Professional Documents

Culture Documents

Nam Dương - Evaporative Air Cooler-Cmt by Hieu

Nam Dương - Evaporative Air Cooler-Cmt by Hieu

Uploaded by

Doan Thanh BinhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nam Dương - Evaporative Air Cooler-Cmt by Hieu

Nam Dương - Evaporative Air Cooler-Cmt by Hieu

Uploaded by

Doan Thanh BinhCopyright:

Available Formats

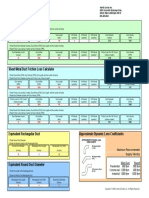

Air Duct: Supply-Exhaust Air Balancing

Legends

1.Galvanized air ducts are fabricated from 0.7 mm thick standard mill galvanized Supply Air Exhaust Air

Balance (%)

sheet for rectangular design. In the case of round spiral design, the thickness Heat Exchanger Ref Mount Type Total Airflow (CMH) Fan Ref Air Flow/Unit(CMH) Total Airflow (CMH)

Heat Exchanger Air Diffusers Natural Exhaust Wall Exhaust Fan Ceiling Exhaust Fan Roof Exhaust Fan

shall be 0.7 mm for 700 mm dia. duct and 0.55 mm for 600 mm dia.duct and - - - - - - -

below.

2.Stainless air ducts are fabricated from 0.55 mm thick standard mill SS 304 sheet

for rectangular design. In the case of round spiral design, the thickness shall be

0.6 mm for 700 and 600 mm dia. duct and 0.4 mm for 400 mm dia.duct and 1- Nên bổ sung thêm lọc túi để đảm

below. bảo chất lượng

2- Khuyến cáo sử dụng thiết bị xử lý

3.Duct construction, fittings, hangers and supports are to Waterline's standards. không khí như hình đính kèm (Fan

Filter Cabinet + Humidifier)

3- Đoạn ống trong nhà nên sử dụng

4.Number of openings for diffusers on air ducts shall follow the design of this

VỆ SINH SỐ 03

ống gió vải, giảm tải trọng cho kết P. HỌP SỐ 03

drawing. Any subsequent change by users can affect the system performance cấu

and Waterline shall not be made responsible.

5.After the commencement of work, any relocation of duct work at the request of

250

user that iccurs additional labor or materials shall be for the user's account.

Cooling Fan #1

Model OS30-T

30.000CMH-360Pa

6.Any obstruction to the piping route as indicated in this drawing that necessitates

Design Condition

Design Area (m ) 447.5

Design Height (m) 4

Design Volume (m ) 1790

a re-route resulting in additional materials and labor cost shall be for user's

Supply Air (m /hr) 60000

Filled Carton Pallet

Air Change per hour 33.5

Exhaust Air (m /hr) 46000

Balance (%) 76.7

accounts.

Carton packing

area

Cooling Fan #2

Model OS30-T

Bag Packing

sealing area

Check Weigher

Check Weigher

30.000CMH-360Pa

Make-Up & Drain:(if included in the scope)

Check Weigher

1.Make-up water piping shall be 1/2" PVC type and drain water piping shall be

BAÊNG TAÛI XEÁP THUØNG

BAÊNG TAÛI XEÁP THUØNG

1-1/2" PVC type.

Packing area

Wall Exhaust Fan

2.Scope of supply of make up and drain piping shall be from the heat exchanger. Model WF-1250

46000CMH - 0Pa

RUÙT MAØ NG CO LOÙC

RUÙT MAØ NG CO LOÙC

MAÙY XEÁP LOÙC

MAÙY XEÁP LOÙC

TÖ Ï ÑOÄNG

TÖ Ï ÑOÄNG

3.Water pressure of 2.5 bar minimum shall be made available by the user at the

inlet to the heat exchanger in order for make-up water to feed. Any requirement

Induction

Sealer

of a water pressurization system shall for the accounts of the user.

Capper

4.Make-up water shall be soft, clean, non-corrosive and free from all suspended

RUÙT MAØN G CO NAÉP

RUÙT MAØN G CO NAÉP

QC

Station Filler

SF 02

and dissolved particles. If a filtration system is found necessary, it shall be

400

200

PHOÙ NG MAØN G CO NAÉP

PHOÙ NG MAØN G CO NAÉP

installed by the user. The supply water quality shall comply to the Recommended

Supply Water Quality under Page 20 of our catalog FOA1.

DAÙ N NHAÕN DECAL

DAÙ N NHAÕN DECAL

Electrical Wiring:

SIEÂU MAØNG NHOÂM

SIEÂU MAØNG NHOÂM

CAÁP NAÉ P - SIEÁT NAÉP

CAÁP NAÉ P - SIEÁT NAÉP

1.Electrical supply cable shall be 1.0mm size run in 1/2" PVC/GI conduit.

2.Control cable shall be 0.75mm size run in shared common 1/2" PVC/GI conduit.

MAÙY CHIEÁT ROÙT

MAÙY CHIEÁT ROÙT

3.Each unit of heat exchanger shall be wired-up to a magnetic breaker located

not more than 25m away from the power supply. Also, the heat exchanger is

wired-up to the speed controller located not more than 18m away for signal

supply. Any request for longer power supply cabling shall be for the user's

(1000L)

account. (1000L)

4.All incoming electrical supply to the said breaker shall be arranged by the user. (1000L)

(1000L) Sử dụng ống gió

Others: vải

1.The design of any steel structure supports (roof-mount, wall-mount, tower-mount)

F SP5

shall be based on Waterline's standard design and specifications.

Wall Exhaust Fan

Buffer Tank (2000Lx2)

Height 2,4 m (by Customer)

5000 CMH

F SP5

2.The design of the supply air system in this drawing is made on the basis that at Tube in tube

least 80% of the supply air is exhausted at the same rate.Hence,either the

Cooling Step2 (1000L/h)

F SP5

workspace is open or some mechanical exhaust aid (exhaust fans or exhaust Jacketed Tank

Cooling Step1 (1000Lx2)

Height 2,4 m

system) is made available by the user.

F SP5

Wall Exhaust Fan

Cooking Tank (1000Lx2)

(by Customer)

3.If the supply air is not properly exhausted, there will be build-up in moisture

Height 2,4 m

F SP5

5000 CMH

Gum (500L)

Height 1,5 m Mixing1 (1000L)

content in the workspace which may affect the production workers' comfort or

Height 2,4 m

F SP5

Modified

starch (500L)

P.THAY ĐỒ Height 1,5 m

the production. Waterline shall not be responsible for that.

4.Where the user attempts to re-use an existing air-conditioning duct system as the

PHÒNG TỦ ĐIỆN 1

Design Condition

supply air system,Waterline accepts it only on the condition that it is a trial and

Design Area (m ) 132.8

Design Height (m) 4

Design Volume (m ) 531.2

Supply Air (m /hr) 18000

error case. If found unsuitable, any alteration to or the re-install of a new duct.

Air Change per hour 33.9

Exhaust Air (m /hr) 10000

Balance (%) 55.5

250

5.The onus is on the user to make known to Waterline if there is any hot, corrosive Centrifugal Fan

Cooling Fan #3

Model OS18-S

or contaminated exhaust from the plant that can affect the air intake to the heat SAF-KRUGER 18.000CMH-140Pa

18.000CMH-800Pa

Filter Box AAF

exchanger. Generally a distance of min 6m clearance is necessary. If a relocation

G4 - F8

of the heat exchanger is necessary after the installation,the additional cost is for

the user's accounts.

6.The onus is also on the use to ensure that the integrity of the building structure

Y

Thay vì sử dụng

NL

các thiết bị rời,

is sound and able to take the load imposed by the equipment supplied under

O

khuyến cáo sử

dụng thiết bị tích

ON N

the contract. hợp - Fan Filter

I

Cabinet (dễ cho

T

vấn đề bảo trì bảo

Type A : Roof Mount Type C : Tower Mount

A

M TR TIO

dưỡng, cũng như

C

R

thi công lắp đặt)

U

Safety Handrail

I N FO R CON S

OR NO F O

Service Platform

T

MẶT BẰNG CAO ĐỘ +10.00M F

Roof Air Duct

Air Duct Design Condition Equipment & Air Diffuser

Team Name Date Signature

Type B : Wall Mount Safety Handrail Area MANUFACTURING Equipment Model Q'ty

Tower Design Area (m ) - OS 18-S - Drawn By. Quoc Truong 10/04/2018

Heat

Wall Design Height (m) - Exchanger OS 30-S - Revised By. Title:

Design Volume (m ) - Mount Type FSI By.

Total Air Flow (m /hr) - Type B: Wall Mount Checked By. EVAPORATIVE AIR COOLER

Service Platform Air Change per hour - D600 - SCALE Customer: NAM DUONG CO., LTD

Air Duct Duct Design Air Diffusers D450 - Project : PROPOSED WORKSPACE COOLING

SCALE TO FIT Location : HIEP PHUOC IP, NHA BE, HCM CITY

Duct Area (m ) - D350 - Drawing No. EHE - 000 - 01

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Asme N 511 2007Document49 pagesAsme N 511 2007monsepack100% (1)

- Material ListDocument8 pagesMaterial ListCheeragNo ratings yet

- R-102 Manual PDFDocument141 pagesR-102 Manual PDFphibet83% (6)

- LearnCAx Course ANSYS ICEM CFD Practice On Geometries For MeshingDocument9 pagesLearnCAx Course ANSYS ICEM CFD Practice On Geometries For MeshingRoberto Carlos Ramos SantillanoNo ratings yet

- Installation Manual PAROC PRO Clad Lamella Mat INTDocument15 pagesInstallation Manual PAROC PRO Clad Lamella Mat INTDiogo EstevesNo ratings yet

- Exhaust Fan KDK - 10 EGKADocument2 pagesExhaust Fan KDK - 10 EGKAHendro YuniantoNo ratings yet

- Fire Dampers Installation Instructions: (Static and Dynamic)Document4 pagesFire Dampers Installation Instructions: (Static and Dynamic)sbalu12674No ratings yet

- FBQ-B7V1 FBQ-B7V3B SMDocument381 pagesFBQ-B7V1 FBQ-B7V3B SMpepeNo ratings yet

- Case Study On Ventilation Method Development For BDocument9 pagesCase Study On Ventilation Method Development For BVladimir García de JesúsNo ratings yet

- Penyerapan Koefisien Bahan Bangunan Umum Dan SelesaiDocument98 pagesPenyerapan Koefisien Bahan Bangunan Umum Dan SelesaikuswandinNo ratings yet

- Effect of Fin SpacingDocument12 pagesEffect of Fin SpacingAnkit LonareNo ratings yet

- Flexible Air Conditioning Solutions With Split and VRF SystemsDocument38 pagesFlexible Air Conditioning Solutions With Split and VRF SystemsOnutu LohengrinNo ratings yet

- Smap3D Piping enDocument8 pagesSmap3D Piping enpatel_devendraaNo ratings yet

- 06 ASLI Floor Diffusers Set PDFDocument13 pages06 ASLI Floor Diffusers Set PDFLâmHoàngDuyNo ratings yet

- BS en 16798-5-1-2017Document80 pagesBS en 16798-5-1-2017Tài Nguyễn ĐứcNo ratings yet

- 10 VESDA Pipe Network Design Guide A4 IE LoresDocument56 pages10 VESDA Pipe Network Design Guide A4 IE Loresfazil yoosufNo ratings yet

- Flexible Duct Friction Loss CalculatorDocument1 pageFlexible Duct Friction Loss CalculatorThinh TranNo ratings yet

- R102-Ansul ManualDocument27 pagesR102-Ansul ManualShainu GovindankuttyNo ratings yet

- PMC Mandaue - Construction GuidelinesDocument23 pagesPMC Mandaue - Construction GuidelinesconeyquNo ratings yet

- Katalog Bss enDocument424 pagesKatalog Bss enrocket-vtNo ratings yet

- g3rv - j180 E2 02 PDFDocument14 pagesg3rv - j180 E2 02 PDFSdiri OùMaimàNo ratings yet

- Chapter 5 Ventilation and Air Conditioning PDFDocument36 pagesChapter 5 Ventilation and Air Conditioning PDFAlvinSotoRíosNo ratings yet

- Ids Blast Room GuideDocument36 pagesIds Blast Room GuideAldi Zuldiansyah100% (1)

- Fabric Expansion Joint - 2021Document46 pagesFabric Expansion Joint - 2021cemalNo ratings yet

- Approved List of Dubai Civil DefenseDocument68 pagesApproved List of Dubai Civil DefenseShaikh Muhammad AteeqNo ratings yet

- 04 - Revisions To Fire & LifeDocument4 pages04 - Revisions To Fire & LifeJanakiRam BabuNo ratings yet

- Clarus 500 GC Installation Guide - 09936590C PDFDocument112 pagesClarus 500 GC Installation Guide - 09936590C PDFLucio AlanNo ratings yet

- NSF 49-2018AnnexEDocument45 pagesNSF 49-2018AnnexELeidy GonzalezNo ratings yet

- Tamil Nadu Fire License ApplicationDocument5 pagesTamil Nadu Fire License Applicationsaravanan ssNo ratings yet