Professional Documents

Culture Documents

MR35-50 Brochure PDF

MR35-50 Brochure PDF

Uploaded by

Xanti Zabala Da RosaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MR35-50 Brochure PDF

MR35-50 Brochure PDF

Uploaded by

Xanti Zabala Da RosaCopyright:

Available Formats

Flexible motion “Arm” robot with 7-axes

MR35/50

MR35

MR50

100

200

300

400

500

600

700

可搬質量(kg)

7-axes structure

• Automation with robot can be possible without enough space.

Harsh production environment

• The new MR (35/50kg) has a std.IP67.

Available IP ratings make the MR Series ideal for various

applications that include harsh environments that previously

required expensive robot covers.

MR35/50

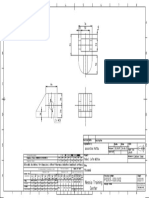

◆ 外形寸法及び動作範囲

Robot specifications Exterior dimensions and operating envelope

Item Specifications

Robot model MR35-01 MR50-01 R360

Construction Articulated construction

Number of axes 7

Drive system AC servo system

J1 ±2.88rad

(±165°

) 33

オ

0

R205 0°

プシ

J2 +0.96∼−2.09rad

(+55∼−120°

)

38 ョ

0°

J3 +2.44∼−2.55rad

(+140∼−146°

)

J4 ±6.28rad

(±360°

)

Max. operating area POINT A

J5 ±2.18rad

(±125°

)

LOCUS

J6 ±7.84rad

(±450°

) (POINT A)

J7 ±3.32rad

(±190°

) 288.6

J1 3.14rad/s

(180°

/s) 3.05rad/s

(175°

/s) 275 350.7 175 990 150

J2 3.05rad/s

(175°

/s) 2.44rad/s

(140°

/s)

150 202

J3 3.14rad/s

(180°

/s) 2.88rad/s

(165°

/s)

Max. speed J4 5.32rad/s

(305°

/s) 4.45rad/s

(255°

/s)

2500

J5 5.32rad/s

(305°

/s) 4.45rad/s

(255°

/s)

900

J6 7.33rad/s

(420°

/s) 6.46rad/s

(370°

/s)

1852

J7 2.27rad/s

(130°

/s)

184.2

35kg 50kg

Wrist

Payload

600

15kg

Forearm

J4 160N・m 210N・m

Allowable static load torque for wrist 593.3

J5 160N・m 210N・m 630 1407

2050 1589

J6 90N・m 130N・m

851

J4 16kg・m² 30kg・m² 198.5

Allowable moment of inertia for wrist※1

J5 16kg・m² 30kg・m²

J6 5kg・m² 12kg・m²

Position repeat accuracy※2 ±0.07mm

175 165 250 ±0.1

Maximum working air pressure 0.49MPa(5.0kgf/cm²)以下

(P.C.D.80) 6.5 205 205

0.49MPa (5.0kgf/cm²) or less 4-φ22

基

Ambient temperature 0∼45℃

φ100h7

250 ±0.1

φ50H7

基

Installation

※3

Floor mounted

205 205

Environmental resistance※4 Body Meets the IP67 standard (for dust and waterproofing)

(P.C.D.80)

Wrist Meets the IP67 standard (for dust and waterproofing)

本体質量 Robot mass 745kg

1[rad] = 180/π[°

], 1[N・m] = 1/9.8[kgf・m]

※1: Note that wrist moment of inertia varies depending on wrist load conditions.

※2: JIS B 8432 compliant.

※3: Inverted, wall, and inclined installations are options.

※4: Fluids that corrode the seal material, such as organic solvents, acids, alkalis,

salts, and petroleum-based cutting fluids, cannot be used.

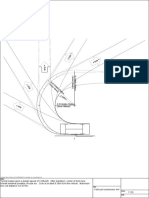

Operating Case

Example loading system using the MR50 When using conventional robots

We’ve provided space in front of the

Robot installed in front of the machine

machine for easier maintenance!

•The specifications are subject to changes without notice.

•In case that an end user uses this product for military purpose or production of weapon, this product may be liable for the subject of export restriction stipulated in the Foreign Exchange and Foreign Trade Control Law. Please go through careful investigation and

necessary formalities for export.

Shiodome Sumitomo Bldg.17F 1-9-2 Higashi-shinbashi, Minato-ku, Tokyo105-0021, Japan

〈Tokyo Head Office〉 Tel: +81-

(0)3-5568-5111 Fax: +81- (0) 3-5568-5206

〈Toyama Head Office〉1 -1-1 Fujikoshi-Honmachi, Toyama 930-8511, Japan

〈Oversea Div.〉 Tel: +81-

(0)

76-423-5111 Fax: +81-

(0)

76-493-5211

Tel: +81-

(0)

3-5568-5245

CATALOG NO. 7331-3

2013.06.X-ABE-ABE

You might also like

- Panasonic AC Servo Driver Technical ReferenceDocument121 pagesPanasonic AC Servo Driver Technical Referenceinalac2No ratings yet

- 3ra Sesion SPT y SPT-T PDFDocument73 pages3ra Sesion SPT y SPT-T PDFSulfure PainchaultNo ratings yet

- Pesticide Formulations: National Pesticide Applicator Certification Core ManualDocument51 pagesPesticide Formulations: National Pesticide Applicator Certification Core ManualSoma Shekar LNo ratings yet

- TM 9 6230 210 13p Floodlight SetDocument264 pagesTM 9 6230 210 13p Floodlight SetAdvocateNo ratings yet

- Bombas TurollaDocument4 pagesBombas TurollaHidroil Neuquen SrlNo ratings yet

- Nachi Robot Catalog 2012Document20 pagesNachi Robot Catalog 2012Xanti Zabala Da RosaNo ratings yet

- Release Notes RobotStudio 2019-5 PDFDocument44 pagesRelease Notes RobotStudio 2019-5 PDFXanti Zabala Da RosaNo ratings yet

- Food Preservation by Refrigeration and Air ConditioningDocument17 pagesFood Preservation by Refrigeration and Air ConditioningARSNo ratings yet

- Kawasaki Controller E Series External I-O Manual PDFDocument84 pagesKawasaki Controller E Series External I-O Manual PDFXanti Zabala Da RosaNo ratings yet

- Kawasaki Controller E Series External I-O Manual PDFDocument84 pagesKawasaki Controller E Series External I-O Manual PDFXanti Zabala Da RosaNo ratings yet

- 5S & TPMDocument19 pages5S & TPMJesus Chi GorosicaNo ratings yet

- Program Editor User ManualDocument14 pagesProgram Editor User ManualXanti Zabala Da RosaNo ratings yet

- Handling Robot With Top Rated Loading Capacity: 700kg PayloadDocument2 pagesHandling Robot With Top Rated Loading Capacity: 700kg PayloadXanti Zabala Da RosaNo ratings yet

- 500 KG Payload Capacity For Optimal Handling of Large and Heavy LoadsDocument2 pages500 KG Payload Capacity For Optimal Handling of Large and Heavy LoadsXanti Zabala Da RosaNo ratings yet

- MC600 BrochureDocument2 pagesMC600 BrochureXanti Zabala Da RosaNo ratings yet

- MZ07F MZ07LF 1Document2 pagesMZ07F MZ07LF 1Loi DoanNo ratings yet

- SRA100/166/210/166L/120EL: World Class Speed RobotDocument2 pagesSRA100/166/210/166L/120EL: World Class Speed RobotXanti Zabala Da RosaNo ratings yet

- SRA166 210 01A BrochureDocument2 pagesSRA166 210 01A BrochureXanti Zabala Da RosaNo ratings yet

- ES12 BrochureDocument2 pagesES12 BrochureXanti Zabala Da RosaNo ratings yet

- Mini PMDC MotorsDocument2 pagesMini PMDC MotorsKarthik ReddyNo ratings yet

- PM20S Stepper MotorDocument1 pagePM20S Stepper MotorNitish KumarNo ratings yet

- 2-3 Turk'S Head Roll SM120A - 75x75 - L75: 33047 REMANZACCO (UD)Document2 pages2-3 Turk'S Head Roll SM120A - 75x75 - L75: 33047 REMANZACCO (UD)Alejandra ChocueNo ratings yet

- ARC Mate 100+D ARC Mate 120+D: Intelligent Arc Welding RobotDocument2 pagesARC Mate 100+D ARC Mate 120+D: Intelligent Arc Welding RobotJose RomeroNo ratings yet

- Model 4Document1 pageModel 4karpagavalli NNo ratings yet

- Grayhill 07272021 7db2d6 0ae3ffad0fce4a2db89a57cea-2509346Document17 pagesGrayhill 07272021 7db2d6 0ae3ffad0fce4a2db89a57cea-2509346ALEJANDRONo ratings yet

- Sharpen (8X) : 1 1 Plate T 1.5Document1 pageSharpen (8X) : 1 1 Plate T 1.5andreas endrasNo ratings yet

- Antena 742290Document2 pagesAntena 742290jljljljl4No ratings yet

- R-2000iC-125L HOJA DATOS PDFDocument1 pageR-2000iC-125L HOJA DATOS PDFgatolefuNo ratings yet

- Single Band Broadband 8', 65 Degree Antenna RET: General SpecificationsDocument2 pagesSingle Band Broadband 8', 65 Degree Antenna RET: General SpecificationsColour BlindNo ratings yet

- FANUC-M-10iA Series - 13Document2 pagesFANUC-M-10iA Series - 13Nadir ChalinNo ratings yet

- M 10ia SeriesDocument2 pagesM 10ia Seriessenior_cor73zNo ratings yet

- Single Mode 1.0625 GBD FC Laser Transceiver 1X9Document3 pagesSingle Mode 1.0625 GBD FC Laser Transceiver 1X9Сергей КолосовNo ratings yet

- Datasheet ArcMate 120ic 12LDocument1 pageDatasheet ArcMate 120ic 12LmuertesalvajeNo ratings yet

- RJ26RJR26Document2 pagesRJ26RJR26joel alvaradoNo ratings yet

- Datasheet M-710iC-12LDocument1 pageDatasheet M-710iC-12LconanbhNo ratings yet

- ARC Mate 100 Robot Working RangeDocument1 pageARC Mate 100 Robot Working RangeTamii LópezNo ratings yet

- Tugas 1 Cs SoketDocument1 pageTugas 1 Cs Soketilham dwi putraNo ratings yet

- MC400L BrochureDocument2 pagesMC400L BrochureXanti Zabala Da RosaNo ratings yet

- Pap 6600-20-v08Document3 pagesPap 6600-20-v08marc_lobert4808100% (2)

- FlexRET 65 Deg Triple Band 96 Inches (KS)Document3 pagesFlexRET 65 Deg Triple Band 96 Inches (KS)gggNo ratings yet

- Single Mode 155 MBD Atm Long Haul Transceiver 1X9: (Absolute Maximum Stress)Document4 pagesSingle Mode 155 MBD Atm Long Haul Transceiver 1X9: (Absolute Maximum Stress)Сергей КолосовNo ratings yet

- Multi Axis Robot DM - (E)Document6 pagesMulti Axis Robot DM - (E)jreinaldoNo ratings yet

- Rod1000 2016 enDocument3 pagesRod1000 2016 enjackyNo ratings yet

- Todo Terreno 4x4Document1 pageTodo Terreno 4x4Mateo Diaz HerreraNo ratings yet

- V 02Document2 pagesV 02azert1100% (1)

- ADU451902 V 06Document2 pagesADU451902 V 06Erick Eriza SurantoNo ratings yet

- 742264V02 PDFDocument2 pages742264V02 PDFJonathan Gonzalez.LNo ratings yet

- Rod Seal TS22PDocument1 pageRod Seal TS22Pfrançois MNo ratings yet

- HS220 Catalog - Eng - Rev3Document1 pageHS220 Catalog - Eng - Rev3anmellaNo ratings yet

- Final - Bai Tap SurfaceDocument6 pagesFinal - Bai Tap SurfaceHiếu HuỳnhNo ratings yet

- Candidate Sim Instruction Ver 1.5 Jun 2018Document3 pagesCandidate Sim Instruction Ver 1.5 Jun 2018rajivpatil11No ratings yet

- Notes: - Max: 43.0kN Nom: 30.7kN Tooth ForceDocument2 pagesNotes: - Max: 43.0kN Nom: 30.7kN Tooth ForceWilderNo ratings yet

- JIS B 2401-1 Series: (Static/Dynamic Application)Document7 pagesJIS B 2401-1 Series: (Static/Dynamic Application)Adhya RazanNo ratings yet

- In/Mm 2:1: B-SIZE 172672Document2 pagesIn/Mm 2:1: B-SIZE 172672GeeNo ratings yet

- Transfer Piece Model1 ModelDocument1 pageTransfer Piece Model1 Modelmochammad sofiNo ratings yet

- 33-03 Closed Slot - GrooveDocument1 page33-03 Closed Slot - GrooveDavid BumbaloughNo ratings yet

- Mitsu C004e-I Solid End MillsDocument358 pagesMitsu C004e-I Solid End MillskatomegumioncrackNo ratings yet

- SOD123Document5 pagesSOD123stefano soriceNo ratings yet

- Datasheet M-710iC-20LDocument1 pageDatasheet M-710iC-20LAntonio SanchezNo ratings yet

- 20GMM11BR001 Rev00Document1 page20GMM11BR001 Rev00Avak ArmeniNo ratings yet

- Lami Upper Cutter and Under Cutter (2 Type) - REV1.0-ModelDocument1 pageLami Upper Cutter and Under Cutter (2 Type) - REV1.0-Modelciptasuryamulia.engNo ratings yet

- R Linear Bearings - Product Range: Closed, Anodised Aluminium AdapterDocument1 pageR Linear Bearings - Product Range: Closed, Anodised Aluminium Adapterlifnur hadiNo ratings yet

- Technical Data: Hall-Effect Single-Turn Rotary Sensor With ShaftDocument6 pagesTechnical Data: Hall-Effect Single-Turn Rotary Sensor With ShaftSathish J EceNo ratings yet

- DSASL0056537Document1 pageDSASL0056537Jose ReyesNo ratings yet

- AM120Document2 pagesAM120Anonymous S8SGcPucNo ratings yet

- Datasheet Crx-25iaDocument1 pageDatasheet Crx-25iajocelyn.peynet.universal.robotsNo ratings yet

- Cage Freewheel SF ... PDocument3 pagesCage Freewheel SF ... PdenisNo ratings yet

- RDamper CatalogDocument12 pagesRDamper CatalogEvandro MoreiraNo ratings yet

- Grayhill Series 50 51 Rotary SwitchDocument7 pagesGrayhill Series 50 51 Rotary SwitchScaricatore92No ratings yet

- A04b 0104 b181 Fanuc Axis Rotary TableDocument2 pagesA04b 0104 b181 Fanuc Axis Rotary Tableclogic26No ratings yet

- Operating Instructions - KL4000 V10 enDocument231 pagesOperating Instructions - KL4000 V10 enXanti Zabala Da RosaNo ratings yet

- RobotStudio Operation Manual PDFDocument298 pagesRobotStudio Operation Manual PDFEmanuelNo ratings yet

- RobotWare 6 DatasheetDocument4 pagesRobotWare 6 DatasheetXanti Zabala Da RosaNo ratings yet

- Cleanroom CR7 E 06.2015Document2 pagesCleanroom CR7 E 06.2015Xanti Zabala Da RosaNo ratings yet

- Ssraen 071 006 - Sra H 01 FD11Document30 pagesSsraen 071 006 - Sra H 01 FD11Eddy AlmeidaNo ratings yet

- SRA100H-SRA133HL Rev2 BrochureDocument2 pagesSRA100H-SRA133HL Rev2 BrochureXanti Zabala Da RosaNo ratings yet

- EZ03-02 Standard SpecificationsDocument28 pagesEZ03-02 Standard SpecificationsXanti Zabala Da RosaNo ratings yet

- NV06 02 FD11 Standard SpecificationsDocument22 pagesNV06 02 FD11 Standard SpecificationsXanti Zabala Da RosaNo ratings yet

- SRA166 210 01A BrochureDocument2 pagesSRA166 210 01A BrochureXanti Zabala Da RosaNo ratings yet

- SC700 Standard SpecificationsDocument15 pagesSC700 Standard SpecificationsXanti Zabala Da RosaNo ratings yet

- SC400L-SC500 Standard SpecificationsDocument26 pagesSC400L-SC500 Standard SpecificationsXanti Zabala Da RosaNo ratings yet

- MZ04 Standard SpecificationsDocument29 pagesMZ04 Standard SpecificationsXanti Zabala Da RosaNo ratings yet

- NV06L 02 FD11 Standard SpecificationsDocument22 pagesNV06L 02 FD11 Standard SpecificationsXanti Zabala Da RosaNo ratings yet

- MZ07-02 Standard SpecificationsDocument18 pagesMZ07-02 Standard SpecificationsXanti Zabala Da RosaNo ratings yet

- NB04L 02 FD11 Standard SpecificationsDocument22 pagesNB04L 02 FD11 Standard SpecificationsXanti Zabala Da RosaNo ratings yet

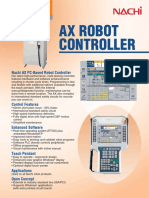

- AX Robot ControllerDocument2 pagesAX Robot ControllerXanti Zabala Da Rosa100% (1)

- MC600 BrochureDocument2 pagesMC600 BrochureXanti Zabala Da RosaNo ratings yet

- MC400L BrochureDocument2 pagesMC400L BrochureXanti Zabala Da RosaNo ratings yet

- Build An AnimalDocument15 pagesBuild An Animalapi-322873594No ratings yet

- Stress-Strain CurveDocument7 pagesStress-Strain CurveR BNo ratings yet

- Postgresql (Open Source Database) Training ProgramDocument11 pagesPostgresql (Open Source Database) Training ProgramRameen NaweedNo ratings yet

- Wilson ToolDocument46 pagesWilson ToolAlex ZuletaNo ratings yet

- OX Assembly ManualDocument50 pagesOX Assembly ManualLillian RamosNo ratings yet

- LANJUTKANDocument79 pagesLANJUTKANPutika ApphaNo ratings yet

- Conducting Corrosion Coupon Tests in Field Applications: Standard Guide ForDocument10 pagesConducting Corrosion Coupon Tests in Field Applications: Standard Guide ForCris GauchoNo ratings yet

- Cisco SPA-112 IP-phone AdapterDocument5 pagesCisco SPA-112 IP-phone Adapterfrans.eriksenNo ratings yet

- 2G Cellular SystemsDocument5 pages2G Cellular SystemsVanagara BharatNo ratings yet

- Aprilaire Owners ManuaDocument16 pagesAprilaire Owners Manuaicemann83No ratings yet

- RADIANTDocument16 pagesRADIANTSalman MNo ratings yet

- Moisture in The Analysis Sample of Coal and Coke: Standard Test Method ForDocument3 pagesMoisture in The Analysis Sample of Coal and Coke: Standard Test Method Formerifie renegadoNo ratings yet

- Domestic Gas Stove Testing With Use of LPG: IS 4246: 2002 Bureau of Indian Standards (Fifth Revision)Document5 pagesDomestic Gas Stove Testing With Use of LPG: IS 4246: 2002 Bureau of Indian Standards (Fifth Revision)Quality Royal HomeNo ratings yet

- FD-FE 1500 Maint Manual Rev 2 11-08Document28 pagesFD-FE 1500 Maint Manual Rev 2 11-08ddeppenjrNo ratings yet

- YF Ch35 Exmpls New - PDF (35.51 Punto 2)Document5 pagesYF Ch35 Exmpls New - PDF (35.51 Punto 2)Cristian Julián Díaz BohórquezNo ratings yet

- Ee-116 Principles of Electrical Engineering - 2014Document96 pagesEe-116 Principles of Electrical Engineering - 2014hmxa91No ratings yet

- Features / BenefitsDocument54 pagesFeatures / Benefitsomar.ash8888No ratings yet

- Decimal System - From China?Document1 pageDecimal System - From China?temujin03No ratings yet

- Invitation To The 10th ISICAM-Dr. Asep Sopandiana Angga, SPJP, FIHADocument2 pagesInvitation To The 10th ISICAM-Dr. Asep Sopandiana Angga, SPJP, FIHAaneu28No ratings yet

- Data Sartocheck PDFDocument2 pagesData Sartocheck PDFBui Thien TinNo ratings yet

- Pre-Reading Reading: "3M Post-It Notes: A Managed or AccidentalDocument12 pagesPre-Reading Reading: "3M Post-It Notes: A Managed or Accidentalajit.alweNo ratings yet

- Twi Tensile TestingDocument10 pagesTwi Tensile TestingchungndtNo ratings yet

- Service Manual: EPSON Stylus PHOTO 890/1280/1290Document205 pagesService Manual: EPSON Stylus PHOTO 890/1280/1290Антон РуслановNo ratings yet

- Lecture-10 Analysis and Design of Flate Plates and Flat SlabsDocument64 pagesLecture-10 Analysis and Design of Flate Plates and Flat Slabskamra khanNo ratings yet