Professional Documents

Culture Documents

Kaplin Seçimi 1

Uploaded by

Ahmet0 ratings0% found this document useful (0 votes)

241 views68 pagesKaplin Seçimi

Original Title

kaplin seçimi 1

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentKaplin Seçimi

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

241 views68 pagesKaplin Seçimi 1

Uploaded by

AhmetKaplin Seçimi

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 68

. _———.

~ A

7cunMakina

$$ OcgiinMakina

ICINDEKILER

CONTENTS

HAKKIMIZDA i

‘ours J

MAKINE PARK! 82

aE PARK he

KAPLIN NEDIR? 33

‘wa SH cOuPUNG? CJ

KAPLIN SEGIM TABLOSU sa

couruma section tie a

KAPLIN HIZALAMA 85

couPums Ace fy

DiSLi KAPLIN KULLANIM ve BAKIM KILAVUZU 36

FRAO ad WATENAYCE STRUCTION FOR O2GN YP GEAR CoUuNES J

TAMBUR KAPLIN KULLANIM ve BARI KILAVUZU 7

CtRaTOW ad WATENRYCE STRUCTION FOR O23 YE J ORUMCOUPNG (J

KAPLIN MUADIL TABLOSU sa| [se

courumsseeci0NTasue aah)

ieaPLINLER 30] [sa

courunss d |

DISLI KAPLINLERE AIT GENEL OZELLIKLER: saz

even Sac oF UPL (J

OZEL TIP KAPLINLER: $43

SPECIAL COUPLINGS LJ

KAMA SEGIM TABLOSU sad

Ae SELECTION TABLE ee

‘$AFT BAGLANTI TIPLERI $48

SF coMNecTON TES LJ

vapuint sa] [a

coven J ld

ALTE KONTROL aa

cum coro. (a

TEST $49 |

st i

iaua sm) [sa

suricronn old

UYGULAMALAR 32) [59

APLICATIONS

old

RREDUKTOR KULLANIM ve BAKIM KILAVUZU sx) [sa

PrRATION an eur NSTRUGTONSFOR GEARBOXES d |

REFERANSLAR

eEnnees

www.ozgunmakina.com.tr

HAKKIMIZDA

ABOUT US

Sirketiniz 1981 yilnda istanbut'dakurulrnugolup, istanbul / Hacky

Sanayi bélgesinde 6.500 m: kapal, 1.500 m? agikalanda 48 personell

ile faaliyet gdstermektedi.

Sirketimizin faaliyet alant ve amact; Gikemizin ve diger endistri

llkelerinin agir sanayihtiyaci olan makine ve yedek pargalarin,

dnya teknolojileini yakindan takip ederek imal edilen her pargaya

yansitmaktr.

Firmamiz 2002 senesi itibari le OZGUN KAPLIN® ve OZGUN

REDUKTOR® olarak marka tesciline, 2004 senesiiibar ile de ISO

9001:2000 Kalite Yenetim Sistemi belgesine sahiptir

KALITE POLITIKAMIZ

ZGUN MAKINA SAN. ve Tic. LTD. STI. olarak; yllarin verdigi

eneyimie, Write glghiimz malar hvala ve hla alien

teknoloji éogrutusunda musteri memnuniyetini 6n planda tutarak;

+ Kalite Yonetim Sisteminin gartlarna uymayt ve etkinliginin

siirokiiyilestirimesini

+ Kaliteyi st dizeyde tuimayt,

+ Rekabet kosullarini ve teknoiojik geligmeleri g6z énine alarak

siirekli geligmeyi

* leemeyi sala iin tm gahgarlarmzeitmey ve ontara

kalite anlayisin agilamay!,

+ Konusunda kalitesini kanilamts tedarikglerle galgmayt,

+ Israfiortadan kaldirarak trinlerini en duguk maliyetle

Uretmey, ke olarak benimsemekte ve taahhiit etmekteyiz.

Uretimimiz, Tirkye'de sired yurtdigindan temin ediimekte olan

basta kaplin ve recuktor olmak tzere cesitli mekine elemanlarinin

imalatUzerinedir. Yaklasik 40 fart tip ve 450 farkl ebatta kaplini

seri olarak imal etmekte ve Tirkiye'deki basta demir celikfabrikalar

‘olmak uzere, aluminyum tesislri,cimento fesisler, Kalo fabrikalan

ve ener tesisler, yurtdisindaki digertirmalarin xalitesinden daha

yksek, daha ekonomik ve daha hizli cdzimler sunmaktayiz,

Our company tablished in 1981, istanbul, and continues

ans ul/Hadimkoy area on a 5.000 m? open land

3.400 m? enclosed facility with 48 employee.

new produets and technolog

ly manufacture

0 apply thes:

the heavy

industry of our

OUR QUALITY POLICY

N. & TI

LTD. §TI. we keep the client

d s

pm

* Obeying the clauses of Quality Management System and improving

the tim

quality at th

* Improvement allt ing the compettion

conditions and technc ents

+ For keeping the improvement we train our employee and impost

their quali

nd removing th

umn

urers ete. with experience

www.ozgunmakina.com.tr

MAKINE PARKI

MACHINERY PARK

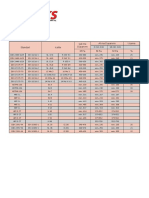

‘Stra No Makina Adi ‘Adet Markast Modell Tipi Kapasitesi

1 Tena Ta 7 Wn =o ors | aa ron 104m

7 Fea Dig Te 7 oar iste TANZIC00 on

a [ire searna bon Tezoat [1 oa ist0 Faze30 tbc

<_ [fire eermadgh Team [1 Toa ie Taz oh

3 [ire ecm dif Tewanr [1 Wo isto aza08 etvozznn (80

& [re eermaogh Taam [1 218 Kona ma 30 2500251

Terence pontine [1 Tate em Tan 25 Taos s

@ eraye Dl Tee 7 esrane Kamm |e aoe 2K songen0 ihn

a Gio Fo Tara 7 Tate Tee [haan Tanto sh

Te bgcncriertsina [1 rate on aro 150 800 00m 5

Prt Thi 7 rate 4 v8 1000509 eh

[loved Seve envatoion [1 rate vee | ao 100759

3 a Snare 1 Ea ars 8 161-1500 o stosoonm

a Siri Taena 7 va a SEEN eater

3 sania 7 [freien seman [88 a 00 e620

é Sata 7 Seni 78 | Sem VAI-T

Det Tsona 7 Wot 7980 3

3 ce Tr 7 Torin ie ni

= ene Tom 7 Tis wer | mareene aes

2 cat Tora 7 Tuning vo esse ator

2 exe Tora 7 Vier 2008 ii st i00onm

2 cut Toma 7 2 wots 0201 2508800

3 xe Tr 7 Tienes ie Tosit-aA |e oneinm a ee

a area Tona 7 Tes Tee 319 1 180e000m

% avert Toa 7 Te Tote S055 st500nm

% OkTors 7 Tuna iar so18 01m

= Diora 7 Sunt Tet 13 250x3z0nmn

3 Tver Fee 7 wi iso sno s00d0onm

[GH Okishe Neve 1 Sar on Vm 180 ToooreePonm

Dice 7 sa ‘20 ws ooo

Cac OnTETe 7 wa ee | antowan Teese

2 cue 1 [tsar one [208 5 snr 200

3 Talo 7 Tore 78 swe est000n

x Tal 1 Sent ve 5189 tenn

3 Faw 7 Terme ‘70 a ostb00m

a Taw 7 Tone 8 Siem rveonteonm

7 Dkr 7 Tres vet soso atm

% KPa 7 tater 78 a sat020onm

2 kPa 1 Tes ies ston

20 ean vowsecFetas [1 7 iso Zo

a Gen Gee fr 7 o mn Sina sO

2 Foal aon 7 Parse "220 ma oro

a roan 7 a oe aoe season

www.ozgunmakina.com.tr 2) 8

KAPLIN NEDiR?

WHAT IS THE COUPLING?

Kaplin Nedir, zgiin Makina kag tip kaplin

imal eder?

Kaplin,sistemin sigortastislevini gdren, far

malzeme tip ve ebatlardan olugan ve ki gat

(ig aktanmm amac il brbirine baslayan bir

makine pargasid. Gzgiin Makina’da 28 fark

tip ve 430 farklt ebat kendi Gzgtin dizaynt

‘olan kaplinin haticinde 6zel tiler de imal

ediimektedir

Kaplin segimi nasi yapiimalidir?

nestle, kaplinsegiminiyapacakpersoneln

tekrik olarak kulanim yeri,ortam satin,

sistem dzelider ve kaplin tile Konusunda

yeterince bilgi sahibiclmast gerekmektedi

Sistemdeki gig bilgis ile beraberintiyag

duyulan maximum eksenel ve agisal

agikikiartespitedlerek uygunkaplin tipi

segilir. Bu segimin igerisindeki bir diger

Gnemli etken ise Servis Fakt6ri olarak

adlandinlan, sistemdeki durus kalkiglar ve

strict makine tiplerinin olusturdugu

degerlerdir. Daha dnce de babsetigimizUzere

kapinn sistemde sigorta olmasi nedenigle

intyacinWzerinde seglecek olan Tork degen,

sistemde gok fark zararlara sebebiyet

verecekt

Kaplinierin montajt ve ayart nasi!

yapilmalidr?

Kaplinin gercek islevini yapabilmesi igin

ncelikle ilk montaj ve ayar esnasinda

konusunda bilgi sahibi personelin yapmast

gerekmektedir

Gnceliki olarak kaplin ve baslanacagi saftin

muhakkak temizligiyapiimis olmalid. Dogru

montaj mesafesi uygulanarak kaplinin agisal

hareketini yapmasi saQlanmalidir. Dikkat

cediimesi gereken diger bir husus ise kaplinin

mile sicak gecirilmesi strasnda stcurmazhik

elemantarinin koruma altina alinmasidi

Montattamamanan kaplinn ve millerin lazer

kaplin ayar cihaz’ ile hizalanmast kaplinin

maximum eksenel ve agisal kagiklicarin:

Yyepabilmesin saglayacak ve kaplin daha uzun

‘mili olacaktw.

What is the “coupling”, and how many

types are there that Ozgiin Machinery

produces?

ne coupling is the insurance ofthe system

But main function of itis, ti

shafts to transmit the

power. It would be produced from different

2s and dif

roduces 28

nt size coupli

ferent type and

de special

How to choose right coupling size?

First of al the tec who will

ling size must be sufficient)

n, environmental

and the system

;uplng size shouldbe

mining ofthe system power informatie

1nd xia misalignments. Ano

and angula

value Is

nts and drive

avoid the system damag

chosen atthe nominal

and should be

ues forthe syst

How should be done the installation and

adjustment of the couplings?

Primarily, the staf should have the required

knowledge about it during first installation

nd adjustment to carry out the actual

function of the coupling

wall

pling should be cleaned

ssary chemicals. Right instal

distance should be applied to provide th

requited angular movement of coupling. All

sealings should be avoid form warmth during

the heating of the shatt. Installed coupiin

should be aligned by laser alignment devi

ui nd to make

plings lifetime longer

coupling and th

with n

www.ozgunmakina.com.tr

4 OrgiinKaplin KAPLIN SECIM TABLOSU

COUPLING SELECTION TABLE

Dogru Kaplin Boyutunu Nasil Secgersiniz?

How To Choose Right Coupling Size

1, Maksimum delik gapini sajlayacak OZGUN TIP kaplini seginiz.

Please choose right O2GUN TYPE coupling up to your maximum bare dame

2. Bu kaplinin gerekli tork kapasitesinde olup olmadigini agagidaki formule gére kontrol ediniz

Please check the essential torque capacity up to calculation below.

9550 x Motor Giicti (kW) x Sf

TORK (Nm) Devir (rpm)

SURUCU MAKINA

(Sf=Servis Faktori)

DRIVER MACHINE (Sf-Service Factor)

Eleaik | _ Hidrolik | Altenalf Hareketl

UYGULAMA ALANLARI Motori pMotartan ve Motorla ve rekats

ve Turbine |pish Surdcdlei| Baslangig Ele

APPLICATIONS anol Ee

evecrale | svorauue | aecipaocaTiNG

wioroRs& | _MoToRS & ENGINE &

‘WABINES |cehAS DRIVERS ELECTRIC MOTORS

FREQUENT STARTS

LJENERATORLER, HAVA ile SOGUTMA VANTILATORLERI,

Hatit | SANTRIFOJ VANALARI, FANLAR, SANTRIFUJ POMPALARI ve

KOMPRESORLER, MAKINE PARGALARFyardime striciler,

TASIYICILAR-kemer ve zncfer, sbityille,yiriyen meravenkr

‘Soklar | dolum ve sigeleme makineler KARISTIRICILAR-sf sw kanghntar

ve bu GALISMA PRENSiBINE UYGUN MAKINELER, 0.9-1.35

Derece

1,35-1.85

Unitorm | Machine tols- auxiliary dr

loaded, escalators; Can fil

Agitators-pure liquids.

es; Conveyors-belt and chain, uni

J machines and batting machinery;

HAVA ile SOGUTMA VANTILATORLER), POMPALAR-igiveyuvalek

Orta_| tile, MAKINE PARGALARI-ana siriciler, TASIVICILAR ving,

Derece | hala takimlan, asensorter, tel sam makinlei, makaraar, kag

Soklar | endistisinde kullemlan zembereklr. SIVI ve KATI KARISTIRICILAR

ve bu GALISMA PRENSiBINE UYGUN MAKINELER, 1.35-1.6 | 1.6-1.85 185-21

Vane compressors; Machine tools-main drives: Cranes, tackes,

elevators; Agitators liquids and solids, liquids variable density; Lobe

=-umps- gear and lobe types; Conveyors-belt and cain not u

{ed bucket and serew; Wire winding machines, reals.

ALTERNATIF HAREKETLI POMPALAR ve KOMPRESORLER,

GAMAGIR KAMA MAKINELER, EME ve BLKME SL INDIRLERL

‘ar | VIDKOIS CEKME MARVEL A) KABUK SOYUCULAR, VERN

MMAKINELERBRIKET MAKINELER, MENTO FRINLAR, MADEN

yada TAS KIRIILAR, CEG IMAL yada KAUGUK IMAL YAPAN

‘Soklar | \AKINELER, METAL IMALI YAPAN MAKINELER-skstc makinler,

TEL DOZLESTIRii MAKINELER, YOL ve TREN YOLUMAKINELERI | 1.6-2.1 | 1.85-235 | 21-26

ve bu CALISMA PRENSIBINE UYGUN MAKINELER

Heavy | Metal mills-forming machines, table conveyors; Draw bench, wire

‘Shocks | drawing and flattening machines; Briquette machines, cement furnace;

Crushes-ore and toe, banmer mil Generators: Reiroating

urns and compressors: ering rl punch press, ppg machines

Barer, landers, paper presses

Derece

KONTROLLU MAKINALAR DRIVEN MACHINE

www.ozgunmakina.com.tr 4

KAPLIN HiZALAMA

COUPLING ALIGNMENT

TiP/ Type 0-250 rpm 251-600rpm | 501-1000 rpm | 1001-2000r—pm | 2001 - 4000 rpm

81-82-83 max. | xw | amex | xw | oma. | xw | amax | xw | amax. | xw

Da-Db-De-Dk | pager (mm) | (mm) | (mm) | (mm) | (rm) J (mm | (mm) | (emmy | (mm | (mm)

DLOueDV

1-4 1-4 02s | 025 | 025 | 025 | 025 | 025 | 015 | 020 | 008 | o10

5-9 5-9 oso | 060 | 050 | o60 | 025 | 035 | o15 | 020 | 008 | o10

10-18 to-14 | 090 | 100 | 050 | o7s | os [035 | 015 | 020

18-20 iso [150 | 100 | 100 | 050 | 050

‘bu tabla vrn dogo

Aneta agnan ante

Toth 0.05 in ro

oot eh pnetaton

Sh

ig ead ede the eaten ce nt an bearings, at

rlerden daha hialanan kapliner, sft ve rlmanlara geen yoke azakacakir. Bunulaeraber art ve gBbeteXl en uygun di terasin salads in,

(AN) dee 0.05" ebseel Kap and lm

en haw

nes nman ve) sau nate ar anpatalgoant

www.ozgunmakina.com.tr

DisLi KAPLIN

KULLANIM ve BAKIMI

OPERATION and MAINTENANCE INSTRUCTIONS

FOR OZGUN TYPE GEAR COUPLINGS

a

i)

MoNTAL

*Kpln ik mona esnasnda tem olmal

‘fru mont mesa! (6) tpt emetic. Hata manta messes kapnn ape

harekain engeleyaceir

*'Kaplinn mt steak gegiilmes!esnasindao-ingle in (8) kor

gurekmekedi.

*kapiin mort esrasinda (12,3) milrin ve kplnin laze kaptn ar ela ite

Fizalamas pln maksimum keel ve asa takin yaa nein gerekle

aplin kaghliinn belitlen fleansardginda ofmast halide kaplin ara gx isa

‘lacalt.

* kapliingdbek deli tleranst munakkakmilintoeransina gre boslksuz olacak

she islenmel. Gegme toleansindabosukolugmas durumunda Kalra bnen

ikartaesa

* Kalanlaca ges tp ullanm emacs vygun olarak gait ablodan (sok

‘sella anata ar tip) seimelc.

ASSEMBLY

1 Ba sure coupling is clean at assembly

* Chick the ight assembly distance (6) Weong assembly stance could lock xi

apabty ot coupling.

Al o-lags (3) shoul be covered tom heat uring shrink ft of shat 0 hub.

“Alga te eouping (23) wth ase sha algrment equipment to prevent maximum

‘land angular misaignmets Lietme of cauping wil be toe sharin ease of sage

1 couplings out of speed misalgnment tolerances.

* Couplings bor cleance shoud be machined upto sats tolerance to prevent much

‘earanca what eases edetonal force on Kepw2y

* Type of oease used in i's Intended use In accordance with the folowing tale at

high temperatures, necessary heavy-duty) should be selece, an qty ram catalogue

DDEMONTAI ve KONTROL

"apni her 8.000 satya da 2 yi tamamen sleek dh (1,2) ve eingletini

(a) sekalmesi ve nzalamtinnkonza edimes gerekmekled

DISASSEMBLING and INSPECTION

* Disassembly and check gears (1,2) and o-ings (8) and allgnment at each 8.000

hours oF 2 years.

Www.ozgunmakina.com.tr

ULLANMA ve BARI

‘Kapila esnasinda het 90 gine bars elenmel kat zelieyoksek

‘seat olan Kuler yererinde daha sik periolaréa degitirmeli ve sek tip

‘imelir. Yada ir, gersineat gres korplebogailaray,agindis metal loz,

Ghried bir made le Tomizienmel ve Kaalogéaeltien miktarda yeni grass

Seiurumata

‘Kalinga ges basinasinda sademazi eleva konto lark agi ser vaya

‘gm lan ong (2) deigtrimelisr Demonia mk clad yerlede

tig laste Uzernge Loves eenetekytgmal,

OPERATION and MAINTENANCE

* Grease should beaded every 80 days, but especialy the usage at high-temperatire

places mor requent ang continous follow-up petodsshoulé be replaced. Empty

‘rese anceinayear an clear insie fhe coupling wih solve, ten add ne grease

{gam asspeced qty on catalogue

*Sztingeauprants shou be checked avr ubrieation an toa serous or warnad

fringe (2)shauld be changed immadiaely. Incase o! saasserly fs net

Posse, c-ngs could be pasted end

aN oO "RR YORLERDE KOLA

TR. foe Ton envy UN

RAL FRAGA LOAOMSTER x

RAL ERAGREASERSEIC-NY x

TRALUE TRAGREASE RSCG MOT x

‘SEL TAN GRTASE EP OS

WOLKOTE BRR PLUS

RLUEBER TROLL GLa

® ENERGREASE LT

TAMBUR KAPLIN

KULLANIM ve BAKIMI

OPERATION and MAINTENANCE INSTRUCTIONS

FOR OZGUN TYPE J DRUM COUPLINGS

3 Fag a

%

MoNTAL

+ Kaplnk mont esnasnda amie alma

* Dajeu manta meses (8) les edna. Matah mont] mesates!Kaplnin at

hate engeleyecet.

+ Kaplinn mi scak egies esnasids o-rngern (4) Koruna tna alnmast

ovresmalteci

*kapinin mont esnasinéa (1,2 8,4 milli ve aptinn lazer kapin aya cha

ite nzalanmastkeplinn maksimum eksenel ve asa Kagan yapabimest 9h

ered. Kapin Ragin ellen flerasler ina cast Nalndekaptn %

oka ceaktr,

kapinn gobek deli tleranst munakkak min toleransina gre bostksuz olacak

fail isonet. Gegme tlransingabogukaugmas urumuna Kavala bnen

yikaracant

*Kaplin monte edilp cwelaln sikeitan sonra ki arafindaki(G) ae ylzeyer

Sranddnl

* Kulantacak ores tp kullanim amacina wygun olarak agai ablodan (yksok

‘eakllarda muha abr tip) selma

ASSEMBLY

+ Be sure couplings clean at assembly.

* Check the right essembly distance (8) Wrong assembly distance could block axial

apalty of coun.

All eings (shoul be covered tom heat during shrink ft of shaft to hub

* Align the coupting (1, 2,3, 4) wih laser shaft algnment equipment fo prevent

‘maximum axial and angular misalignments. ittime of coupling wil be too shart In

as usage of couplings out of sperad misalgnmant tolerances.

* Couplings bore toeance should be machined up ta shat tolerance to prevent much

‘eaance wha eases adeonal oe on es.

* Stig surfaces (6) at two sides ofthe coupng should be mies after coupling

‘ssombled and bls have been tightened

* Type of grease sed in i's enced use In accordance with the folowing table at

high temperatures, necessary esi) shoud be selected, nd ty trom eataoo

DEMONTAI ve KONTROL

“Hapa opin deri agra sees’ seen nie (AN)

bulunmabtadr fu zg 5 yca sols dogs kaplan son apna noktlert. Bu

Nokia gle tpl dethayensi le ed gtnlmet

Kepler 8.000 sel ye de 2 ya tram sole cgfh (1,2) ve o-ngernin

i) okies ve izalanasinn Konral egies! geokmekted,

ISASSEMBLING and INSPECTION

‘There ae signs (MAX) atthe ont ace of couplings which shows ct ol oath

Pease chang your couping imately te arom tthe end of gt orsign,

sDiasamly nd ehek gear, 2) and ons (4) an agnment t each 8.005

outs or 2 year

KULLARMA ve BAKIN

‘Aap nin sulla esnasina her 89 Unde ir gres een att zt yksok

‘eal la klum yelernde daa sk peiyolarda de timel ve sre ak

‘dimeli Vida i, Iersindek gre komple Boga, agi metal tz

Stale bir mate Be temienmel ve katalogda elites riktarda yeni ges le

Solouuimatr

*Kapline ner ges bastmesindasrénmazikelemarla konto ellerek gm ert veya

aginmis_ olan o-ringler (é) ceigticlmelicir. Demontajin mumaun

‘lai yererde o-ring Laster Uevindeucitaesenarek yapqtrnals,

OPERATION and MAINTENANCE

‘ Grase should be adced avery 80 days, ut especialy the usage a hightemperature

places mote frequent and contiuaus follow-up pariods shouldbe replaced. Ematy

‘grease once ina yar and evar inside of te coupling vith

Solent, hen 2d new grease again as specie ay on eaalogue

* Sealing eaulments should eenecked every lubrication and oo sleous or warned

‘rings shouldbe changes immediately Incase of sassembly i not possible, o-

rings could be pasted ends.

ry oo "AER YONGERDE KUL

od Eee Tan Hen Ou

TRALEE | ERAGREDSE LOVOWASTERE ©

ERALLRE ERAGREASE ASEM x

FRALUBE ERAMOLY 2 PLUS

SHELL TANIA GREASE EP DS

TOLKOTE Baa PLUS

LUEBER THOU GLa

ENERGREASE La

www.ozgunmakina.com.tr

KAPLIN MUADIL TABLOSU

COUPLING SELECTION TABLE

= al GREMGES & :

Z| weno | omsnom | rocerer] | items | wre | | |g

waxsore | 8S 2 2) 2/6

‘CAPACITY: MB | NTS | 621 622 °

cro | seve | sare | seis | sere 20N | co | 2 Jamon} ame | AFC] gp | 80-4] oF

(mm) yinen) [size | size | sie | sie | size rie Sere | 420 | Serle | Sere tle] Serie

0 a

» jw owe | 01

20 2

- to 012 | ott 6 4 1

oy or m2 2 | 2

14 ots LOZ] 2 | o2 a | st 30 0

wo pin ois

Lise | 45 8 ‘0

cao | 02> s i

on 7 7 ets |) fue

@ pm os | os [8 so | st ole

Leaia | 20 | 025 | 025 1

aiz | 20 w|%fmlnl. oT [2

. 030 | 030 4 . bed *

4 4 wo | at '

® a ses | 150 . co 202

2 0 on 60 * 3

ar] gs | 95 | 05:

’ wo | s

035, 0 4 100 101 100 70 400 | 100 s

ma 06 06 4

: . i os x0 [an © | is

1” % 200 120 os ane

Late oo

2s | 8 ra 5

1 os @ |i 128

Ls

130 — os 234 | a9 141 140 100 | 449 4

“0 oso | 08 | os us

vo bP si0 25 ‘

980 0 9 151 110

0 gay | 262 | 160 160 160 412

6 oso 16 wes |

o 1% 7

[ose 00s w |

m— sso J set | 180 10

<0 oss avs | 20s wl ef

0 ——7 140

70

ai | | goz MTT gis | aza | 200 | 201 200 9 Jou

20s

2

Ls 160

20 ® 355 5

2] 2 | gg 20 to

008 oo | 2 230

fs 180 | ovo

7 505 404 7

w ast n

oo 20

Pa 240

A wf

L, vas 200

www.ozgunmakina.com.tr 8

COUPLING EQUIVALENT TABLE

52] rou | S 2uRN ESCOGEAR HR OreiinKaplin

mux | PE 5

gs 2 nak wax. Bone

= = CAPACITY.

crac reat fa | too | a-w | too | 200 | aio | asr fost] esr | nme | neu Jno) >

nm) pinch

» hw

0 » 7M

woof | 4 1 sooo adi L

40 o | FY

38 “ bei

© 2 ne

48 ° oie

rots sso | 112 | ror va | 201 v2 | stso s|s|r |i o

‘s baa

1020 2 2 200 2 02 202 | 6200 65 70 FB 4 *

oe | 0

102s | ava | ave} 250 | ave | roe | ane. | aas0 wo | os | rs | 15 we

Das oo he

woof 2 | 2 | ao | 2 | sm | ans | cow 100 | 100 | 65 | 16

1

bas

1025 } aa | ave} aso | ave | son | ane-ve | oes0 vo | ro | we | a7 wo

te

bas

1040 4 4 400 4 104 204 | 6400 140 140 is 18 0

Ww posse

pr)

1045 | 41/2 | 4/2 | 450 | 44/2 | 1041/2 | 2041/2 | 6450 160 | 160 FB 19 oe

1

Lee

1050 5 5 500 5 105, 205 | 6500 180 | 180 a 110 [288 79

180 ?

1055 | sis | sis | 50 | s1is | 10512 | 205-12 | 50 200 | 20 | eo Jin | oe} 1% Lop

200

Ls

1060 6 6 600 6 106 206 | 6600 220 | 220 | Fit 112. | Dato 210

Lsie

2

att | aes

wr] 7 | 7 | m0] 7 | tor | 207 | e700 no | ow | ee |i

2 tei

9

zea | 280 | ete | ita | one Lw

9 www.ozgunmakina.com.tr

0% OcgiinKaplin

KAPLIN TiPLERi

COUPLING TYPES

tea Tle bb Tipov

PEA TyPE PED

3 fe rr

rip Bt (ara 1) tee

PCB fake i

ie oe

Tee

TP 32 (arake 2) —— tier

PE

S25

ies

Wee

S26

miPH

We

AT iss

Tip Dik

Tip Ds Pee

PE De

S21

www.ozgunmakina.com.tr

cL

“Welt -16 TWIT-118

KAPLIN TIPLERI ¥ OzgiinKaplin

(OZEL Tir KAPLINLER,

CIA. COUPLINGS

COUPLING TYPES

@

www.ozgunmakina.com.tr

0% OzgiinKaplin TIPA

Amn ne

TiPA ai [az | as | aa | as | as | a7 | as | ag | ato | ant | arz | ais

max a4 | 60 | 75 | 95 | 105 | 130 | 150 | 165 | 190 | 210 | 230 | 260 | 280

* min "" Fas [| 16 | 20 | 2 | ao | as | as | 5 |e | 7 | 100 | 115 | 140

Tpeak nm | 2050 | 4300 | s400 | 14400 | 23400 | s4ga0 | 5000 | 76000 | 102400|134600|176000| 269000| 360009]

Tnominal nim | 1025 | 2150 | 4200 | 7200 | 11700] 17200 | 27500 | 38000 | 1200 | 67300 | s8000 | 134500] 180009]

Devir/Revolution] min* | 3000 | 2500 | 2000 | 1700 | 1500 | 1300 | 1150 | tos0 | 960 | ss0 | soo | 700 | 650

Ha. kristine] frac | 2x0.75 | 2x0.75 | 2x0.75 | 2x0.75 | 2x0.75] 2x0.75 | 2x0.75| 2x0.75 | 2x0.75 | 2x0.75 | 2x0.75 | 2x0.75 | 2x0.75

coewlctehiaidoivene| mms | 038 | 045 | 055 | 06s | o7s| 1 | 11 | 12 | 13 | 15 | 16 | 17 | 2d

agirtiweight | ko | 5 | 7 | 13 | 21 | 30 | 39 | 64 | 82 | 110 | 140 | 167 | 260 | 320

Yaglama/Greasing| am? | 0.05 | 0.07 | 0.13 | o21 | 0.36 | os2 | 0.80 | 098 | 151 | 202 | 243 | 3.29 | 644

MassMomes!otineria | kam? | 0.006 | 0.015 | 0.046] 0.12 | 02 | o26 [125] 2 | 29 | a7 | 75 | 128 | 187

A mm | 16 | 146 | 166 | 198 | 218 | 243 | 280 | s10 | 350 | aaa | ai2 | 472 | ste

B mm | 60 | 79 | tor | 120 | 143 | 170 | 200 | 220 | 250 | 275 | 200 | 340 | 370

D mm | 102 | 122 | 152 | 180 | 203 | 229 | 267 | 293 | 330 | 358 | a2 | 440 | 475

E mm | 55 | 70 | 80 | 95 | 105 | 120 | 135 | 150 | 170 | 185 | 200 | 280 | 250

a ma {| 6 | 6 | 6 | 8 | 8 | 8 | w | 10 | tw | w | | 2 |

H mm | 105 | 125 | 155 | 188 | 212 | 242 | 282 | 305 | 335 | 373 | 395 | 455 | 590

u mm | 12 | 14 | 16 | 1 [ ts | 20 | 20 | 22 | 24 | 26 | 26 | a0 | 30

v mm | 12 | 14 | t6 | 16 | 18 | 20 | 20 | 22 | 24 | 26 | 26 | 30 | 30

Y mm | 24 | 33 | 40 | so | 56 | 62 | 7o | 72 | 77 | 81 | 6 | 102 | 102

Zz mm | 19 | 22 | 26 | 30 | 23 | 37 | a1 | a | a6 | so | 54 | a2 | 62

{AISI 4140 DOVE RRALZEMEDEW IMAL EDILEREK ISLA EDILMEXTEDIR 280-220H8}.Digh

URI FROM I 4140 MATERIAL AND QUENCH

ISIMLARI NITRASYON vaya INDUXSIVONLA SEATLESTIRILMEKTEDIR,

HAVE SEEN HARDENING BY ITAA

www.ozgunmakina.com.tr 12 |

RODUCTS HAVE BEEN MA

TIP B1 (Brake 1)

nase

Be, Saya 42 Ps check Pag 42

Tip 61 Bi-1 | 81-2 | 81-3 | 81-4 | B15 | B16 | 61-7 | B18

max 4 [| 60 | 75 | 95 | 110 | 10 | 185 | 175

od mm

min of of o fof o | ss | 6 | 80

Tpeak Nm | 2700 | 5700 | 11000 | 21000 | 33000 | 45000] s5000 | 93000

‘Tnominal Nm | 1350 | 2850 | 5500 | 10500 | 16500 | 22500 | 32500 | 46500

Max. Devir/ Revolution | min* | 6500 | 6000 | 5200 | 4820 | 4200 | 4000 | 3800 | 3600

Mar, Ag / Angular Missalignment | */arad | 2x0.75 | 2x0.75 | 2x0.75 | 2x0.75 | 2x0.75 | 2x0.75| 2x0.75] 2x0.75

ene Kapiti Displacement | mm= | 0.38 | 0.45 | oss | 065 [07s | 1 | 11 | 12

a6 | 135] 27 | 42 | 58 | 90 | 120 | 155

‘Agurik / Weight ko | 115] 155] 30 | 46 | 63 | 96 | 126 | 169

185 | 34 | 51 | 69 | 110 | 140

205 | 39 | 57 | 75

Yaglama/Greasing | dm | 0.05 | 0.07 | 0.13 | 021 | 036 | 052 | 08 | 098

Mass Moment one kom? | 0.006 | 0.015 | 0.046] 0.12 | 02 | o26 | 125] 2

A mm | 105 | 119 | 143 | 175 | 203 | 233 | 263 | 293

D mm | a1 | tar | s7t | 210 | 234 | ara | 12 | 37

E mm | 445 | sts | 635 | 785 | 925 | 107 | 122 | 196

6 mm | te | 16 | s6 | 18 | 18 | 19 | 19 | at

250 | 31s | 395 | 445 | 495 | 625 | 625 | 705

R mm | 315 | 355 | 445 | 495 | 550 | 705 | 705 | 795

395 | 495 | 550 | 625 | 795 | 795

445_| 550 | 625 | 705

8 mm | 14 | is [ 19 | 2 | 30 | a0 | a5 | 26

Xapline ak ier gern bakin Saya 10- Tip Da/ Phase chock Page T0~ Type Dao seo other Gnensions

FREN DiSKLERI GGGS0 MALZEMEDEN IMAL EDILEREK, DINAMK 2ALANS! ALINMAKTADIR

200), TOOT SURFACES HAVE BEEN HARDENING BY RATION OR ROVCTION TEMPER

www.ozgunmakina.com.tr

TIP B2 (Brake 2)

0 OcgiinKaplin

Xone

“24¢ Saya 2/

Tip 2 B26 | B27 | B28

max] | 45 | 60 | 75 | 95 | 110 | 190 | 155 | 175

mn] “" [Po fo fe fo | |= | a

Tpeak tim | 2700 | 8700 | 11000 | 21000 | 33000] 48000] 65000 93000

Tnominal tim | 1350 | 2850 | 3600 | 10500] 16800] 22500] 32500 46500

Max. Devir /Revolution | min-1 | 6500 | 6000 | 5200 | 4820 | 4200 | 4000 | 3800 | 3600

75 | 135] 24 | 42 | 55 | 94 | 139 | 168

95 | 175] 31 | 43 | 60 | 100 | 149 | 178

Agirlk / Weight ko 245 | 36 | 6t | 73 | 109 | 193 | 222

49 73 251

88

yoo | 116 | 140 | 174 | 202 | 234 | 265 | 295

io2 | 116 | 142 | 176 | 204 | 234 | 265 | 295

A mm. 118 | 142 | 176 | 204 | 234 | 268 | 298

146 204 298

204

D mm | ati | tai [ 171 | ato | 204 | ara | aia | 397

E mm | 445 | 515 | 635 | 785 | 925] 107 | 122 | 136

a | is] 13 | a7 | a7 ] 20 | at | 23

x | 13 | 15 | 19 | 19 | 20 | at | 23

6 mm is | 15 | 19 | 19 | 20 | 2 | 26

19 19 26

19

co | 75 | 95 | 118 | 118] 150 | 190 | 190

7 | 9 | 118 | 130 | 180] 170 | 195 | 195

Pp mm. 118 | 130 | 150 | 150 | 190 | 236 | 236

180 170 265

190

160 | 200 | 250 | 215 | 315 | 400 | S00 | 500

200 | 250 | 315 | 350 | 350 | 450 | 530 | 530

R mm. 315 | 350 | 400 | 400 | 500 | 630 | 630

400 450 710

500

8 mm | aq | 15 | 19 | 2 | a0 | 30 | a5 | 36

alia at dior Slr in bake Saya 10 Tip Da Plate ch

Page 10- Type Dao seo athe dimensions.

FREN KASNAKLARI GOGSO MILZENEDEN IMAL EDILEAEX, DINAMK BALANSI ALINMAKTADIR

{AISI 440 DOVE MALZEMEDEN IMAL EDILEREKISLAH EDILMEXTEDIR (280-120H8).DISLIKISIMLARI NTRASYON veya INDUXSIVONLA SEATLESTIRIL

RAKE ORUMS HAVE BEEK NAUFACTUANG FROM GZGSO MATERIAL AND WILE EALANCED DYRAMIALLY.

PRODUCTS NAVE EEN WFACTURING FROM ASI 440 ATERIAL AND QUENCHING TEUPERIG 250-2048. TOTH SU

www.ozgunmakina.com.tr 14

Ve BE HARDEN BY TATION OR

TIP B3 (Brake 3) a

Sure oot

JL

el sf oe saya a2

TiP Bs B3-1 | B32 | B33 | B34 | B35 | B36 | B37 | BIB

max 4 | 60 | 7 | 95 | 110 | 190 | 195 | 175

min} "" [> fo fo] o | o | % | 6 |

Tpeak um | 2700 | 8700 | 11000 | 21000 | 3000 | 45000 | 65000 | 93000

Trominal nm | 1350 | 2850 | 5500 | 10800 | 16500 | 22800 | 32500 | 4@500

Max. Devir/ Revolution | min* | 6500 | 6000 | 5200 | 4820 | 4200 | 4000 | 3800 | 3600

96 | 135] 28 | 47 | 69 | 105 | 180 | 209

‘Ngik/ Weight kg | 115] 155] 35 | 58 | 70 | 128 | 191 | 220

ais | 46 | 72 | 4 | 150 | 248 | 277

285 | 60 107 308

129

1525 | 1595 | 1965 ] 2385 | 2525 | a13 | 343 | a79

1625 | 1695 | 2115 | 2985 | 252.5 | 323 | 343 | 379

A mm 1795 | 21155 | 2535 | 267.5 | 333 | 378 | 409

1945 | 2265 2775 424

287.5

D mm | 111 | tar | at | 210 | 2a¢ | aa | aia | 337

E mm | 445 | 515 | 635 | 785 | e25 | 07 | 122 | 196

105 | 105 | 130 | 155 | 155 | 200 | 220 | 235

105 | 115 | 145 | 155 | 155 | 210 | 220 | 235

a mm 125 | 145 | 170 | 170 | 220 | 250 | 265

140 | 160 180 280

199

3fafs3fs]sfefeéeles

3/3 ]/3}5]s5]6]s6]e

6 mm 3] 3 }5]5]}6]6]e

a] 3 5 8

5

co | eo | 95 | 118 | 118 | 150 | 190 | 190

7 | 75 | 118 | 130 | 130 | 170 | 195 | 195,

P mm 95 | 130 | 150 | 150 | 190 | 236 | 236

113 | 150 170 265

190

360 | 160 | 250 | ats | 318 | 400 | 500 | 500

200 | 200 | 315 | 350 | 360 | 450 | 530 | 530

R mm 250 | 350 | 400 | 400 | 500 | 630 | 630

316 | 400 450 710

500

3 mm [74 | 15 | 19 [ 2 | 30 | 30 | 35 | 96

apn at berger pn ba Sayfa 10-Tip Da Please shook Page 10- Type Dao see athe dimensions

FREN KASHAKLARI GOGSOMIALZEREEDEN IMAL EDILEAEX, DINAMK BALANSI ALINMAKTADIR

AISI 440 DOVME MALZEMEDEN IMAL EDILEREKISLAH EDILMEXTEDIR (280-820H8).DISLI KISIMLARI NITRASYON veya INDUXSIVONLA SEATLESTIRILMEKTEDIR,

IL AND WL BALANCED DYRAMICLLY.

TURING FROW AIS 440 MATERIAL AMD QUENCHIVGTEMPERING (280-20, TOOT SUR

15 www.ozgunmakina.com.tr

ave BE HARDENING BY MTRATION CR MOUETIONTENPERIN,

0% OcgiinKaplin

ar,

cous

Lane

TIPC

Tipc c1 | cz | ca | ca] cs | co | c7 | ce | co | cro

od max mm | 14 | 19 | 24 | 28 | 32 | 28 | 42 | 48 | es | 80

TKNominat | Nm | 10 | 16 | 20 | 45 | 60 | 80 | 100 | 140 | 380 | 700

TK Max, nm | 20 | 32 | 40 | 90 | 120 | 160 | 200 | 280 | 760 | 1400

Max, Hr min* |+4000]11800|10600| 8500 | 7500 | 6700 | 6000 | 5600 | 4000 | 3150

Max. Ag °

Angular degree} 3 | 3 | 3 | 3s Ja} 3a)afs)asa3

Misalignment _| grad

‘Amax. mm | 50 | 54 | 56 | 84 | 84 | 4 | 88 | to4 | 114 | 186

B mm | 25 | 32 [ 36 | 44 | 50 | ss | 65 | 68 | 96 | 124

D mm | 40 | 48 | 52 | 66 | 76 | 83 | 92 | 95 | 132 | 175

E mm | 23 | 25 | 26 | 40 | 40 | 40 | 42 | 45 | 55 | 90

F mm | a7 | 37 | a1 | 46 | 48 | 43 | 50 | 50 | 68 | 93

& m | 2[2fe2f[2]2f[2]f2[2]f2 [2

IN GOBEKLERI AISI 7040 OOVME MALZEMEDEN, ZARFLARI CAST POLYAMID MALZ

ING HUBS HAVE SEEN MANUFACTUAING FROM AISI 1040 MATERIAL, SLEEVES Ha

www.ozgunmakina.com.tr

16

Tip Da 2 OzgiinKaplin

Anan 5* 4

am

‘

i

Seswpenisigg

Tip Da Dat | Da2 | Dad | Dad] Das | Da6 | Da7 | Da8 | Da9 |Da10|Da11|Dat2|Da13|Da14] Dat5|Dat6 [Da17|Da18|Dat9 D220}

max | am 45 | 60 | 75 | 95 | 110] 130 | 155 | 175 | 195 | 215 | 240 | 275 | 280 | 320 | 360 | 400 | 450 | 500 | 530 | 560

“ min 0 | 0 | 0 | O | O | 55 | 65 | 80 | 90 | 100} 120 | 150 | 180 | 200 | 220 | 260 | 280 | 300 | 330 | 350

Devir / Revolutian | min*|6500|6000]5200|4820|4200]4000|3800|3600]3450|3300|3050|2750|1700] t600] 1400| 1500] 1300] 1100] 1000] s00

i Agr Wp | ya [20.73] 7520 75015 0.752025 20.750 7520.75 0.720.750 75 v0 75 5 | 2075]

as [as

rat Dgkama| me [0.38] 0.45 [0.55 ]0.65]0.75| 1 [1.1] 12/13/15] 16/17] 21 | 22 | 24 | 26 [28] 29] 32] 33

AgurtiWeight | ka | 45 | a5 | 15 | 27 | 39 | 60 | 90 ]119] 170] 225] 280 | 420 | 600 | 770 | 1000/1260 2400 | 2900]

Yaglama/Greasing| dm’ |0.05|0.07]0.13|0.21|0.26]0.52| 0.8 |o.98]1.51]2.02|2.43]3.29|6.44] 7 | 12 | 13 24 | 26

Mass Moment otineta | xar*]0.006[0.015]0.046/0.12] 0.2 fo.26]1.25| 2 | 29] 47|75 |125]187| 29 | 42 | 56 240 | 325

a aim | 2 [106 | 130 | 162] 190 | 220 [250 | 280] 514] 364 304 [ase [575] 60s | 627 | 80 | 720 | 770 | a5 [570

aim | 67 | 87 | 107 | 133] 185 | 179 [214 | 295] 267 | 200] 320 | 376 [387 436 | 486 | 40 [B05 | 638 | 6a0 | 730

aim 0 [roa s}i2ea| 186] 181 [212 [247 [273] 307 | 298] 368 | aze [472] ste | 562 | 20 [aaa | 750 | 7a7 [on

mmm [141 | 141 | 171 [210 | 284 | 274 [312 | 887 380 405 | a [506 [501 | sto | 64 [ 42 [804 | oe | 65 [1029

nim [44.5] 51.5[63.5[785]92.5| 107 | 122 | 136] 153] 178] 198 [2 psa.s 205 | 07 [seas sa.fars.s| a [tos

aim | 2 | 94 [117 137] 168 [196 [217 [242 264] 303 | 390 [367 [480] 468 | 502 | 20 [sas | 602 | 68 | 56

omfsfafsals|sfefelsla|s|s fli] sl sls la] o|

aim | 96 [122 [760 | 184] 208 | 242 [280 [305] 345] a68 | 406 [460 [530] 500 | 62 [ae [rae

ime |e [a |ero| ioe |r fa] ve] mnie ne enzo fz0| | ca fz |e | a | ae | ee

am | 14 | 15 | 19 | 25 | 30 | 30 | a5 | 36 | as | 54 [ss fee] - | - | -f-[-]-[-]-

AISI 440 DOVE MUALZEMEDEW IMAL EDILEREK ISLA EDILMEXTEDIR(280-820HB). DSL KISIMLARI NTRASYON veya ND

TURNS FRO AIS 440 MATERIAL AMD QJENCHIGTEMPERING (8020, TOOT SUR

17 www.ozgunmakina.com.tr

IYONLA SEATLESTIILMEKTEDI.

AVE BEE HARDENING BY TRATION MOUCTIONTENPERIN,

“Be. Sa

42

TiP bb

Dbt

Dott

od max|

mm.

45

240

120

dt max]

rmin|

mm.

55

280

120

‘Tpeak

Nm

2700

l224009

Tnominal

in

1960

17009}

ny gr sagan

"oad

078

075

‘AgurivWeight

kg

46

300

Yajlama/Greasing

am?

0,023

1.215

Mass Mom, of inertia

kgm

0,006

78

a

mm

89.5

393

mm

67

320

mm

80

368

mm

itt

444

mm

445

193

mm

41

165

mm

43.5

196

mm

10

mm

96

406

M6

M6

mm

14

55

{AISI 4140 DOVE RRALZEMEDEW IMAL EDILEREK ISLA EDILMEXTEDIR 280-220H8}.Digh

ROM AS14740

RODUCTS HAVE BEEN MA

www.ozgunmakina.com.tr

URN

ISIMLARI NITRASYON vaya INDUKSIVONLA SERTLESTIR

HARDENING BY

18

TiP Dc ¥ OzgiinKaplin

finan se 4 .

(=—

“Bk. Sayfa 42

Tip oc Det | Dez | 0c3 | Dea | p05 | oe6 | de7 | nes | veg | Det0] oct1 | det2 | pers | Dera

‘od max] 45 | 60 | 75 | 95 | 110 | 120 | 155 | 175 | 195 | 215 | 240 | 27s | 280 | 320

mm

min} o | o | of o | o{ s | 6 | a0 | 90 | 100] 120 | 150 | 180 | 200

Tpeak Nm | 2700 | 5700 | 11000]21000] 33000] 45000] 65000] 93000 127000] 171000|234000]351 000] 490000] 90000

Trominal__ | Nm | 1360 | 2850 | 5500 | 10600) 16500] 22500] 32500] 46800 | 63500 | 38500) 117000|175600) 245000 [296000

Devir / Revaluation} min*| 6500 | 6000 | 5200 | 2820 | az00 | 4000 | 3800 | 300 | 2480 | 3300] 3080 | 2750 | 1700 | 1600

‘Mx. Afar Masaligment}“/grad ] 2x0.75 | 2x0.75 | 2x0.75 | 2x0.75 | 2x0.75 | 2x0.75 | 2x0.75 | 2x0.75 | 2x0.75 | 2x0.75] 2x0.75 | 2x0.75 | 2x0.75 | 2x0.75

aoibeniignenl|mme| 0.35 | 04 | os | 06 | o7 | oo | + [ia] a2 [ia f as |i] 2 | 2a

Aaunnaweignt | ko | 53 | 112 | 195] 3¢ | 51 | 71 | 108 | 198 | 195 | 260 | 325 | sto | 700 | 996

Ya§lama/Greasing} dm’ | 0.05 | 0.07 | 0.13 | 0.21 | 0.36 | 0.52 | 08 | 0.98 | 1.51 | 2.02 | 2.43 | 3.29 | 6.44 | 7.6

Mase Moment eine kan | 0,006 | 0.018 [0.046] 02 | 02 | 026 | 125] 2 | 29 | a7 | 78 | 125| 137 | 2

a mmm | 1285 | 1695 | 1975] 2915 | 2645] 285 | 921 | aa7 | 285 | 441 | ase | 588 [7075] 783

B mm| 67 | 87 | 107 | 133 | 155 | 179 | 214 | 235 | 267 | 290 | 320 | 376 | 287 | 436

c mm 0 | 103s] 1295] 156 | 181 | 212 | 247 | 273 | 207 | 38 | 368 | aze | 472 | sia

D mm| ait | tai | 74 | 210 | 234 | 274 | aia | 337 | 980 | 405 | 444 | sos | 501 | 640

E mm | 445 | 1.5 | 635 | 785 | 925 | to7 | 122 | 136 | 153 | 178 | 193 | 223 [2825] 295

E mm| at | 115 | 131 | 148 | 167 | 172 | 193 | 203 | 224 | 255 | 2a5 | ass | 415 | a7s

F mm| 82 | 94 | 117 | 137 | 164] 196 | 217 | 242 | 264 | 303 | 330 | 367 | 450 | 468

G mis | 3sf[s3sfs5[s][ef[s«][s][s]s fs |i] wo | 1

H mm| 96 | 122 | 150 | 208 | 208 | 242 | 280 | 305 | 245 | 368 | 406 | 460 | 530 | 580

M me | me | ma | mio | mio | wz | wiz | wiz | wae | mie | mite | mtz0 | wo | mo

8 mm| 14 | 15 | 19 [| 25 | 20 [| 30 | a5 | 36 | 43 | sa | 55 | ee | - | -

AISI 440 DOVE MMALZEMEDEW IMAL EDILEREK ISLA EDILMEXTEDIR(280-820H6). DiS KISIMLARI NTRASYON veya ND

TURDG FRO AIS 440 MATERIAL AMD QJENCHIGTEMPERING (8020), TOOT SU

IYONLA SEATLESTIILMEKTEDI.

AVE BEE HARDENING BY TRATION MOUCTION TEMPER,

[19 www.ozgunmakina.com.tr

TiP Dk

“Bh Sata 42

Tipbk [okt | Dez | oka | owt | ois | oie | oi7 | ie | oi | pido | oid | pxaz | vias | oxa

max as | 60 | 75 | 95 | 110 | 190 | 155 | 175 | 195 | 215 | 240 | avs | 280 | 320

* min! [0 [0 fo | o | o | 5 | os | 0 | 00 | v00 | 10 | a0 | 100 | 20

Tpeak um | 2700 [ 5700 [11000] 21000] 33000] 46000 [65009] 23000 [127000] 171000] 284000]351000| 490000] 530000

Tnominal tin | 1360 | 2880 | $600 | 10500] 1650020500 [32500 | 46500 [800 [85500117000] 175500] 248000) 295000

Nat Atal isaanen [gaa] 0.75 | 078 | 075 | 075 | 07s | 075 | 076 | 075 | 075 | 075 | 075 | o75 | 075 | 075

Yablama/Greasing | drw [exn.025|a,0.097|2x0085|20105| 2018 [20.26 | x04 | 20.49 [2076 [axt.01 [ax1.21 axa.04| 202 | 23.8

A mm 152 | 186 | 220 | 272 | 300 | 350 | 380 | ato | a7a | saa | 554 | oie | 751 | 799

B mm| 67 | 87 | 107 | 133 | 155 | 179 | 214 | 235 | 267 | 290 | 320 | are | 387 | 436

c mm| 80 [1035] 1285] 186 | 181 | 212 | 247 | 273 | so7 | 238 | 368 | aze | 472 | st

D mm att | sat | a71 | 210 | 294 | 27a | sie | 937 | 380 | 40s | 444 | soe | sot | cao

E mm | 445 | 515 | 635 | 785 | 925 | 107 | 122 | 136 | 159 | 17a | 193 | 22a | 2825] 295

F mm| 41 | 47 [585] 65 | 82 | 98 [ross] 121 | 132 [151s] 165 |1e05| 225 | 234

6 mm{ 60 | 80 | 90 | 110 | 110 | 130 | 130 | 130 | t60 | 160 | 160 | 160 | 170 | 190

H mm| 96 | 122 | 150 | 184 | 208 | 242 | 280 | 308 | 345 | 26a | 406 | aso | 530 | 580

™ me | we [me | wto | wio [mia | nite [mia [mie [ote | nate | zo | n2o | mao

8 mm 14 | is [19 | 25 | 30 | 30 | a5 | a5 | a3 | se [os | oe | - | -

‘AISI 4140 DOVE MALZEMEDEN IMAL EDILEREK ISLAM EDILMEXTEDIR (280-220

ULLANILABILECEK MAKSIMUM G 8OYUIGIN LUTFEN SORUNUE,

PRODUCTS WAVE BEEN MA\EACTURING FROM AS14540 MATERIAL AND

ASK FOR WARIMUM LENGTH

Ee

chs TEMPERNG

www.ozgunmakina.com.tr

NB) DiSLKISIALARI MITRASYON ve

80-2048.

iNDUXSIVONLA SERTLESTIRILMEKTEDIR,

QOT SURFACES HAVE BEN HARDEN IG ITRATION OR ROVCTION TEMPEANG.

TiP Dt

an]

|

|

ty

it ote Sarat wart Se:

Ble Saya 4/7, Cove Pane

Tip ot on | oi | os | pv | ots | pte | ot? | ote | Dt9 | Dro | ont | or2

max 45 | 60 | 75 | 95 | 110 | 130 | 155 | 175 | 195 | ats | 240 | 275

min |" Fo fe fo | o ] | ss | 6 | so | 2 | 100 | 120 | 100

Theak tun_| 2700 | $700 [11000 | 21000 | 3000 aS000 | 68000 | 92000 [127000] 171000)234000)361000

Tnominal win | 1380 | 2860 | 5600 | 10500 | 16500 | 22600 | 22500 | 46500 | 62500 | a8500 [117000] 175500

Devir / Revolution mint | 6500 | 6000 | 5200 | 4820 | 200 | 4000 | sa00 | 3600 | 2450 | 3300 | 060 | 2760

Max. Agt/ Angular Missalignment | ‘/orad |2x0.75 |2x0.75 | 2x0.75 |2x0.75 | 2x0.75 [2x0.75 | 2x0.75 | 2x0.75| 2x0.75 2x0.75 | 2x0.75] 2x0.75

Esenel Kagbik/ Axa Displacement | mms | 0.98 | 045 | 055 | 065 | 075] 1 | 14 | 12 | 13 | 15 | 16 | 17

‘Agurtk / Weight « | 5 | 9 | 16 | 28 | 42 | 63 | 94 | 125 | 17 | 204 | 290 | 450

Yaglama / Greasing an® | 0.05 | 0.07 | 0.13 | 021 | 036 | 052 | 08 | 098 | 1.51 | 2.02 | 243 | 3.29

Mass Moment of inertia | kam? [0.006 | 0.015 | 0.046 | 0.12 | 02 | 0.26 | 125[ 2 | 29 | a7 | 75 | 125

a mm | 95 | 109 | 133 | 165 | 193 | 225 | 255 | 285 | sie | 70 | 400 | 462

8 mm | 67 | a7 | tor | 133 | 195 | 179 | ata | 235 | 267 | 200 | 320 | 376

c mm | 80 [1035 | 1205 | 156 | tei | 212 | 2ar | 270 | s07 | sxe | 368 | 426

D mm | ai [tat | avi | 2i0 | 204 | 27a | ate | aa7 | a0 | aos | aaa | 506

E mm | 445 | 515 | 635 | 705 | 925 | 107 | 122 | 136 | 153 | 170 | 102 | 228

F mm | 105 | 127 | 160 | 190 | 247 | 282 | ats | 356 | 402 | 463 | 502 | 569

6 miefel[sfsfs[nfua]s]o ful wii

a mm | 26 | 36 | 46 | 58 | a8 | 92 | i02 | 120 | 146 | tes | 180 | 212

@ mm | 10 | 16 | 28 | 2 | a5 | 53 | o | 7 | o7 | woe | ata | a0

# mm | 96 | 122 | 150 | 184 | 208 | 242 | 280 | 30s | 34s | 08 | 206 | 460

™ me [me [me | mio | omio | wiz | wiz | m2 | me | one [ome | w120

AISI 4140 DOVE MALZEMEDEN IMAL EDILEREK ISLA! EDILMEXTEDIR (290

PRODUCTS HAVE BEEN MANUFACTURING FROM AS14140 MATERIAL AND:

8), DigLIKISINLARI NTRASVON vaya INDUKSIVONLR SEATLESTIRILMEKTEDI.

CHING. TEMPERING (40-20), TOOT SURFACES HAVE AEN HARDEN BY NTRATION OR DUCTION TEMPERING

{21 www.ozgunmakina.com.tr

TIP Dtk

‘AISI 4140 DOVE MALZEMEDEN IMAL EDILEREK ISLAM EDILMEXTEDIR (280-220

ULLANILABILECEK MAKSIMUM G 8OYUIGIN LUTFEN SORUNUE,

Be, Saya 42 Pls. Chesk Page

TiP Dik Dic | tka | otk | Dike | Dus | pixe | otK7 | Dike | ptka | Dtkt0 [Dutt | DKIZ

max] [4 | 60 | 75 | 96 | 110 | 130 | 155 | 175 | 195 | 215 | ato | 275

ois of ofa] o |] o | 55] 65 | 80 | 90 | 100 | 120 | 10

Tpeak um | 2700 | 8700 | 11000] 21000] 32000 | 45000] e000 92000] 12700017: 000/234000|251009)

Tnominal um | 1350 | 2860 | 5500 | 10500] 14500] 22500] 22500] 46500] 62800 | 85500 |1 17000|175509]

Devir/Revolution | min* | ¢500] 6000 | 5200 | 4820 | 4200 | 4000] 3800 | 3600 | 3450 | 3300 | 3050 | 2750

Mat, Angular Misslignment | */rad | 2x0,75]2x0.75|2x0.75| 240.75] 240.75] 2x0.75| 20.75 [2x0.75| 240.75] 2x0.75 | 240.75 | 20.75

Aserel Kaiti Disgiacenent | mm | 0.38] 0.45 | 055] 065/075] 1 | 14 | 12] 13 [15 | 16 | 17

Yaglama/Greasing | am’ | 0.05 | 0.07 | 0.13 | 0.21 | 0.26 | 052] 08 | 0.98 | 1.51 | 202 | 243 | 329

‘Mass Moment of inertia | kam? /0.006/0.015]0.046] 0.12] 02 |o2s] 1.25] 2 | 29] 47 | 75 | 125

A mm | 273 | 313 | 353 | 415 | 455 | sos | 566 | 628 | 758 | 768 | 778 | 790

B mm | 67 | 87 | t07 | 133 | 155 | 179 | 214 | 235 | 267 | 290 | 320 | 376

c mm | 80 [103.5[129.5| 186 | 181 | 212 | 247 | 273 | 307 | 338 | 368 | 426

D mm | att [sat [ 171 | 210 | 224 | 27a | 212 | 937 | 280 | 405 | 444 | 506

E mm | 105 | 115 | 130 | 150 | 170 | 185 | 215 | 245 | 295 | 300 | 305 | 310

F mm | 105 | 127 | +60 | 190 | 247 | 282 | 313 | 356 | 402 | 463 | S02 | 569

8 mm | 60 | 80 | 90 | 110 | 110 | 130 | 130 | 130 | 160 | 160 | 160 | 160

a mm | 96 | 122 | 150 | 184 | 208 | 242 | 280 | 205 | 345 | 368 | 406 | 460

™ me | we | ms [mo [ mio | riz | a2 | wma | aie | nie | are | 20

PRODUCTS WAVE BEEN MA\EACTURING FROM AS14540 MATERIAL AND

Ee

ASK FOR WARIMUM LENGTH

www.ozgunmakina.com.tr

chs TEMPERNG

NB) DiSLKISIALARI MITRASYON ve

80-2048.

iNDUXSIVONLA SERTLESTIRILMEKTEDIR,

GOT SURFACES HAVE FEN HARDEN GB NITATION OR DUCTION

TeNPERIG,

Tip Dv F OzeiinKaplin

Dik Kaplin

a max. 15°

Tir bv vt | Ov2 | va [Dv4 | vs | ové | ov7 | bv8 | bya [ov10|ovt1 ovi2 [ovis] ov14| ovis] ov16 ovi7|pvt8|Dv19|ovz0

max ] [45 | 60 [ 75 | 96 | 410] :a0 [155] 175 [195 | 215 | 240 275 | 280 320 | 260 | ano [480 | so | 530 [soo

= nin 0 [0 | 0 | 0 | o [55 | @ | a0 | 90 | 100] 120] 150 180 | 200 | 220 | a0 | 200 | 300 | 230 | 350

Tpeak —_| Nm | 2700] 570010002100] 330004500] 000 o30n| zoe ron eseans tonnes] rz fio ar sx zn

Tnominal | tim | 1350] 2860] $500 [1050 e500|20500|3250 as] e500] aso | ron] rss 20 ssn |4cnnfzma sc ru to

Devir / Revolution | mi] 6500|6000|5200|4820] 4200) 4000] 3800|3600|8450|8300|3050|2750|1 709] 1600] 140015001300] 100 r000| s00

a Act sag | 20.750 7520.75.75. 0.075075. 20 75 [20 75.5 rad | ats 2. ns as [a5 | 20.5

eacatcenaidepeenn| rin=| 0.38 [0.45] 0.88 [o6s]0.75| 1 [11 [1219] 15 18[ 17 [21] 22 | 24 [26 2a [32 [33

Agurinweight | ka | 45 | 85 | 15 | 27 | 39 | 60 | 90 | 119] 170 | 225 | 280 | 420 | 600 | 770 | 1000] 1250] 1600] 2000] 2400 2900]

Yaglama/Greasing| cm’ |0.05|0.07]0.13|0.21|0.36]0.52| 0.8 |o.98|1.512.02|2.43]3.29|644] 76 | 12 | 1 2 | 26

Mass Moment otneta | kon |o.00e[0.ors]o.o4elo.12| 0.2 Jo.2e|125| 2 [29] 47] 7s |r2sl1sz7| 29 | 42 | 56 | 115 | 165 | 240 | 325

A mm] 96 | 109] 133 | 165 | 193 225 | 286 | 285 | 319] 370 | 400 | 462 | 581 | sto | 634 | 67 | 728 | 778 | 92 | 973

mm | 67 | 87 | 107|193| 155] 179 | 214 | 285 | 267 | 290 | 320 | 376 | 387 | 435 | 486 | 540 | 60s | 635 | 680 | 730

mm] 80 |102.5]129.5| 186 | 181 | 212 | 247 | 272 | 207 | 938 | 268 | 426 | 472|| ste | sez | 620 | 682 | 732 | 77 | 801

mm] 111] 141] 171 [210 | 234] 274 | 312 [337 | 380 | 408 | 444 506 | 501 | 640 | 094 | 742 | 804 | o0e | o65 | 1029

mm ]44.5]51.5]63.5|78.5| 92.5] 107 | 122 [136 | 153 | 178 | 198 | 228 psa.q| 295 | 207 [323.5[352.5[875.5] 403 [425.5]

mm] 82 | 94 | 147 [197 | 164] 196 | 217 | 242 | 264 | 303 | 330 | 367 | 450 | 468 | 502 | 528 | 506 | 602 | 626 | 666

mm] 6} 6 |e] as] a fa] i fis] sa] ta | 14 | 16 [16 | 20 | 20 | 20 | 20 | 27 | a

mm] 96 | 122 150 | 184 208 | 242 280 | 305 | 345 | 268 | 408 | 460 | 520 00 | saa | waz | 744

me | me | as |ario[ vo] anr2|ian2| maiz) mre [mre] m6|n420 | m2o| azo | za | nace [za | a | a42 | nae

mm] sf3f3i3s[3fs]s[s/s]elelele[7{7]7]7]sfale

mm] 14 | 18 | 19 | 25 | 30 | 30 | 35 | 36 | 43 | 54 | 55 | 02

{AISI 440 DOVE MMALZEMEDEW IMAL EDILEREK ISLA EDIL MEXTEDIR 280-820H8). Dig KISIMLARI NITRASYON veya INDUXSIVONLA SEATLESTIRILMEKTEDIR,

TURNS FRO AIS 440 MATEALAL AND QUENCHIGTEAPERMG (28020, TOOTH SURFACES HAVE AEN HARDEN BY ITAATION OR ROVCTION TEMPER

23 www.ozgunmakina.com.tr

TIPE

TPE e1 | e2 | 63 | ea | es | 66

‘od max az | 38 | 48 | 60 | 80 | 100

mm

min 12 | 12 | 15 | 20 | 2 | 2

Devir/Revotution | min’ | 4000 | 4900 | 4000 | 000 | 2000 | 1800

Max. Power | HPetoaoueek| 12 | 25 | 41 | 72 | 181 | 329

A mm — | 613 | 713 | 354 | 1385/1414 1898

mm | 42 | 56 [ 70 | a3 | ata | 143

D mm | 78 | 100 | 122 | 144 | 188 | 236

E mm | 28 | 32 [385] 62 | 62 | a5

F mm | 60 | 70 | 34 | 192 | 140 | 188

8 mn | 53 | 73 [84 | 95 [174 | 198

H mm | 62 | 78 [ 96 | 116 | 160 | 204

KAPLIN ZARFLARI AISI 12 MALZEMEDEN, ZINCIR DISLILER AISI 1040 MALZEMEDEN MAL.

SLES HAE BEEN MARUEACTURIG FROM A 12 MATERIAL, CHAR GEARS HAVE BEEN MARUFACTURN

THBERING (482)

www.ozgunmakina.com.tr 24

LEREK DIL KISIVLARIINDUKSIVONLA SERTLESTIRILMEKTEDIR (48-52 HAC),

OM lS 140 TERI AND TOOTH SURFACES HAVE BEEN HARDENING BY DUCTION

Tip F F OzeiinKaplin

Lome

"Bk, Saya 42s. Check Page

TiPF fi | r2 | F3 | ra | 5 | Fe | F7 | Fe | ro | Fto | Fit | riz | Fi | Fa

ad max 40 | 55 | 70 | a5 | 100 | 120 | 140 | 160 | 180 | 200 | 220 | 250 | 280 | 320

min "| 0 | a | 28 | o5 | 4 | a8 | os | a0 | 20 | 100 | 120 | 150 | 10 | 200

Tpeak nim | 1800 | 3300 | 5800 | 10900 | 16600 | 25300 |41000 | 56200 | 78200 |117000| 228000] 284000] 420000 50000

Tnominal nim | 900 | 1650 | 2900 | 5450 | 8300 | 12650|20500 28100 [3910058500 111500] 142000] 245000|275000|

Devir/Revolution [min] 7400 | 6500 | 5800 | 5200 | 4800 | 4500 | 4100 | 3860 | 3650 | 2450 | 3300 | 3100 | 2850 | 2700

Max, Angular Missaignment [grad] 2x1.5 | 2x4.5 | 2x1.5 | 2x1.5 | 2xt.s | 2x1.5 | 2x1.6 | 2x1. | 241.5 [ex0.75] 210.75] 2x0.75] 290.75 | 200.75,

bene Kapital Displacement [mme| 0.75 | 08 | 1.1 | 12 | 14 [175 [195 | 23 | 25 | 145 | 155] 175] 21 | 22

Agietinrweight | xg | 42 | 84 | 14 | 25 | 36 | 58 | 83 | 110 | 160 | 215 | 265 | 380 | 600 | 770

YaglamayGreasing | am | 0.047 [0.063 [0.122 | 0.284 | 034 [0.453] 0.89 | 1.21 | 1.64 | 293 | 252 | 372 | 644 | 76

Mass Moment of inertia |kgm| 0.005 | 0.02 | 0.04 [0.102 | 0.19 | 0.43 | 0.78 | 1.24 | 2.94 | 3.65 | 5.1 | 96 | 202 | 313

A mm| 92 | 106 | 180 | 162 | 190 | 220 | 250 | 280 | ata | a64 | 04 | ase | 575 | 603

B mm| 60 | 77 | 97 | 119 | 144 | 165 | 190 | at7 | 242 | 270 | 205 | 335 | 306 | aaa

c mm| 77 | 97 | 128 | 151 | 175 | 201 | 235 | 263 | 204 | s2a | 55 | aos | 472 | 518

D mm] 117 | 152 | 178 | 213 | 240 | 280 | 318 | 47 | 300 [425s] 457 | 827 | sot | 640

E mmm] 445 | 515 | 685 | 785 | 92.5 | 107 | 120 | 196 | 153 | a78 | 193 | 223 [2az5 | 295

F mm| 84 [ 96 | 118 | 198 | 164 | 196 | 214 | 240 | 262 | aoe | a0 | 300 | 450 | ase

6 mm] 3 [3 [sfs]s]6|s6|{s|s|s]s | | w | 1

4 mm| 96 | 122 | 150 | 184 | 208 | 242 | 280 | 305 | 345 | 36a | 406 | 460 | 530 | 580

™ me | me | me | mito | mo | wre | mia | an2 | mre | ote | ate | mao | mao | w20

s mm 16 | 19 | 20 | 2 | 2 | a3 | ao | @ | a | a | 50 | 66

{AISI To40 DOVE MUALZEMEDEW IMAL EDILEREKDiSLKISIMLARINITRASYON veya IND

PRODUCTS HAVE BEEN MANUFACTURING FROM AISI 1040 MATERIAL AND TOOTH SUR

| 25 www.ozgunmakina.com.tr

IYONLA SERTLESTIRI.MEKTEDIR (8-52 HRC)

HAVE BEEN HARDENING BY RMRATIONOR DUCTION TEMPERING 48-52 HRC),

a z ina. 15°

-

a

att

=a “Wa, Sata 42, Check Page 42

TPG ci | a2 | G3 | G4 | as | G5 | G7 | a8 | Go | Gi] cn | cz] os | ots

‘sd max 40 | 55 | 70 | 85 | 100 | 120 | 140 | 160 | 180 | 200 | 220 | 250 | 260 | 320

min) |o | 0 | 2 | 8 | a | ss | a8 | 80 | 90 | 100 | 120 | 150 | 180 | 200

sad1 max| 85 | 70 | 90 | 110 | 120 | 150 | 170 | 200 | 220 | 260 | 275 | 300 | 360 | 400

in|" [0 [0 | 25 [ a5 | 45 | 65 | 75 | 90 | 90 | 100 | 120 | 150 | 180 | 200

Tpeak tim | 1800 | 3800 | 5800 | 10900] 1660025300] 41000 56200 [78200 | 117000223000] 284000] 420000) 550000

Tnominal | Nm | 900 | 1660 | 2900 | 5450 | 8300 | 12650] 20500 [28100 | 39100 | 58500] 11150042000) 248000] 275000]

Max Ager Miscignenl|*oas] 1.8 | 15 ] 15 | 15] 15] 15] ts | 15 | ts | 18 [15] 15 | 15] 15

Agitk/Weight | kg | 44 | 87 | 143 | 255 | 37 | 59 | 89 | 115 | 170 | 230 | 280 | 400 | 655 | a3

Yajlama /Greasing | dm’ | 0.025 | 0.032 [0.062 |0.117| 0.17 | 0.23 | 0.45 | ost | 082 | 12 | 13 | 19 | 32 | 38

Mass Mom. of Inertia kgme | 0.008] 0.92 [0.042 [0.106 [0.395] 0495] 082 | 13 | 25 | 39 [538 | 105 [2265] s46

A mm | 89.5 | 103.5 | 126.5 | 198.5 | 185.5 | 2145] 241.5| 273 | 311 | 361 | 393 | 456 | 575.5] 6015

B mm 60 | 77 | o7 | 119 | 144 | 05 | 190 | 217 | 24 | 270 | 205 | aas | 206 | aaa

c mm | 7 | 97 | 128 | 151 | 175 | 201 | 235 | 263 | 290 | a2e | 355 | aoa | a72 | oie

D mm | 117 | 152 | 178 | ata | 240 | 280 | sie | 347 | 200 [4255] 457 | ser | sor | oo

E mmm | 445 | 515 | 635 | 785 | 925 | 107 | 122 | 196 | 153 | 176 | 193 | 228 [2525] 205

F mm 42 | 48 | 89 | 69 | 82 | 98 | 107 | 120 | 131 | 151 | 170 | 198 | 205 | 20

A mm | 435 | 605 | 615 | 775 | 906 [1045] 1165 | 193 | 154 | 179 | 196 | 228 | 288 | 300

@ mm{ 5} s|s{e|ofesles|s | s | s [ofa] |

# mm | 96 | 122 | 150 | 1a | 208 | 242 | 280 | 05 | 24s | 268 | 406 | 460 | 520 | 580

™ we | me | we | mio [rato | mia | mre | ota | te | we | wie | mao | w20 | 20

s mm 1 | 19 | 20 | 2 | 2 | a3 | 4 | at | 4 | a | 50 | 66

{AISI Todo DOVE MARLZENEEDEW IMAL EDILEREK DISLIKISIMLAR Nii

PRODUCTS HAVE BEEN MANUFACTURING FROM AIS

SON vya iN

0TH sua

WYORLA SERTLESTIRILMEKTEDIR.

www.ozgunmakina.com.tr 26 | &

HAVE BEEN HARDENING BY NITRATION OR IND.

Tip H F OzeiinKaplin

mee F

ba, Saya 42 Ps. Check Page 42

am

TiPH a [wz [us [na [ns | 6 | w7 | ne | x9 | ato [wit] H12 | waa | Ha

ad max 40 | 55 | 70 | a6 | 100 | 120 | 140 | 160 | 180 | 200 | 220 | 250 | 280 | 320

mm.

min o | o [ 2 | a5 | 4 | 55 | 65 | 80 | 90 | 100 | 120 | 180 | 180 | 200

‘Tpeak Nm | 1800 | 3300 | 5800 [10900 | 16600] 25200 | 41000] 56200| 78200 | 117000|223000] 284000 480000] 60000]

Tnominal nim | s00 | 1650 | 2900 | 5450 | 8300 [12650] 20500] 28100] 39100 | 58500111500] 142000|245000] 275000]

Devir/Revolution _[min*] 7400 | 6500 | $800 | 5200 | 4800 | 4500 | 4100 | s8s0 | 3650 | 3450 | 3300 | 3100 | 2850 | 2700

Man. AuAnularWissalignment|*grd | 2x1.5 | 2x1.6 | 2x1.5 | 2xt.5 | 2x1.s | 2x1.5 | 2x1.5] 2xt.5 | 2x15 [ex0.75] 2x0.75 | 2x0.75| 290.75 | 200.75

seal Kk nial igazment [mms] 0.75 | 08 | 11 | 12 | 14 | 175] 195] 23 | 26 | 145 [155 | 175 21 | 22

‘Agjik/ Weight kg | 5 | 11 | 18 | 30 | 44 | 67 | 97 | 128 | 180 | 242 | 300 | 445 | 700 | 930

Yaglama/Greasing | dm’ | 0.047 | 0.063 | 0.122 | 0.234 | 0.34 |o.453 | 0.89 | 1.21 | 1.64 | 293 | 252 | 372 | 64a | 76

Mass Moment of inertia] kom 0.006 | 0.025 [0.045 ]0.115 [0.215] 0.46 | 084] 132] 255] 4 | 56 | 102 | 225 | 357

a mm| 130 | 170 | 199 | 231 | 266 | 268 | 300 | saa | are | 4ai | aac | 500 [7125] 788

8 mm{ 60 | 79 | 99 | at9 | 144 | 166 | 192 | 218 | 24a | 272 | 297 | a7 | 306 | asa

c mm| 77 | 97 | 128 | 181 | 175 | 201 | 234 | 262 | 204 | 2a | ass | aoe | a7 | sie

D mm [117 | 152 | 178 | ats | 240 | 280 | ata | 247 | 300 [aes] 457 | 27 | sor | 640

E mmm | 445 | 515 | 635 | 785 | 925 | 107 | 122 | 136 | 153 | 178 | 198 | 228 [ears] 295

E mm | 625 [1185] 1925 |1475| 1685] 175 | 195 | 205 | 215 | 255 | 285 | 360 | 420 | 480

F mm{ 4 | 96 | 118 | 138 | 164 | 196 | ata | 240 | 262 | a02 | 340 | 290 | 450 | ase

@ m{sf3afefs{s[«]oef[sfsfs|s [| wo]

H mm{ 96 | 122 | 150 | 184 | 208 | a2 | 260 | 305 | 24s | 36a | 406 | 460 | 530 | 580

™ we | 6 | ma | amo | io | m2 | mia | m2 | te | mate | ante | m20 | w2o | w20

5 mm{ 16 | 19 | 20 | 2 | 28 | x3 | a | a | aa | a | 50 | 6

{AISI Todo DOVE NARLZENEDEW IMAL EOILEREK DSL KISIMLAR Nii

AQDUCTS HAVE BEEN MANUFACTURING FROM AISI 1040 NERTEAA

| 27 www.ozgunmakina.com.tr

SON vya iN

0TH sua

WYONLA SERTLESTIRILMEKTEDIR.

HAVE BEEN HARDENING BY NITRATION OR IND)

[ON TEMPERING.

0% OcgiinKaplin TIP |

re Wires

TiP | ia} 12} 13 | ia} is | 6 | a7 | re} ag favo} itt | atz fits} ava | as

sd max 32 | 42 | 7 | 70 | a5 | 100 | 120 | 140 | 160 | 180 | 200 | 220 | 250 | 280 | 320

min]" [0 [0 | 22 | 2 | 38 | 36 | ss | a5 | a0 | 90 | 100 | 20 | 150 | 180 | 200

Toeak Nm | 1200 | 2800 | 4000 | 6560 | 1350]17100]26360|41000] 56500] 78500] 17000|228000|282000| 49000 1000

Tominal wm | 600 [11500] 2000 | 327s | 567s | 8550 | 12675] 20500) 28250] s02s0|se500|111500 142000244509

Devir /Revolution | in| 7650 | 7100 | 6100 | 5500 | 5000 | 4700 | 4500 | 4100 | 3850 | 3650 | 2450 | 3800 | 3100 | 2850

Max. AyAnuar Misalignment grad] 230.75 240.75] 2x0.75] 2x0.75] 2v0.75|2x0.75] axt.s | 2x1.5 | 2x1.5 | 2x0.75]200.75 | 2¥0.75 |[2x0.75] 2x0.75,

mmnz| 0.09 [013] 0.13] ors] o2ifo2t] a1] 1317 fae] 4 [11 [13] 18 | 19

Agurhk/Weight | ko | 2 | 35] 6 | 92 [155] 30 | a8 | 65 | 95 | 127 | 183 | 225 | 320 | 540 | 690

Yaglama/Greasing | dm’ | 0.022 0.036] 0.063 | 0.114] 0.201] 027 | 0.31 | o62| o9 | 11 | 15 [155] 26 | 56 | 68

Mass Moment a inertia | kgm?| 0.02 | 0.005] 0.01 [0.025] 0.055 [0.125] 0.25 | 0.45 | 0.89 | 1.45 | 252 | 2.75 | 6.85 | 16.1 | 249

A mm| so | 95 | 110 | 120 | 140 | 222 | ate | 246 | 273 | 308 | 358 | 388 | 450 | 570 | 597

mm] 50.9 | 604] 826] 100 | 121 | 143 | 165 | 190 | 216 | 242 | 270 | 295 | 335 | 394 | 432

mm| 84 | 96 | 120 | 140 | 168 | 190 | ato | 243 | 278 | 305 | 340 | 364 | 404 | 472 | ste

mm| 385 | 46 [535] 87 | 67 | 108 | 105 | 120 | 15 | 160 | 175 | 190 | 220 | 280 | 202

mm| so | 65 | 63 | 80 | 95 | 102 | 173 | 190 | 214 | 220 | 256 | 280 | 323 | ato | 428

6fe[e]e]s |] safes] s | w] ol

mia | aie | mie | wie | 20 | azo | 20

mm] 3 | 3

{AISI 440 DOVE MUALZEMEDEW IMAL EDILEREK ISLA EDIL MEXTEDIR 280-820H8). Dig KISIMLARI NITRASYON veya INDUXSIVONLA SEATLESTIRILMEKTEDIR,

PRODUCTS NAVE Een JACTURING FROM AISI 4°40 ATERIAL AND QUENCHING TEUPERING 260-208. TOTH SURFACES HAVE EEN HARDENING BY MITRATION 8

www.ozgunmakina.com.tr 28 |

TIP J

SL 078

Tips [93 [4 [98 [98 [a7 [8 | o9 [oto | ott J ate | ats | ata

sdmax| | s0 | 65 | 90 | 100 | 110 | 130 | 150 | 170 | 200 | 220 | 250 | 280 | 00 | 320

min} ™” 19 | 25 35 | 45 | 55 | 55 | 65 70 | 100 | 120 | 150 | 180 | 180 | 200

Tpeak Nm | 7200 | 9600 | 17200 | 28800 | 36800 | 45200 | 74000 |124000162000)260000) 320000] 620000] 770000/1000000)

Tnominat | Nm | 8600 | 4800 | 8600 [1440018400] 2260087000 | 62000] 81000 [180000] 16000] 31000] 38000| 500000

RadiatLoad | w_|12400|16400 [20200] 38400 /47000| 59400 [aa000| 12000 152000|18000| 2100] 3400] 34300] 390000

ax. AguAnguar Misalignment 075 | 075 | 0.75 | 075 [075 | 075 [075 | o75| os | o5 | 05 | 05 | 05 | 05

agutiyweight | xo | 12 | 15 | 25 | 36 | a3 | 55 | 73 | 110 | 175 | 205 | 240 | 380 | 450 | 575

Yaglama/Greasing | dm’ | 0.07 | 0.07 | 0.1 | 0.18 [0.17 | 021 | 023 | o44 [053 | o6 | oss] 1 | 12] 2

‘Mass Moment of inertia [kom | 0.045 | 0.065 0.15 | 03 | 04 | 065 | o8 | 17 [352] 49 | 65 | 127 | 178 | 185

a mm} 90 | 100 | 100 | 125 | 130 | 145 | 170 | 185 | 220 | 240 | 260 | 315 | 320 | 350

B mm} 75 | 95 | 135 | 150 | 170 | 190 | 210 | 240 | 290 | 320 | aso | 410 | aao | 470

c mm] 140 | 160 | 200 | 220 | 240 | 260 | 280 | 340 | 400 | 420 | 450 | 530 | seo | 600

D mm | 230 | 250 | 290 | 340 | 360 | 380 | 400 | 450 | si0 | 50 | s80 | 650 | 680 | 710

E mm] 42 | 42 | 42 | 45 | 45 | 45 | 45 | 60 | 60 | 60 | 60 | 65 | 65 | 81

F mm] 12 | 12 | 12 | 15 | ts | 15 | 15 | 20 | 20 | 20 | 20 | 25 | 25 | 25

6 mm } 200 | 220 | 260 | 300 | 320 | 340 | 360 | 400 | 460 | 500 | 530 | 580 | 600 | 640

4 mm | 200 | 220 | 260 | 300 | 320 | 340 | 360 | 400 | 460 | soo | s30 | 600 | 630 | 660

8 mn} 6 | 6 | 6 | 10 | to | 10 | ts | 15 | 25 | 25 | 25 | 30 | 30 | 30

a wi] s[s6{e«[s6]{s6]{s6 {6 ]{6]e6]e6]{s]s |]

Pp mm] 14 | 14 | 14 | 13 | ts | 13 | 18 | 23 | 23 | 22 | 23 | 23 | 23 | 23

R mm] 25] 25 | 25] 25 | 25] 25 [25] 25]25]25]e5]4]4 | 4

T maiz | mia [wiz | te | mie | mate | ie | azo | mz0 | 20 | ozo | mao | zo | mao)

™ ms | ms | mio | wiz | mie | wie | mie | mite | ozo | mz0 | mo | mao | zo | m2o

{AISI 4140 DOVE RRALZEMEDEW IMAL EDILEREK ISLA EDILMEXTEDIR 280-220H8}. Dig

ANG FM IS 40 TERIAL AND QUENCHING TEMPER

ISIMLARI NITRASYON vaya INDUXSIVONLA SEATLESTIRILMEKTEDIR,

TOOTH SUREACES HAVE BEN IARDEN IS BY RATION O& DUCTION TEMPER

www.ozgunmakina.com.tr

0% OcgiinKaplin TiP K

“Biz Saya 42/ Ps. Check Page 4

TiP K wi [x2 | xs [ xa] x5 | xe | «7 | xe | ko | xto | Kit | x12 | Kis | kta

‘od max| 40 | 55 | 70 | a6 | 100 | 120 | 140 | 160 | 180 | 200 | 220 | 250 | 280 | 320

min" |o | o | 25 | a5 | 45 | s5 | es | a0 | 2 | 100 120 | 150 | 180 | 200

Tpeak m | 1800 | 3200 | s800 | 10900] 14600] 2530041000 56200 |78200 | 117000] 222000|284000| 420000] 550000

Tnominal nn | 900 | 1650 | 2800 | 5450 | 8300 |12650]20500] 28100 [39100 | 58500] 111500|142000] 245000 | 275000]

Max AvArular Missalignment| as [is [as [1s [1s [1s [1s [1s [15 [075 | 075 | 075 | 075 | 075

Yaglama/Greasing | dm’ [2x0.025]2x0.032 240 062] 290.117] 2.0.17] 240.28 | 20045 | 2x0.61 | 20082 | axt.2 | at | ato | 292 | 20.8

A mm | 152 | 186 | 220 | 272 | 300 | 350 | 380 | a10 | 47a | 524 | s5¢ | o16 | 745 | 793

B mm] eo | 77 | 97 | 119 | 144] 166 | 190 | 217 | 242 | 270 | 295 | 235 | 396 | 434

c mm] 77 | 97 | 123 | 151 | 175 | 201 | 235 | 263 | 294 | 324 | 355 | 404 | 472 | 58

D mm | 417 | 152 | 178 | 213 | 240 | 280 | sta | 347 | 390 | 425.5] 457 | 527 | 591 | 640

E mm | 445 | 515 | 635 | 785 | 925] 107 | 122 | 136 | 153 | 173 | 193 | 223 | 2025] 295

F mm] 42 | 48 | 59 | 69 | 82 | 98 | 107 | 120 | 131 | 151 | 170 | 195 | 225 | 204

6 mm] 60 | 80 | 90 | 110 | 110] 130 | 130 | 120 | 160 | 160 160 | 160 | 170 | 190

H mm] 96 | 122 | 150 | 184 | 208] 242 | 280 | 305 | 345 | 368 | 406 | 460 | 530 | 580

M me | me | ms | io | mio | wiz | wiz | m2 | mie | te | mie | zo | w20 | 20

8 mm] t6 | 19 | 20 | 25 | 28 | 33 | ao | 41 | a9 | 49 [ 50 | 66

{AISI To40 DOVE MALZEMEDEW IMAL EDILMEKTEDIR. Dig KISIMLARI NITRASYON ve

PRODUCTS HAVE BEEN MANUFACTUAING FROM ASI 1040 MATERIAL AND TOOTH SURI

iYONLA SERTLESTIRILMEKTEDIR.

HAVE BEEN HARDENING BY NITRATION OR IND.

www.ozsunmakina.com.tr 30 J

ana

TiPN 0 OzeiinKaplin

mae 15°

“Bh Sal 421s. cee Pog 42

TiPN M1 N2 | N3 | N4 | NS | NG | N7 | NB | NO | N10 | N11 | N12 | NI3 | NIG

sd max} mm] 325 | 370 | 400 | 430 | 475 | 510 | 530 | 580 | 610 | 680 | 780 | 860 | 950 | 1020

Tpeak ‘um [536000| 770000000 eso eso een anon 200 too sano ono gonee rn esr

Tnominal 'nm }278000]388000| 498000688000 846000) 995000| 1200000 15e0000] 1820000[2s20000|2550000|

Devir Revolution [min] 1150 | 1020] 930 | 1s | 725 | 680 | 645 | 550 | 535 | 480 | 420 | 365 | 30 | 310

20.75 | 230.75 |2x0.75 | 240.75 | ax0.75| 240.75 | 240.75] 2x0.75 | 240.75 | 2x0.75 | 2x0.75 | ax0.75 | 240.75 | 200.75

700 | 930 | 1250 | 1624 | 2102 | 2519 | 3024 | 3786 | 4572 | 6090 | 8735 [11269] 14880| 18395,

6 | 7 | 9 [1 | 13 | 20 | 23 | a7 | a | s2 | 65 | 92 | 118 | 130

494725 | 778120 | 44254

250000]

Max. AAngular Misslignment|

Agirlk/Weight

Yajlama/Greasing

‘Mass Moment of inertia | kym*| 20790 | 3371253685 | 84215 | 129952] 17

A mm| 512 | 862 | 622 | 672 | 722 | 780 | 840 | a80 | 950 | 1050 | 1150 | 1260 | 1360 | 1480

mm] 400 | 450 | 490 | 550 | 610 | @s0 | 680 | 750 | 790 | 870 | 1000 | 1100 | 1220 | 1310

mm| 493 | 543 | 587 | 647 | 7:2 | 753 | 03 | 878 | 928 | 1028 | 1163 | 1268 | 1398 | 1498

mm | 580 | 630 | 700 | 760 | 825 | 885 | 935 | 1010 | 1088 | 1185 | 1340 | 1440 | 1575 | 1705

mm| 250 | 275 | 305 | 230 | 355 | 280 | ato | 430 | 460 | sto | 560 | eto | aso | 710

mm| 442 | 490 | 524 | s60 | 84 | @30 | 454 | 692 | 770 | 828 | 920 | 1014 1196 | 1204

mm] 12 | 12 [| 12 | t2 [ 12 | 20 [ 20 | 20 | a0 | a0 | a0 | 40 | 40 | 40

mm | 540 | 590 | 645 | 705 | 770 | 820 | 870 | 945 | tot0 | 1110 | 1255 | 1355 | 1490 | 1605

za | 24 | 30 | miso | mao | mse | wae | mae | mae | a2 | mas | was | mas | mse

382i

2

4 | 4898125

{AISI 440 DOVE MALZEMEDEW IMAL EDILEREK ISLA EDIL MEXTEDIR (280-820H8). Dig KISIMLARI NITRASYON veya INDUXSIVONLA SEATLESTIRILMEKTEDIR,

TURNS FRO AIS 440 MATEALAL AND QUENCHIGTEAPERMG (280204), TOOTH SURFACES HAVE AEN HARDEN MG BY ITAATION OR ROVCTION TEMPER

www.ozgunmakina.com.tr

“Bt San 42, Cnc Pae

TiPR Ri | R2 | R3 | R4 | RS | RE | R7 | RB | RO | RIO | R11 | R12 | R13 | R14

sdmax} | 40 | 5 | 70 | a5 | 100 | 120 | 140 | 160 | 180 | 200 | 220 | 250 | 280 | az0

min" | 0 [0 | 26 | a6 | 4 | 55 | 65 | 80 | 90 | 100 | 120 | 150 | 180 | 200

Theak Nm [ 1800 | 2200 | s800 | 10800 | 16600 25200 | 41000 e200 | 76200 | 17000] zzeon [aston | senna | non

Tnominat | Nm} 260 | +650 | 2500 | se60 | 8300 [12650 [20500] 28100| 36100 | 5850011500) <2000| sno [27000

Devir Revolution | min-'| 3900 | 3500 | 3280 | 2900 | 2500 | 2100 | 1950 | 1750 | 1600 | 1400 | 1350 | 1300 | 1200 | 1150

‘Max. At / Agua issaigament | rad | 20.75 | 240.75 | 2x0.75 | 240.75 | 240.75] 240.75 | 2x0.75| 2x0.75| 240.75] 2x0.5 | 2x0. | 2x05 | 2x05 | 2x05

sna Kgit del Dilacement| mnie | 0.65 | 0.75 | 0.85 | 0.95 | 4.4 | 1.25 | 1.35 | 1.45 | 1.55 | 1.35 | 4.48 | 1.55 | 1.75 | 1.85

agitk/Weight | ko | 9 | 18 | 27 | 45 | ot | 100 | 195 | 175 | 240 | 312 | 285 | 555 | 825 | 1090

Yaijlama /Greasing | dm? [2x0.0%5 | 240.22 | 20.65 [240.115] 240.18 | 240.25 | 2x0 45 | 240.62] 200.85 | axt 25 | 231.95 | ax. 95 | 248.29 | 20.8

Mass Moment of inertia | kgm?| 0.02 | 0.06 | 0.11 | 0.29 | 051 | 1.12 | 1.78 | 275 | 455 | 6a5| a5 [175] 32 | 55

A mm | 134 | 156 | 188 | 222 | 252 | 297 | 328 | 365 | 402 | 473 | sto | 585 | 691 | 719

mm {so | 77 [ 97 | 119 | 144 | 166 | 190 | 217 | 242 | 270 | 295 | 335 | 396 | 434

mm | 77 | 97 [ 123 | 151 | 175 | 201 | 295 | 263 | 294 | 324 | 365 | 404 | ave | si8

mm | 117 | 152 | 178 | 213 | 240 | 280 | ata | 47 | 390 [4255] 457 | sez | sot | 640

mm | 445 | 91.5 | 635 | 785 | 925 | 107 | 122 | 126 | 159 | 178 | 193 | 223 [2825] 295

mm | 42 | 48 | 59 | @9 | 82 | 98 | 107 | 120 | 131 | 151 | 170 | 195 | 225 | 234

mm 45 | 53 [ 61 | 65 | 67 | 83 | 84 | 93 | 96 [ 117 | 124 | 139 | 126 | 129

mm | 96 | 122 | 150 | 184 | 208 | 242 | 280 | 205 | 345 | 368 | 406 | 460 | 530 | 580

mm{ 36 | 45 [ 45 | 80 | 50 | 62 | 62 | 65 | 65 [ 80 | 80 | 100 | 100 | 100

mm | 155 | 194 [ 228 | 267 | 300 | 358 | ae4 | 428 | 470 | 524 | 560 | 656 | 720 | 739

me_|_me_|_we_| wo | mio [wiz | omn2 | m2 | wie | wie | mite | 20 | mz0 | 20

mm [16 | 19 [ 20 | 25 [ 28 | a3 | 40 | 41 | 49 [ 49 | 50 | 66

AISI Todo DOVE NARLZEMEDEN IMAL EOILMEXTEDIR

PRODUCTS HAVE BEEN MANUFACTURING FROM AIS

SL KISIVLARINITRASYONLA veya INDUKSIVONLA SEATLESTIRILMEKTEDIR

IATERIAL AND TOOTH SURFACES HAVE SEEN HARDENING BY NITRATION OR ID

www.ozgunmakina.com.tr 3

[ON TEMPERING,

TiP s6 1-17 $F OrgiinKaplin

oD

a6

od

|

|

|

Tip s6 86-1 | $6-2 | $6-3 | $6-4| 86-5] 6-6 | 86-7 | 86-8 | $6-9 |S6-10]86-11]S6-12|86-13| 6-14] 86-15] S6-16) S6-17|

sdmax fmm] 41 | 50 | 65 | 75 | 87 | 95 | t07 | 117 | 131 | 145 | 156 | 165 | 178 | 192 | 206 | 220 | 233

Tpeak | Nm | 500 [1160 | 2400 [4200 | 6800 | 9400 | 14200 | zoa00 | 29000 «4000 | 87000 | 116000| 150000] 187000] 287000

Tnominal | Nm | 250 | 580 [12002100] 3400| 4700] 7100 | so4on | t4800 | 21000 | zan00 | s2000 | 42500 | 8000 | 75000 | 90500 | 11850)

Anuatticlanen|'924 15] 15] 15 [15] 15] 19] 10] 10 | 10] 10] 10] 19] 10} 10 | 10 | 10 | 10

EsenelKapiik

‘Axial Displacement

‘Agirnk/ Weight | ka [ 1.4 [ 23 | 38 | 64 | 99 [135] 19 | 29 | 37 | 49 [eos] 73 | 96 | 124 | 151 | 191 | 233

Wass Moment tinea [kom® [o.0012]0.003 [0.007 [0.017]0.037]0.061| 0.11 [0.21 [0.32 | 050 [0.71 | o.98 | 157] 293] 3.32 | 489 | 6.69

A mm | 87.5 [108.4 |128.4]151.2| 174 [195.5] 217.5[2505|271.2|204.4|316.0]398.2| 372 [403.2[426.4] 458.2] 502

mm | 58 | 70 | 89 | 104 | 121 | 132 | 150 | 163 | 183 | 201 | 219 | 220 | 249 | 269 | 289 | 309 | 327

mm | 92 | 412 | 134 | 160 | 187 | 204 | 230 | 57 | 280 | 304 | 327 | 347 | 382 | aie | 442 | 477 | S07

mm | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 115 | 125 | 195 | 145 | 155 | 170 | 185 | 195 | 20 | 230

mm] 75 | 84 | 84 [12] 14 [155 [ 175 [205 [212[ 244] 26 [2a2| 32 [332 [3e4[ sao | 42

mm:}o75} 1 [13] 15] 18] 19] 21] 23]26}28]s2]s4]as]41| aa] ar] 5

FLANSLAR Ast 1040 MALZE

FLANGES KAVE BEEN MANLI

EDEN, ARA PARCALAR SSSI7 MALZEMEOEN IMAL EDILMEKTEDIR,

JING FROM AISI 1040 MATERIAL, DISCS HAVE BEEN MANUFACTURED FROM SSSI? MATERIAL

33 www.ozgunmakina.com.tr

TIP S8 17-34

Tip $8 ‘88-1 s8-2 | s8-s| se-4] sa-s | se-6 | s8-7| s8-8 | se-9 |s8-10]s8-11 [s8-13[s8-14]s8-15|s8-16]s8-17|

sdmax | mm | 131 | 145 | 156 | 168 | 178 | 192 | 206 | 220 | 233 | 238 | 250 | 265 | 275 | 290 | 300 | 315 | 330

Tpeak | Nm [42000 62000 | 76000 | s1000| 128000174000) 22000]278000| 252000] 444000] 520000] 36000770000] 510000 fogoon| 22000 scon0

Tnominal | Nm [21000 31000| 38000] 47000 s4o00 | 87000 [111000]139000|176000) 222000] 28000018000) 38s000|4s8000/s30000] e100 | rosoea

Aiqaaltknen{ ive] 05 | 05 | 05 | 05 | 05] 05] 05 | 05 | 05} 05] os | 05 | os | 05 | os | os | os

atsealraeitt Inns] 18 | 2 | 21 | 23 25| 27] 2s [sr [as | se] ss | ae] a1] 42 | 44] 46 | a

‘Agiruk/ Weight | ka [ 39 | st | 63 | 75 | 101 | 130 | 158 | 200 | 245 | 272 | 320 | a1 | 44s | sat | oto | 685 | 792

‘Mass Nomeot ofinerta [kar [0.248 0.5400.756| 1.03 | 1.68 | 251 | 3.59 | 5.25 | 7.22 | 867 [11.49[15.39|20.42] 27.9 | 33.9 | 41.3 | 52.41

A mm [271.2|294.4] 316 [338.2] 372 [403.2[426.4|458.2] S02 | $26 [591 6]583.2|620.8[665.2|698.8|731.2|7728

mm | 183 | 201 | 219 | 230 | 249 | 269 | 280 | 309 | 327 | 330 | 350 | 270 | 38s | ato | 420 | 440 | 460

mm | 280 | 304 | 327 | 247 | 382 | 412 | a2 [477 | sor | S42 | 572 | e07 | 37 | 677 | 702 | 732 | 762

mm | 125 | 135 | 148 [ 185 | 170 | 185 | 195 | 210 | 220 | 240 | 250 | 265 | 280 | 300 | 315 | 330 | 350

mm | 212[244| 26 | 282[ 32 [sa2]sealas2| a2 | 46 [51.6 [ 532] cos [652 | ea | 712[728

FLANSLAR AIS! 1040 MALZEMEDEN, ARA PARGALAR SSSi7 MALZEMEDEN IMAL EDILMEKTEDIR,

FLANGES KAVE BEEN MANUFACTURING FROM AISI 1040 MATERIAL, OISCS HAVE BEEN MANUFACTURED FROM SSSI7 KATERIAL

www.ozgunmakina.com.tr 34

en

oe

3

teed "|

TiP T6 1-17 $F OzgiinK aplin

nm

‘

:

af

(e)

‘

©

oO

TiP 6 T6-1 | 16-2 | 16-3 | T6-4 | T6-5 | T6-6 | T6-7 | T6-8 | T6-9 | T6-10)| T6-11] T6-12| T6-13 |T6-14 | T6-15 |T6-16 | T6-17|

simax fmm] 41 | 60 | 65 | 75 | 87 | 95 | 107 | 147 | 134 | 145 | 156 | 465 | 178 | 192 | 206 | 220 | 233

Tpeak [Nm | 500 | 1160 | 2400 | 4200 | e800 | s4oo | 14200] 20800| 29000] 42000| s2000] 6400087000 16000 50000] 187000[237000

Tnominal | Nm | 250 | 80 | 1200 | 2100 | 3400 | 4700 | 7100 | 1o400|14800] 21000] 26000] 32000] 43500 s8o00 | 75000 | 2500 [118500]

Agulaticagenen (94 15] 18] 1s] tsfasfrfafatafrfafatafafafada

aceasta] 15 | 21] 26] 31] 37] a8] 42) 4752] 57] 65] es]76| a2 | as | a5} ios

‘Rgrrnk/ Weight [ kg | 21 | 29 [55 | 86 15 | 21 | 30 | 40 | s7 | 74 | a9 | 109 | 146 | 190 | 224 | 208 | 306

ass Moment tinea [ka [0.002] 0.004[0.012[ 0.025[0.063] 0.11 | 0.2 | 0.32 [056 | 0.86 | 1.17| 1.63 [2-64 | 4.04 [5.45 | 8.20 [11.96

A nm | 151 | 188 | 228 | 264 | 300 | 338 | 374 | 426 | 468 | 504 | 544 | 580 | 636 | 690 | 724 | 778 | 54

mm | 58 | 70 | 89 | 104 | 121 | 192 | 150 | 163 | 183 | 201 | 219 | 200 | 249 | 269 | 289 | 309 | 327

mm | 92 | 112 | 134 | 160 | 187 | 204 | 230 | 257 | 280 | 304 | 327 | 347 | 382 | 412 | 442 | 477 | 507

mm] 40 | 80 | 60 | 70 | a0 | 90 | 100 | 115] 125 | 195] 148 | 155 | 170 | 185 | 195 | 210 | 230

mm] 75 | 34 | a4 [ii2| 14 [195] 175 [205] 212] 244] 26 | 282| 92 [332] 364 | o82| 42

mm | 71 | 88 | 108 | 124 | 140 | 158 | 174 | 196 | 218 | 234 | 254 | 270 | 296 | 320 | 334 | 358 | 394

FLANSLAR AIS! 1040 MALZEMEDEN, ARA PARGALAR SSSi7 MALZEMEDEN IMAL EDILMEKTEDIR,

JING FROM AISI 1040 MATERIAL, DISCS HAVE BEEN MANUFACTURED FROM SSSI? MATERIAL

www.ozgunmakina.com.tr

TIP T8 18-34

20

oe

a6

Tip 18 18 | 18-2 | 18-3 | 18-4 | 18-5 | 18-6 | 1-7 | 19-8 | 18-9

[r8-10|78-11]r8-12]18-13 8-14] 8-15] 18-16] 18-17

sdmax | mm] 131 | 145; 165 | 178 | 192 | 208 | 220 | 233,

296 | 250 | 265 | 278 | 290 | 200 | ats | 330

Tpeak | Nm | 42000] é2000 94000 [128000] 174000222000 [278000] 352009

44400020000) 5100006000 e000 0200

Tnominal | Nm | 21000] 31000

-4700n | 64000] 87000 [111000| 139000) 17¢000|

zzeooo| zeo000| 3 48000530000] etoan 7son0

Marta fog

AngutMignnen [924] 5 | 05 | 05 | 05 | 05 | 05 | 05 | 05 | 05

05 | 0s] os |os]o5]| os | os | os

Exsonel Kagikik

lariat Displacement|™™*| 37] 4 | 43] 46 | 5 | 54] 5a | 63 | 67

72|78|78| 82] 34] 89] 92] 96

Ajurik /Weight | a | 59 [77 | 92 | 112 | 150] 195 [220 | 295 | 274

54 [ 535 | 617 | 728 | 875 | 1021] 1130] 1310

ass Moment tinea kgm 0.573[0.878] 1 199]1.660]2.715] 4.11 | 5.54 | 8.32 [12.13]

16.77] 22.02] 28.00|36.64] 48.62] 62.26] 74.87|94.87

a mm | 468 | so4 | 54a | seo | 636 | 690 | 724 | 778 | 854

96 | 950 | 1004 | 1081 [1158| 1215] 1270 1342

mm | 183 | 201 | 219 | 230 | 249 | 269 | 299 | 209 | 227

330 | 350 | 270 | 396 | 410 | 420 | 440 | 460

mm | 280 | 304 | 327 | 347 | 382 | 412 | aaa | 477 | 507

542 | 572 | or | 637 | 677 | 702 | 732 | 762

mm | 125 | 135 | 145 | 155 | 170 | 185 | 195 | 210 | 230

240 | 250 | 265 | 280 | 300 | 315 | 330 | 350

mm| 212] 244 | 26 [282] 32 | 382] 36.4 | 36.2| 42

46 | 516| 532 [608 | 65.2 [68a | 712] 728

mm | 218 [ 224 | 254 [ 270 | 296 | 320 [ 324 | 958 | 294

ane [ 450 [ 474 | 521 | 558 [ 595 | 10 | 622

FLANSLAR AIS! 1040 MALZEMEDEN, ARA PARGALAR SSSi7 MALZEMEDEN IMAL EDILMEKTEDIR,

FLANGES KAVE BEEN MANUFACTURING FROM AISI 1040 MATERIAL, OI

www.ozgunmakina.com.tr

HAVE BEEN MANUFACTURED FROM SSS\7 MATERIAL

Tipy $F OrgiinK aplin

2 mmo"

Tiry vi | v2 | v3 | v4 | vs | ve | v7 | ve | vo | vio] vir | viz

admax| mm| 20 | 22 | 22 | a2 | 55 | 65 | a5 | 100] 110 | 110 | 120 | 180

‘Tpeak num | 20 | 40 | 100 | 200 | 440 | 900 | 1800 | 3200] 6000 | 10000] 17000] 25000

Tnominal um] 10 | 20 | 50 | 100 | 220 | 450 | 900 | 1600] 3000 | 5000 | 8500 12500

Max, Devil, Revolution min-| 4000 | 4000 | 4000 | 3000 | 3000 | 2500 | 2500 | 2000 | 2000 | 1600 | 1250 | 900

A mm| 50 | 64 | 98 | 125 | 150 | 174 | 200 | 216 | 244 | 280 | 360 | 450

mm| 30 | 34 | 43 | 65 | a0 | 95 | 125 | 150] 160 | 160 | 180 | 270

mm| 86 | 104 | 136 | 178 | 210 | 263 | 310 | 370 | 402 | 450 | 550 | 700

mm| 20 | 28 | 40 [ ss | «5 | 75 | 90 | 97 | 110 | 120 [ 135 | 173

mm| 86 | 67 | 77 | 103 | 112 | 190 | 146 | 159 | 163 | 197 | 296 | 379

mm| 10 | 8 [ 8 [ 19 | 20 | 24 | 20 | 22 | 24 | ao | 90 | 104

mm| 42 | 50 | 65 | as | 110 | 140 | 180 | 235 | 260 | 260 | 20 | 360

mm| 16 | 6 | 13 | 35 | a8 | 44 | 42 | 48 | 50 | 70 | 120 | 150

FLANSLAR

FLAN

IS! 10¢0 MALZEMEDEN, LASTIC5 KAT KAUGUKTAW MAL EDILMEKTEDIR.

/EREEN MANUFACTURING FROM A/S 1040 MATERIAL, TYRE HAVE BEEN MANUFACTURED FROM SPECIAL AUBEER, Wi

| 37 www.ozgunmakina.com.tr

IS 5 STORE CLOTHED

TIP Za

rated Ds.208

a4 | 2a5 | za6 | za7 | za8 | 209

gel Golik / sivo

45

‘mim

min 6 | 8 [wo | 1

edmax|mm| 25 | 35 | 40 | 43 | a5 | 62 | 74 | a0 | 95

min | mm| 0 0 0 0 0 0 0 0 0

ait [mm| 18 | a7 | 30 | a6 | 48 | ot | oo | 68 | 80

Toeak [Nm] 34 | 120 | 320 | 405 | 900 | 1080 | 1370 | 1880 | sa40

Tnominal Nm | 17, 60 | 160 | 325 | 450 | 525 | 685 | 940 | 1920

A mm| 66 | 78 | 90 | 114 | 126 | 140 | 160 | 185 | 210

8 mm| 1 | 18 [ 20 | 24 | 26 | 28 | 20 | 35 | 40

BI mm| 12 | 14 [ 15 [ 18 [ 20 [ 21 | 22 | 26 | 30

c mm 35 | 95 | 110] 115 | 135

D mm| 40 | 5 | 65 | 80 | 95 | 105 | 120 | 135 | 160

E mm| 25 | 30 | a5 | 45 | so | 56 | 65 | 75 | a5

F mm 2s | 32 | 37 [| 47 | 83

APL LASTIKLER 85-98 SHOE PoLIURETAKDAN URETIL

COUPLING AUBBEAS HAVE BEEN RUFACTURED FROM POLY

TE OUP KIRNIZI RENKTEDIR

THANE MATERIAL WHICH HAS 95-98 SHORE HARDNESS AND RED COLOURED.

www.ozgunmakina.com.tr 33) Bee.

Tip zr 1-14 0% OzgiinKaplin

ne ype ype

Tpzeaat Tipzen2 Tipz9-14

TiP 211-14 ai | 22 | 23 | 24 | 25 | 26 | 2e7 | 28 | 29 | 2r10 | 2r11 | 22 | 213 | 24

od max. 38 | 48 | 55 | 60 | 70 | 80 | 90 | t00 | 110] 120 | 130 | 140 | 140 | 180

min{™"Fo fo | ofofofofo fo | | ss | 6 | 7 | a | o

Tpeak 380 | 640 | 960 | 1440 | 1800 | 2600 | 4200 | s200 | 8200 | 10400] 15000] 24000 | 36000 | 48000

Tnominal nm] 190 | 320 | 480 | 720 | 900 | 1250 | 2100 | 2600 | 4100 | 5200 | 7500 | 12000 | 18000] 24000

Devir / G24