Professional Documents

Culture Documents

V-102 MP Separator: Outlet ND

Uploaded by

ToyinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

V-102 MP Separator: Outlet ND

Uploaded by

ToyinCopyright:

Available Formats

Gas outlet

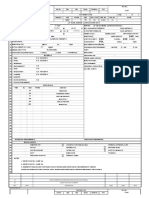

MP SEPERATOR SIZING

###

##

Vessel tag number

Vessel designation

Case

V-102

MP SEPARATOR

By

DOA

Rev.

K02

Date

22/07/2010

ID

?DORIS Engineering 2007 - (v1.02)

OPERATING CONDITIONS

Pressure

46.55 Bar g

Temperature

65.05 C

ID

Inlet d

SCRUBBER DATA

(L/D=3.5)

1 000 mm

686

mm

Outlet ND

20

A12

h1

inch

(CS)

Vane Pack

h2

FLUID DATA (1)

OUTLET GAS

0.0127 MMSCFD

15

Sm/h

13.68 kg/h

21.6

g/mol

40.93 kg/m

Standard flowrate (5)

Mass flowrate

Molecular weight

Actual density

0.6 kmol/h

INLET LIQUID

13880

608.9

23.1

3 488

22.80

Mass flowrate

Actual density

Actual vol. flowrate

Actual vol. flowrate

Outlet vol. Flowrate (4)

kg/h

kg/m

Am/h

Abbl/day

Am/h

Inlet ND

20

A12

h3

inch

(CS)

h4

d

LAHH

h5

h6

GAS SECTION

K (2)

vg max

value

(m/s)

0.106

0.39

Area

(m)

0.79

h1 - To Gas outlet

Top TL

h2 - Top Demister

h3 - Bot. Demister

h4 - Top Inlet device

h5 - Bot. Inlet device

h6 - LAHH

LAH

NLL

h7 - LAL

LALL

Bottom TL

vg

(m/s)

0.00

vg/vgmax

(%)

0%

Mini. height (mm)

3 500

H - TL/TL (mm)

3 500

LAH

h7

NLL

h8

height

LIQUID SECTION

Level

Vol.

Dvol

Dt

(mm)

(mm)

(m)

(m)

(min)

900

500

300

600

300

300

300

300

300

300

300

0

4 400

3 500

3 000

2 700

2 100

1 800

1 500

1 200

900

600

300

0

3.46

2.75

2.36

2.12

1.65

1.41

1.18

0.94

0.71

0.47

0.24

0.00

0.71

0.39

0.24

0.47

0.24

0.24

0.24

0.24

0.24

0.47

0.24

0.00

1.9

1.0

0.6

1.2

0.6

0.6

0.6

0.6

0.6

1.2

0.6

0.0

min.

Optimized

Level

(mm)

3203.4

2303.4

3046.2

2896.2

2286.2

915.0

610.0

LAL

Criteria

h9

0.5 x (Demister outlet diameter - Gas outlet nozzle diameter

LALL

h10

Min. 6" (Vendor to confirm.)

Bottom TL

Min. 24" (610mm)

2d

Min. 12" (305mm)

Min. 12" (305mm)

Outlet ND

5

A12

inch

Liquid outlet

305.0

Min. 12" (305mm)

NOZZLES

LAL to LAH :

at Outlet volume flowrate

Inlet

Gas out.

Liq. out.

Notes: (1) Fluid physical properties and operating conditions have been taken from HYSYS simulation.

(2) K value as per GPSA

(3) Piping Class is selected based on material & rating of Nozzle.

(Based on piping ID) (3)

ID (mm) v (m/s) v (kg/m/s)

ND

Piping Class

20 inch

A12

489

0.0

20 inch

A12

489

0.0

5 inch

A12

127

0.5

v (kg/s)

Criteria

6000 kg/m/s

6000 kg/m/s

1.0m/s

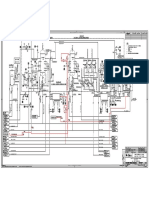

FUEL GAS SCRUBBER- Sizing Case

###

##

Vessel tag number

Vessel designation

Case

Gas outlet

036-V-0680

FUEL GAS SCRUBBER

Design Capacity (7.5MMSCFD) - CASE 1 PROD YR 2014

By

SRK

Rev.

K01

Date

30/03/2010

ID

?DORIS Engineering 2007 - (v1.02)

OPERATING CONDITIONS

Pressure

26.57 Bar g

Temperature

43.12 C

ID

Inlet d

SCRUBBER DATA

(L/D=3.22)

816

mm

102

mm

Outlet ND

4

B8

h1

inch

(CS)

Vane Pack

h2

FLUID DATA (1)

OUTLET GAS

7.5

MMSCFD

8 849 Sm/h

7807

kg/h

20.9

g/mol

23.79 kg/m

Standard flowrate (5)

Mass flowrate

Molecular weight

Actual density

374.3 kmol/h

INLET LIQUID

8

641.1

0.0

2

0.7

Mass flowrate

Actual density

Actual vol. flowrate

Actual vol. flowrate

Outlet vol. Flowrate (3)

kg/h

kg/m

Am/h

Abbl/day

Am/h

Inlet ND

4

B8

h3

inch

(CS)

h4

d

LAHH

h5

h6

GAS SECTION

K (2)

vg max

value

(m/s)

0.06

0.31

Area

(m)

0.52

vg

(m/s)

0.17

vg/vgmax

(%)

57%

Mini. height (mm)

2 236

H - TL/TL (mm)

2 626

LAH

h7

NLL

h8

height

LIQUID SECTION

Level

Vol.

Dvol

Dt

(mm)

(mm)

(m)

(m)

(min)

h1 - To Gas outlet (6)

Top TL

h2 - Top Demister

h3 - Bot. Demister

h4 - Top Inlet device

h5 - Bot. Inlet device

h6 - LAHH

LAH

NLL

h7 - LAL

LALL

Bottom TL

0

376

150

800

300

300

100

150

150

300

0

0

2 626

2 626

2 250

2 100

1 300

1 000

700

600

450

300

0

0

1.37

1.37

1.18

1.10

0.68

0.52

0.37

0.31

0.24

0.16

0.00

0.00

0.00

0.20

0.08

0.42

0.16

0.16

0.05

0.08

0.08

0.16

0.00

0.00

0.0

16.2

6.4

34.4

12.9

12.9

4.3

6.4

6.4

12.9

0.0

0.0

LAL to LAH :

17

min.

2236.4

2236.4

1879.5

1729.5

1119.5

915.0

610.0

LAL

Criteria

Optimized

Level

(mm)

h9

0.5 x (Demister outlet diameter - Gas outlet nozzle diameter

LALL

h10

Min. 6" (Vendor to confirm.)

Bottom TL

Min. 24" (610mm)

2d

Min. 12" (305mm)

Min. 12" (305mm)

Outlet ND

2

B8

inch

Liquid outlet

305.0

Min. 12" (305mm)

NOZZLES

at Outlet volume flowrate

Inlet

Gas out.

Liq. out.

Notes: (1) Fluid physical properties and operating conditions have been taken from HYSYS simulation.

(2) K value as per GPSA

(3) 17.5m3/d of Outlet Vol. Flowrate is considered as per Design Basis sec.6.4.20.

(4) Piping Class is selected based on material & rating of Nozzle.

(5) Design capacity of fuel gas system is 7.5MMSCFD.

(6) Vessel top is ended with a body flange.

(Based on piping ID) (4)

ID (mm) v (m/s) v (kg/m/s)

ND

Piping Class

v (kg/s)

Criteria

4 inch

B8

102.26

11.1

2 940

32 706

6000 kg/m/s

4 inch

B8

102.26

11.1

2 931

32 528

3750 kg/m/s

2 inch

B8

49.22

0.1

1.0m/s

You might also like

- Separator SizingDocument26 pagesSeparator SizingToyinNo ratings yet

- 3 Phase SizingDocument2 pages3 Phase Sizingc_nghiaNo ratings yet

- Horizontal SeparatorDocument16 pagesHorizontal SeparatorMaryJane Ayisha Sado-Obah100% (1)

- Cvts - Tag No. Mpt-tv-4161Document2 pagesCvts - Tag No. Mpt-tv-4161biswasdipankar05No ratings yet

- MP Separator1Document2 pagesMP Separator1ToyinNo ratings yet

- Separator Sizing and DesignDocument44 pagesSeparator Sizing and DesignKay EenNo ratings yet

- Horizontal Separator Adequacy CheckDocument4 pagesHorizontal Separator Adequacy CheckTech ManagerNo ratings yet

- Fuel gas filter sizing calculationDocument1 pageFuel gas filter sizing calculationIndraharja FerryNo ratings yet

- Flare Knock Out Drum Sizing ReportDocument4 pagesFlare Knock Out Drum Sizing ReportSaid Ahmed Salem100% (1)

- Seperator Sizing Sheet (Ken Arnold)Document2 pagesSeperator Sizing Sheet (Ken Arnold)Hani KirmaniNo ratings yet

- C06 006 Process Calculation (02V 6010) RevEDocument6 pagesC06 006 Process Calculation (02V 6010) RevEAlphaEcc EngineeringTeamNo ratings yet

- Vessel - Vertical Sizing - IPunitsDocument25 pagesVessel - Vertical Sizing - IPunitsAnders FTNo ratings yet

- Allowable DP CalculationDocument22 pagesAllowable DP CalculationAJAY1381No ratings yet

- 3 PhaseDocument7 pages3 PhaseMufleh IdrisNo ratings yet

- Pump SizingDocument3 pagesPump Sizingtimayaa1000No ratings yet

- Liquid - Gas Phase SizingDocument12 pagesLiquid - Gas Phase Sizingeke23No ratings yet

- Natural Gas Processing Separator TechniquesDocument37 pagesNatural Gas Processing Separator TechniquestahaNo ratings yet

- Three Phase Separator Sizing - Bucket & PipeDocument2 pagesThree Phase Separator Sizing - Bucket & PipeSaeid Rahimi MofradNo ratings yet

- CNG ADK 3,5 MMSCFD 13 Desember 2019 New Inlet Pressure with Heater After DiDocument1 pageCNG ADK 3,5 MMSCFD 13 Desember 2019 New Inlet Pressure with Heater After Dirandi martaNo ratings yet

- Horizontal Three Phase Separator Sizing CalculationDocument3 pagesHorizontal Three Phase Separator Sizing CalculationDazzy 265No ratings yet

- Hydraulics - Summary: Including Cutting Weight & Tool JointDocument5 pagesHydraulics - Summary: Including Cutting Weight & Tool JointAnonymous U5t9NYzhLWNo ratings yet

- Calculation For Steam Blow Rev03Document6 pagesCalculation For Steam Blow Rev03tauqeerNo ratings yet

- 2-Phase Vertical SeparatorDocument9 pages2-Phase Vertical SeparatorTolstoy LeoNo ratings yet

- D-1309 Sizing Calc Sht1Document1 pageD-1309 Sizing Calc Sht1NKNo ratings yet

- Condensate Line SizingDocument2 pagesCondensate Line SizingAnonymous oVRvsdWzfBNo ratings yet

- Specification Sheet For Separator: Operating Conditions SketchDocument12 pagesSpecification Sheet For Separator: Operating Conditions SketchAngelikaOdimer100% (1)

- Vertical Two-Phase Separator Sizing (SI Units) : Client Proj No Project Calc No Subject Sheet OFDocument4 pagesVertical Two-Phase Separator Sizing (SI Units) : Client Proj No Project Calc No Subject Sheet OFJhonnatan Fredy Gomez DominguezNo ratings yet

- Filter Vessel Shell VelocityDocument12 pagesFilter Vessel Shell VelocityAye KyweNo ratings yet

- Vertical Separator SizingDocument8 pagesVertical Separator SizingAnonymous yLPPdPwNo ratings yet

- TEMA SheetDocument2 pagesTEMA SheetFrancisco RenteriaNo ratings yet

- Optimizing Gas/Liquid Separator PerformanceDocument14 pagesOptimizing Gas/Liquid Separator PerformanceWendellReeceFrankNo ratings yet

- ExamSlip - 148865 - 20190401 - 1520 VladDocument23 pagesExamSlip - 148865 - 20190401 - 1520 VladNikolaus PanjaitanNo ratings yet

- Guide For Vessel Sizing PDFDocument24 pagesGuide For Vessel Sizing PDFManish542No ratings yet

- FGCP Line Sizing CalculationsDocument86 pagesFGCP Line Sizing CalculationsToyinNo ratings yet

- PVV Cal Sheet LabixDocument45 pagesPVV Cal Sheet LabixPranpath Narupantawart50% (2)

- Control ValveDocument1 pageControl ValveAjay TiwariNo ratings yet

- Horizontal 3 Phase Separator With Boot SizingDocument16 pagesHorizontal 3 Phase Separator With Boot Sizingzamijaka100% (1)

- Quick estimation compressor settle out conditionsDocument1 pageQuick estimation compressor settle out conditionsAhmed GattoufiNo ratings yet

- Weymouth Gas Flow CalculationsDocument44 pagesWeymouth Gas Flow CalculationsPierre GermaineNo ratings yet

- Sizing Three Phase Horizontal SeparatorDocument1 pageSizing Three Phase Horizontal SeparatorekabudiartiNo ratings yet

- 2 Phase Separator Sizing Spreadsheet: Client Proj No Project Calc No Subject SheetDocument1 page2 Phase Separator Sizing Spreadsheet: Client Proj No Project Calc No Subject SheetMohammad Mehdi JafariNo ratings yet

- 3.2.G.2.3.D Two Phase Sep Sizing API 521 SI Units1Document1 page3.2.G.2.3.D Two Phase Sep Sizing API 521 SI Units1Mike DukasNo ratings yet

- Three Phase Separator Sizing - Overflow WeirDocument2 pagesThree Phase Separator Sizing - Overflow WeirSaeid Rahimi MofradNo ratings yet

- Ppgj-Pro-Cal-190 Hot Oil Return Pump (P-1004)Document10 pagesPpgj-Pro-Cal-190 Hot Oil Return Pump (P-1004)Tifano KhristiyantoNo ratings yet

- Separator (1) Sizing Spread SheetsDocument21 pagesSeparator (1) Sizing Spread SheetsSteve WanNo ratings yet

- Vessel Sizing Calculation Data Sheets: Customer Name: Project Title: Cpe Job #: Document #Document13 pagesVessel Sizing Calculation Data Sheets: Customer Name: Project Title: Cpe Job #: Document #Michael HaiseNo ratings yet

- Separator SizingDocument3 pagesSeparator SizingMaryJane Ayisha Sado-ObahNo ratings yet

- Equipment DesignDocument8 pagesEquipment Designnirmal_subudhiNo ratings yet

- Three Phase Separator Sizing (Double Weir 2)Document3 pagesThree Phase Separator Sizing (Double Weir 2)12377466790% (2)

- Sample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)Document15 pagesSample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)Mustafa AhsanNo ratings yet

- Line Losses (Fittings) ΔP (ft) ΔP (ft)Document3 pagesLine Losses (Fittings) ΔP (ft) ΔP (ft)ahmadlieNo ratings yet

- Fuel Gas ScrubberDocument2 pagesFuel Gas ScrubberToyin100% (3)

- Flare Ko Drum SizingDocument5 pagesFlare Ko Drum SizingSujith Sekar100% (2)

- LP Gas Amine Contactor Process DataDocument6 pagesLP Gas Amine Contactor Process DataEddy RainNo ratings yet

- Slug CatcherDocument2 pagesSlug CatcherToyinNo ratings yet

- 3 Phase - Overflow WeirDocument5 pages3 Phase - Overflow WeirAnonymous R23prjoKnoNo ratings yet

- Example 1: Size A 2-Phase Vertical Separator: Job SpecificationsDocument20 pagesExample 1: Size A 2-Phase Vertical Separator: Job SpecificationsagusnnnNo ratings yet

- 1) Flow: 239869283.xls - Ms - Office Piping Pressure Drop and Pump Design Calculation SheetDocument4 pages1) Flow: 239869283.xls - Ms - Office Piping Pressure Drop and Pump Design Calculation SheetHemantk8731100% (1)

- Htri FileDocument24 pagesHtri FileEalumalai MuthuNo ratings yet

- Hid Ro CycloneDocument1 pageHid Ro CycloneEDUARDONo ratings yet

- David Work Model 2Document1 pageDavid Work Model 2ToyinNo ratings yet

- Engineer in SocietyDocument17 pagesEngineer in SocietyToyinNo ratings yet

- Chemistry Questions Answers: 43. The Nuclear Particles Which Are Assumed To Hold The Nucleons Together Are ?Document5 pagesChemistry Questions Answers: 43. The Nuclear Particles Which Are Assumed To Hold The Nucleons Together Are ?ToyinNo ratings yet

- Maintenance EngineeringDocument12 pagesMaintenance EngineeringToyinNo ratings yet

- Information Communication Technology (Ict) Compliance For EngineersDocument37 pagesInformation Communication Technology (Ict) Compliance For EngineersToyinNo ratings yet

- Chemistry Questions Answers: 57. The Chemical Symbol of Sodium IsDocument5 pagesChemistry Questions Answers: 57. The Chemical Symbol of Sodium IsToyinNo ratings yet

- Chemistry Questions Answers: 15. What Nucleus of Atom Contains ?Document5 pagesChemistry Questions Answers: 15. What Nucleus of Atom Contains ?ToyinNo ratings yet

- 6Document5 pages6ToyinNo ratings yet

- Chemistry Questions Answers: 8. Oil of Vitriol IsDocument5 pagesChemistry Questions Answers: 8. Oil of Vitriol IsToyinNo ratings yet

- Chemistry Questions Answers: 64. The Main Chemical Constituent of Clay Is ?Document5 pagesChemistry Questions Answers: 64. The Main Chemical Constituent of Clay Is ?ToyinNo ratings yet

- NseDocument1 pageNseToyinNo ratings yet

- Chemistry Questions Answers: 8. Oil of Vitriol IsDocument5 pagesChemistry Questions Answers: 8. Oil of Vitriol IsToyinNo ratings yet

- Chemistry Questions Answers: 50. Iodine Can Be Separated From A Mixture of Iodine and Potassium Chloride by ?Document5 pagesChemistry Questions Answers: 50. Iodine Can Be Separated From A Mixture of Iodine and Potassium Chloride by ?ToyinNo ratings yet

- Chemistry Questions Answers: 36. Which of The Primary Component of Natural Gas?Document5 pagesChemistry Questions Answers: 36. Which of The Primary Component of Natural Gas?ToyinNo ratings yet

- 249-1-REP-158 Rev.4 (Vent Scrubber Process DS)Document4 pages249-1-REP-158 Rev.4 (Vent Scrubber Process DS)ToyinNo ratings yet

- NseDocument1 pageNseToyinNo ratings yet

- Chemistry Questions Answers: 64. The Main Chemical Constituent of Clay Is ?Document5 pagesChemistry Questions Answers: 64. The Main Chemical Constituent of Clay Is ?ToyinNo ratings yet

- 249-1-REP-304 Rev.2 (P&IDs Fuel Gas System)Document3 pages249-1-REP-304 Rev.2 (P&IDs Fuel Gas System)ToyinNo ratings yet

- 249-1-REP-253 Rev.3 (UFS-Fuel & Inst. Gas Sys)Document4 pages249-1-REP-253 Rev.3 (UFS-Fuel & Inst. Gas Sys)ToyinNo ratings yet

- OLGA ExampleDocument99 pagesOLGA ExampleCuando la dictadura es un hecho, la Revolución es un derechoNo ratings yet

- 249-1-REP-253 Rev.3 (UFS-Fuel & Inst. Gas Sys)Document4 pages249-1-REP-253 Rev.3 (UFS-Fuel & Inst. Gas Sys)ToyinNo ratings yet

- 04 - AbsorbersDocument11 pages04 - AbsorbersRafael ReyesNo ratings yet

- 05 PumpsDocument80 pages05 PumpsRoberto O'ConnorNo ratings yet

- Stoichiometric Calculations for Combustion AnalysisDocument47 pagesStoichiometric Calculations for Combustion AnalysisHandayani KesumadewiNo ratings yet

- Process Engineering Training Guide for Oil & Gas FacilitiesDocument1 pageProcess Engineering Training Guide for Oil & Gas FacilitiesToyinNo ratings yet

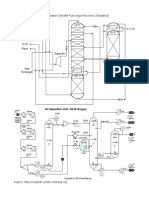

- CScasebook ASUDocument3 pagesCScasebook ASUsvnaik14No ratings yet

- Hysys Assay ManagementDocument12 pagesHysys Assay ManagementDaniele Cirina100% (2)

- 249-1-REP-254 Rev 2 (Fuel Inst Gas System Calc)Document3 pages249-1-REP-254 Rev 2 (Fuel Inst Gas System Calc)ToyinNo ratings yet

- Stoichiometric Calculations for Combustion AnalysisDocument47 pagesStoichiometric Calculations for Combustion AnalysisHandayani KesumadewiNo ratings yet

- 2017 Winners' Personalized Prophetic Declarations - Approved Copy - Home MissionDocument2 pages2017 Winners' Personalized Prophetic Declarations - Approved Copy - Home MissionToyinNo ratings yet

- Topic 13 ThermochemistryDocument32 pagesTopic 13 ThermochemistryJaaizah JaafarNo ratings yet

- Design A Distillation Column With A Total Condenser and Partial Re Boiler For The Following SeparationDocument41 pagesDesign A Distillation Column With A Total Condenser and Partial Re Boiler For The Following SeparationSihanu Subasingha100% (1)

- Heat of Solutions - Exp 2Document6 pagesHeat of Solutions - Exp 2owl lawletNo ratings yet

- Ch8 NotesDocument14 pagesCh8 NotesTriet NguyenNo ratings yet

- Single Correct (4 &-1Document3 pagesSingle Correct (4 &-1Ansh GuptaNo ratings yet

- Aspirin TitrationDocument6 pagesAspirin TitrationAmita RanaNo ratings yet

- Past Paper - Acids and Alkalis - LQDocument10 pagesPast Paper - Acids and Alkalis - LQapi-3739994100% (2)

- Aakash FT 01 Neet 2023Document31 pagesAakash FT 01 Neet 2023Ismart Manoj50% (2)

- Collision Theory Is The Key To Understanding Why Some Reactions Are Faster Than OthersDocument16 pagesCollision Theory Is The Key To Understanding Why Some Reactions Are Faster Than OthersRicki HanNo ratings yet

- Worksheet 5Document2 pagesWorksheet 5joanne0% (1)

- Chemistry Matters Textbook Full SolutionsDocument46 pagesChemistry Matters Textbook Full SolutionsongjiachengedricNo ratings yet

- Experiment To Determine The Empirical Formula of MagnesiumDocument3 pagesExperiment To Determine The Empirical Formula of MagnesiumSumaliny SubramaniamNo ratings yet

- Chemistry Booklet Science and Fun Part 1Document102 pagesChemistry Booklet Science and Fun Part 1ext.xd6948No ratings yet

- 2.2. Chemical ReactionsDocument4 pages2.2. Chemical Reactionsasfass sfasfasfasNo ratings yet

- Worksheet Paper2Document8 pagesWorksheet Paper2Pranita PokharelNo ratings yet

- Standardize NaOH with Oxalic Acid TitrationDocument4 pagesStandardize NaOH with Oxalic Acid TitrationRezaul KarimNo ratings yet

- Cclec MidtermsDocument65 pagesCclec MidtermsAngela ReyesNo ratings yet

- Mass Relationships in Chemical ReactionsDocument21 pagesMass Relationships in Chemical ReactionsVince DulayNo ratings yet

- Chapter 3 Material Balance - Part 1Document58 pagesChapter 3 Material Balance - Part 1Renu Sekaran100% (3)

- Boiler - Air Requirements DeterminationDocument46 pagesBoiler - Air Requirements DeterminationAnonymous j5XYgIuNo ratings yet

- Diamond Stone International School IGCSE Weekly Lesson PlanDocument1 pageDiamond Stone International School IGCSE Weekly Lesson PlanjanithaNo ratings yet

- GCSE Exam QuestionsDocument155 pagesGCSE Exam Questionsdanielphilip68No ratings yet

- Understanding Crystalline and Amorphous SolidsDocument31 pagesUnderstanding Crystalline and Amorphous SolidsSuzanne MalapitanNo ratings yet

- Test 1 Review-SolutionsDocument11 pagesTest 1 Review-SolutionsdavidchoikekekekNo ratings yet

- UP Academic League of Chemical Engineering Students (UP ALCHEMES)Document10 pagesUP Academic League of Chemical Engineering Students (UP ALCHEMES)Jerremiah YuNo ratings yet

- Questions & Solutions Chemistry... (NEET REPEATERS) 13-01-2020Document45 pagesQuestions & Solutions Chemistry... (NEET REPEATERS) 13-01-2020iram ferozNo ratings yet

- 4 Mass Transfer Coefficients PDFDocument17 pages4 Mass Transfer Coefficients PDFYee LingNo ratings yet

- Competencies - Gen Chem 1Document5 pagesCompetencies - Gen Chem 1Chi StephNo ratings yet

- Lab 1 Dehydrogenation HydrogenationDocument3 pagesLab 1 Dehydrogenation HydrogenationJason Chen100% (1)

- Chapter 3 Exam Review and Practice ProblemsDocument3 pagesChapter 3 Exam Review and Practice ProblemsNURUL HUSNA ABDUL MUTALIBNo ratings yet