Professional Documents

Culture Documents

Ijciet 08 03 043 PDF

Uploaded by

Mohan BhalmeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijciet 08 03 043 PDF

Uploaded by

Mohan BhalmeCopyright:

Available Formats

International Journal of Civil Engineering and Technology (IJCIET)

Volume 8, Issue 3, March 2017, pp. 423–431 Article ID: IJCIET_08_03_043

Available online at http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=8&IType=3

ISSN Print: 0976-6308 and ISSN Online: 0976-6316

© IAEME Publication Scopus Indexed

RELATION AMONG MECHANICAL

PROPERTIES OF GROUND GRANULATED

BLAST FURNACE SLAG CONCRETE

Rakesh Kumar

Associate Professor, Department of Civil Engineering,

MNNIT, Allahabad, India

P.K. Mehta

Professor, Department of Civil Engineering,

MNNIT, Allahabad, India

P.R. Pal

Assistant Professor, Department of Civil Engineering,

MNNIT, Allahabad, India

TP Muhammed Ashiq

P.G. Student, Department of Civil Engineering,

MNNIT, Allahabad, India

ABSTRACT

Ground granulated blast furnace slag (GGBS) is a well known pozzolanic

material. In the present work, an attempt has been made to study the effect of GGBS

inclusion on the fresh and hardened concrete properties (workability, compressive

strength, flexural strength and split tensile strength), and to develop relationship

among the different strength parameters. Eight concrete mixes containing 0, 10, 20,

30, 40, 45, 50 & 55% GGBS (weight basis) as cement (OPC) replacement were

prepared to find the optimum replacement level of GGBS. M35 grade concrete with

cement content of 460 kg/m3 was used as a referral concrete. Test specimens were

cured in tap water for 7, 28, 56, 90 days after the demoulding for compressive

strength, while, the specimen for flexural and split tensile strengths were cured for 28

days only. This study shows that the workability increases with increase in the

replacement level. The compressive strength, flexural strength and split tensile

strength of concrete mixes increase with GGBS content till an optimum replacement

level of 40%. Further addition, beyond this level shows a decrease in strength but still

the strengths are generally more than the referral.

Key words: Compressive Strength, Flexural Strength, Split Tensile Strength, GGBS,

Workability.

http://www.iaeme.com/IJCIET/index.asp 423 editor@iaeme.com

Relation among Mechanical Properties of Ground Granulated Blast Furnace Slag Concrete

Cite this Article: Rakesh Kumar, P.K. Mehta, P.R. Pal and TP Muhammed Ashiq,

Relation among Mechanical Properties of Ground Granulated Blast Furnace Slag

Concrete. International Journal of Civil Engineering and Technology, 8(3), 2017, pp.

423–431.

http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=8&IType=3

1. INTRODUCTION

Now a days, a lot of attention is being paid on the selection of construction materials and their

impact on environment. The Ordinary Portland Cement (OPC) is one of the main ingredients

used for the production of concrete. Unfortunately, production of OPC involves emission of

large amounts of carbon-dioxide (approximately, 1Ton CO2 /Ton of OPC production) gas

into the atmosphere, a major contributor for green house effect and the global warming [1-3].

It is estimated that the emissions of CO2 from OPC production worldwide is about 6-8% of

the total global CO2 emission [4-6]. So, it is need of the time to search alternative main binder

or supplementary cementitious material (SCM) without compromising the properties of

concrete, environment and natural resources. Such materials, which can be used as SCM

should lead to global sustainable development and lowest possible environment impact [7-9].

Fly ash (FA), ground granulated blast furnace slag (GGBS), rice husk ash (RHA), high

reactive metakaoline and silica fume (SF) are some of the pozzolanic materials/SCM, which

can be used in the concrete for the partial replacement of cement. A number of studies are

going on in India as well as abroad to study the impact of SCM for part replacement of OPC

in concrete. These SCM not only enhance the mechanical properties of concrete but also

improve the pore structure of concrete. GGBS is one of the SCM [10]. It is a byproduct

obtained from the blast furnaces used to produce Iron. Jin and Li [11] reported that the

mechanical properties of young concrete (less than an age of 7 days) play an important role in

determining construction speed and quality, especially for high rise buildings and nuclear

power plants. A better understanding of the mechanical properties of young concrete is

essential to make a right decision during the construction stage. However, it is usual to take

the 28-days compressive strength as index of concrete quality. Hooton and Emery [12]

reported that the properties of GGBS influence the glass content, chemical composition,

mineralogical composition etc of concrete. Swamy and Bouikni [13] reported that, by a

proper mix proportioning, GGBS concrete can be produced with strengths comparable to

those with OPC from 3rd day onwards. Authors proposed that the total cementitious material

is to be increased by 10% for 50% replacement of OPC by GGBS, and by 20% for 65%

replacement to attain strengths comparable to normal concretes. Ganesh Babu et al [14]

observed that for obtaining equal strength in concretes at 28 days, an additional 8.5% and

19.5% increase in the total cementitious materials is required for50% and 65% OPC

replacement levels.

Oner and Akyuz [15] observed that on increasing the GGBS inclusion, the water-to-

binder ratio decreases for the same workability. Also, it is observed that the early age strength

of GGBS concrete was lower than the control concrete with the same binder content.

However, as the curing period is extended, the strength increase was higher for the GGBS

concrete. They explained that the pozzolanic reactivity was slower at early age because of the

late release of calcium hydroxide. The compressive strength of GGBS concrete increases as

the GGBS content is increased up to an optimum point, after which the compressive strength

decreases. The optimum level of GGBS content for maximizing strength is about 55–59% of

the total binder content. Wu et al [16] studied the effect of GGBS and flyash content on the

compressive and flexural strengths of Ultra high performance concrete (UHPC). Authors

reported that flowability of concrete increases with inclusion of GGBS in UHPC. Authors

http://www.iaeme.com/IJCIET/index.asp 424 editor@iaeme.com

Rakesh Kumar, P.K. Mehta, P.R. Pal and TP Muhammed Ashiq

also reported that the addition of GGBS in concrete had limited influence on compressive

strength; however, the flexural strength increases with replacement of OPC with GGBS upto

40%.

The relation between the flexural strength (fcr, MPa) and characteristic compressive

strength (fck, MPa) is given in IS:456-2000 [17] in the form of Eq. 1:

fcr =0.7 (fck)n (1)

where, coefficient n=0.5 for OPC concrete

A number of empirical formulae showing the relation between the splitting tensile

strength (ft, MPa) and compressive strength of cylindrical specimen (fc,MPa)) are suggested

by many investigators. The general form is given as Eq.2:

ft = k (fc)n (2)

where, k and n are coefficients.

The values of n suggested by different investigators to lie between ½ and ¾. The former

value is used by the American Concrete Institute (ACI); however, Gardner and Poon [18]

found the value nearer to the latter. Raphael [19] suggested the following expression (Eq. 3)

relating the tensile strength and compressive strength.

ft =0.3(fc)n (3)

where, n = 2/3

Later, Oluokun [20] modified Eq. 3, and suggested the following expression (Eq. 4):

ft = 0.2(fc)n (4)

where, n = 0.7.

In this paper, the results of an experimental investigation carried out to find the: i) effect

of GGBS inclusion on the fresh concrete property i.e., workability; ii) optimum dose of

GGBS as partial replacement of OPC in concrete, in respect of mechanical properties of

hardened concrete (compressive, flexural and split tensile strengths) are presented.

2. MATERIALS AND MIX PROPORTIONING

The concrete mix was designed using JAYPEE 43-grade OPC confirming to IS: 8112-1989

[21]. The specific gravity, soundness and fineness (90μ sieve) were 3.15, 2.0 mm and 4.0%,

respectively. The GGBS was procured from FINESSE SCM Pvt. Ltd. Mumbai (India). The

physical properties and chemical composition of GGBS are given in Table 1. The fine and

coarse aggregates were procured form the local quarries. Coarse aggregate of size 10 mm

having specific gravity and fineness modulus of 2.65 and 6.26, respectively was used. The

specific gravity and fineness modulus of fine aggregate were 2.71 and 2.05, respectively. The

aggregates confirmed to the requirements of IS: 383-1970 [22]. The water absorption of

coarse aggregate and fine aggregates were 0.47% and 0.90%, respectively. The volume

percentage of fine aggregate to the total volume of aggregate was kept 32% in all the

mixtures. Polycarboxylic Ether based super plasticizer ‘GLENIUM’, procured from BASF

(India) was used in this investigation. The referral concrete of M-35 grade with OPC content

of 460 kg/m was used, and it was designed as per SP: 23 – 1982 [23] and IS: 10262-2009

[24]. The resulting mix proportion of cement: fine aggregate: coarse aggregate was

1:1.24:2.58 with water cement ratio of 0.40. The different mixes of concrete were prepared

using GGBS for partial replacement of OPC, and the replacement levels varied were 10, 20,

30, 40, 45, 50 and 55 % by weight of OPC. Water to binder ratio of 0.40 and air content of

2% was kept constant in all the mixtures. The super plasticizer (1 % by the weight of binder)

was added to maintain the workability over 100 mm in all the mixes. The Plain Cement

Concrete (PCC) cubes(referral) of 100 mm size for compressive strength, 100x100x500 mm

http://www.iaeme.com/IJCIET/index.asp 425 editor@iaeme.com

Relation among Mechanical Properties of Ground Granulated Blast Furnace Slag Concrete

specimens for flexure test, and cylindrical specimens of 100 mm diameter and 200 mm height

for split tensile test were cast, and demoulded after 24 hours, and put in tap-water for curing.

The vibration table was used for compaction of the concrete. Abram’s cone apparatus was

used to determine the slump of different mixes. The mix proportioning and slump of different

mixes are given in Table 2. Compression test was conducted on a 2000 kN ‘AIMIL’

compression testing machine. Load was applied as per IS: 14858-2000 [25] and IS: 5816-

1999 [26] for compressive strength and split tensile strength, respectively. Hydraulic Jack of

capacity 250 kN was used for flexural strength test, and the load was applied as per IS:516-

1959 [27]. For each mix of the concrete, the compressive strength of the hardened concrete

was found at 7, 28, 56 and 90 days of the curing. The split tensile strength and flexural

strength of all the mixes were determined after 28 days of curing.

Table 1 Physical and Chemical Properties of GGBS

Colour Specific Specific SiO2 Al2O3 Fe2O3 CaO MgO Na2O K2O LOI

Gravity Surface Area (%) (%) (%) (%) (%) (%) (%) (%)

White 2.92 4250 39.1 10.18 2.02 32.8 8.52 1.14 0.30 ˂ 1.0

cm2/gm 8 2

Table 2 Mix Proportioning and Slump of different concrete mixes

Replacement Cement (kg) GGBS Water CA FA Slump (mm)

level (%) (kg) (Litre) (kg) (kg)

0.0 460 0 184 1187 570 105

10.0 414 46 184 1187 570 108

20.0 368 92 184 1187 570 110

30.0 322 138 184 1187 570 114

40.0 276 184 184 1187 570 116

45.0 253 207 184 1187 570 120

50.0 230 230 184 1187 570 122

55.0 207 253 184 1187 570 125

3. RESULTS AND DISCUSSIONS

3.1. Properties of Fresh Concrete

The mix proportioning of concrete and slump of different concrete mixes are given in Table-

2. It is evident from Table-2 that the workability of concrete mixes is increases from 105 mm

to 125 mm on increasing the GGBS inclusion (0 to 55 %). An increase in the slump of

concrete mixes on increasing the GGBS content is also reported [15 &16]. This may be due

to the lesser specific surface area and spherical particles character of GGBS.

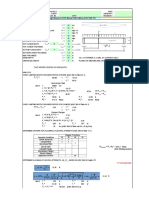

3.2. Compressive Strength of Different Concrete Mixes

The compressive strength of the different GGBS concrete mixes obtained at 7, 28, 56 and 90

days of curing is plotted in Fig. 1. It is observed from this figure that the strength gain is a

function of time. The addition of GGBS improved the compressive strengths at all the ages.

The strength is increased even at 55% replacement leve,l but the maximum strength gain is

obtained at the 40% replacement level(Optimum). At optimum replacement level, the

increase in strength is found to be 16.85%, 9.19%, 14.95% and 25.6% at the age of 7, 28, 56

and 90 days, respectively, as compared to the referral sample. Oner and Akyuz [15] reported

the optimum level of replacement as 55-59%, however, Wu et al [16] reported replacement

upto 40%, without much influence over the compressive strength. In the present

investigation, the optimum level at lower percentage may be due to better glass content,

http://www.iaeme.com/IJCIET/index.asp 426 editor@iaeme.com

Rakesh Kumar, P.K. Mehta, P.R. Pal and TP Muhammed Ashiq

chemical composition and mineralogical composition of GGBS. Further the compressive

strength of GGBS added concrete is more than the referral concrete at 7 days (Fig.1). This

may be beneficial in construction activities, where young concrete plays an important role.

56 GGBS0

Compressive Strength (MPa) %

GGBS1

49 0%

GGBS2

0%

GGBS3

42

0%

GGBS4

35 0%

0 7 14 21 28 35 42 49 56 63 70 77 84 91 98

Age (days)

Figure 1 Variation of Compressive Strength of GGBS Concrete with age at different replacement

levels

3.3. Flexural Strength of Different Concrete Mixes

The inclusion of GGBS also brought marginal improvement in flexural strength of concrete.

The flexural strength results obtained at the age of 28 days are listed in Table 3.The

maximum improvement in flexural strength is found at 40% replacement level and the

increase is 18.75% as compared to the referral; however, beyond that level the improvement

is not much. The ratio of flexural strength to compressive strength at 28 days is almost similar

in all the mixes and is in the range of 18.39 - 20.12%. The optimum replacement level (40%)

is similar to finding of Wu et al [16].

Table 3 Value of coefficient ‘n’ in the relation between Compressive and Flexural strengths of

different Concrete Mixes.

Replacement Compressive Strength at 28 Flexural Strength at 28 Value of ‘n’

level (%) days(MPa) days (MPa) From Eq.1

(Size 100x100x100) (Size 100x100x500)

0.0 43.5 8.0 0.645

10.0 44.5 8.5 0.657

20.0 45.3 8.9 0.666

30.0 46.2 9.3 0.674

40.0 47.5 9.5 0.675

45.0 46.5 9.1 0.668

50.0 45.1 8.4 0.652

55.0 43.0 8.1 0.650

3.4. Relation between Compressive Strength and Flexural Strength

The results obtained in the present investigation were plotted to get a relation between

flexural and compressive strengths (Fig. 2). The relation obtained is given as Eq. 5:

Y =0.349X -7.047 with R2= 0.908 (5)

where, Y (fcr) = Flexural strength of concrete specimen of size 100x100x500 mm (MPa),

X (fck) = Characteristic compressive strength of 100mm concrete cube (MPa)

http://www.iaeme.com/IJCIET/index.asp 427 editor@iaeme.com

Relation among Mechanical Properties of Ground Granulated Blast Furnace Slag Concrete

The flexural (fcr) and compressive strength (fck) values obtained for the different concrete

mixtures were fitted in Eq.1. The value of coefficient ‘n’ for GGBS concrete was obtained in

the range of 0.645 -0.675 (Table-4), instead of 0.5 suggested by IS code for OPC concrete,

and its standard specimen sizes. The maximum value of 0.675 was found at 40%

replacement. This increase in coefficient ‘n’ may be due to marginal increase in ductility of

concrete mixes due to the inclusion of GGBS.

Table 4 Values of ‘n’ in the relation between Split Tensile and Compressive Strengths of different

Concrete Mixes.

Replacement Compressive Strength Split Tensile Strength Value of ‘n’

level (%) (MPa) (MPa)

28days 28 days From Eq. 3 From Eq. 4

0.0 43.5 3.85 0.676 0.784

10.0 44.5 3.92 0.677 0.783

20.0 45.3 4.12 0.687 0.793

30.0 46.2 4.41 0.701 0.807

40.0 47.5 4.93 0.725 0.830

45.0 46.5 4.52 0.706 0.812

50.0 45.1 4.15 0.689 0.796

55.0 43.0 3.81 0.675 0.783

9.8

9.6

9.4

Flexural Strength(MPa)

9.2

9 y = 0.349x - 7.047

8.8 R² = 0.908

8.6

8.4

8.2

8

7.8

42 43 44 45 46 47 48

Compressive Strength (MPa)

Figure 2 Relation between flexural and compressive strengths of different concrete mixes at 28 days

3.5. Split Tensile Strength of Different Concrete Mixes

The results of split tensile strength of different concrete mixes are given in Table-4. The split

tensile strength of mixes was found to increase upto 40% replacement level, and thereafter, a

decreasing trend was observed. However, strength was found to be more than the referral

concrete upto the replacement level of 50.0%. The split tensile strength of mix at 40%

replacement level is 24.06% more than the referral concrete. The ratio of split tensile strength

to compressive strength of different mixes at 28 days is almost similar, and lies in the range

of 0.087-0.104. The optimum replacement level of 40% may be used for structural purposes,

after studying the mineral composition of GGBS.

http://www.iaeme.com/IJCIET/index.asp 428 editor@iaeme.com

Rakesh Kumar, P.K. Mehta, P.R. Pal and TP Muhammed Ashiq

3.6. Relation between Compressive Strength and Split Tensile Strength

For developing a relation between the split tensile strength and compressive strength results

from this investigation, a best fit curve (Fig. 3) was drawn. The relation obtained is given as

Eq. 6:

Y= 0.243X-6.796 with R2= 0.925 (6)

Where, Y (ft) = Splitting strength of cylindrical concrete specimen of size 100x200 mm

(MPa), X (fck) = Compressive strength of 100mm cube specimen of concrete (MPa).

The result of split tensile (ft) and compressive strength (fck) obtained for the different

concrete mixtures were fitted in Eqs. 3 and 4. The value of ‘n’ obtained in the present

investigation with referral concrete is 0.676 (Table-4), which is similar to the results of

Gardener and Pool [18]. However, when GGBS replacement level varies between 10-55%,

the value of ‘n’ varies in the range of 0.675-0.725 (Table-4), which is slightly higher than the

referral concrete. The maximum value of 0.725 was found at 40% replacement. Again, using

Eq. 4, the value of ‘n’ obtained from the results of the present investigation for referral

concrete is found to be 0.784 (Table-4), which is higher than that obtained from Eq. 4.

However, the value of ‘n’ varies in the range of 0.783-0.830 (Table-4), when GGBS

replacement level varies between 10-55%. The maximum value of ‘n’ was found to be 0.830

at 40% replacement. So, the relation between compressive strength and split tensile strength

is very close to Eq. 3, and there is a significant deviation from Eq. 4. The higher value of ‘n’

may be due to improved pore structure of the concrete after inclusion of GGBS.

4.9

4.7

4.5

Split Tensile Strength

y = 0.243x - 6.796

4.3 R² = 0.925

4.1

3.9

(MPa)

3.7

3.5

42 43 44 45 46 47 48

Compressive Strength (MPa)

Figure 3 Relation between split tensile and compressive strengths of different concrete mixes cured at

28 days.

4. CONCLUSIONS

The following conclusions can be drawn from this study.

The workability of mixes is increased on part replacement of OPC by GGBS and depends on

the replacement level.

The mechanical properties viz., compressive strength, flexural strength and split tensile

strength, in general, increases at all the replacement level, except the split tensile strength

which decreases at a level of 55%. The optimum replacement level is 40% for structural

purposes.

At the replacement level of 40%, the gain in compressive strength at the ages of 7, 28, 56 and

90 days is found in the range of 9.19-25.6% as compared to referral concrete.

http://www.iaeme.com/IJCIET/index.asp 429 editor@iaeme.com

Relation among Mechanical Properties of Ground Granulated Blast Furnace Slag Concrete

At the optimum replacement level of 40%, the gain in flexural and split tensile strengths at the

age of 28 days is 18.75% and 24.6%, respectively, as compared to the referral concrete.

The value of ‘n’ obtained is higher in case of GGBS concrete in comparison to the value of

‘n’ suggested for relation between flexural strength and compressive strength (Eq.1).

The value of ‘n’ obtained for different mix proportions is slightly higher than the value of ‘n’

suggested by Eq. 3 for relation between split tensile strength and compressive strength.

However, it is significantly higher at optimum replacement level of 40%.

The value of ‘n’ found in the present investigation is significantly higher than those

suggested in Eq. 4. So these results do not fit in Eq. 4.

The increase in ‘n’ values shows that the GGBS concrete is more ductile than referral

concrete.

Flexural strength of GGBS concrete may be estimated by using the Eq.5.

The split tensile strength of GGBS concrete may be estimated by using the Eq.6.

REFERENCES

[1] S.Teng, T.Y.D. Lim, B.S. Divsholi, Durability and Mechanical properties of high strength

concrete incorporating Ultra fine ground granulated blast-furnace slag, Construction and

Building Materials 40,2013, pp. 875-881.

[2] B.O’Rourke, C. McNally, M.G. Richardson, Development of Calcium Sulfate-GGBS-

Portland Cement Binders, Construction and Building Materials 23 (1),2009, pp. 340-346.

[3] S.O. Ogbeide, Developing and Optimization Model for CO2 Reduction in Cement

Production Process, Engineering Science and Technology Review, 3 (1), 2010, pp. 85-88.

[4] E.Benhelal, G. Zahedi, E. Shamsaei, A. Bahadori, Global Strategies and Potential to curb

CO2 emissions in Cement Industry, The journal of Cleaner Production 51, 2013, pp. 142-

161.

[5] K.H. Yang, K.H. Lee, J.K. Song, M.H. Gong, Properties and Sustainability of Alkali-

Activated Slag foamed Concrete, The Journal of Clear Production, 68, 2014, pp. 226-233.

[6] R.Kajaste, and M. Hurme, Cement Industry Greenhouse Gas Emission e Management

options and abatement cost, The Journal of Cleaner Production112 (5), 2016, pp. 4041-

4052.

[7] G.Hebert, J.B.D Espinose de Lacaillerie and N. Roussel, An Environmental evaluation of

Geopolymer based Concrete Production: Reviewing current Research Trends, The journal

of Cleaner Production 19 (11), 2011, pp. 1229-1238.

[8] K.H.Yang, J.K. Song, K.I. Song, Assessment of CO2 reduction of Alkali-activated

Concrete, The journal for Cleaner Production, 39, 2013, pp. 265-272.

[9] K.H. Yang, Y.B. Jung, M.S. Cho and S.H. Tae, Effect of Supplementary Cementitious

Materials on Reduction of CO2 Emissions from Concrete, The Journal of Cleaner

Production, 103, 2015, pp. 774–783.

[10] R. Siddique and R. Bennacer, Use of Iron and Steel Industry by-product (GGBS) in

Cement Paste and Mortar, Resources, Conservation and Recycling 69, 2012, pp. 29–34.

[11] X.Jin and Z. Li, Investigation on Mechanical Properties of Young Concrete, Materials and

Structures/Materiaux et Constructions, Vol. 33, December, 2000, pp 627-633.

[12] R.D. Hooton and J.J. Emery, Glass content Determination and Strength Development

Predictions for Vitrified Blast Furnace Slag, ACI SP 79, 1983, pp. 943-962.

http://www.iaeme.com/IJCIET/index.asp 430 editor@iaeme.com

Rakesh Kumar, P.K. Mehta, P.R. Pal and TP Muhammed Ashiq

[13] R.N. Swamy and A. Bouikni, Some Engineering Properties of Slag Concrete as

influenced by Mix Proportioning and Curing, ACI material Journal, 87, 1990, pp. 210-

220.

[14] K. Ganesh Babu and V. Sree Rama Kumar “Efficiency of GGBS in Concrete” Cement

and Concrete Research, 30, 2000, pp.1031-1036.

[15] A. Oner and S. Akyuz, An Experimental Study on Optimum Usage of GGBS for the

Compressive Strength of Concrete, Cement & Concrete Composites, 29, 2007, pp.505–

514

[16] Wu Zemei, Shi Caijun and He Wen, Comparative Study on Flexural Properties of Ultra-

high performance Concrete with Supplementary Cementitious Materials under different

curing regimes, Construction and Building Materials, 136, 2017, pp.307-313.

[17] IS: 456-2000, Plain and Reinforced Concrete – Code of Practice, BIS, New Delhi.

[18] Gardner N J and Poon S M, Time and Temperature effects on tensile, bond and

compressive strengths, Journal of American Concrete Institute,73, No.7, 1976, pp.405-

409.

[19] Raphael J M, Tensile Strength of Concrete, ACI Materials Journal, 81/2, 1984, pp.158-

165.

[20] Oluokun F A, Prediction of Tensile Strength from Compressive Strength; Evolution of

Existing Relation for Normal Weight Concrete, ACI Materials Journal, 88/3, 1991, pp.

302-309.

[21] IS 8112-1989, Specification for 43 grade Ordinary Portland Cement, BIS, New Delhi.

[22] IS: 383-1970, Specification for Coarse and Fine aggregate from Natural Sources of

Concrete, BIS, New Delhi.

[23] SP: 23-1982, Hand Book of Concrete Mixes, BIS, New Delhi.

[24] IS: 10262-2009, Indian Standard for Concrete Mix Proportioning – Guidelines, BIS, New

Delhi.

[25] IS: 14858-2000, Compression Testing Machine used for Testing of Concrete, BIS, New

Delhi.

[26] IS: 5816-1999, Split Tensile Strength of Concrete Method of Test, BIS, New Delhi.

[27] IS: 516-1959, Methods of Tests for Strength of Concrete, BIS, New Delhi.

[28] V. Subbamma and Dr. K. Chandrasekhar Reddy, Experimental Study on Split Tensile

Strength of Concrete with Partial Replacement of Cement by Flyash and Metakaοlin.

International Journal of Civil Engineering and Technology, 7(6), 2016, pp.73 – 81.

[29] Vinod B Shikhare and L. G. Kalurkar, Effect of Different Types of Steel Fibers with

Metakaolin & Fly Ash on Mechanical Properties of High Strength Concrete. International

Journal of Civil Engineering and Technology (IJCIET), 4(3), 2013, pp.73–79

http://www.iaeme.com/IJCIET/index.asp 431 editor@iaeme.com

You might also like

- Standard: Robust, Durable, Dense Aggregate BlocksDocument3 pagesStandard: Robust, Durable, Dense Aggregate BlocksMohan BhalmeNo ratings yet

- Structural Bearings and Expansion Joints For Bridges PDFDocument89 pagesStructural Bearings and Expansion Joints For Bridges PDFMohan Bhalme67% (3)

- Tarmac Buildingproducts Blocks Durox Supabloc v1Document3 pagesTarmac Buildingproducts Blocks Durox Supabloc v1Mohan BhalmeNo ratings yet

- Recent Questions and Answers in Bridge Engineering - Civil Engineering Technical Questions Answers - Ask A Civil Engineer PDFDocument2 pagesRecent Questions and Answers in Bridge Engineering - Civil Engineering Technical Questions Answers - Ask A Civil Engineer PDFdineshNo ratings yet

- Concrete BasementsDocument184 pagesConcrete BasementsMohan BhalmeNo ratings yet

- For Axial Compressive Load & Biaxial Bending Moments, Including Slenderness Effect, As Per Is:456-2000Document43 pagesFor Axial Compressive Load & Biaxial Bending Moments, Including Slenderness Effect, As Per Is:456-2000Mohan BhalmeNo ratings yet

- ArchSmarter Revit Shortcut Cheat Sheet v1Document2 pagesArchSmarter Revit Shortcut Cheat Sheet v1Mohan BhalmeNo ratings yet

- Crab Steering MechanismDocument15 pagesCrab Steering MechanismMohan BhalmeNo ratings yet

- Finite Element AnalysisDocument39 pagesFinite Element AnalysisMohan BhalmeNo ratings yet

- 5 Cross Section Classification HandoutDocument2 pages5 Cross Section Classification HandoutMohan BhalmeNo ratings yet

- Abaqus AnalysisDocument12 pagesAbaqus AnalysisMohan BhalmeNo ratings yet

- 8Document6 pages8Mohan BhalmeNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chapter 12 Aluminium and Magnesium Casting Alloys PDFDocument41 pagesChapter 12 Aluminium and Magnesium Casting Alloys PDFDANIEL ALEJANDRO FERNANDEZ GARCIANo ratings yet

- Composites Science and Technology: S. Fliegener, J. Hohe, P. GumbschDocument11 pagesComposites Science and Technology: S. Fliegener, J. Hohe, P. GumbschThắngNguyễnNo ratings yet

- MIL-F-5509D - Fittings, Flared Tube, Fluid ConnectionDocument18 pagesMIL-F-5509D - Fittings, Flared Tube, Fluid ConnectionthomasNo ratings yet

- Ultratech PPC 53 Grade CementDocument1 pageUltratech PPC 53 Grade CementGovind SharmaNo ratings yet

- Univeristy of Engineering and Technology Peshawar: Steel StructuresDocument77 pagesUniveristy of Engineering and Technology Peshawar: Steel StructuresMuhammad SaqibNo ratings yet

- Investigation of Tensile and Flexural Properties oDocument18 pagesInvestigation of Tensile and Flexural Properties oAhmad Haikal Mohd HalimNo ratings yet

- Date of Test: Non-Destructive Testing (NDT) / Ultrasonic Pulse Velocity (UPV) & Compressive Testing Strenght (CTM)Document65 pagesDate of Test: Non-Destructive Testing (NDT) / Ultrasonic Pulse Velocity (UPV) & Compressive Testing Strenght (CTM)GaneshNo ratings yet

- Ceiling Material ListDocument7 pagesCeiling Material ListVannara RongNo ratings yet

- Iso 7151 1988Document8 pagesIso 7151 1988MusfiqAtifNo ratings yet

- TirupathiDocument14 pagesTirupathiEkta Adlakha100% (1)

- Sustainable 3D Printing With Recycled Materials: A Review: Journal of Mechanical Science and Technology 37 (11) 2023Document27 pagesSustainable 3D Printing With Recycled Materials: A Review: Journal of Mechanical Science and Technology 37 (11) 2023DANTE DELEGUERYNo ratings yet

- Public GoodsDocument37 pagesPublic GoodsSiti Nur RosifahNo ratings yet

- Surface Repair Using Form-and-Pour Techniques: Reported by ACI Committee E 706Document7 pagesSurface Repair Using Form-and-Pour Techniques: Reported by ACI Committee E 706Carlos Gonzalez100% (1)

- SR TestDocument10 pagesSR TestkuladeepkatragaddaNo ratings yet

- BMC Assignment S5 (HARDBOARD&GLULAM)Document19 pagesBMC Assignment S5 (HARDBOARD&GLULAM)Ebin JoyNo ratings yet

- ExpametDocument14 pagesExpametvklsNo ratings yet

- Ae Pu25Document3 pagesAe Pu25Shimmy AntonyNo ratings yet

- Oxidation - VLSI TechnologyDocument15 pagesOxidation - VLSI TechnologyDeepak Khushalani0% (1)

- NO. Jenis Barang Spesifikasi Harga 1 2 3 5 Meja, Kursi, LemariDocument8 pagesNO. Jenis Barang Spesifikasi Harga 1 2 3 5 Meja, Kursi, LemaribobyNo ratings yet

- Ex RC 2214Document1 pageEx RC 2214Erik TiendaNo ratings yet

- Basic Science Yr9 WK7&8 Lesson NoteDocument6 pagesBasic Science Yr9 WK7&8 Lesson NotePearl PhareeNo ratings yet

- Ingredient Percentage in Cement: Lime Silica Alumina Magnesia Iron Oxide Calcium Sulfate 0.1-0.5 Sulfur Trioxide AlkalineDocument13 pagesIngredient Percentage in Cement: Lime Silica Alumina Magnesia Iron Oxide Calcium Sulfate 0.1-0.5 Sulfur Trioxide AlkalineAnupam KumarNo ratings yet

- Semi-Hard Triflex ™: Technical Data SheetDocument2 pagesSemi-Hard Triflex ™: Technical Data SheetSantosh JayasavalNo ratings yet

- Chemsheets GCSE 1143 Electrolysis of Melts 2Document1 pageChemsheets GCSE 1143 Electrolysis of Melts 2Sumaiya Iqbal780% (1)

- Model Answer Paper Summer 2019Document16 pagesModel Answer Paper Summer 2019utkarshdeshmukhNo ratings yet

- Appendix 1 - Internal Non-Haz. Waste Manifest - A5Document1 pageAppendix 1 - Internal Non-Haz. Waste Manifest - A5herlambangNo ratings yet

- @sanitary PVC Pipes Fittings PDFDocument3 pages@sanitary PVC Pipes Fittings PDFDesiree jayne NoriegaNo ratings yet

- ACT SEMINAR PHD VENKATESHDocument26 pagesACT SEMINAR PHD VENKATESHGyanesh PatnaikNo ratings yet

- Abrasives Selection Guide: Choose From Our Extensive Range of Discs, Wheels, Burrs and Sanding ProductsDocument27 pagesAbrasives Selection Guide: Choose From Our Extensive Range of Discs, Wheels, Burrs and Sanding Productsagniva dattaNo ratings yet

- GGBS Product BrochureDocument8 pagesGGBS Product BrochureSoumyakanti S. Samanta (Pgdm 09-11, Batch II)No ratings yet