Professional Documents

Culture Documents

Data Sheet 3 PDF

Uploaded by

Ahmed BeyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet 3 PDF

Uploaded by

Ahmed BeyCopyright:

Available Formats

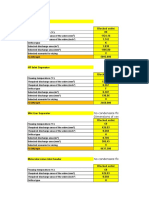

VERTICAL LP SEPARATOR (2 phase)

INPUT LP SEPARATOR OUTPUT

Feed GAS MIX. LIQUID RESIDENCE TIMES Specified Actual ** WARNINGS **

Flow (t/d) 136.5 443.6 (mins) (mins)

Density (kg/m3) 16.88 930.0 HLL-HLSD 0.1 0.3 OK

Viscosity (cP) 0.0114 1.254 NLL-HLL 0.3 0.6 OK

Droplet Size, (μ) Oil in Gas 200 NLL-LLL 0.2 0.3 OK

K Value (m/s) from mist extractor data GPSA fig.7.18 0.12 LLL-LLSD 0.2 0.4 OK

ρ.v2 max for inlet nozzle (kg/m.s2) 3600 LLSD to bottom 0.3 0.6 OK

ρ.v2 max for gas outlet nozzle (kg/m.s2) 3600

Max vel. in Oil outlet nozzle (m/s) 3.00 SETTLING VELOCITY CRITERION

Mixture density (kg/m3) 67.75 K Factor Gas Velocity (m/s) 0.90 OK

Choose Dished end shape by clicking on arrow. Gas Velocity (m/s) - calculated 0.10

semi-ellipsoidal

See note 6 Oil Droplet Velocity (m/s) 0.36 OK

Gravity Settling Method

CALCULATIONS

LIQUID / VAPOUR SEPARATION

K Value Method Oil from Gas (Gravity Settling Laws method)

Dmax is the upper particle size limit for each of the laws.

(Note 2)

Kcr is the critical constant for maximum particle size Particle / droplet size calc for determination of appropriate law

K Value 0.12 m/s (from GPSA Handbook).

Max allow. Velocity (Vmax) 0.90 m/s Vt is the settling velocity in m/s. Settling Velocity 0.36 m/s

Gas Velocity 0.10 m/s Settling Law Used Intermediate law

Minimum Vessel Diameter 364 mm

Law Used: Kcr Vt Dp max

Actual Gas Velocity OK (m/s) (μ)

Stoke's Law 0.03 1.75 31

Stoke's Law (Kcr = 0.025) Intermediate Law (Kcr = 0.334) Newton's Law (Kcr = 18.13) Intermediate Law 0.33 0.36 414

Newton's Law 18.13 0.57 22465

Vt = 1488 g Dp (ρl - ρv) Vt = 3.54*g0.71 Dp1.14 (ρl - ρv)0.71 Vt = 1.74 * SQRT(g Dp (ρl-ρv) / ρv )

2

ρv * μ0.43

0.29

18μ

TITLE

SEPARATOR SIZING SPREADSHEET VERTICAL LP SEPARATOR

PROJ.

CALCULATION SHEET PT. PERTAMINA EP REGION SUMATERA

BY DATE CHECKED DATE CALC.NO

FT BP

PT. GERBANG SARANABAJA 2012 - 05 - SPR - 02

DATE AND TIME PRINTED: 13-Jun-12 9:45 AM PAGE 2 OF 4

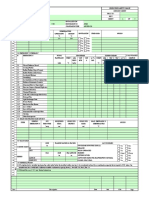

VERTICAL LP SEPARATOR (2 phase)

SKETCH

Act Gas Outlet Nozz. Size = 146 mm

Min Gas Outlet Gas = 136.46 t/d

3

Nozz. Size = 90 mm 336.84 Am /h

Calculated Total 300 mm

T/T Height: 3040 mm

consider 3048 mm with L/D of approx 152 mm Wire Mesh Demister

2.8

ID=1099mm

750 mm (Note 4)

Inlet GAS

438 mm (Note 5)

Min Inlet Nozzle Size = 132 mm

Act Inlet Nozzle Size = 194 mm 650 mm (Note 2)

HLSD 750 mm Volume increment

NOMENCLATURE HLL 650 mm 0.09 m3

LLSD Low Level Shut Down

LLL Low Liquid Level 0.18 m3

NLL Normal Liquid Level NLL 457 mm

HLL High Liquid Level

HLSD High Level Shut Down OIL 0.10 m3

g Gas constant

Dmax Upper Particle Size Limit LLL 350 mm

ρL Liquid density (kg/m3) LLSD 200 mm (Note 3) 0.14 m3

ρV Vapour density (kg/m3) Volume to LLSD including dished end = 0.36 m3

Dp Droplet diameter (μ)

μ Gas viscosity Cp

Vt Settling Velocity (m/s)

VMAX Maximum vapour velocity (m/s)

K Design vapour velocity factor (m/s) Min Liquid Outlet Oil = 443.58 t/d

KCR Proportionality constant, dimensionless. Act Liquid Outlet Nozz. Size = 67 mm Nozz. Size = 50 mm 19.87 m3/h

TITLE

VERTICAL LP SEPARATOR

SEPARATOR SIZING SPREADSHEET

PROJ.

CALCULATION SHEET

PT. PERTAMINA EP REGION SUMATERA

BY DATE CHECKED DATE CALC.NO

FT BP PT. GERBANG SARANABAJA 2012 - 05 - SPR - 02

DATE AND TIME PRINTED: 13-Jun-12 9:45 AM PAGE 3 OF 4

VERTICAL LP SEPARATOR (2 phase)

CALCULATIONS Cont'd

AREA & VOLUME INFORMATION Area Cylinder Volume + Volume

Volume Dished Increment

(m2) (m3) end (m3) (m3)

GAS Cross Sectional Area 0.949

STORAGE (Volume from Bottom)

Oil HLSD 0.949 0.711 0.885 0.095

Oil HLL 0.949 0.617 0.790 0.183

Oil NLL 0.949 0.434 0.607 0.102 Dished End Type Dished End

Oil LLL 0.949 0.332 0.506 0.142 Volume

Oil LLSD 0.949 0.190 0.363 0.190 (m^3)

semi-ellipsoidal 0.174

0.174 hemispherical 0.348

NOTES

1. Maximum allowable vapour velocity is calculated from the equation:

VMAX = K [ (ρL - ρV) / ρV ] 0.5

2. 150 mm minimum.

3. Space for instrument nozzles and/or emergency liquid capacity - minimum 150 mm.

4. 60% of vessel diameter or 750mm whichever is greater.

5. twice inlet nozzle diameter.

3

6 .Semi-ellipsoidal end-volume is calculated using the formula V = (Π x (ID) )/24 which applies to one end only of the separator (ie. the bottom).

Hemispherical end-volume for one dished end is calculated using the formula: V = (P x (ID)3 )/12

Information taken from GPSA handbook Sections SI - 6, and in particular, figs. 6.21&6.22

TITLE

VERTICAL LP SEPARATOR

SEPARATOR SIZING SPREADSHEET

PROJ.

CALCULATION SHEET

PT. PERTAMINA EP REGION SUMATERA

BY DATE CHECKED DATE CALC.NO

FT BP PT. GERBANG SARANABAJA 2012 - 05 - SPR - 02

DATE AND TIME PRINTED: 13-Jun-12 9:45 AM PAGE 4 OF 4

You might also like

- Spreadsheet To Design SeparatorsDocument21 pagesSpreadsheet To Design SeparatorsreninbabaskiNo ratings yet

- Sizing Separators and Accumulators PDFDocument4 pagesSizing Separators and Accumulators PDFjt_breakdanceNo ratings yet

- 3 PhaseDocument7 pages3 PhaseMufleh IdrisNo ratings yet

- API-521 Flare KOD Design and Even More - Part 2.desbloqueadoDocument6 pagesAPI-521 Flare KOD Design and Even More - Part 2.desbloqueadoFernando Mendez100% (1)

- Horizontal 3 Phase Separator With Boot SizingDocument16 pagesHorizontal 3 Phase Separator With Boot Sizingzamijaka100% (1)

- PSV Sizing TableDocument14 pagesPSV Sizing TablebadelitamariusNo ratings yet

- Thermosyphon Reboiler (Horizontal) GPSADocument6 pagesThermosyphon Reboiler (Horizontal) GPSAsyamsudin2006No ratings yet

- Design Data: 2" Threadolet CalculationDocument2 pagesDesign Data: 2" Threadolet Calculationgrabetty50% (2)

- Sizing StrainerDocument8 pagesSizing Strainerchadvillela0% (1)

- Vertical 2 Phase Separator SizingDocument5 pagesVertical 2 Phase Separator SizingJermaine Heath100% (1)

- Knock Out KO Drum SizingDocument10 pagesKnock Out KO Drum SizingJermaine HeathNo ratings yet

- Separator SizingDocument9 pagesSeparator SizingTolstoy LeoNo ratings yet

- 25nb y StrainerDocument1 page25nb y StrainerKailas NimbalkarNo ratings yet

- Valve SizingDocument6 pagesValve Sizingcarlosiq37No ratings yet

- Sizing Three Phase (Gas - Oil) Horizontal Separator: As Per API 12JDocument1 pageSizing Three Phase (Gas - Oil) Horizontal Separator: As Per API 12JekabudiartiNo ratings yet

- Vent Sizing For Fire Considerations For External Fire Duration Diers Users Group Ers Design For Fire CommitteeDocument19 pagesVent Sizing For Fire Considerations For External Fire Duration Diers Users Group Ers Design For Fire CommitteekglorstadNo ratings yet

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Document2 pagesMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqNo ratings yet

- Master - Three Phase Horizontal Separator Rev 0Document6 pagesMaster - Three Phase Horizontal Separator Rev 0Naeem HussainNo ratings yet

- Sizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesDocument5 pagesSizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesJavierNo ratings yet

- BAsket Strainer Sizing HaywardDocument1 pageBAsket Strainer Sizing Haywardmarcoo8No ratings yet

- Tube Rupture (Two Phase-Omega Method) PDFDocument1 pageTube Rupture (Two Phase-Omega Method) PDFAmin RoisNo ratings yet

- Horizontal 2 Phase Separator SizingDocument10 pagesHorizontal 2 Phase Separator SizingJermaine Heath100% (1)

- Seperator Sizing v3Document5 pagesSeperator Sizing v3camasa2011No ratings yet

- The Outside Diameter As Their Nominal DiameterDocument75 pagesThe Outside Diameter As Their Nominal Diameterngutor100% (2)

- Nozzle CriteriaDocument2 pagesNozzle CriteriaKhalil LasferNo ratings yet

- FGCP Line Sizing CalculationsDocument86 pagesFGCP Line Sizing CalculationsToyinNo ratings yet

- Gas Line Sizing - Api 14E Input Description Unit: General DataDocument13 pagesGas Line Sizing - Api 14E Input Description Unit: General DataSamuel Onyewuenyi100% (1)

- No Yes No Yes No Yes No Yes No Yes No YesDocument8 pagesNo Yes No Yes No Yes No Yes No Yes No YesEkundayo JohnNo ratings yet

- Horizontal Three Phase Separator vap-IPDocument5 pagesHorizontal Three Phase Separator vap-IPasifhameed1100% (8)

- Strainer CalculationDocument3 pagesStrainer CalculationMuhammad Hariri Shofa0% (2)

- Pressure Drop and Pipeline Flow CalculatorDocument1 pagePressure Drop and Pipeline Flow CalculatorgrabettyNo ratings yet

- Liquid Valve CV CalcDocument4 pagesLiquid Valve CV Calcamit_kt1973No ratings yet

- DemisterDocument4 pagesDemistermariniabrahanNo ratings yet

- 3Ph Vert Sep 2010 Weir VerA FPS PDFDocument5 pages3Ph Vert Sep 2010 Weir VerA FPS PDFhaiderNo ratings yet

- Gas Coalescer SizingDocument6 pagesGas Coalescer SizingAde IskandarNo ratings yet

- Two Phase Vertical Separator SizingDocument4 pagesTwo Phase Vertical Separator Sizingkamal100% (2)

- Jet Mixing CalculationDocument3 pagesJet Mixing CalculationRachel FloresNo ratings yet

- Volume Calculation For Pressure Vessel TankDocument2 pagesVolume Calculation For Pressure Vessel Tanksai srikarNo ratings yet

- Three Phase Separator Sizing - Overflow WeirDocument2 pagesThree Phase Separator Sizing - Overflow WeirSaeid Rahimi MofradNo ratings yet

- Liquid-Vapor Separation Efficiency (Envp0102)Document24 pagesLiquid-Vapor Separation Efficiency (Envp0102)jbl_No ratings yet

- The Lease Pumper Testing, Treating, and Selling Crude Oil Section B Methods Used To Treat BS&W B-1. Overview of Treating MethodsDocument4 pagesThe Lease Pumper Testing, Treating, and Selling Crude Oil Section B Methods Used To Treat BS&W B-1. Overview of Treating Methodsgad48050% (2)

- Sonic VelocityDocument2 pagesSonic Velocityganeshdhage100% (1)

- Flare KOD SizingDocument4 pagesFlare KOD SizingSaid Ahmed Salem100% (1)

- Datasheet For PACE Mist Eliminator/s (Demister) : Existing DetailsDocument1 pageDatasheet For PACE Mist Eliminator/s (Demister) : Existing DetailsAnonymous LLLK3pq50% (2)

- CPF-010 Process Line Sizing Attachment - 0Document38 pagesCPF-010 Process Line Sizing Attachment - 0goodspeed_ph100% (1)

- Gas Pipeline Blowdown TimeDocument7 pagesGas Pipeline Blowdown TimeKarun DasNo ratings yet

- Guide For Vessel Sizing PDFDocument24 pagesGuide For Vessel Sizing PDFManish542No ratings yet

- Strainer SizingDocument20 pagesStrainer Sizingaliscribd46No ratings yet

- 3phase Separator Size 2010 VerADocument24 pages3phase Separator Size 2010 VerACristina BarbulescuNo ratings yet

- Control Valve SizingDocument3 pagesControl Valve Sizingkaveh-bahiraeeNo ratings yet

- Saddle Support Calculation PD 5500,2000 Annex.G)Document26 pagesSaddle Support Calculation PD 5500,2000 Annex.G)Neeraj Kumar33% (3)

- Disturbance FactorDocument46 pagesDisturbance FactorBossNo ratings yet

- Steam Blowout CalculationDocument46 pagesSteam Blowout CalculationRamachandran VenkateshNo ratings yet

- Line SizingDocument18 pagesLine SizingNathaniel Thomas100% (1)

- Slug CatcherDocument2 pagesSlug CatcherToyinNo ratings yet

- Cvts - Tag No. Mpt-tv-4161Document2 pagesCvts - Tag No. Mpt-tv-4161biswasdipankar05No ratings yet

- MP Separator1Document2 pagesMP Separator1ToyinNo ratings yet

- V-102 MP Separator: Outlet NDDocument2 pagesV-102 MP Separator: Outlet NDToyinNo ratings yet

- Shell & Tube Condenser Design Method: Propanol WaterDocument4 pagesShell & Tube Condenser Design Method: Propanol WaterwestewrNo ratings yet

- Horizontal SeparatorDocument16 pagesHorizontal SeparatorMaryJane Ayisha Sado-Obah100% (1)

- W2301-ME-PS-1000 - B (2 - 2) - Unit-2 CT Torque Tube R2Document1 pageW2301-ME-PS-1000 - B (2 - 2) - Unit-2 CT Torque Tube R2Fitroh MalikNo ratings yet

- MWG 90Document6 pagesMWG 90Fitroh MalikNo ratings yet

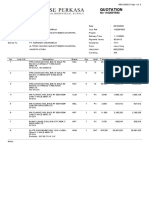

- Quotation: Customer Date Your Ref 1102007652 Project Delivery Time Payment Terms Incoterms From Valid Until CurrencyDocument2 pagesQuotation: Customer Date Your Ref 1102007652 Project Delivery Time Payment Terms Incoterms From Valid Until CurrencyFitroh MalikNo ratings yet

- Esme TF Ger 1570527 00Document1 pageEsme TF Ger 1570527 00Fitroh MalikNo ratings yet

- Technical RFQDocument3 pagesTechnical RFQFitroh MalikNo ratings yet

- Time Line Absorber and Washing TowerDocument1 pageTime Line Absorber and Washing TowerFitroh MalikNo ratings yet

- Data Sheet Rectangular - BG22383Document12 pagesData Sheet Rectangular - BG22383Fitroh MalikNo ratings yet

- Pressure Drop - Ado Kero Bukit BatremDocument1 pagePressure Drop - Ado Kero Bukit BatremFitroh MalikNo ratings yet

- AGP Test SeparatorDocument7 pagesAGP Test SeparatorFitroh MalikNo ratings yet

- GA Pig PDFDocument3 pagesGA Pig PDFFitroh MalikNo ratings yet

- AGP Test SeparatorDocument7 pagesAGP Test SeparatorFitroh MalikNo ratings yet

- Welder Coninuity Log0001 PDFDocument2 pagesWelder Coninuity Log0001 PDFFitroh MalikNo ratings yet

- Data Sheet 2Document1 pageData Sheet 2Fitroh MalikNo ratings yet

- Data Sheet 3Document3 pagesData Sheet 3Fitroh MalikNo ratings yet

- Pressure Drop - Mfo MDF PDFDocument1 pagePressure Drop - Mfo MDF PDFFitroh MalikNo ratings yet

- Data Sheet 1Document7 pagesData Sheet 1Fitroh MalikNo ratings yet

- 61-25399-C046 Rev0Document1 page61-25399-C046 Rev0Fitroh MalikNo ratings yet

- 0405-12 TSF Spillway Pipeline - Bend DetailsDocument1 page0405-12 TSF Spillway Pipeline - Bend DetailsFitroh MalikNo ratings yet

- Ache-High Pour Point Feb11Document21 pagesAche-High Pour Point Feb11Poncho RmzNo ratings yet