Professional Documents

Culture Documents

Informacja Eng

Uploaded by

hamidrezachamaniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Informacja Eng

Uploaded by

hamidrezachamaniCopyright:

Available Formats

LIMITS ON SULPHUR CONTENT

IN MARINE FUELS

OPERATIONAL HAZARDS

RELATED TO MAITENANCE

OF DIESEL ENGINES

AND FIRED AUXILIARY BOILERS

POLSKI REJESTR STATKÓW

MACHINERY DEPARTMENT

2009

CONTENTS:

PREVENTION OF AIR POLLUTION FROM SHIPS IN VIEW OF

THE LATEST REQUIREMENTS OF THE EU, USA CALIFORNIA

STATE AND ANNEX VI TO MARPOL CONVENTION

GUIDELINES FOR SHIPS FIRING LOW SULPHUR OIL FUELS

GUIDELINES FOR PROPER OPERATION AND MAINTAINING

OF THE SAFETY AND OPERABILITY OF DIESEL ENGINES

FIRING LOW SULPHUR OIL FUELS

GUIDELINES FOR PROPER OPERATION, MAINTENANCE,

SAFETY AND AVAILABILITY OF MARINE BOILERS

BURNING LOW-SULPHUR FUELS

Terms used in the guidelines:

ECA – Emission Control Area

FMEA – Failure Modes and Effects Analysis

HAZOP – Hazard and Operability Study

HFO – Heavy Fuel Oil

MGO – Marine Gas Oil

MDO – Marine Diesel Oil

LSDO – Low Sulphur Distilate Oil

NEW LIMITS ON SULPHUR CONTENT IN MARINE FUELS

– NEW REQUIREMENTS FOR SHIP OWNERS

AND ASSOCIATED HAZARDS

As a ship owner bears the sole responsibility for ensuring that the ship installations use low

sulphur marine fuels required by the regulations specified by the EC (see Council Directive

1999/32/EC as further amended), International Maritime Organization (Annex VI to MARPOL

Convention) and by national regulations of other countries (California state of USA), Polski

Rejestr Statków S.A. recommends, that before commencement of operation of any auxiliary

installations using such a fuel, ship owners should contact their manufacturer.

From the viewpoint of operational safety and the ship itself, it is important that engines, pumps,

boilers and boiler burners be properly adjusted for the maintenance and burning of low sulphur

marine fuels.

Where modification of the installations are necessary due to the requirement to use such fuels,

such installations shall have been previously approved by PRS S.A. and then subjected

to the survey to demonstrate the possibility of their safe operation.

Ship owners shall apply the following guidelines taking account of the safety, proper operation

and operability of marine engines and boilers associated with the usage of LSDOs (Low Sulphur

Distillate Oil) in accordance with standards ISO-8216-1 and PN-ISO 8216-1.

NEW LIMITS ON SULPHUR CONTENT IN MARINE FUELS 1

OPERATIONAL HAZARDS IN RUNNING DIESEL ENGINES AND BOILERS

PRS 2009

PREVENTION OF AIR POLLUTION FROM SHIPS

IN VIEW OF THE LATEST REQUIREMENTS

OF THE EU, USA CALIFORNIA STATE

AND ANNEX VI TO MARPOL CONVENTION

EU REQUIREMENTS

In accordance with the requirements of Directive 1999/32/EC, as amended by Directives

2005/33/EC and 2009/30/EC, since 1 January 2010, the fuel oil used while ‘at berth’ in EU ports

shall not exceed 0.10 % m/m sulphur content1).

This requirement applies to all types of marine fuels used on board the ship (main engines,

auxiliary engines and boilers).

The above stated sulphur content is not required during the ship manoeuvring, it shall, however,

be fulfilled as soon as possible after arrival and as late as possible prior departure.

The above mentioned requirements do not apply to ships:

a) which are, according to published timetables, due to be at berth for less than two hours;

b) certain named ships as specified in the annex to the Directive and engaged on voyages solely

within the territory of the Hellenic Republic, until 1 January 2012;

c) ships which switch off all engines and boilers and use shore-side electricity while at berth in

ports.

The requirements of Directive 1999/32/EC, as further amended, were incorporated in the Polish

law by the regulation by the Minister of Infrastructure of 25 March 2009 (The Journal of Laws

No. 58, item 477).

CALIFORNIA STATE REQUIREMENTS

California State Administration, USA, has formulated their internal regulations, namely

the California Code of Regulations (CCR), section 93118.2, title 17, “Airborne Toxic Control

Measure for Fuel Sulphur and other operational Requirements for Ocean-going Vessels within

Californian Waters and 24 Nautical Miles of the California Baseline”. These regulations specify

the following limits on sulphur content in marine gas oils (MGO) and marine diesel oils (MDO):

(A) in auxiliary diesel engines where:

i. from the entry of these regulations into force until 30 December 2011, marine

gas oil (MGO) with the maximum sulphur content 1.5% or marine diesel oil

(MDO) with the maximum sulphur content 0.5% may be used;

ii. from 1 January 2012, marine diesel oil (MDO) with the maximum sulphur

content 0.1%,

(B) in main diesel engines and auxiliary boilers where:

1)

this requirement applies to sea-going ships and inland waterways vessels ‘at berth’ in EU ports *) as well as

floating docks used on waters administered by Polish Maritime Offices, including the shipyard facilities.

*)

ship ‘at berth’ in an EU port means a ship in a sheltered position in an EU port which is secured at anchor, on

moorings (including single buoy moorings) or alongside irrespective of whether they are working cargo or not or

they are embarking and disembarking passengers.

NEW LIMITS ON SULPHUR CONTENT IN MARINE FUELS 2

OPERATIONAL HAZARDS IN RUNNING DIESEL ENGINES AND BOILERS

PRS 2009

i. from 1 July 2009, marine gas oil (MGO) with the maximum sulphur content

1.5% or marine diesel oil (MDO) with the maximum sulphur content 0.5%

may be used;

ii. from 1 January 2012, marine gas oil (MGO) or marine diesel oil (MDO)

with the maximum sulphur content 0.1% may be used.

REQUIREMENTS OF ANNEX VI TO MARPOL

Regulations for prevention of air pollution from ships included in Annex VI to MARPOL 73/78

specify, among others, limits on maximum sulphur content in marine fuels.

Annex VI entered into force on 19 May 2005. After three years of its application, the need for

numerous amendments to the regulations for prevention of air pollution from ships. Therefore,

a number of amendments to this Annex were adopted to take effect on 1 July 2010.

Emission Control Areas

In the new proposals, the idea of SOX Emission Control Area – SECA has been amended

and extended to constitute Emission Control Area – ECA.

This is due to:

− introduction in Regulation 14 of Annex VI to MARPOL of a new noxious factor

associated with emission from ships, which has not been covered by the rules so far, and

with taking control of the compliance with the requirements concerning the emission of

Particulate Matter – PM;

− introduction in Regulation 13 of Annex VI to MARPOL provisions on special

requirements concerning NOX emissions Emission Control Areas.

According to the new requirements, ECA means an area where special obligatory requirements

have been adopted to prevent, reduce and control air pollution with SOX, NOX, and particulate

matter and their attendant adverse impacts on human health and the environment.

New ECAs cover the present SOX Emission Control Areas, i.e. the Baltic Sea and the North Sea

inclusive of its access routes and the English Channel.

New ECA is intended to be designated off the US shore.

Sulphur Oxides (SOX)

Emission of environmentally harmful sulphur oxides (SOX) originated from the combustion on

ships is being reduced, by setting limits of the sulphur content of marine fuel oils, to comply with

the requirements of Regulation 14.

New limits on the sulphur content of marine fuel oils used outside the ECAs shall be reduced

as follows:

− until 1 December 2011, the sulphur content limit will be 4.5 %;

− since 1 January 2012, the sulphur content limit will be 3.5 %;

− since 1 January 2020 – 0.5%,

Within ECA:

− until 1 July 2010, the sulphur content limit will be 1.5 %;

− from 1 July 2010 to 31 December 2014 , the sulphur content limit will be 1.0 %;

− since 01.01.2015 – 0.1 %,

NEW LIMITS ON SULPHUR CONTENT IN MARINE FUELS 3

OPERATIONAL HAZARDS IN RUNNING DIESEL ENGINES AND BOILERS

PRS 2009

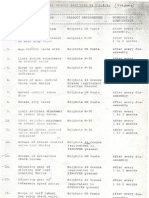

which is indicated in Table 1 and Fig. 1 below.

Table 1. Limits on sulphur content in marine oil fuels

Sulphur content limits [% m/m]

Effective from

SOX ECA Total

15 May 2005 1.5%

4.5%

01 July 2010

1.0 %

01 January 2012

3.5%

01 January 2015

0.1%

01 January 2020x 0.5 %

Note:

x

The requirement of 0.5% sulphur content in marine oil fuels will be I 2018 subject to assessment by a team of IMO

experts appointed to check the possibility for the use of such an oil fuel taking account of the future trends

and market availability. In case a negative assessment has been issued, the requirement of 0.5% sulphur content

in marine oil fuels will take effect as late as on 1 January 2025.

Fig. 1. Limits of sulphur content in oil fuels according to Annex VI to MARPOL

http://www.dieselnet.com/standards/inter/imo.php

NEW LIMITS ON SULPHUR CONTENT IN MARINE FUELS 4

OPERATIONAL HAZARDS IN RUNNING DIESEL ENGINES AND BOILERS

PRS 2009

GUIDELINES FOR SHIPS

FIRING LOW SULPHUR OIL FUELS

Provision of Adequate Capacity of Oil Fuel Tanks

and Modification of Existing Oil Fuel Storage Installation

Where a ship’s arrival at the port of call is performed through the ECA, it may be necessary

for the ship to use 2 or even 3 different types of marine fuel oil.

For the existing ships, it will be necessary to:

provide adequate capacity of oil fuel tanks and lubricating oil tanks and proper

arrangements for different classes of oil fuel and lubricating oil;

divide and install new service tanks of oil fuel;

frequently pump out and fill service tanks of distillate fuel.

Service tanks should fulfil the requirements of:

Regulation II-1/26.11 of SOLAS;

IACS Unified Interpretation SC 123 Machinery installation – Service Tank

Arrangements;

IACS Recommendation Machinery installations of ships intended to navigate in SOX

Emission Control Areas – Service Tank Arrangements.

Furthermore:

LSDO tanks should not be located adjacent to hot walls of HFO,

temporary or provisional arrangements for oil fuel tanks and systems, e.g. application

of hoses or other pipes are not acceptable.

NEW LIMITS ON SULPHUR CONTENT IN MARINE FUELS 5

OPERATIONAL HAZARDS IN RUNNING DIESEL ENGINES AND BOILERS

PRS 2009

GUIDELINES FOR PROPER OPERATION AND MAINTAINING

OF THE SAFETY AND OPERABILITY OF DIESEL ENGINES

FIRING LOW SULPHUR OIL FUELS

Before the first usage of LSDO, ship owners of vessels

navigating in SOX Emission Control Areas have to

adjust the installed engines for the combustion of such

oils, and the oil fuel supply systems for the oil fuel type

frequent change-over procedures during operation.

For the limited experience of ship owners and the

manufacturers of marine engines, using low sulphur oil

fuels and out of concern for the save operation of ships,

Polski Rejestr Statków specify below their

recommendations on the preparation of ship owners for

fulfilment of the new requirements.

http://www.ship technology.com/contractors/noise/gerb/gerb4.html

The ship owner should:

• obtain from the engine manufacturer, recommendations on the scope of the required

modifications to the oil fuel system and preparation of the engine for combustion

of LSDO;

• make changes to the engine fuel supply system to enable bypassing the oil fuel heaters

– during the changeover from HFO to LSDO – to avoid rapid heating of LSDO and its

excessive evaporation, and consequently the risk of unstable operation of the engine,

loss of its power and event the loss of ship propulsion.

Ship owner should require the engine manufacturer:

• to provide a detailed procedure for the engine supply changeover from HFO to LSDO

and vice versa. During the process of changeover, undesirable components may

precipitate, as well as air-locks in the fuel supply system or disruption of the engine work

may occur;

• to specify the maximum period of continuous operation of the engine using the LSDO

without the necessity for the cylinder oil change as long-lasting combustion of LSDO

requires application of an oil with lower alkalinity;

• to provide information regarding the effect of oil fuels with lower viscosity on

the operation and wear of the fuel apparatus components and to specify those assembled

of the engine which consequently require other maintenance intervals than before;

• to provide guidance on the need for possible changes of the alarm settings (temperature,

viscosity, fuel pressure) depending on the currently used type of oil fuel.

NEW LIMITS ON SULPHUR CONTENT IN MARINE FUELS 6

OPERATIONAL HAZARDS IN RUNNING DIESEL ENGINES AND BOILERS

PRS 2009

Ship owner, taking account of the lower viscosity of LSDO, should:

• specify the programme for the oil fuel supply system inspections, particularly

for detection and repair of the fuel leaks, as lover viscosity favours the occurrence of fuel

leaks and evaporation, which increases the risk of accumulation of flammable vapours

and, consequently, the risk of fire (explosion);

• regularly monitor the oil viscosity after the operation with LSDO, especially for trunk-

piston engines;

• regularly monitor the technical condition of the systems of storage, transport, preparation

and engine fuel supply so as to avoid contamination of LSDO with HFO as a result

of mixing and a consequential increase in the SOX emissions;

• regularly monitor the safety and alarm systems associated with the engine.

GUIDELINES FOR PROPER OPERATION, MAINTENANCE,

SAFETY AND AVAILABILITY OF MARINE BOILERS

BURNING LOW-SULPHUR FUELS

When low sulphur marine distillate oil (LSDO) is to be used instead of heavy

fuel oils (HFO), the following risks should be taken into account:

1. boiler furnace explosion,

2. burner failure or the associated fuel system failure (e.g. failure of

delivery pumps).

Boiler Furnace Explosion

Accumulation of flammable gases is more likely to develop due to easier

evaporation of the LSDO, compared to HFO, increasing the risk of explosion,

in particular in case of:

- improper gas scavenging,

- failure of the ignition devices,

- excessive vaporized fuel amount/insufficient air flow during light-off.

http://www.aalborg-industries.com

Breakdowns of Burners and Associated Fuel System

Due to different characteristics of LSDO (lower viscosity, higher heat value, lower density, etc.

compared to HFO) and different LSDO combustion processes, different is also operation

of the burner and associated fuel system.

Boiler components which require special attention to be paid during the changeover from burning

HFO to LSDO are the following:

1. Burner and its Control System

During the changeover from burning HFO to LSDO, and vice versa, special attention should be

paid to the burner and its control system. Particularly important are the following issues:

NEW LIMITS ON SULPHUR CONTENT IN MARINE FUELS 7

OPERATIONAL HAZARDS IN RUNNING DIESEL ENGINES AND BOILERS

PRS 2009

– each procedure for the fuel type change has to performed in accordance

with the boiler/burner manufacturer’s specifications;

– burner and its components: lance, steam/air nozzle, rotary cup, etc., as well as burner

spraying pressure have to be adjusted to the particular fuel type – in accordance

with burner manufacturer’s specifications;

– in burners, where LSDO is sprayed with air, special requirements concerning

the compressed air have to be fulfilled, and additionally an air excess factor may require

to be readjusted;

– programming control and relevant settings have to prevent ignition if safe conditions are

not established. For instance, special attention should be brought to the pre-scavenge

duration and to the ignition sequence. Due to an increased amount of LSDO vapours,

the pre-scavenge time should be prolonged. The control system should also allow the

post- scavenge of the whole furnace space;

– ignition devices (ignition burner or spark igniter) are to be so located as to allow

efficient ignition of the fuel spray;

– number and location of flame detectors should be consistent with the flame pattern

depending on the currently used type of oil fuel;

– heat stream generated during the combustion of each used fuel grade has to be approved

by the boiler manufacturer for different areas of the boiler.

2. Fuel Supply System

While using LSDO, special attention shall be paid to the following issues associated with boiler

fuel oil supply system:

– potential problems with LSDO excess gassing within a heated boiler fuel oil service

piping system. To avoid this, the heaters should be bypassed and fuel pipe tracing shut

off. The alternative is to convert the piping system to enable simplified and safe

changeover (direct feed). This may even require the fuel oil cooling;

– potential problems with LSDO gassing when applying steam in conjunction with marine

gas oil in atomizing steam burners. This may require modifications to enable air

atomizing or use of external mix type lances (fuel oil supply lines);

– if an atomizing steam line is led to the burner, it may be necessary to shut it off except

where the burner is specially designed for the use of LSDO with steam for atomizing

of the fuel oil;

– due to reduced viscosity and reduced lubrication ability of LSDO, the proper operation

of such fuel pumps should be checked. For pumps running continuously when the boiler

is in the stand-by mode, modification of the control system to stop pumps when running

on LSDO may be considered;

– fuel oil shut-off valves and quick closing valves have to be checked for leakage,

proper and safe operation on LSDO fuel.

NEW LIMITS ON SULPHUR CONTENT IN MARINE FUELS 8

OPERATIONAL HAZARDS IN RUNNING DIESEL ENGINES AND BOILERS

PRS 2009

Ship owner should obtain – from the manufacturer of a boiler, burner or burner control system –

possible guidance on the required modifications to the fuel oil system and the boiler adjustment

to LSDO burning.

The boiler, burner or burner control system manufacturer has to check and ensure that the burner

and the associated systems are suitable for running with different types of fuel or perform their

necessary modifications and readjustments.

Boiler/burner Operation, Inspection and Maintenance are to comply

with the following provisions:

– an inspection and maintenance programme is to be established and followed on board

the ship. It should cover in particular the tests of:

safety and alarm systems,

safety system, flame detection system and switch-off system,

boiler control system,

scavenge and ignition system,

boiler operation on LSDO with variable (including low) load sustaining the stable

flame,

boiler operation on LSDO with maximum load (specified by the boiler/burner

manufacturer);

– availability, on board the ship, of detailed procedures for the fuel changeover as well as

records of fuel changeovers are to be checked;

– compliance of the procedures with fuel changeover (from HFO to LSDO) operations

is to be checked;

– condition of flanges, gaskets and fittings is to be checked for possible leakage;

– tightness of the shut-off valves is to be checked;

– the crew is to be properly trained before performing fuel switching and operating

the boiler with LSDO;

– a procedure is to be established and applied to monitor the quality of fuel oils,

in particular their viscosity and flashpoint.

GENERAL REMARKS:

• As far as possible, fuel oils should be purchased in the same ports from reliable suppliers

and quality of the supplied fuel oils should be periodically verified by sending fuel oil

samples to the approved laboratories. Following this rule is particularly important where

fuel oils are ordered by the charterer rather than the ship owner.

• Documentation concerning the intended modifications to the fuel oil installations

for storage, transporting, preparation and supplying the engines and boilers, to the safety,

monitoring and alarm systems of the engines and boilers as well as venting and fuelling

systems shall be submitted to the Machinery Department of Polski Rejestr Statków S.A.

to be considered for compliance with the relevant provisions.

NEW LIMITS ON SULPHUR CONTENT IN MARINE FUELS 9

OPERATIONAL HAZARDS IN RUNNING DIESEL ENGINES AND BOILERS

PRS 2009

• Modifications made to the equipment and installations are subject to verification during

the ship survey.

• Procedures for the changeover from high to low sulphur oil fuels and vice versa shall be

a part of the ship’s ISM file.

• Furthermore, it is recommended that FMEA or HAZOP risk analysis be performed

covering the oil fuel supply systems as well as the control, monitoring and safety systems

of engines and boilers.

• Polski Rejestr Statków S.A. will require that the risk of failure or explosion while using

LSDO, especially during the fuel mode changeover, determined in accordance

with the above mentioned analyses be as little as possible.

Auxiliary materials:

1. Directive 1999/32/EC as amended by Directives 2005/33/EC and 2009/30/EC.

2. California Code of Regulations (CCR), section 93118.2, title 17.

3. MARPOL Annex VI.

4. IACS – Technical Meeting on the use of 0.1% Sulphur Content Marine Fuel at Berth

under Directive 2005/33/EC, EMSA 2009.

NEW LIMITS ON SULPHUR CONTENT IN MARINE FUELS 10

OPERATIONAL HAZARDS IN RUNNING DIESEL ENGINES AND BOILERS

PRS 2009

You might also like

- New Technologies for Emission Control in Marine Diesel EnginesFrom EverandNew Technologies for Emission Control in Marine Diesel EnginesNo ratings yet

- Green Ports: Inland and Seaside Sustainable Transportation StrategiesFrom EverandGreen Ports: Inland and Seaside Sustainable Transportation StrategiesRating: 5 out of 5 stars5/5 (1)

- Imo 2020 Comprehensive Guide v17 PDFDocument28 pagesImo 2020 Comprehensive Guide v17 PDFTianhui HothNo ratings yet

- 10.10.14 SOx Reg14Document1 page10.10.14 SOx Reg14juan mendozaNo ratings yet

- Emission Control RegulationsDocument2 pagesEmission Control RegulationsmagedaminhassanmagedNo ratings yet

- IMO Guidelines For Sulphur CapDocument4 pagesIMO Guidelines For Sulphur CapVarunNo ratings yet

- ECA Compliance EbookDocument62 pagesECA Compliance EbookbuzbonNo ratings yet

- New 1% fuel sulphur limits for Baltic, North Sea, English ChannelDocument1 pageNew 1% fuel sulphur limits for Baltic, North Sea, English ChannelSubramoniam MarineNo ratings yet

- 2020 Sulphur Limit FAQ 2019Document5 pages2020 Sulphur Limit FAQ 2019madhu mahatoNo ratings yet

- 2020 IMO Fuel Sulphur RegulationDocument7 pages2020 IMO Fuel Sulphur Regulationlucas100% (1)

- Guidelines for Ships Using Alternative FuelsDocument325 pagesGuidelines for Ships Using Alternative FuelsVikram SinghNo ratings yet

- Imo 2020 - Cutting Sulphur Oxide Emissions: Home Media Centre HottopicsDocument19 pagesImo 2020 - Cutting Sulphur Oxide Emissions: Home Media Centre HottopicsBadass BreakerNo ratings yet

- Emission Control Areas (Eca) DevelopmentsDocument2 pagesEmission Control Areas (Eca) DevelopmentsaloordominicNo ratings yet

- Technical Bulletin: Sulphur Oxide EmissionsDocument2 pagesTechnical Bulletin: Sulphur Oxide Emissionsanilsingh1983No ratings yet

- MARPOL 73/78 Annex VI Regulations for NOx, SOx and Fuel QualityDocument5 pagesMARPOL 73/78 Annex VI Regulations for NOx, SOx and Fuel QualityRAMSINGH CHAUHANNo ratings yet

- IMO - Marine - Engine - Regulation - Docx Filename UTF-8''IMO Marine Engine RegulationDocument6 pagesIMO - Marine - Engine - Regulation - Docx Filename UTF-8''IMO Marine Engine RegulationPyae Sone KyawNo ratings yet

- IMO Marine Engine Regulations SummaryDocument5 pagesIMO Marine Engine Regulations Summaryraph33No ratings yet

- Sulphur Oxides (Sox) - Regulation 14Document2 pagesSulphur Oxides (Sox) - Regulation 14Arunoday SinghNo ratings yet

- MARPOL 73/78 Annex VI Regulations ExplainedDocument4 pagesMARPOL 73/78 Annex VI Regulations ExplainedYoucefGMANo ratings yet

- EC Sulphur Directive Amended to Align with MARPOL Annex VIDocument1 pageEC Sulphur Directive Amended to Align with MARPOL Annex VILyubomir LazarovNo ratings yet

- What Are The Soxeca Application Dates and Why Are They Different From Annex Vi?Document4 pagesWhat Are The Soxeca Application Dates and Why Are They Different From Annex Vi?vdevivNo ratings yet

- Regulations For Air Emissions From Ships: Sox and Particulate Matter EmissionsDocument3 pagesRegulations For Air Emissions From Ships: Sox and Particulate Matter Emissionsinmran.gNo ratings yet

- Air Pollution Prevention: Entered Into Force in 2005Document11 pagesAir Pollution Prevention: Entered Into Force in 2005sabeerNo ratings yet

- Marine Environment ProtectionDocument2 pagesMarine Environment Protectionshax001No ratings yet

- (Panamá Maritime Authority) (General Directorate of Merchant Marine) (Department of Control and Compliance)Document15 pages(Panamá Maritime Authority) (General Directorate of Merchant Marine) (Department of Control and Compliance)DeepakNo ratings yet

- Air Emission Regulations and Their Impact on ShippingDocument29 pagesAir Emission Regulations and Their Impact on ShippingEmm100% (1)

- RESOLUTION MEPC.320 (74) 2019 Guidelines For Consistent Implementation of The 0.50% Sulphur Limit Under Marpol Annex ViDocument19 pagesRESOLUTION MEPC.320 (74) 2019 Guidelines For Consistent Implementation of The 0.50% Sulphur Limit Under Marpol Annex Vivishal_bhandari_1No ratings yet

- EU Low Sulphur DirectiveDocument6 pagesEU Low Sulphur DirectiverpNo ratings yet

- List of Amendments Expected To Enter Into Force in The Coming YearsDocument6 pagesList of Amendments Expected To Enter Into Force in The Coming YearsVinod NautiyalNo ratings yet

- Low SulphurDocument55 pagesLow SulphurАлександр РусскихNo ratings yet

- MEPC 1-Circ 878Document13 pagesMEPC 1-Circ 878Li Ann ChungNo ratings yet

- Safety at Sea-Legal BackgroundDocument4 pagesSafety at Sea-Legal BackgroundLuciana cNo ratings yet

- Sox NoxDocument16 pagesSox NoxPanagiotis MouzenidisNo ratings yet

- Operational Information Sulphur Limits For Ships in EU PortsDocument1 pageOperational Information Sulphur Limits For Ships in EU PortsArun SNo ratings yet

- Regulations For Air Emissions From Ships: PurposeDocument3 pagesRegulations For Air Emissions From Ships: Purposeinmran.gNo ratings yet

- Regulations For Air Emissions From Ships: PurposeDocument3 pagesRegulations For Air Emissions From Ships: Purposeinmran.gNo ratings yet

- Assignment C Extra First Class Course - Part ADocument13 pagesAssignment C Extra First Class Course - Part ARohit SethNo ratings yet

- Anexa NR 3 msn1819Document37 pagesAnexa NR 3 msn1819Creatine AngliaNo ratings yet

- 1652880710783389Document44 pages1652880710783389Владислав СирбуNo ratings yet

- List of Amendments Expected To Enter Into Force in The Coming Years LATEST 2011Document3 pagesList of Amendments Expected To Enter Into Force in The Coming Years LATEST 2011virendra302No ratings yet

- Hughes E IMODocument18 pagesHughes E IMOmustafasenbagci3693No ratings yet

- Emission Estimate Methodology For Maritime NavigationDocument12 pagesEmission Estimate Methodology For Maritime NavigationdenizinakNo ratings yet

- SummaryRevisionsMARPOL AnnexVIDocument3 pagesSummaryRevisionsMARPOL AnnexVIAkhilvjohnNo ratings yet

- IMO2020 Fuel Oil Sulphur Limit - Cleaner Air, Healthier PlanetDocument4 pagesIMO2020 Fuel Oil Sulphur Limit - Cleaner Air, Healthier PlanetHiago GasparNo ratings yet

- Aritime Air Emissions Marpol Annex Vi: Strategies and ConsequencesDocument16 pagesAritime Air Emissions Marpol Annex Vi: Strategies and ConsequencesDan MillerNo ratings yet

- Cleaning Up Bunker Fuels. But at What Cost?: January 2010Document4 pagesCleaning Up Bunker Fuels. But at What Cost?: January 2010api-25890976No ratings yet

- Implementing China's New Marine Emission Control AreasDocument79 pagesImplementing China's New Marine Emission Control AreasMai PhamNo ratings yet

- Solas Latest Ammendments: 1 January 2017 - SOLAS - IGF CodeDocument1 pageSolas Latest Ammendments: 1 January 2017 - SOLAS - IGF CodeTMI Official PhotographyNo ratings yet

- Guidelines For Ships Using Low Flashpoint Fuels (Methyl-Ethyl-Alcohol-Lpg) 2019 - Nippon Kaiji KuokaiDocument151 pagesGuidelines For Ships Using Low Flashpoint Fuels (Methyl-Ethyl-Alcohol-Lpg) 2019 - Nippon Kaiji KuokaiPeter NomikosNo ratings yet

- Mepc 181Document9 pagesMepc 181Gabriel Elano CostaNo ratings yet

- Environmental Evaluation of The Use of Diesel Engine in ShipsDocument3 pagesEnvironmental Evaluation of The Use of Diesel Engine in ShipsMalaNo ratings yet

- New UN regulations aim to reduce ship pollutionDocument1 pageNew UN regulations aim to reduce ship pollutionmarinedgeNo ratings yet

- Amendment in MarpolDocument10 pagesAmendment in MarpolGaurav Kumar SinghNo ratings yet

- Service Bulletin WCH Rt-82 Issue2Document20 pagesService Bulletin WCH Rt-82 Issue2aleventNo ratings yet

- 15-06-2020-1592206359-6-Ijme-1. Ijme - Human-Induced Violation of Imo Regulations On EmissionDocument10 pages15-06-2020-1592206359-6-Ijme-1. Ijme - Human-Induced Violation of Imo Regulations On Emissioniaset123No ratings yet

- Annex 2019 Guidelines Marpol 6 Sulphur GuideDocument20 pagesAnnex 2019 Guidelines Marpol 6 Sulphur GuideZeki OzdenNo ratings yet

- Marine and Offshore Pumping and Piping SystemsFrom EverandMarine and Offshore Pumping and Piping SystemsRating: 4.5 out of 5 stars4.5/5 (2)

- Oil Spill Remediation: Colloid Chemistry-Based Principles and SolutionsFrom EverandOil Spill Remediation: Colloid Chemistry-Based Principles and SolutionsNo ratings yet

- In-Line Defl Agration Flame Arrester: For Biogas, Sewage Gas and Landfi LL Gas, Concentric Design, BidirectionalDocument4 pagesIn-Line Defl Agration Flame Arrester: For Biogas, Sewage Gas and Landfi LL Gas, Concentric Design, BidirectionalhamidrezachamaniNo ratings yet

- Modelling Attempts To Predict Fretting-Fatigue Life On Turbine ComponentsDocument12 pagesModelling Attempts To Predict Fretting-Fatigue Life On Turbine ComponentshamidrezachamaniNo ratings yet

- Powders Cogne MXDocument5 pagesPowders Cogne MXhamidrezachamaniNo ratings yet

- Coupling AlignmentDocument14 pagesCoupling Alignmentkutts76No ratings yet

- Structure Analysis and Improvement of Diesel Engine Block: Weineng Zhang, Xiaohui CaoDocument4 pagesStructure Analysis and Improvement of Diesel Engine Block: Weineng Zhang, Xiaohui CaoMiguel Rueda CuerdaNo ratings yet

- Schematic Diagrams ExplainedDocument4 pagesSchematic Diagrams ExplainedhamidrezachamaniNo ratings yet

- Mitigation of Fretting Fatigue Damage in Blade and Disk Pressure Faces With Low Plasticity Burnishing PDFDocument9 pagesMitigation of Fretting Fatigue Damage in Blade and Disk Pressure Faces With Low Plasticity Burnishing PDFhamidrezachamaniNo ratings yet

- Generation and Use of Standardised Load Spectra and Load-Time Histories-Helix-FelixDocument17 pagesGeneration and Use of Standardised Load Spectra and Load-Time Histories-Helix-FelixhamidrezachamaniNo ratings yet

- A Critical Analysis On The Lubrication Circuit of A Non-Road Diesel Engine by Adopting A 3D and 1D ApproachesDocument11 pagesA Critical Analysis On The Lubrication Circuit of A Non-Road Diesel Engine by Adopting A 3D and 1D ApproacheshamidrezachamaniNo ratings yet

- Lubrication, Bearings & Detailed PumpsDocument2 pagesLubrication, Bearings & Detailed PumpshamidrezachamaniNo ratings yet

- Guidelines For Diesel Engine Lubrication Impact of Low Sulphur Fuel On Lubrication of Marine EnginesDocument23 pagesGuidelines For Diesel Engine Lubrication Impact of Low Sulphur Fuel On Lubrication of Marine EngineshamidrezachamaniNo ratings yet

- Powering The SystemDocument3 pagesPowering The SystemhamidrezachamaniNo ratings yet

- KMT Stellite Wrought Brochure en REVISEDDocument12 pagesKMT Stellite Wrought Brochure en REVISEDhamidrezachamaniNo ratings yet

- Spectrum Loading and Surface Finish Effects in AL7075-T73-GoodDocument7 pagesSpectrum Loading and Surface Finish Effects in AL7075-T73-GoodhamidrezachamaniNo ratings yet

- An Investigation of Influence of Diesel Fuel Sulphur Content On Particulates Emissions From Direct Injection Common Rail Diesel VehicleDocument10 pagesAn Investigation of Influence of Diesel Fuel Sulphur Content On Particulates Emissions From Direct Injection Common Rail Diesel VehiclehamidrezachamaniNo ratings yet

- Some Factors Influencing Damage Tolerance Under Helicopter SpectraDocument8 pagesSome Factors Influencing Damage Tolerance Under Helicopter SpectrahamidrezachamaniNo ratings yet

- Effects of Sulphur and Vanadium in Diesel Fuel on Engine Performance and EmissionsDocument5 pagesEffects of Sulphur and Vanadium in Diesel Fuel on Engine Performance and EmissionshamidrezachamaniNo ratings yet

- Caterpillar PDFDocument54 pagesCaterpillar PDFIngrid Garcia de JaureguiNo ratings yet

- Understanding CFPP: The Cold Filter Plugging PointDocument2 pagesUnderstanding CFPP: The Cold Filter Plugging PointNenad PopovicNo ratings yet

- Effects of High Sulphur Content in Marine Fuels On Particulate Matter Emission CharacteristicsDocument11 pagesEffects of High Sulphur Content in Marine Fuels On Particulate Matter Emission CharacteristicshamidrezachamaniNo ratings yet

- IUST v6n3p2198 enDocument13 pagesIUST v6n3p2198 enhamidrezachamaniNo ratings yet

- A Model For Estimation of De-Rating in Diesel EnginesDocument7 pagesA Model For Estimation of De-Rating in Diesel EngineshamidrezachamaniNo ratings yet

- 350hp 1Document1 page350hp 1hamidrezachamaniNo ratings yet

- Shock Analysis of Electronic Comonents - MingYao DingDocument39 pagesShock Analysis of Electronic Comonents - MingYao DingRaki Rock100% (1)

- Relationship Between Cavitation Structures and Cavitation DamageDocument9 pagesRelationship Between Cavitation Structures and Cavitation DamagehamidrezachamaniNo ratings yet

- 3d Crack Fracture Wb145 CAEADocument21 pages3d Crack Fracture Wb145 CAEAAh-Young ParkNo ratings yet

- RPT - 95 3 2004 01303 01 eDocument51 pagesRPT - 95 3 2004 01303 01 ehamidrezachamaniNo ratings yet

- Low Alloy Steel For Fracture Splitting Connecting RodDocument5 pagesLow Alloy Steel For Fracture Splitting Connecting RodhamidrezachamaniNo ratings yet

- Development of High Strength Microalloyed Steel For Powertrain Applications (Philip Clarke Matthew Green and Richard Dolman)Document8 pagesDevelopment of High Strength Microalloyed Steel For Powertrain Applications (Philip Clarke Matthew Green and Richard Dolman)hamidrezachamaniNo ratings yet

- 10 5923 J Ajps 20160601 01Document11 pages10 5923 J Ajps 20160601 01Anonymous pyYutzGNo ratings yet

- ANSWER QUESTIONS 1, 2, 3 and One Other: The University of The West IndiesDocument9 pagesANSWER QUESTIONS 1, 2, 3 and One Other: The University of The West IndiesKwame DowridgeNo ratings yet

- BHEL Approved Molykote ProductsDocument2 pagesBHEL Approved Molykote ProductsProject Sales CorpNo ratings yet

- RajDocument2 pagesRajRaj KumarNo ratings yet

- 2006 Nissan XTrail HandbookDocument281 pages2006 Nissan XTrail Handbooksumtzu100% (1)

- 319 Docol Product ProgramDocument2 pages319 Docol Product Programchristos032No ratings yet

- Anti Corrosion LeafletDocument10 pagesAnti Corrosion LeafletDheeraj VermaNo ratings yet

- Plrcapbv1a102 KVDocument8 pagesPlrcapbv1a102 KVamruta21No ratings yet

- XAS37-97 Hard HatsDocument6 pagesXAS37-97 Hard Hatstruck diesel solutionNo ratings yet

- Slow Pyrolysis of Paulownia Wood. Effects of Pyrolysis Parameters On Product Yields and Bio-Oil CharacterizationDocument11 pagesSlow Pyrolysis of Paulownia Wood. Effects of Pyrolysis Parameters On Product Yields and Bio-Oil CharacterizationCora CoraNo ratings yet

- MEET423b PLC Programming Lecture - Urinal Auto-FlushDocument7 pagesMEET423b PLC Programming Lecture - Urinal Auto-FlushJake Polo SantiagoNo ratings yet

- Guentner Products Air Coolers V4 EN PDFDocument25 pagesGuentner Products Air Coolers V4 EN PDFvikashNo ratings yet

- AGN 076 - Alternator Bearings: Application Guidance Notes: Technical Information From Cummins Generator TechnologiesDocument8 pagesAGN 076 - Alternator Bearings: Application Guidance Notes: Technical Information From Cummins Generator TechnologiesP.p. Arul Ilancheeran0% (1)

- Xitanium Prog LeafletDocument8 pagesXitanium Prog LeafletCarlos Jose Sanchez EsparzaNo ratings yet

- RCBDocument35 pagesRCBNesarNo ratings yet

- Small-Scale Biomass GasifierDocument88 pagesSmall-Scale Biomass Gasifierkylden100% (6)

- Gerard - Blokdijk - Prince2 100 Success Secrets PDFDocument209 pagesGerard - Blokdijk - Prince2 100 Success Secrets PDFa4104165No ratings yet

- Guia Tecnica Condensadora YorkDocument70 pagesGuia Tecnica Condensadora YorkAndrewNo ratings yet

- Khemer HouseDocument10 pagesKhemer HousejustchriszNo ratings yet

- Modeling and Simulation of DIGSILENT-based Micro-Grid SystemDocument8 pagesModeling and Simulation of DIGSILENT-based Micro-Grid SystemAli KarasukogluNo ratings yet

- Yamaha XT 225Document2 pagesYamaha XT 225Pablo ArevaloNo ratings yet

- Company Profile - PATDocument78 pagesCompany Profile - PATmahendra_kolheNo ratings yet

- Vocabulary TermDocument4 pagesVocabulary TermMurugananthamParamasivamNo ratings yet

- Arduino 2 PDFDocument5 pagesArduino 2 PDFaudreyKrizNo ratings yet

- Autpciu Huvoç kui Nuμçev oc oaqìuio tqç up¿uiuç 4ekiouç otov HupvuoooDocument8 pagesAutpciu Huvoç kui Nuμçev oc oaqìuio tqç up¿uiuç 4ekiouç otov HupvuoooStella KatsarouNo ratings yet

- 177-Sd5-Ifc-14 11 - 10 - 2018Document775 pages177-Sd5-Ifc-14 11 - 10 - 2018maythem swadi100% (1)

- Material Requirements for Steel and Concrete StructuresDocument38 pagesMaterial Requirements for Steel and Concrete StructuresSimon LsmNo ratings yet

- Comparison of Protection Relay Types: Characteristics and ApplicationsDocument6 pagesComparison of Protection Relay Types: Characteristics and ApplicationsVasudev AgrawalNo ratings yet

- 2000w BLDC Motor Specs and Controller DetailsDocument13 pages2000w BLDC Motor Specs and Controller DetailsGaurav ChaudhariNo ratings yet

- IL Digital June2018Document116 pagesIL Digital June2018AndresMartinez28No ratings yet