Professional Documents

Culture Documents

Certificate of Conformance: Q1 Lot Number: 15163483

Uploaded by

interx00Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Certificate of Conformance: Q1 Lot Number: 15163483

Uploaded by

interx00Copyright:

Available Formats

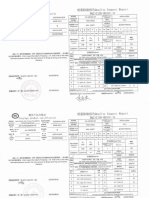

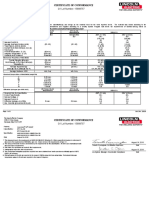

The Lincoln Electric Company

22801 St. Clair Avenue CERTIFICATE OF CONFORMANCE

Cleveland, Ohio 44117-1199

Q1 Lot Number: 15163483

Product: Fleetweld® 5P+

Classification: E6010

Specification: AWS A5.1:2012, ASME SFA-5.1

Date June 30, 2016

This is to certify that the product named above is of the same classification(s) and design as the material used for the tests reported herein. The

material was tested according to the specification(s) indicated and met all requirements. It was manufactured and supplied according to a Quality

System Program that meets the requirements of ISO9001 among others as documented on The Lincoln Electric web page

(http://www.lincolnelectric.com/en-us/company/Pages/certifications.aspx).

E6010

Operating Settings Requirements RESULTS

Electrode Size 1 5/321inch 3/162inch

Current Type/Polarity DC+ DC+ DC+

Nominal Voltage, V 25 26

Nominal Current, A 140 170

Average Heat Input, kJ/mm (kJ/in) 2.1 (53) 2.5 (63)

Pass/Layers 18/9 16/8

Preheat Temperature, °C (°F) (225 min.) 105 (225) 105 (225)

Interpass Temperature, °C (°F) (225 - 350) 150 (300) 150 (300)

Postweld Heat Treatment As-welded As-welded As-welded

Mechanical properties of weld deposits

Tensile Strength, MPa (ksi) (60 min.) 550 (79) 490 (71)

Yield Strength, 0.2% Offset, MPa (ksi) (48 min.) 440 (64) 390 (57)

Elongation % 22 min. 28 29

Average Impact Energy (20 min.) 89 (66) 93 (69)

Joules @ -29 °C (ft-lbs @ -20 °F) 84,91,93 (62,67,68) 84,96,100 (62,71,73)

Average Hardness, HRB Info. Only 88 82

Chemical composition of weld deposits (weight %)

C 0.20 max. 0.13 0.13

Mn 1.20 max. 0.66 0.52

Si 1.00 max. 0.25 0.15

S Not Specified 0.007 0.005

P Not Specified 0.009 0.009

Cr 0.20 max. 0.03 0.03

Ni 0.30 max. 0.04 0.04

Mo 0.30 max. 0.01 0.01

V 0.08 max. 0.01 0.00

Mn+Ni+Cr+Mo+V Not Specified 0.74 0.60

1. The electrode sizes required to be tested for this classification are 5/32 inch and 3/16 inch. All other sizes manufactured will also meet these

requirements.

2. Fillet Weld Test (positions as required): Met requirements.

3. Radiographic Inspection: Grade 2 - Met requirements.

4. The strength and elongation properties reported here were obtained from tensile specimens artificially aged at 105°C (220°F) for 48 hours.

5. Strength values in SI units are reported to the nearest 10 MPa converted from actual data. Preheat and interpass temperature values in SI units are

reported to the nearest 5 degrees.

June 30, 2016 June 30, 2016

Toronto Cunningham, Certification Date Marie Quintana, Director, Consumable Date

Supervisor Compliance

Page 1 of 1 Cert. No. 30055

You might also like

- Your UNIX Linux The Ultimate Guide 3rd Edition by Sumitabha Solution ManualDocument1 pageYour UNIX Linux The Ultimate Guide 3rd Edition by Sumitabha Solution ManualAasif Wani0% (1)

- Supplier Web Share Downloads CQI-15 Welding System AssessmentDocument50 pagesSupplier Web Share Downloads CQI-15 Welding System AssessmentMostafa Abd El Alem83% (6)

- Quality Requirements for Suppliers (QRSDocument160 pagesQuality Requirements for Suppliers (QRSJairo E. V RNo ratings yet

- AdvancesDocument20 pagesAdvancesZeeshan MohamedNo ratings yet

- TL 256 en 2022Document8 pagesTL 256 en 2022Michal BílekNo ratings yet

- DrillMaster ISO 9001 - 2000 Hydraulic Hose and FittingsDocument1 pageDrillMaster ISO 9001 - 2000 Hydraulic Hose and FittingsmarcotplNo ratings yet

- S690ql ThyssenkruppDocument7 pagesS690ql ThyssenkruppSivabalan100% (1)

- Instrument TransformersDocument47 pagesInstrument TransformersabwarisNo ratings yet

- Hopper Cars 3250Document1 pageHopper Cars 3250ikkimvpNo ratings yet

- 52812-FiatDocument10 pages52812-FiatAndres SuarezNo ratings yet

- MS 50002-2019Document42 pagesMS 50002-2019bruno.abuaf100% (1)

- Mpaps G-20Document6 pagesMpaps G-20PANKAJ CHAUHANNo ratings yet

- Hydrogen Embrittlement Relief Process StandardDocument10 pagesHydrogen Embrittlement Relief Process StandardFeliceNo ratings yet

- Daido SUS PDFDocument1 pageDaido SUS PDFKetnipha SukwannawitNo ratings yet

- A 48 Gray Iron CastingsDocument5 pagesA 48 Gray Iron Castingswasatiah05No ratings yet

- WPS GTAW-SMAW h1Document1 pageWPS GTAW-SMAW h1Jesus Gabrielw Blanco GhostbustersIzNo ratings yet

- Stock Specifications - Plates - S355G10 MDocument2 pagesStock Specifications - Plates - S355G10 Macadjournals. comNo ratings yet

- Cqi 15Document1 pageCqi 15JanNo ratings yet

- FCA - PS.50009 (2014) - Ex PS.5570Document7 pagesFCA - PS.50009 (2014) - Ex PS.5570FeliceNo ratings yet

- Sae J82-2013Document6 pagesSae J82-2013Marcos RosenbergNo ratings yet

- BK91 1328 01 FSF 000 PIP RFI 0070 Pipe Fitting AttachmentDocument67 pagesBK91 1328 01 FSF 000 PIP RFI 0070 Pipe Fitting AttachmentPanneer SelvamNo ratings yet

- Painting Instructions For Domestic Projects: Document No. 70008187Document7 pagesPainting Instructions For Domestic Projects: Document No. 70008187Baskaran BossNo ratings yet

- AÇOS VILLARES VF800-AT - InglesDocument2 pagesAÇOS VILLARES VF800-AT - InglesAmy Griffin100% (1)

- GPS1 enDocument5 pagesGPS1 enKlocNo ratings yet

- Sheet Steel For Cold Forming Component Design SpecificationsDocument13 pagesSheet Steel For Cold Forming Component Design SpecificationsHuahua ChuengNo ratings yet

- MacGregor Welding Systems Operation Manual - m3 - DC2003PDocument78 pagesMacGregor Welding Systems Operation Manual - m3 - DC2003PBernie Wire100% (2)

- Baosteel hot rolled steel plate quality certificateDocument3 pagesBaosteel hot rolled steel plate quality certificateDang TranNo ratings yet

- Manual Bios Intel Dp35dpDocument32 pagesManual Bios Intel Dp35dpMarcelo CheloNo ratings yet

- Mazda Engineering Standard: Teruhisa MorishigeDocument10 pagesMazda Engineering Standard: Teruhisa Morishigemohammad yazdanpanahNo ratings yet

- SAE-J423: Distribution Statement ADocument9 pagesSAE-J423: Distribution Statement Ayorf1989No ratings yet

- Luoyang Jiecheng Bearing Technology Co., LTD: PrefixesDocument5 pagesLuoyang Jiecheng Bearing Technology Co., LTD: PrefixesAnand ChinnakrishnanNo ratings yet

- Material de Inspección VisualDocument27 pagesMaterial de Inspección VisualGuillermo BarragánNo ratings yet

- A560 - Castings Chromium Nickel AlloyDocument3 pagesA560 - Castings Chromium Nickel AlloychemtausifNo ratings yet

- GUIA DE MATERIALES ACERODocument11 pagesGUIA DE MATERIALES ACEROGracielaNo ratings yet

- WPS - 2Document3 pagesWPS - 2aleventNo ratings yet

- CS-11000Document17 pagesCS-11000Engenharia APedro100% (1)

- Ss Grade 50 - Galvanized Steel Coils & SheetsDocument1 pageSs Grade 50 - Galvanized Steel Coils & SheetshealgoseNo ratings yet

- Metacut 302Document6 pagesMetacut 302Representaciones y Distribuciones FALNo ratings yet

- Brinell Scale HBW 10/3000 ChartDocument1 pageBrinell Scale HBW 10/3000 ChartMark BrailsfordNo ratings yet

- Jfe Cold Rolled Steel SheetDocument26 pagesJfe Cold Rolled Steel SheetaayopercivalNo ratings yet

- PPAP Performance Test ResultsDocument1 pagePPAP Performance Test ResultsPraveen MalavaeNo ratings yet

- DU Sliding Material SpecificationsDocument55 pagesDU Sliding Material SpecificationsMichał AmborNo ratings yet

- ASTM B881 17 Standard Terminology Relating To Aluminum and Magnesium Alloy ProductsDocument7 pagesASTM B881 17 Standard Terminology Relating To Aluminum and Magnesium Alloy Products오덕환Oh DuckhwanNo ratings yet

- Global Logistics Directive Version 20184 English - 20200626 PDFDocument27 pagesGlobal Logistics Directive Version 20184 English - 20200626 PDFMarek DurinaNo ratings yet

- CELCON CE66FC - Unfilled: Celanese Engineered Materials Product Data DatasheetDocument2 pagesCELCON CE66FC - Unfilled: Celanese Engineered Materials Product Data DatasheetNguyễn Hồng NamNo ratings yet

- Chemical Composition: LM6 LM4Document2 pagesChemical Composition: LM6 LM4SiDdu KalashettiNo ratings yet

- SABRE Edition 2Document40 pagesSABRE Edition 2edgarNo ratings yet

- Dri Loc 218 Data SheetDocument2 pagesDri Loc 218 Data Sheetpalani.djpNo ratings yet

- Wall Chart SEDEX Filters EngDocument1 pageWall Chart SEDEX Filters EngGermano BissonNo ratings yet

- De 82004 0005 BR enDocument108 pagesDe 82004 0005 BR enAndor Tony CiguNo ratings yet

- Din 2393-2Document0 pagesDin 2393-2Yalavarthi ChandrasekharNo ratings yet

- dpvc-09 Petrobras PDFDocument47 pagesdpvc-09 Petrobras PDFBilly TanNo ratings yet

- FW F436 P PDFDocument2 pagesFW F436 P PDFLuis CarlosNo ratings yet

- xDIN ISO 34804-2002.10-ENDocument5 pagesxDIN ISO 34804-2002.10-ENAustine ChrisNo ratings yet

- A514 Grade S Brochure 06-25-08Document2 pagesA514 Grade S Brochure 06-25-08anjangandak2932No ratings yet

- Vermont Gage CatalogDocument120 pagesVermont Gage CatalogRobert RothNo ratings yet

- Q1 Lot Number: 14997588: Certificate of ConformanceDocument3 pagesQ1 Lot Number: 14997588: Certificate of ConformanceOscar BasantesNo ratings yet

- Excalibur 11018M MR CertDocument2 pagesExcalibur 11018M MR CertAminNo ratings yet

- Q1Display 15843280Document3 pagesQ1Display 15843280Oscar BasantesNo ratings yet

- Lincoln (Data Sheet) Murex E7024Document2 pagesLincoln (Data Sheet) Murex E7024PubcrawlNo ratings yet

- Q1 Lot Number: 15888757: Certificate of ConformanceDocument2 pagesQ1 Lot Number: 15888757: Certificate of ConformanceDesdeAquiHastaAllaNo ratings yet

- CertMaterialTestReport E6010 Fletweld SP 1-8Document1 pageCertMaterialTestReport E6010 Fletweld SP 1-8gerosuca800No ratings yet

- NuevoDocumento 2019-03-19 11.59.22Document1 pageNuevoDocumento 2019-03-19 11.59.22interx00No ratings yet

- Present Perfect Tense Conjugation With Time ExpressionsDocument8 pagesPresent Perfect Tense Conjugation With Time Expressionsinterx00No ratings yet

- Fast Ways Webinar Can Grow Your Business PDFDocument16 pagesFast Ways Webinar Can Grow Your Business PDFGodfrey Jos DE LA CruzNo ratings yet

- Plot Plan B43Document1 pagePlot Plan B43interx00No ratings yet

- Piping Class B31Document142 pagesPiping Class B31interx00No ratings yet

- Piping Spec Book 1Document259 pagesPiping Spec Book 1interx00No ratings yet

- Cédula y Diámetro EquivalenteDocument9 pagesCédula y Diámetro Equivalenteinterx00No ratings yet

- Star Wars - Star WarsDocument36 pagesStar Wars - Star Warsinterx00No ratings yet

- Base de Combustible Iisapetrol 2017Document33 pagesBase de Combustible Iisapetrol 2017interx00No ratings yet

- Grundfos: 1"#., Informe Técnico 1"#.Document21 pagesGrundfos: 1"#., Informe Técnico 1"#.Cristobal CamposNo ratings yet

- Create Your Re - PocketModDocument1 pageCreate Your Re - PocketModinterx00No ratings yet

- Introduction To Subsea SystemsDocument56 pagesIntroduction To Subsea SystemsadventourerNo ratings yet

- Mud Logger Training Manual PDFDocument4 pagesMud Logger Training Manual PDFAnonymous oe5mdI0% (1)

- Equations of RetailDocument12 pagesEquations of RetailMichael Ross100% (1)

- CD4071BC - CD4081BCDocument8 pagesCD4071BC - CD4081BCGustavo ZuñigaNo ratings yet

- Rize Build June 2ND WeekDocument8 pagesRize Build June 2ND WeekAbhishek RajputNo ratings yet

- C++ Arrays - TutorialspointDocument3 pagesC++ Arrays - TutorialspointevilplueNo ratings yet

- Adaptive Active Phased - Array 'Multifunction' Radars Seminar Report 03Document21 pagesAdaptive Active Phased - Array 'Multifunction' Radars Seminar Report 03praveenpv7No ratings yet

- Coax 2014Document340 pagesCoax 2014TrầnTuấnViệtNo ratings yet

- Reparatii DrujbaDocument279 pagesReparatii Drujbaest_nuNo ratings yet

- Dry BlockDocument2 pagesDry BlockSheik SulthanNo ratings yet

- VRX932LAExplodedViewDocument4 pagesVRX932LAExplodedViewHumberto ChaconNo ratings yet

- Establishment ManualDocument370 pagesEstablishment ManualYaasir AliNo ratings yet

- ULN200x, ULQ200x High-Voltage, High-Current Darlington Transistor ArraysDocument39 pagesULN200x, ULQ200x High-Voltage, High-Current Darlington Transistor ArraysRadoNo ratings yet

- Samsung PN51F5500 Calibration ReportDocument2 pagesSamsung PN51F5500 Calibration Reportty_at_cnetNo ratings yet

- New Features For INSITE 8.1.0: 1. Installation and Compatibility A. Upgrade CapabilityDocument6 pagesNew Features For INSITE 8.1.0: 1. Installation and Compatibility A. Upgrade CapabilityMisael CaffarelNo ratings yet

- Video Porteiro UrmetDocument2 pagesVideo Porteiro Urmettony0078No ratings yet

- ANSWERDocument1 pageANSWERengr valderrama adrianNo ratings yet

- HSBCDocument21 pagesHSBCHarsha SanapNo ratings yet

- Kidde FM200Document116 pagesKidde FM200amechmar593583% (6)

- MB ResetDocument2 pagesMB ResetGIRISH PATELNo ratings yet

- Aung Ye Htun3409894643578177227Document3 pagesAung Ye Htun3409894643578177227Aungye HtunNo ratings yet

- Chat FAQ'sDocument1 pageChat FAQ'sShelly BarrettNo ratings yet

- MODEL PC-171 - Transformer Temperature IndicatorDocument6 pagesMODEL PC-171 - Transformer Temperature IndicatorMKNo ratings yet

- Plan Budget Healthcare PDFDocument299 pagesPlan Budget Healthcare PDFAboubacar Sompare100% (1)

- Open Source Frequency Counter DIY Kit 10Hz-250MHzDocument10 pagesOpen Source Frequency Counter DIY Kit 10Hz-250MHzBruno Santos de Miranda100% (1)

- Advanced Technologies in Reciprocating Compressor PDFDocument211 pagesAdvanced Technologies in Reciprocating Compressor PDFziza20 Ziza100% (1)

- ERP Training ProcessDocument28 pagesERP Training Processritesh_gandhi_7100% (1)