Professional Documents

Culture Documents

Evaporation Rates To Prevent Plastic Shrinkage Cracking 322 PDF

Evaporation Rates To Prevent Plastic Shrinkage Cracking 322 PDF

Uploaded by

AlyssonFloresSoaresOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Evaporation Rates To Prevent Plastic Shrinkage Cracking 322 PDF

Evaporation Rates To Prevent Plastic Shrinkage Cracking 322 PDF

Uploaded by

AlyssonFloresSoaresCopyright:

Available Formats

Estimating Evaporation

Rates to Prevent Plastic

Shrinkage Cracking

Q. The standard specifications I’m modifying for a

project require the contractor to take steps to prevent

plastic shrinkage cracking when the rate of evaporation

Ta = air temperature, °F (°C);

r = relative humidity in percent/100; and

V = wind velocity, mph (km/h).

exceeds 0.2 lb/ft2/h (1 kg/m2/h). How is the contractor Readily solved using commonly available calculators,

supposed to measure this? the equation provides results nearly identical to those

found using the nomograph—for the previous example,

A. Plastic shrinkage cracks occur when the surface of

the concrete dries rapidly and shrinks before it can

gain sufficient tensile strength to resist cracking. When

this equation predicts an evaporation rate of 0.24 lb/ft2/h

(1.15 kg/m2/h).

An additional tool, a free online computer program,5

ambient conditions and concrete temperatures combine not only calculates evaporation rates for given conditions,

to produce conditions that create a high evaporation but can vary one parameter at a time to determine

rate, the chances of the surface drying prematurely and conditions for an evaporation rate of 0.1 lb/ft2/h. For the

shrinkage cracks forming increases. Although most previous example, the program calculates an evaporation

people associate high evaporation rates with hot, dry rate of 0.24 lb/ft2/h.

weather, it’s important to note that placing hot concrete It’s important to obtain the data used to calculate

on a cold, dry day can actually create a much worse evaporation rates properly. An average wind speed (not

condition. the maximum gust speed) should be used, and it should

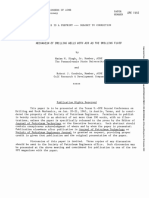

The nomograph shown in Fig. 1 is a commonly used be measured at an elevation about 20 in. (0.5 m) above

method to estimate evaporation rates. This nomograph the surface of the concrete. Reported wind speeds from

was first published by the National Ready Mixed Con- weather stations and airports are typically measured at

crete Association in 19601 and is included in References 2 an elevation of 33 ft (10 m) above grade. Wind speed

and 3 as well as several other publications related increases with height above grade (the wind speed at

to concrete construction. In this nomograph, the rate of 20 in. [0.5 m] above grade will only be about 2/3 of the

evaporation is estimated by following the four steps wind speed at 33 ft [10 m] above grade4). Because

listed on the left side of the chart. The arrows demon- reported wind speeds also will not include the effects

strate an example for a day where the ambient air of local terrain and surrounding obstructions, these

temperature is 80 °F (27 °C), the relative humidity is 50%, reported wind speeds should not be used in the chart.

the concrete temperature is 87 °F (31 °C), and the wind The relative humidity and air temperature should be

velocity is 12 mph (19 km/h). The resulting rate of measured in the shade, upwind of the placement, and 4 to

evaporation is about 0.25 lb/ft2/h (1.2 kg/m2/h). 6 ft (1.2 to 1.8 m) above the concrete surface. Hand-held,

The following equation from a 1998 ACI Materials electronic weather stations are now available and cost

Journal paper4 is also used to predict evaporation rates less than $250. These devices make it much easier to

obtain site-specific air temperature, relative humidity,

E = (Tc2.5 – rTa2.5)(1 + 0.4V ) × 10–6 (in.-lb units) and wind velocity data.

One important variable—concrete bleeding rate—is

E = 5([Tc – 18]2.5 – r[Ta + 18]2.5)(V + 4) × 10–6 (SI units) not included in the nomograph but affects the probability

of plastic shrinkage cracking.3 If the concrete has a lower

where bleeding rate, the evaporation rate needed to prematurely

E = evaporation rate, lb/ft2/h (kg/m2/h); dry the concrete surface will be reduced. High amounts

Tc = concrete temperature, °F (°C); of fine material (such as cement, silica fume, or fly ash)

80 MArch 2007 / Concrete international

Fig. 1: Nomograph for estimating the rate of evaporation of water from a concrete surface. The arrows demonstrate an example for a

day where the ambient air temperature is 80 °F (27 °C), the relative humidity is 50%, the concrete temperature is 87 °F (31 °C), and

the wind velocity is 12 mph (19 km/h). The resulting rate of evaporation is about 0.25 lb/ft2/h (1.2 kg/m2/h) (Figure courtesy of Portland

Cement Association)2

Concrete international / march 2007 81

Questions in this column were asked by users of ACI documents and have been answered

by ACI staff or by a member or members of ACI technical committees. The answers do

not represent the official position of an ACI committee. Only a published committee

document represents the formal consensus of the committee and the Institute.

We invite comment on any of the questions and answers published in this column. Write

to the Editor, Concrete International, 38800 Country Club Drive, Farmington Hills, MI

48331; contact us by fax at (248) 848-3701; or e-mail Rex.Donahey@concrete.org.

in the concrete decrease bleeding rate and increase References

susceptibility to plastic shrinkage cracking. Although 1. Bloem, D., “Plastic Cracking of Concrete,” Engineering Information,

synthetic fibers also tend to reduce bleeding, they have National Ready Mixed Concrete Association/National Sand and Gravel

become popular for use in concrete flatwork for control Association, July 1960, 2 pp.

of plastic shrinkage cracking.6 Conditions that cause high 2. Kosmatka, S.H.; Kerkhoff, B.; and Panarese, W.C., Design and

evaporation rates can make it difficult to judge the proper Control of Concrete Mixtures, Engineering Bulletin 001, 14th Edition,

time to start finishing high-fines concretes because the Portland Cement Association, Skokie, IL, 2002, p. 236.

dry surface suggests that finishing can begin before all 3. ACI Committee 305, “Hot Weather Concreting (ACI 305R-99),”

of the bleed water has come to the surface. When the American Concrete Institute, Farmington Hills, MI, 1999, 20 pp.

surface is finished before all of the bleed water has 4. Uno, P.J., “Plastic Shrinkage Cracking and Evaporation Formulas,”

evaporated, a plane of weakness can form near the ACI Materials Journal, V. 95, No. 4, July-Aug. 1998, pp. 365-375.

surface and decrease durability. When high-fines 5. Snell, L., and Munir, A., “Evaluating Concrete Curing

concretes are exposed to conditions causing high Conditions,” http://construction.asu.edu/cim/curing/

curingfirstpage.htm.

evaporation rates, initial curing procedures discussed

6. ACI Committee 544, “Report on Fiber Reinforced Concrete (ACI

in ACI 308R-01, “Guide to Curing Concrete,”7 may be

544.1R-96),” American Concrete Institute, Farmington Hills, MI, 1996,

necessary before the start of finishing operations.

66 pp.

Because the nomograph produces an estimate of the

7. ACI Committee 308, “Guide to Curing Concrete (ACI 308R-01),”

evaporation rate, and the bleeding rate of various concrete

American Concrete Institute, Farmington Hills, MI, 2001, 31 pp.

mixtures can vary significantly, it’s best to view evaporation

rates as an indicator of how quickly initial curing procedures Thanks to Luke Snell at Arizona State University and Khishgee

will have to be started, rather than as a hard limit for the Radnaabazar at Mongolian University of Science and Technology for

initiation of plastic shrinkage cracking. reviewing the answer to this question.

Visit the new

ACI MEMBERSHIP DIRECTORY

www.concrete.org

click on “Membership”

4 Quickly and easily obtain detailed contact

information for other ACI members (members only)

4 Conduct detailed searches by job category for

ACI’s corporate members

4 Local, regional, and international listings

4 Open to the public (limited access) for business-

development opportunities

Connecting and networking with ACI members has

never been easier. The new ACI MEMBERSHIP

DIRECTORY is one of six new benefits available to all

ACI members; visit www.concrete.org or call 248-848-3800 to learn what else is new!

Verify your listing—Only ACI members can be listed in this directory—to opt out or modify

your listing, simply login to www.concrete.org and click on “My Contact Information” or call

248-848-3800 if you have questions. ACI’s Organizational and Sustaining Members receive

detailed corporate listings; ACI’s Student, Junior, and Individual Members receive personal listings.

82 MArch 2007 / Concrete international

You might also like

- CT-631. Design Calculation Sheet. Rev.0 PDFDocument101 pagesCT-631. Design Calculation Sheet. Rev.0 PDFErnest Navarro100% (1)

- Hydraulic Fracturing Explained: Evaluation, Implementation, and ChallengesFrom EverandHydraulic Fracturing Explained: Evaluation, Implementation, and ChallengesNo ratings yet

- CT-631. Design Calculation Sheet. Rev.01 PDFDocument136 pagesCT-631. Design Calculation Sheet. Rev.01 PDFErnest Navarro100% (1)

- Guide For The Preparation of Concrete Surfaces For Repair Using Hydrodemolition MethodsDocument80 pagesGuide For The Preparation of Concrete Surfaces For Repair Using Hydrodemolition MethodschabaloonNo ratings yet

- Structural Design Calculation Sheet For Aluminum PergolaDocument58 pagesStructural Design Calculation Sheet For Aluminum PergolaErnest Navarro100% (2)

- Villa Calculation Sheet - Rev0Document44 pagesVilla Calculation Sheet - Rev0Ernest NavarroNo ratings yet

- Parameters:: 32.0 Mpa 460.0 Mpa 3000.0 MM 300.0 MM 502.0 MM 2700.0 KN-M 450.0 KN 30 MMDocument6 pagesParameters:: 32.0 Mpa 460.0 Mpa 3000.0 MM 300.0 MM 502.0 MM 2700.0 KN-M 450.0 KN 30 MMErnest NavarroNo ratings yet

- Technocast Precast L.L.C.: Design Calculation SheetDocument5 pagesTechnocast Precast L.L.C.: Design Calculation SheetErnest NavarroNo ratings yet

- Asi09-048 Site Investigation Report PDFDocument68 pagesAsi09-048 Site Investigation Report PDFErnest NavarroNo ratings yet

- Mechanisms of Air Entrainment in ConcreteDocument9 pagesMechanisms of Air Entrainment in Concretecarjamu100% (1)

- Soil Investigation Report PDFDocument174 pagesSoil Investigation Report PDFErnest NavarroNo ratings yet

- Understanding The Pumpability of ConcreteDocument14 pagesUnderstanding The Pumpability of Concretecesarale100% (1)

- Reduce FoulingDocument6 pagesReduce FoulingJeEJyZaNo ratings yet

- Fouling Mitigation by DesignDocument6 pagesFouling Mitigation by DesignJoseAndresCarreñoNo ratings yet

- The Causes and Prevention of Pipeline Failures (Metallurgical Consultants) PDFDocument24 pagesThe Causes and Prevention of Pipeline Failures (Metallurgical Consultants) PDFscofiel1100% (1)

- Plastic ShrinkageDocument4 pagesPlastic ShrinkageukshettyNo ratings yet

- Concrete Q&ADocument3 pagesConcrete Q&AJoseph AsfourNo ratings yet

- Plastic Shrinkage CracksDocument7 pagesPlastic Shrinkage CracksvkmsNo ratings yet

- Cracking Risks Associated With Early Age Shrinkage: E. Holt, M. LeivoDocument10 pagesCracking Risks Associated With Early Age Shrinkage: E. Holt, M. LeivoratnasaiNo ratings yet

- 7 International Conference On Concrete Pavements - Orlando, Florida, USA - September 9-13, 2001Document13 pages7 International Conference On Concrete Pavements - Orlando, Florida, USA - September 9-13, 2001nanga1970No ratings yet

- A Review of Hot Climate Concreting and The ApproprDocument11 pagesA Review of Hot Climate Concreting and The Approprdr_masamaraNo ratings yet

- A Review of Hot Climate Concreting and The ApproprDocument11 pagesA Review of Hot Climate Concreting and The ApproprYouness FarezNo ratings yet

- Part3 Chapter1 SubdrainageDocument32 pagesPart3 Chapter1 Subdrainageerika guerreroNo ratings yet

- 3 - Investigation of The Significance of Factors Affecting Long-Term Creep of Concrete Using Screening Designs (ICAMC 2019)Document9 pages3 - Investigation of The Significance of Factors Affecting Long-Term Creep of Concrete Using Screening Designs (ICAMC 2019)Sara HassounNo ratings yet

- Crude Oil Pipeline Scale Deposition Causes and Removal MethodsDocument6 pagesCrude Oil Pipeline Scale Deposition Causes and Removal MethodstomNo ratings yet

- Control of Air Content in Concrete: Portland Cement AssociationDocument8 pagesControl of Air Content in Concrete: Portland Cement AssociationBhupesh MulikNo ratings yet

- Aircraft Engine Bleed System Tubes - Material and Failure Mode AnalysisDocument13 pagesAircraft Engine Bleed System Tubes - Material and Failure Mode Analysisstuart smythNo ratings yet

- Erosion in Long-Radius Elbows and Straight PipesDocument3 pagesErosion in Long-Radius Elbows and Straight PipesPedro MarquezNo ratings yet

- Conferinta C60 - Geobrugg - Comparatie CO2 SCURTDocument4 pagesConferinta C60 - Geobrugg - Comparatie CO2 SCURTDvmLemNo ratings yet

- Drilling Fluid LifecycleDocument17 pagesDrilling Fluid LifecycleMehrez AssidyNo ratings yet

- Casting v2Document13 pagesCasting v2keya2020No ratings yet

- Nano Coating Application For Corrosion Reduction in Oil and Gas Transmission Pipe: A Case Study in South of IranDocument7 pagesNano Coating Application For Corrosion Reduction in Oil and Gas Transmission Pipe: A Case Study in South of IranInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Spring 95Document3 pagesSpring 95Minhquang NgoNo ratings yet

- Avalia Modelos de ErosaoDocument17 pagesAvalia Modelos de ErosaoJoão Guilherme CyrilloNo ratings yet

- PTC 2017 AchterkampDocument12 pagesPTC 2017 AchterkampBoulHich BoulHichNo ratings yet

- Evaluation of Environmental Requirements For Sustainable Ready-Mix Concrete Production in Abu Dhabi EmirateDocument7 pagesEvaluation of Environmental Requirements For Sustainable Ready-Mix Concrete Production in Abu Dhabi EmirateeorenusNo ratings yet

- Crude Oil Pipeline Scale Deposition: Causes and Removal MethodsDocument5 pagesCrude Oil Pipeline Scale Deposition: Causes and Removal MethodsfarzadsadeghzadNo ratings yet

- Concretes With High Fly Ash Content: Jorge Tito Adolfo Aranzales Michelle ChatmanDocument7 pagesConcretes With High Fly Ash Content: Jorge Tito Adolfo Aranzales Michelle ChatmanAsad AbbasNo ratings yet

- Application of Different Fibers To Reduce Plastic Shrinkage Cracking of ConcreteDocument8 pagesApplication of Different Fibers To Reduce Plastic Shrinkage Cracking of ConcreteMehdi BakhshiNo ratings yet

- Spe 1052 MsDocument31 pagesSpe 1052 MsSi BotakNo ratings yet

- Case Studies in Construction Materials: S. Talukdar, R. HeereDocument6 pagesCase Studies in Construction Materials: S. Talukdar, R. HeereAmin ZuraiqiNo ratings yet

- Air Impacts of Increased Natural Gas Acquisition, Processing, and Use: A Critical ReviewDocument11 pagesAir Impacts of Increased Natural Gas Acquisition, Processing, and Use: A Critical ReviewMonica Jaimes PalomeraNo ratings yet

- Environmental Aspect of Concrete: Problems and Solutions: January 2001Document15 pagesEnvironmental Aspect of Concrete: Problems and Solutions: January 2001heri supraptoNo ratings yet

- Fulltext01 PDFDocument6 pagesFulltext01 PDFCatnis TomNo ratings yet

- Admixture in Concrete in The Machanism Research: Chemical EngineeringDocument6 pagesAdmixture in Concrete in The Machanism Research: Chemical EngineeringBely MobaNo ratings yet

- S S E B E: Life Cycle Assessment of Pre-Cast Concrete vs. Cast-In-Place ConcreteDocument18 pagesS S E B E: Life Cycle Assessment of Pre-Cast Concrete vs. Cast-In-Place ConcreteN.a. M. TandayagNo ratings yet

- No27 Effect of Slag Cement On Shrinkage in ConcreteDocument2 pagesNo27 Effect of Slag Cement On Shrinkage in Concretetzeliang_lNo ratings yet

- Temperature - 1Document2 pagesTemperature - 1ksshashidharNo ratings yet

- Aeration System in WWTPDocument10 pagesAeration System in WWTPashokNo ratings yet

- Bubble Free Resin For Infusion ProcessDocument8 pagesBubble Free Resin For Infusion ProcessVenkat GiriNo ratings yet

- FDOT BB978 RPTDocument14 pagesFDOT BB978 RPTirfanquadriNo ratings yet

- UNO P.J. Plastic Shrinkage Cracking +evaporation Formulas ACI-1998 Vol95-M34Document12 pagesUNO P.J. Plastic Shrinkage Cracking +evaporation Formulas ACI-1998 Vol95-M34Olesea NesterencoNo ratings yet

- Meira CCCDocument10 pagesMeira CCCpadilhajrNo ratings yet

- Air Entrainment and ConcreteDocument6 pagesAir Entrainment and Concretemanish_shashikantNo ratings yet

- Cement and Concrete Standards ResearchDocument4 pagesCement and Concrete Standards ResearchHilary WatsonNo ratings yet

- Comparison of Cost and Environmental Impact of Concrete and Asphalt RoadsDocument9 pagesComparison of Cost and Environmental Impact of Concrete and Asphalt RoadsZuri GarricksNo ratings yet

- Environmental Impacts of Recycled Rubber in Light - Fill AplicationsDocument20 pagesEnvironmental Impacts of Recycled Rubber in Light - Fill AplicationsVictor Hugo Parra ArrayaNo ratings yet

- Plastic Limit ReportDocument12 pagesPlastic Limit ReportEiyra NadiaNo ratings yet

- Three Equations Method For Normal Concrete Mix DesignDocument5 pagesThree Equations Method For Normal Concrete Mix DesignSEP-PublisherNo ratings yet

- Lu 2021Document26 pagesLu 2021seanpaustineNo ratings yet

- Driving Rain Loads For Canadian Building DesignDocument58 pagesDriving Rain Loads For Canadian Building DesignJohn Straube100% (1)

- Asphalt DiseasesDocument9 pagesAsphalt DiseasesAzhar MohamedNo ratings yet

- What Is Green Concrete PDFDocument3 pagesWhat Is Green Concrete PDFVelchuri SairamNo ratings yet

- Thermal Segregation of Asphalt M 2017 Journal of Traffic and TransportationDocument12 pagesThermal Segregation of Asphalt M 2017 Journal of Traffic and Transportationabrham basaNo ratings yet

- Irc 061-1976Document13 pagesIrc 061-1976harivennelaNo ratings yet

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsFrom EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNo ratings yet

- Shop Drawing Submittal: Project: Project No. Client: Consultant: Contractor: 20-373-DS-ARC-PE-21Document129 pagesShop Drawing Submittal: Project: Project No. Client: Consultant: Contractor: 20-373-DS-ARC-PE-21Ernest NavarroNo ratings yet

- Scanned 160201153438 PDFDocument41 pagesScanned 160201153438 PDFUsmanRandhawa31No ratings yet

- 5 - Moment-Area MethodDocument103 pages5 - Moment-Area MethodAkela Richard100% (1)

- Groutec Data Sheet PDFDocument24 pagesGroutec Data Sheet PDFErnest NavarroNo ratings yet

- Masonry Blocks: ProductsDocument5 pagesMasonry Blocks: ProductsErnest NavarroNo ratings yet

- Partial Fixity in ETABSDocument3 pagesPartial Fixity in ETABSErnest NavarroNo ratings yet

- Menaa M-03 4110-002R4 (Main Stadium-Sectors A&B Precast Structural Calculations - Rev4) 2012 - 1012 PDFDocument176 pagesMenaa M-03 4110-002R4 (Main Stadium-Sectors A&B Precast Structural Calculations - Rev4) 2012 - 1012 PDFErnest NavarroNo ratings yet

- Aci318m-11code Requirements For Beams Under Combined Shear and TorsionDocument11 pagesAci318m-11code Requirements For Beams Under Combined Shear and TorsionErnest NavarroNo ratings yet

- Loadbearing Architectural PrecastDocument24 pagesLoadbearing Architectural PrecastErnest NavarroNo ratings yet