Professional Documents

Culture Documents

Risk Analysis

Uploaded by

Raffandi Rolando0 ratings0% found this document useful (0 votes)

6 views2 pagesRisk analysis

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRisk analysis

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views2 pagesRisk Analysis

Uploaded by

Raffandi RolandoRisk analysis

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

RISK ANALYSIS

There are three types of risks that can be identified in the walnut oil processing industry which

is Biological, Chemical and Physical. All of the risk that can be identified are listed in tables

below.

Table 1 below shows the raw materials and the identified risks.

Table 1: Risk Analysis for raw materials

Raw Material Type of Risk Risk Description Significant Solution

B P C

Walnuts / Moulds, aflatoxins Yes Qualified suppliers

/ Foreign bodies like Yes verification,

stones, dirt, metal etc. prevention of cross

/ Lead, cadmium, No contamination

mercury etc.

Packing Bottles / Dust No Qualified Suppliers

/ Bacillus No

Table 2 below shows the identified risk for each type of process

Table 2: Risk Analysis for each type of process

Step of process Type of Risk Risk Description Significant Solution

B P C

Drying / Growing of mould, Yes Prevent cross

production of aflatoxin. contamination,

Contamination with practises good

bacteria from soil or handling of

animals. equipment.

Storage / Growing of mould, Yes Good handling

contamination through practice, keep in a

Vermin dry and closed

place, pest

control.

Cracking / Staph, aureus No Good

/ Foreign bodies No manufacturing

practice,

Verification

Sorting / Foreign bodies like Yes Check before

shells, hair etc. loading the Press

Pressing / Cleaning water residues No GHP, CIP

/ Detergents, Oil residues No

Filtration / Bacteria from water No GHP, CIP

remained in filter after

cleaning

/ Detergent residue No

Filling, / Damaged bottles and No Indicator, Visual

Capping stoppers check before

filling or capping

Label / Manufacturing and Yes Check visually

expiry dates before packing

Store and / Chemical reactions and No GHP: Store at

Transport glass can break 30ᵒC, keep away

from sun and

handle carefully.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Lavender MsdsDocument7 pagesLavender MsdsRaffandi RolandoNo ratings yet

- Ex PhosphonatesDocument1 pageEx PhosphonatesBapu ReddyNo ratings yet

- ObjectivesDocument1 pageObjectivesRaffandi RolandoNo ratings yet

- GanntProject Introduction For BeginnersDocument65 pagesGanntProject Introduction For Beginnersamir.workNo ratings yet

- Weekly Report (Week 1)Document2 pagesWeekly Report (Week 1)Raffandi RolandoNo ratings yet

- Part PandiDocument3 pagesPart PandiRaffandi RolandoNo ratings yet

- Distillation - REsult V3Document2 pagesDistillation - REsult V3Raffandi RolandoNo ratings yet

- Assignment 1Document2 pagesAssignment 1Raffandi RolandoNo ratings yet

- Project Scheduling: 2-May 22-May 11-Jun 1-Jul 21-Jul 10-Aug 30-Aug A B C D E F G HDocument3 pagesProject Scheduling: 2-May 22-May 11-Jun 1-Jul 21-Jul 10-Aug 30-Aug A B C D E F G HRaffandi RolandoNo ratings yet

- Factor TablesDocument29 pagesFactor TablesRaffandi RolandoNo ratings yet

- Assignment CoverDocument1 pageAssignment CoverRaffandi RolandoNo ratings yet

- Auld Lang SyneDocument1 pageAuld Lang SyneRaffandi RolandoNo ratings yet

- Homelessness SummaryDocument2 pagesHomelessness SummaryRaffandi RolandoNo ratings yet

- Introduction (Distillation)Document2 pagesIntroduction (Distillation)Raffandi RolandoNo ratings yet

- Table of Content (Dye)Document1 pageTable of Content (Dye)Raffandi RolandoNo ratings yet

- Experimental Procedure (CKRDL)Document3 pagesExperimental Procedure (CKRDL)Raffandi RolandoNo ratings yet

- ReferencesDocument1 pageReferencesRaffandi RolandoNo ratings yet

- Outline Term PaperDocument3 pagesOutline Term PaperRaffandi RolandoNo ratings yet

- Term Paper 1st DraftDocument4 pagesTerm Paper 1st DraftRaffandi RolandoNo ratings yet

- Full Name: Personal Profile (Optional)Document3 pagesFull Name: Personal Profile (Optional)Raffandi RolandoNo ratings yet

- 3 JM 3 1 +2 3 La'coques Boys 1 1 0 1: POS Group A GF GA GD PointsDocument2 pages3 JM 3 1 +2 3 La'coques Boys 1 1 0 1: POS Group A GF GA GD PointsRaffandi RolandoNo ratings yet

- Business PlanDocument3 pagesBusiness PlanRaffandi RolandoNo ratings yet

- Homelessness Summary 2Document2 pagesHomelessness Summary 2Raffandi RolandoNo ratings yet

- Newton'S Divided Difference Interpolating PolynomialsDocument3 pagesNewton'S Divided Difference Interpolating PolynomialsRaffandi RolandoNo ratings yet

- Linear IzationDocument16 pagesLinear Izationangori2No ratings yet

- HPV and VaccinationDocument9 pagesHPV and VaccinationRaffandi RolandoNo ratings yet

- Vapor Pressure Data Representation by Polynomials and EquationsDocument2 pagesVapor Pressure Data Representation by Polynomials and EquationsRaffandi RolandoNo ratings yet

- Lesson 4: Two Tanks in Series: Spring 2006 Process Dynamics, Operations, and Control 10.450Document37 pagesLesson 4: Two Tanks in Series: Spring 2006 Process Dynamics, Operations, and Control 10.450tresmilhoesNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Kaldnes Moving Bed Process For Wastewater Treatment at Pulp and Paper MillsDocument3 pagesThe Kaldnes Moving Bed Process For Wastewater Treatment at Pulp and Paper Millsvinhphat90No ratings yet

- Catalogo Microbe LiftDocument40 pagesCatalogo Microbe Liftanipet08No ratings yet

- TM 9-2320-340-10Document924 pagesTM 9-2320-340-10Advocate100% (2)

- Tutorial Eleven Reaction: 4 Edition, Jan. 2018Document10 pagesTutorial Eleven Reaction: 4 Edition, Jan. 2018komodiemoNo ratings yet

- Cellulosic ElectrodeDocument12 pagesCellulosic Electrodecisar0007No ratings yet

- Water Soluble Polymer Flocculants Synthesis, PDFDocument43 pagesWater Soluble Polymer Flocculants Synthesis, PDFruizgj2011No ratings yet

- Denver Equipment Company Handbook guides engineersDocument0 pagesDenver Equipment Company Handbook guides engineersalvarezri100% (1)

- TDS - 3765 - Texotile Spray-On - Euk - GB PDFDocument3 pagesTDS - 3765 - Texotile Spray-On - Euk - GB PDFSomanith KoumNo ratings yet

- Science of The Total Environment: Steven G. Brown, Shelly Eberly, Pentti Paatero, Gary A. NorrisDocument10 pagesScience of The Total Environment: Steven G. Brown, Shelly Eberly, Pentti Paatero, Gary A. NorrisJuana CalderonNo ratings yet

- Series 3000 Cooling Tower SpecificationsDocument9 pagesSeries 3000 Cooling Tower SpecificationsTahseenNo ratings yet

- Unit 1 Solutions Key ConceptsDocument12 pagesUnit 1 Solutions Key ConceptsOreena DsouzaNo ratings yet

- What We Know About The Ohio Train DerailmentDocument3 pagesWhat We Know About The Ohio Train DerailmentEmma RubintNo ratings yet

- Histamine, Serotonin & The Ergot AlkaloidsDocument31 pagesHistamine, Serotonin & The Ergot AlkaloidsnicewanNo ratings yet

- Interaction Between Active Sites and Sorbents During TheDocument9 pagesInteraction Between Active Sites and Sorbents During TheJulian De BedoutNo ratings yet

- Bio CokeDocument1 pageBio CokeMAYANK GUPTANo ratings yet

- Performance Coatings - Greenheck FansDocument12 pagesPerformance Coatings - Greenheck Fansprsum_572100% (1)

- 5980 10143 1 SM PDFDocument11 pages5980 10143 1 SM PDFfaustinaNo ratings yet

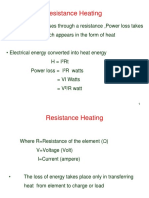

- Resistance Heating ExplainedDocument13 pagesResistance Heating ExplainedMaheshk GowdaNo ratings yet

- A Brief Note On Plants of Medicinal Importance To LivestockDocument84 pagesA Brief Note On Plants of Medicinal Importance To LivestockSunil100% (1)

- Column Base Plate (Hinge Type)Document14 pagesColumn Base Plate (Hinge Type)Mesgina G-herNo ratings yet

- M13 Jacketed High-Pressure Fuel Pipe of Diesel EngineDocument10 pagesM13 Jacketed High-Pressure Fuel Pipe of Diesel EngineMaxwellNo ratings yet

- Preventive Maintenance Program For Spherical Blowout PreventerDocument19 pagesPreventive Maintenance Program For Spherical Blowout Preventernjava1978100% (1)

- D475a-5gen00051 Fa-03Document240 pagesD475a-5gen00051 Fa-03Gabo GaboNo ratings yet

- CR Mo Issues of Concern 6Document33 pagesCR Mo Issues of Concern 6Suthan M RNo ratings yet

- InsufineMineral TDSDocument2 pagesInsufineMineral TDSEgyp XsNo ratings yet

- Bulking of SandDocument2 pagesBulking of SandEngr Sarang KhanNo ratings yet

- Raw Mill Area-HamzaDocument21 pagesRaw Mill Area-HamzaAdnan rasoolNo ratings yet

- SDS Safety Data SheetDocument8 pagesSDS Safety Data SheetAnonymous vhMCGINo ratings yet

- TI Oxydur PTB 206 - en PDFDocument5 pagesTI Oxydur PTB 206 - en PDFgonzalogvargas01100% (1)

- NMAT 17 Crash Course Review - Biochemistry ReviewerDocument6 pagesNMAT 17 Crash Course Review - Biochemistry ReviewerMikaela Rome Bigay83% (6)