A325, Type 1, PlainjcNo ratings yet

- Fastenal Hcs - Gr5.yz.08Document2 pagesFastenal Hcs - Gr5.yz.08darkangelitaNo ratings yet

- Stud Bolt, ASTM A193/A193M and ASME SA193/SA193M Grade B7, Blue Fluoropolymer CoatedDocument2 pagesStud Bolt, ASTM A193/A193M and ASME SA193/SA193M Grade B7, Blue Fluoropolymer CoatedfernandoraiasaNo ratings yet

- Dados Dos ParafusosDocument2 pagesDados Dos ParafusosGabriel MacedoNo ratings yet

- HHSB A325 Asmbl PDocument2 pagesHHSB A325 Asmbl PjoseocsilvaNo ratings yet

- Asme B 18.2.2 2015Document14 pagesAsme B 18.2.2 2015Plinio Pazos50% (2)

- HHSB A325 WN HDGDocument2 pagesHHSB A325 WN HDGcristi_mtNo ratings yet

- Butt Weld Tuerca UnionDocument1 pageButt Weld Tuerca UnionRodrigo Galdo MartínezNo ratings yet

- FW F436 TH ZDocument1 pageFW F436 TH ZfernandoraiasaNo ratings yet

- Hex Jam Nut, SAE J995 Grade 5, Plain Finish: DocumentosDocument2 pagesHex Jam Nut, SAE J995 Grade 5, Plain Finish: DocumentosDiego ChavezNo ratings yet

- Fastenal Product Standard: FNL - PP.SOCKET - FS.LC.P: Pipe Plug, Socket, Merchant Steel, Flush Seal 7/8" Taper, PlainDocument1 pageFastenal Product Standard: FNL - PP.SOCKET - FS.LC.P: Pipe Plug, Socket, Merchant Steel, Flush Seal 7/8" Taper, PlainravivelamarthyNo ratings yet

- STPE510 - Dadi Per Saldatura A Filo (SUMITOMO)Document10 pagesSTPE510 - Dadi Per Saldatura A Filo (SUMITOMO)LucaNo ratings yet

- Asme B18.16.6Document1 pageAsme B18.16.6Mario FonsecaNo ratings yet

- FW F436 P PDFDocument2 pagesFW F436 P PDFLuis CarlosNo ratings yet

- Flat Washers, ASTM F436, Thru-Hardened, Plain: Page 1 of 2 REV-03 Date: November 17, 2015 FW.F436.PDocument2 pagesFlat Washers, ASTM F436, Thru-Hardened, Plain: Page 1 of 2 REV-03 Date: November 17, 2015 FW.F436.Pluis martinezNo ratings yet

- Flat Washers, ASTM F436, Thru-Hardened, Plain: Page 1 of 2 REV-03 Date: November 17, 2015 FW.F436.PDocument2 pagesFlat Washers, ASTM F436, Thru-Hardened, Plain: Page 1 of 2 REV-03 Date: November 17, 2015 FW.F436.PLuis CarlosNo ratings yet

- Flat Washers, ASTM F436, Thru-Hardened, Plain: Page 1 of 2 REV-03 Date: November 17, 2015 FW.F436.PDocument2 pagesFlat Washers, ASTM F436, Thru-Hardened, Plain: Page 1 of 2 REV-03 Date: November 17, 2015 FW.F436.PJ. Fabián MenaNo ratings yet

- FW F436 P PDFDocument2 pagesFW F436 P PDFLuis CarlosNo ratings yet

- Flat Washers, ASTM F436, Thru-Hardened, Plain: Page 1 of 2 REV-03 Date: November 17, 2015 FW.F436.PDocument2 pagesFlat Washers, ASTM F436, Thru-Hardened, Plain: Page 1 of 2 REV-03 Date: November 17, 2015 FW.F436.PJ. Fabián MenaNo ratings yet

- ASME B18.8.2: Pin Materials and Hardness Pin FinishesDocument2 pagesASME B18.8.2: Pin Materials and Hardness Pin FinishesIvan SmolejNo ratings yet

- Hoja Tecnica ASTM A449Document2 pagesHoja Tecnica ASTM A449fernandoraiasaNo ratings yet

- Experimental Setup - NewDocument9 pagesExperimental Setup - Newshoaib ahmedNo ratings yet

- Peer Bearings For Conveyor IndustryDocument2 pagesPeer Bearings For Conveyor Industrymaxx.blyumNo ratings yet

- BJ Model SV-5 Cement Retainer PDFDocument2 pagesBJ Model SV-5 Cement Retainer PDFmohammad teimuriNo ratings yet

- Twelve Point Flange Screws: Earnest Technical BulletinDocument1 pageTwelve Point Flange Screws: Earnest Technical Bulletinflasher_for_nokiaNo ratings yet

- Testing-Drill Screw SpecificationsDocument3 pagesTesting-Drill Screw SpecificationsJerry Huang100% (1)

- TD-4615 HRDocument8 pagesTD-4615 HRjosfwangNo ratings yet

- Viking Braidline Nylon: ContactDocument1 pageViking Braidline Nylon: Contactmehdi HKNo ratings yet

- Flat Washers, Low Carbon, SAE, Zinc: Page 1 of 1 REV-09 Date: July 18, 2017 FW - Lc.Sae.ZDocument1 pageFlat Washers, Low Carbon, SAE, Zinc: Page 1 of 1 REV-09 Date: July 18, 2017 FW - Lc.Sae.ZclintNo ratings yet

- Threaded Taper PinsDocument2 pagesThreaded Taper PinsEmmanuelNo ratings yet

- Hex Cap Screw Grade 8 May 4 2009Document5 pagesHex Cap Screw Grade 8 May 4 2009Chris MedeirosNo ratings yet

- PVC Fittings WebDocument80 pagesPVC Fittings WebRasmy NaamyNo ratings yet

- Fastenal Product Specification Sheet: 304 Stainless Steel Hex Cap ScrewsDocument5 pagesFastenal Product Specification Sheet: 304 Stainless Steel Hex Cap ScrewsChris MedeirosNo ratings yet

- Victaulic Refuse-to-Fuse Coupling For Plain End HDPE Pipe Style 905Document8 pagesVictaulic Refuse-to-Fuse Coupling For Plain End HDPE Pipe Style 905maycolvNo ratings yet

- Stage 1 Diffusion Master Worksheet: Disclaimer and InstructionsDocument6 pagesStage 1 Diffusion Master Worksheet: Disclaimer and InstructionsSpectre Spectre0% (1)

- Handbook - Calculations 10 PDFDocument1 pageHandbook - Calculations 10 PDFSmith SivaNo ratings yet

- Eaton 12v 540w Battery Brochure PA162003ENDocument2 pagesEaton 12v 540w Battery Brochure PA162003ENRafael AguileraNo ratings yet

- Racks and Pinions Gears, Drive Systems Manufacturers in IndiaDocument90 pagesRacks and Pinions Gears, Drive Systems Manufacturers in IndiaKrey MayerNo ratings yet

- Master Link A345Document1 pageMaster Link A345Hunnymijie NorNo ratings yet

- Dextra - Marine Tie RodsDocument6 pagesDextra - Marine Tie Rodspangalengan zaxNo ratings yet

- Standard Pipe Schedules and Sizes Chart Table Data - Engineers EdgeDocument6 pagesStandard Pipe Schedules and Sizes Chart Table Data - Engineers EdgeGVNo ratings yet

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- STS 12 2006 Operator ManualDocument97 pagesSTS 12 2006 Operator ManualMarceloGonçalvesNo ratings yet

- PrairieAdvanceEFMY10 GA5061430 R1.3 OpmDocument222 pagesPrairieAdvanceEFMY10 GA5061430 R1.3 OpmMarceloGonçalvesNo ratings yet

- MY13 Parts Manual: Prairie EcoDocument156 pagesMY13 Parts Manual: Prairie EcoMarceloGonçalvesNo ratings yet

- Gp-Pomadbl-2012 - Adblue Transfer UnitsDocument12 pagesGp-Pomadbl-2012 - Adblue Transfer UnitsMarceloGonçalvesNo ratings yet

- 2700 BDL Air 18Document51 pages2700 BDL Air 18MarceloGonçalvesNo ratings yet

- Special3000LMY10 GA5061415 PM PDFDocument155 pagesSpecial3000LMY10 GA5061415 PM PDFMarceloGonçalvesNo ratings yet

- Special3000LMY10 GA5061415 PM PDFDocument155 pagesSpecial3000LMY10 GA5061415 PM PDFMarceloGonçalvesNo ratings yet

- Split Lock Washer: Med Split LW Asme B 18.21.1Document1 pageSplit Lock Washer: Med Split LW Asme B 18.21.1MarceloGonçalvesNo ratings yet

- Bt-Pom00808 - Pegasus 4000-6000 PDFDocument175 pagesBt-Pom00808 - Pegasus 4000-6000 PDFMarceloGonçalvesNo ratings yet

- KTR - Cooling SystemDocument42 pagesKTR - Cooling SystemMarceloGonçalvesNo ratings yet

- IFI 100 Prevailing Torque LocknutsDocument7 pagesIFI 100 Prevailing Torque LocknutsMarceloGonçalvesNo ratings yet

- MICHELIN Agribib Row Crop UK PDFDocument2 pagesMICHELIN Agribib Row Crop UK PDFMarceloGonçalvesNo ratings yet

- MICHELIN SprayBib 2016Document5 pagesMICHELIN SprayBib 2016MarceloGonçalvesNo ratings yet

- Service Manual: Valeo TM08, TM13, TM15 & TM16 CompressorsDocument56 pagesService Manual: Valeo TM08, TM13, TM15 & TM16 CompressorsMarceloGonçalvesNo ratings yet

- LT36497 RevE - 0 PDFDocument133 pagesLT36497 RevE - 0 PDFMarceloGonçalvesNo ratings yet

- 520L0557 - General Gear Pumps and Motors - TI - 10-2003 - A PDFDocument76 pages520L0557 - General Gear Pumps and Motors - TI - 10-2003 - A PDFMarceloGonçalvesNo ratings yet

- 0012 - Manual de Uso e Instalação CFX-750 (Portugues) PDFDocument150 pages0012 - Manual de Uso e Instalação CFX-750 (Portugues) PDFMarceloGonçalves100% (1)

- Torque-Hub Planetary Final Drive 7000 Series Service Brakes: Manual WithDocument66 pagesTorque-Hub Planetary Final Drive 7000 Series Service Brakes: Manual WithMarceloGonçalves100% (1)

- 3300 Series Installation ManualDocument2 pages3300 Series Installation ManualMarceloGonçalvesNo ratings yet

- FiltersDocument28 pagesFiltersMarceloGonçalvesNo ratings yet

- Proven Performance - H1 Piston Pumps and Motors: Exceptional EfficiencyDocument8 pagesProven Performance - H1 Piston Pumps and Motors: Exceptional EfficiencyMarceloGonçalvesNo ratings yet

- Jan - POWER JET 2.650Document4 pagesJan - POWER JET 2.650MarceloGonçalves100% (2)

- ECE Handbook For GEASDocument4 pagesECE Handbook For GEASMariz-Elaine Noceja Rodriguez100% (1)

- Sodium Phosphate TribasicDocument2 pagesSodium Phosphate TribasicAbdul RafaeNo ratings yet

- Chloride Attack On ConcreteDocument12 pagesChloride Attack On Concretevikram kumarNo ratings yet

- Stable Solid Deodorant Product Grape Fruit1Document15 pagesStable Solid Deodorant Product Grape Fruit1sabunbeningNo ratings yet

- RefractometersDocument40 pagesRefractometersHarry AuliaNo ratings yet

- Chem NotesDocument40 pagesChem NotesFelicia LeNo ratings yet

- Symptoms: Cyanide Toxicity Is Often Associated With The Odor of Almonds On BreathDocument2 pagesSymptoms: Cyanide Toxicity Is Often Associated With The Odor of Almonds On BreathRyan PanNo ratings yet

- Eas DLP 6-16-2017Document1 pageEas DLP 6-16-2017Charline A. RadislaoNo ratings yet

- 04 - Paints and Pigments IndustryDocument17 pages04 - Paints and Pigments IndustryNaumanNo ratings yet

- Weathering Erosion InteractiveDocument47 pagesWeathering Erosion InteractiveSunny YadavNo ratings yet

- Types of CatalysisDocument14 pagesTypes of CatalysisEnamulHaque1100% (3)

- Eur. J. Org. Chem.2012, 6856-6860Document5 pagesEur. J. Org. Chem.2012, 6856-6860Thinh DangNo ratings yet

- Unit 2 Advanced Polymeric MaterialsDocument21 pagesUnit 2 Advanced Polymeric MaterialsAditya SalunkheNo ratings yet

- Chemistry Lecture Planner: Sno Chapter Name Topics No. of Lectures Total No of Date of Lecture Date of CompletionDocument7 pagesChemistry Lecture Planner: Sno Chapter Name Topics No. of Lectures Total No of Date of Lecture Date of CompletionLØST๛ PAINNo ratings yet

- A-Level Ap1 Paper 2Document13 pagesA-Level Ap1 Paper 2umerNo ratings yet

- Water Soluble MatterDocument9 pagesWater Soluble Matterdineshdesai100% (1)

- BIO121 Chapter 7 Releasing Chemical EnergyDocument45 pagesBIO121 Chapter 7 Releasing Chemical EnergyggttettanNo ratings yet

- A Case Study Failur of Cooling Tower Troubleshooting ModificationDocument12 pagesA Case Study Failur of Cooling Tower Troubleshooting ModificationMohamad Mostafa AhmedNo ratings yet

- Elaboration and Characterization of Co-Zn Sio PigmentsDocument4 pagesElaboration and Characterization of Co-Zn Sio PigmentslaklainNo ratings yet

- Chemistry LawDocument5 pagesChemistry LawShai Sta CatalinaNo ratings yet

- Case Study 101Document9 pagesCase Study 101AtlantislandNo ratings yet

- Instant Download Test Bank For Macroeconomics in Modules 4th Edition Paul Krugman Robin Wells PDF EbookDocument32 pagesInstant Download Test Bank For Macroeconomics in Modules 4th Edition Paul Krugman Robin Wells PDF Ebookjordangonzaleswqigpzmcst94% (17)

- 10 1002@ejoc 201900449Document9 pages10 1002@ejoc 201900449Md. Sohanur RahmanNo ratings yet

- Online-8-17020032 Lattice ParameterDocument4 pagesOnline-8-17020032 Lattice ParameterSatadal GhoraiNo ratings yet

- DNA Extraction and Quantitation For Forensic AnalystsDocument37 pagesDNA Extraction and Quantitation For Forensic AnalystsXama CortijoNo ratings yet

- UntitledDocument13 pagesUntitledUpagya AwasthiNo ratings yet

- The Durability of Cement-Treated Clay Granite Powder and Slag-Treated Clay Granite Powder Composites Under Seawater ExposureDocument1 pageThe Durability of Cement-Treated Clay Granite Powder and Slag-Treated Clay Granite Powder Composites Under Seawater ExposureJoyce Persie SilverNo ratings yet

- Hydrogen ProjectDocument8 pagesHydrogen Projectdont email meNo ratings yet

- Dielectric Constants Chart: How To Use This GuideDocument10 pagesDielectric Constants Chart: How To Use This GuideNitin MahajanNo ratings yet

- Advanced Level Problems: Q. No. 1 To 3 (3 Questions)Document78 pagesAdvanced Level Problems: Q. No. 1 To 3 (3 Questions)Saravanan BNo ratings yet