Professional Documents

Culture Documents

02.04.2014 Business Trip Report - RO - Moreli

Uploaded by

Bolat AurelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

02.04.2014 Business Trip Report - RO - Moreli

Uploaded by

Bolat AurelCopyright:

Available Formats

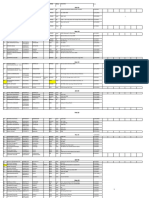

PO-11-01 F01 Version 3 General Department

BUSINESS TRIP REPORT

Date 03.04.2014

Name of company visited MORELLI INPORT - EXPORT

Location of company visited Brasov - Romania

Visit timeframe 03/04/2014

Purpose of visit Check the process for aluminum die casting. Also check the

situation of cost analyze.

Visited company- attendees Rucsanda Nicolae Sales Responsable

Gabriela Doroftei Technical and Quality Responsable

MMR attendees C.Alexandru Manufacturing Engineering

A.Bolat Product Engineering

Current situation

Morelli Import-Export - Romania

MMR visit again this supplier to make a detailed evaluation of processes and the cost analyze.

The time for casting for one cast is 61 sec included manual deburring for side burrs and

preparing the mold, next step is storage for trimming, there the casting pieces are cooled in air

for 45 min until the lot is manual moves, not robotic moves, to trimming machine. The time for

trimming for two casting pieces is 31 sec, first step after trimming is visual inspection pasts, next

step is cleaning tool, next step is the positioning and fixing casting parts and for last step is

trimming, and then the parts are visual inspecting and recycles the excess material. Next step is

moving lot parts to blasting tool, hear is wait until the blasting tool is released, then the lot parts

are transported to bench for manual trimming and visual inspection, it takes about 25 sec per

pieces. The good point of supplier is the large amount of delivery and quality for Gears Housings

for us. Not good point is the equipment because the cooling is done outdoors and not in water

as needed to make. Not good point is the cast pieces is cooling in air once that out, then that lot

of pieces waiting for trimming, after trimming are stored for blasting. But the blasting for Gears

Housings is rarely because the trimming is moving very low.

Conclusions/ Suggestions

Morelli Import-Export We visit Morelli Import-Export becouse he need 4 pieses cooling in air, 4

pieses cooling in water and 2 pieses cooling in air after blasting.

Mr. C.Alexandru will testing the pieces becouse he wants to see machinability and the wear

knives for each sample.

Checked by,

Department Manager General Manager General Director

Mr. Shusaku Wakatsuki Mr. Gabriel Anghel Mr. Hideyuki Kawase

Signature Signature Signature

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hungarian Special Machinery ManufacturingDocument13 pagesHungarian Special Machinery ManufacturingBolat AurelNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Cold ChamberDocument6 pagesCold ChamberBolat AurelNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Operating Sequence of The Hot-Chamber Standard Die Casting ProcessDocument5 pagesThe Operating Sequence of The Hot-Chamber Standard Die Casting ProcessBolat AurelNo ratings yet

- Laser Heat TreatmentDocument8 pagesLaser Heat TreatmentBolat AurelNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Laser Heat TreatmentDocument8 pagesLaser Heat TreatmentBolat AurelNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- IMST 2011-2012 Rezultate StudentiDocument4 pagesIMST 2011-2012 Rezultate StudentiBolat AurelNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Cartea MasiniDocument6 pagesCartea MasiniBolat AurelNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 54LS138/DM54LS138/DM74LS138, 54LS139/DM54LS139/DM74LS139 Decoders/DemultiplexersDocument8 pages54LS138/DM54LS138/DM74LS138, 54LS139/DM54LS139/DM74LS139 Decoders/DemultiplexersakulNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Web App SuccessDocument369 pagesWeb App Successdoghead101No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Operacion de Sistemas Power Shift - D4EDocument6 pagesOperacion de Sistemas Power Shift - D4ERenato LicettiNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Registered Consulting CompanyDocument8 pagesRegistered Consulting CompanyChristian Nicolaus MbiseNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 4.1 Rectangular Tied Columns: CHAPTER 4: Reinforced Concrete ColumnsDocument12 pages4.1 Rectangular Tied Columns: CHAPTER 4: Reinforced Concrete ColumnsRigobertoGuerraNo ratings yet

- Sucker Rods Training Final PDFDocument189 pagesSucker Rods Training Final PDFMajdi Jerbi100% (2)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Service Copy NewDocument86 pagesService Copy NewSKS MOTERS DEVARA HIPPARGINo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Cognizant Training FacilityDocument1 pageCognizant Training FacilityPiyush SinhaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- VESDADocument4 pagesVESDAamijetomar08No ratings yet

- 3GPP TS 22.368Document25 pages3GPP TS 22.368santanameroNo ratings yet

- Proserv Type 5 10k 700cc PDFDocument1 pageProserv Type 5 10k 700cc PDFRefisal BonnetNo ratings yet

- Presentation On Gravity DamDocument22 pagesPresentation On Gravity DamSarvesh Bhairampalli100% (2)

- Fact Sheet DPR6000B enDocument2 pagesFact Sheet DPR6000B enMudhi putraNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Floor plan of a cottage with two bedrooms and living areaDocument1 pageFloor plan of a cottage with two bedrooms and living areaNithinNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Co-extrusion process for multi-layer plasticsDocument2 pagesCo-extrusion process for multi-layer plasticsSupreeth PremkumarNo ratings yet

- North Reading Set 2 Group BDocument2 pagesNorth Reading Set 2 Group Bapi-281321560No ratings yet

- B777 Thrust Reference Anomaly BriefDocument1 pageB777 Thrust Reference Anomaly Briefken.pascoeNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- MillionDollarPipsManual PDFDocument12 pagesMillionDollarPipsManual PDFOnes RoseNo ratings yet

- DGEG EsquemaDocument15 pagesDGEG EsquemaAlexander James ThorntonNo ratings yet

- Chat group discusses joining details for new roleDocument106 pagesChat group discusses joining details for new rolejigarsampat0% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Cobham Antenna Systems Product Range Data Sheet LinksDocument5 pagesCobham Antenna Systems Product Range Data Sheet LinksMarco AlfieriNo ratings yet

- Jailbreak TweaksDocument2 pagesJailbreak TweakstruongthoailieuNo ratings yet

- Pastor StatementDocument11 pagesPastor StatementPaulNo ratings yet

- Why Is Bandwidth Expressed in 3db and Not in 4db or 5db?: 2 AnswersDocument5 pagesWhy Is Bandwidth Expressed in 3db and Not in 4db or 5db?: 2 AnswersRajeev Mohan VermaNo ratings yet

- GEARBOXDocument16 pagesGEARBOXhyundai31050% (2)

- Strategic and Operational PlanningDocument5 pagesStrategic and Operational Planningangie lloyd saligan100% (1)

- Cameron Middle East Skid Structural Calculation ReportDocument33 pagesCameron Middle East Skid Structural Calculation Reportsridhar100% (1)

- FM 200Document2 pagesFM 200José AravenaNo ratings yet

- Jeffrey Epstein39s Little Black Book Unredacted PDFDocument95 pagesJeffrey Epstein39s Little Black Book Unredacted PDFasdasdasd75% (4)

- Logical Security SOP SampleDocument13 pagesLogical Security SOP SampleAnton Mymrikov0% (1)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)