Professional Documents

Culture Documents

Technical Insight: NSK Motorized Ball Screw Actuator (Mbsa Series)

Uploaded by

marcoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Insight: NSK Motorized Ball Screw Actuator (Mbsa Series)

Uploaded by

marcoCopyright:

Available Formats

TECHNICAL INSIGHT

PRODUCT AND APPLICATION ENGINEERING INFORMATION A PUBLICATION OF NSK AMERICAS

NSK MOTORIZED BALL SCREW ACTUATOR (MBSA SERIES):

NSK Achieves Space Saving Design with Linear Precision for Medical Applications

During the 21st century, our society has been at the forefront of discovering new solutions through advanced technology for

medical device and clinical laboratory applications. These innovative solutions have utilized linear motion to develop state-

of-the-art medical imaging, diagnostic and surgical equipment. Linear motion is a common need for all types of advanced

equipment and machines; but precise, smooth, reliable, and repeatable linear motion is fundamentally important for several

applications within the medical industry. Precision ground ball screws have become the preferred choice for precise linear

motion because they deliver smooth and accurate movement ensuring reliable and repeatable results.

The demand to reduce the size of linear screw actuators, but maintain precision,

is evident in several medical diagnostic and imaging applications. A diagnostic

device, such as a desktop blood analyzer, can process multiple samples at a faster

speed and higher accuracy in comparison to its predecessor that was the size of an

automobile. Health care practitioners rely on small ball screw actuators on syringe

pumps to accurately dispense precise levels of medication. In imaging applications,

such as CT scanners, small actuators position aperture plates to control the X-ray

beam. In each of these applications, a lead screw or ball screw is combined with a

small electric motor to translate the motor’s rotary motion into linear motion.

Illustrated: MBSA used in a Blood Analyzer

Pictured: MBSA Series

LEAD SCREWS VS. PRECISION GROUND BALL SCREWS Therefore the ball screw thread profile is different than that of a

In order to achieve linear motion for medical applications, the lead screw. The ball screw has a U-shaped groove, or Gothic arch,

traditional solution combines a lead screw with an electric to house the precision ball bearings. The nut thread profile acts

stepping motor. Lead screws use a V-shaped helical thread on as the outer raceway and the groove along ball screw shaft acts

the shaft with a matching thread inside the nut, similar to a nut as the inner raceway for ball bearing travel.

and bolt you can get at a hardware store. Lead screws (and ACME

screws) rely on sliding contact between the surfaces of the nut

Nut

thread and the shaft thread to produce linear motion.

Ball

The benefit of a lead screw is the small nut relative to the axial

load it can support due to the large flat contact surface areas of

the mating threads. However, the flat surfaces sliding across

each other generate heat caused by friction. A large motor is Shaft

required to overcome friction. As a result, this solution does

Illustrated: Precision Ground Ball Screw Gothic Arch Raceway

not provide smooth consistent motion and will require more

maintenance due to considerable wear. “Backlash” is inherent The ball bearings provide a rolling contact point between the nut

with the typical lead screw design caused by clearance between and the shaft that lowers the coefficient of friction. The result

the nut thread and the shaft thread. The backlash affects the is a highly efficient (90% to 95%) mechanism that requires less

linear positioning accuracy of the screw. NSK understands the torque to convert rotational motion into linear motion making

importance of minimizing or eliminating backlash and now offers ball screws a better fit for the challenges inherent to medical

an alternative solution. applications. By using

100 03 a precision ground ball

0.0

µ=

(Backlash) thread clearance 90 05 µ=0.0

1 screw, the application

Thread 0.0

µ=

contact 80 results in lower operating

Ball screw

70 temperatures, smoother

Efficiency h1 (%)

60 motion, reduced motor

Nut 0.1

Direction of load 50 µ= size, less energy

40 consumed, less wear, and

0.2

30 µ=

longer life in comparison

Screw 20

Acme screw to a lead screw solution.

10

Illustrated: Lead Screw Nut and Shaft showing

Axial and Radial Clearance 0 1 2 3 4 5 6 7 8 9 10 In order to adhere to

Lead angle (degree)

Regarded as the world’s leading manufacturer of precision small size constraints for

Efficiency of normal operation

(Converting rotary motion to linear motion) the nut body, NSK uses

ground ball screws, NSK sought to integrate its precision ground µ: Friction coefficient

ball screw into an electric stepping motor resulting in the new a bridge-type deflector

Illustrated: Ball Screw vs recirculation piece to

MBSA Series. Similar to a lead screw, a ball screw also has a Lead Screw Efficiency

helical thread on the shaft and inside the nut; but a ball screw guide the ball bearings

uses precision ball bearings between the nut and the shaft. between adjacent ball thread grooves or raceways providing the

recirculation necessary for a ball screw. Since the deflectors sit

NSK MOTORIZED BALL SCREW ACTUATOR (MBSA SERIES) 2

below the surface of the nut body outside diameter, this area High positioning accuracy is the result of a precision ground

can be used as a pilot surface for instruments or components ball screw with a preloaded nut that eliminates backlash. Lead

attached to the nut. accuracy is measured by calculating the difference between

the actual linear distance traveled by the ball screw nut in one

Ball nut shaft revolution versus the theoretical distance traveled (equal

Deflector Deflector

(bridge type) to the lead). The International Organization for Standardization

(ISO) has set lead accuracy standards for precision ball screws.

To conceptually visualize the accuracy, the average human hair

is 0.080mm in diameter. For the MBSA Series, NSK uses a C3

Screw shaft accuracy ball screw which has a lead accuracy of 0.006mm per

Deflector

shaft revolution. The stepping motor paired with the ball screw

has 200 counts per revolution resulting in a motor resolution

Illustrated: Deflector-Type Ball Screw of 0.005mm for a 1mm lead ball screw. When measuring lead

accuracy over 300mm (or 1 foot) of travel, the actual nut position

HOW TO PREVENT BACKLASH deviation from the theoretical nut position is a maximum of

0.008mm for a C3 accuracy ball screw. Comparatively, a lead

To eliminate backlash or axial play between the screw shaft and

screw can have a deviation as large as 0.250mm in 300mm of

the nut, NSK uses slightly oversized balls to create a light preload.

travel. Therefore the MBSA Series is the optimal solution for

The elastic deformation of the balls creates an internal force

highly precise medical devices and laboratory equipment.

between the nut and the screw shaft to eliminate clearance. The

result is precise linear movement of the object attached to the

INTEGRATING BALL SCREWS AND MOTORS

ball screw nut with zero backlash between shaft rotation and

nut linear movement. This preload allows for better positioning In the development of the MBSA Series, NSK replaced the electric

control for medical applications with multi-directional axial loads. motor output shaft with a journal that is part of the ball screw

shaft. The motor directly rotates the ball screw shaft which

Ball nut

translates the nut for linear motion. This design eliminates the

need for a separate motor-to-ball screw coupling. The MBSA

Series allows for a compact space-saving design that reduces

system inertia and eliminates alignment error that can occur

when the motor and ball screw are separately mounted. This

Oversized ball

new product series is small enough to fit in the palm of your

hand.

Lead Lead

4-Point

Contact

Ball nut The MBSA Series is also designed to accommodate a configurable

encoder mounted to the back of the stepping motor. The stepping

motor can communicate with a wide variety of controllers/

Screw drivers. Customers may customize by selecting the controller/

shaft

driver of their choice.

Illustrated: Ball Screw Preload using Oversized Ball

Bearing resulting in 4 Points of Contact

NSK MOTORIZED BALL SCREW ACTUATOR (MBSA SERIES) 3

SIZING AND AVAILABILITY

Customers can choose from the following standard NEMA motors

sizes for the MBSA Series: 14, 17 or 23. The use of smaller motors,

for example NEMA 8, is possible by selecting a custom design.

Standard ball screw sizes will range in diameter from 6mm

to 8mm and a lead range of 1mm to 2mm to allow for more

precise positioning. NSK’s MBSA Series will be available to the

marketplace in early 2017.

As our world continues to evolve, medical devices and laboratory

equipment used in diagnostics, syringe pumps, microfluidics,

imaging, cancer treatment, and other applications requiring

automation will benefit from these types of integrated solutions.

To learn more about how NSK’s MBSA Series can ensure

precise, reliable and repeatable movement for your medical

application, contact us (1.888.446.5675) or visit our website

(www.nskamericas.com).

Pictured: NEMA14 MBSA with Optional Encoder and

Support Bearing Installed

www.nskamericas.com MBSA / ATI / 16

You might also like

- NSK Linear Guide: Miniature PU Series/PE SeriesDocument7 pagesNSK Linear Guide: Miniature PU Series/PE Seriesjaime cerdaNo ratings yet

- Sensors Throttleposition PDFDocument3 pagesSensors Throttleposition PDFIvan LeongNo ratings yet

- An900 Esp Pump PsDocument1 pageAn900 Esp Pump PsAbdelmalik BombiNo ratings yet

- Bending - Shear Interaction in Rbs Short Coupling Beams-LibreDocument10 pagesBending - Shear Interaction in Rbs Short Coupling Beams-LibreSakisNo ratings yet

- Tsubaki Power Lock Ad N SeriesDocument5 pagesTsubaki Power Lock Ad N SeriesRizal IephoNo ratings yet

- Design of Machine Elements 1E52Document29 pagesDesign of Machine Elements 1E52Thirumal K SNo ratings yet

- Presentation PosterDocument1 pagePresentation PosterMatthew Gary NesbittNo ratings yet

- Bomba Duplo Estagio SIHIsterivac - EDocument4 pagesBomba Duplo Estagio SIHIsterivac - ERicardo BoriniNo ratings yet

- Shock Sub BRDocument4 pagesShock Sub BRJose Manuel Lezama SantaellaNo ratings yet

- PDF - SB Acoustics - MR16P-8 - 1Document1 pagePDF - SB Acoustics - MR16P-8 - 1milenkotulencicNo ratings yet

- Satori MR16PNW 8Document1 pageSatori MR16PNW 8hamzah fitraNo ratings yet

- SB Acoustics - SB23CACS45-8 - CeramicDocument1 pageSB Acoustics - SB23CACS45-8 - CeramickosarobNo ratings yet

- LIS Dharampur Brang 2Document2 pagesLIS Dharampur Brang 2Rishav ChaudharyNo ratings yet

- Sewing 01-Blindstitching With Groz-Beckert V-Needles PDFDocument4 pagesSewing 01-Blindstitching With Groz-Beckert V-Needles PDFfriendztoall4351No ratings yet

- CIM Motor Curve Am 0255Document1 pageCIM Motor Curve Am 0255Julio CostaNo ratings yet

- EBM Pabst - CPAP - BlowerDocument4 pagesEBM Pabst - CPAP - BlowerlouisNo ratings yet

- Rectilinear Displacement Transducer For Mounting Inside Hydraulic ActuatorsDocument2 pagesRectilinear Displacement Transducer For Mounting Inside Hydraulic ActuatorsGopal HegdeNo ratings yet

- Installation Pipework: Distribution Main Pipe Distribution Pipe 1 Distribution Pipe 2Document4 pagesInstallation Pipework: Distribution Main Pipe Distribution Pipe 1 Distribution Pipe 2Mukesh KumarNo ratings yet

- Shock Sub Tool: Impact and Vibration Reduction ToolDocument4 pagesShock Sub Tool: Impact and Vibration Reduction ToolLeonardo Barrios0% (1)

- Geared Wirewound Potentiometers: PD2310 SeriesDocument2 pagesGeared Wirewound Potentiometers: PD2310 SeriesKSNo ratings yet

- Brushless AC Motor PDFDocument2 pagesBrushless AC Motor PDFnitin9860No ratings yet

- RS-CE Rotary Actuators: External Dimensions Torque ProfilesDocument3 pagesRS-CE Rotary Actuators: External Dimensions Torque ProfilescarlcoxNo ratings yet

- RC Cantilever DeflectionDocument1 pageRC Cantilever Deflectionklára LudínováNo ratings yet

- Pot Bearing - Fix Bearing DesignDocument2 pagesPot Bearing - Fix Bearing Designtrichandra maharjanNo ratings yet

- Analysis On Shielding Effectiveness of Board Level Shielding With Apertures - Interference TechnologyDocument2 pagesAnalysis On Shielding Effectiveness of Board Level Shielding With Apertures - Interference Technologydbm010102No ratings yet

- KELLER (SWCC) Pile: 19 Boredpile Blow: 3 (Test: 21-Nov-2020 11:57:) 23-Nov-2020 GULF CONSULT (Geotechnical Division) CAPWAP (R) 2006Document4 pagesKELLER (SWCC) Pile: 19 Boredpile Blow: 3 (Test: 21-Nov-2020 11:57:) 23-Nov-2020 GULF CONSULT (Geotechnical Division) CAPWAP (R) 2006Zara BhaiNo ratings yet

- Bolts and Power Screws - LongDocument5 pagesBolts and Power Screws - LongAmeeh TorionNo ratings yet

- PV Layout FinalDocument1 pagePV Layout FinalRahul SahaNo ratings yet

- PL310Document2 pagesPL310Ivailo ZapryanovNo ratings yet

- Cornell - AgricultureDocument8 pagesCornell - AgricultureSBM LagunaNo ratings yet

- Atlas Tube ASTM A1085 HSS Flyer 2016-05-15Document2 pagesAtlas Tube ASTM A1085 HSS Flyer 2016-05-15Todd HenryNo ratings yet

- LIS Gopalpur Thouna SubmersibleDocument2 pagesLIS Gopalpur Thouna SubmersibleRishav ChaudharyNo ratings yet

- MRF-140CG Magneto-Rheological Fluid: Lord Technical Data Lord Technical DataDocument2 pagesMRF-140CG Magneto-Rheological Fluid: Lord Technical Data Lord Technical DataSoroush RahimiNo ratings yet

- Catalogo Transductores Novotechnik PDFDocument4 pagesCatalogo Transductores Novotechnik PDFGerEspNo ratings yet

- TLH PDFDocument4 pagesTLH PDFhassanchaarNo ratings yet

- TLH PDFDocument4 pagesTLH PDFvalter mNo ratings yet

- Microsoft PowerPoint - Axial-and-FlexureDocument37 pagesMicrosoft PowerPoint - Axial-and-Flexuremanish_shashikantNo ratings yet

- BTA Rotary Actuators: Saia-Burgess SolenoidsDocument10 pagesBTA Rotary Actuators: Saia-Burgess SolenoidsBuenotech - Classificadores de frutasNo ratings yet

- CM Construction and Features: One Moving ComponentDocument4 pagesCM Construction and Features: One Moving ComponentJohn Jairo SimancaNo ratings yet

- Sheaves and Grooves PDFDocument4 pagesSheaves and Grooves PDFRui Miguel SalvadorNo ratings yet

- TubirneDocument13 pagesTubirneTc7 CnNo ratings yet

- Quasi-Steady Analytical Model Benchmark of An ImpuDocument12 pagesQuasi-Steady Analytical Model Benchmark of An ImpuTc7 CnNo ratings yet

- Cen 50X40-200Document1 pageCen 50X40-200bocahjeblogNo ratings yet

- Articulating JointDocument4 pagesArticulating JointJoseph JoseNo ratings yet

- Flyer Powersource Motoweld-Rl350 e 02.2017Document8 pagesFlyer Powersource Motoweld-Rl350 e 02.2017Jorge Martinez PeraltaNo ratings yet

- AMACS Multipocket Vane WebDocument1 pageAMACS Multipocket Vane WebadrianioantomaNo ratings yet

- Belt Tension CalculatorDocument1 pageBelt Tension CalculatorhenrengNo ratings yet

- LK Linear-Couplings PDFDocument2 pagesLK Linear-Couplings PDFRuben Dario HerreraNo ratings yet

- Three-Axis Active Control Magnetic Bearing With Asymmetric Structure For High-Temperature MachinesDocument1 pageThree-Axis Active Control Magnetic Bearing With Asymmetric Structure For High-Temperature Machinesxiaoqi dengNo ratings yet

- Bellin - Inglese Eccentric Screw PumpDocument8 pagesBellin - Inglese Eccentric Screw PumpAlexis ValleNo ratings yet

- BF02323554Document7 pagesBF02323554Fernando CruzNo ratings yet

- Casquillos ETPDocument2 pagesCasquillos ETP434lapNo ratings yet

- LIS Chauntra Khadiyar and DolDocument2 pagesLIS Chauntra Khadiyar and DolRishav ChaudharyNo ratings yet

- Modulus of Resilience: 248 C H A P T E R 6 Mechanical Properties of Metals IDocument1 pageModulus of Resilience: 248 C H A P T E R 6 Mechanical Properties of Metals IMattia MatrangaNo ratings yet

- Product Specifications:: Bhitrackpage ("Bit","Bit Stylesheet") %Document1 pageProduct Specifications:: Bhitrackpage ("Bit","Bit Stylesheet") %Joe CruzNo ratings yet

- Polypac BalseleDocument18 pagesPolypac BalseleRenato GouveiaNo ratings yet

- 3MN0667 00 MN ARRAY 1550 M FAB ACR SERIES - CompressedDocument2 pages3MN0667 00 MN ARRAY 1550 M FAB ACR SERIES - CompressedMukhlas JauharNo ratings yet

- Datasheet 515 Complete Technical DocumentationDocument18 pagesDatasheet 515 Complete Technical DocumentationMohammad FakhryNo ratings yet

- Ficha Tecnica Sv200neoDocument1 pageFicha Tecnica Sv200neoMauricio Ramirez PerezNo ratings yet

- Unit VDocument26 pagesUnit VSabik NainarNo ratings yet

- Machinery Canada - DC Swiss Taps NPTDocument2 pagesMachinery Canada - DC Swiss Taps NPTmachineCanNo ratings yet

- Bolts InformationDocument12 pagesBolts InformationsathyakumaryjNo ratings yet

- Pitch Conversions Threads Per Inch TPI Pitch in Inches and Pitch in MM For Taps and DiesDocument3 pagesPitch Conversions Threads Per Inch TPI Pitch in Inches and Pitch in MM For Taps and DiesChetan HinganeNo ratings yet

- GLDocument248 pagesGLMERMANo ratings yet

- Kidkraft Outdoor Playhouse 00132Document16 pagesKidkraft Outdoor Playhouse 00132vipulpratapNo ratings yet

- Gears and Gear TrainsDocument127 pagesGears and Gear TrainsVikki KotaNo ratings yet

- Din - 3962 1 1978Document18 pagesDin - 3962 1 1978Carlos Cortes100% (3)

- TCL004 - SGD - V4 (Fasteners) PDFDocument82 pagesTCL004 - SGD - V4 (Fasteners) PDFJela ParadiseNo ratings yet

- Gears: What Is A Gear?Document36 pagesGears: What Is A Gear?Diana RivasNo ratings yet

- Wera Torque ToolsDocument60 pagesWera Torque ToolsAlief PambudhiNo ratings yet

- Tronxy x1 Assembly GuideDocument26 pagesTronxy x1 Assembly GuideВайсер Евгений100% (1)

- Case 580 SLPDocument9 pagesCase 580 SLPRbm Info0% (1)

- Answer by True or False For Each Following Sentences: (Circle The Right Answer)Document2 pagesAnswer by True or False For Each Following Sentences: (Circle The Right Answer)tinhinane MEDJKANENo ratings yet

- Rx4 Gearbox DiagnosisDocument4 pagesRx4 Gearbox Diagnosisδαιβελ εςριησςαNo ratings yet

- Squarehead BoltsDocument3 pagesSquarehead Boltshitesh cHAUDHARINo ratings yet

- Iso 2306 1972Document8 pagesIso 2306 1972quietensNo ratings yet

- Hardrock Fabrication (P) Limited: SL - NO. Part No. Description TA66096Document5 pagesHardrock Fabrication (P) Limited: SL - NO. Part No. Description TA66096AMSONIC ROCKSNo ratings yet

- Pitting Load Capacity of Helical GearsDocument6 pagesPitting Load Capacity of Helical GearsSwarnava PaulNo ratings yet

- Design of Helical GearDocument58 pagesDesign of Helical Gearkyaji rautNo ratings yet

- Translated Copy of (DIN 3976 - 1980-11) - Zylinderschnecken, Maße, Zuordnung Von Achsabständen Und Übersetzungen in SchneckenradsätzenDocument16 pagesTranslated Copy of (DIN 3976 - 1980-11) - Zylinderschnecken, Maße, Zuordnung Von Achsabständen Und Übersetzungen in Schneckenradsätzensantosh kumarNo ratings yet

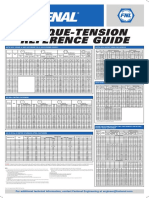

- Torque-Tension Reference GuideDocument1 pageTorque-Tension Reference GuidemaxNo ratings yet

- Parts Checkout ListDocument4 pagesParts Checkout Listjohn useyNo ratings yet

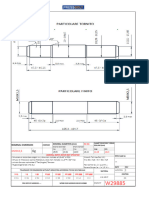

- Nominal Dimension: 18,28 18,25 General Notes When Not SpecifiedDocument1 pageNominal Dimension: 18,28 18,25 General Notes When Not SpecifiedDaniele Fazio MusicNo ratings yet

- Machine ToolsDocument2 pagesMachine ToolsDarien Gale EgdaneNo ratings yet

- Tugas Laporan Plant Layout PlanningDocument37 pagesTugas Laporan Plant Layout Planningxinke laoNo ratings yet

- Machine Design-Ii: GearsDocument50 pagesMachine Design-Ii: Gearsmuhammad hamzaNo ratings yet

- PATTA Screws Cat2018 - 1Document28 pagesPATTA Screws Cat2018 - 1Vengatesh HariNo ratings yet

- Nuts - Viterie Venete Balkan FastenersDocument4 pagesNuts - Viterie Venete Balkan FastenerssurubNo ratings yet