Professional Documents

Culture Documents

b47-1 2007 Erra-012010 PDF

Uploaded by

Marko's Brazon'0 ratings0% found this document useful (0 votes)

7 views2 pagesOriginal Title

b47-1_2007_erra-012010.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views2 pagesb47-1 2007 Erra-012010 PDF

Uploaded by

Marko's Brazon'Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Copyrighted material licensed to Stanford University by Thomson Scientific (www.techstreet.com), downloaded on Oct-05-2010 by Stanford University User.

No further reproduction or distribution is permitted. Uncontrolled wh

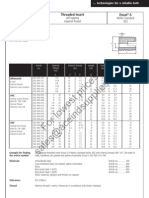

ERRATA

to

ASME B47.1-2007

Gage Blanks

On page 48, Table 32, decimal range for line 8-T corrected. Lines 9-T and 10-T added. The

revised table is on the following page.

THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

Three Park Avenue, New York, NY 10016-5990

January 2010

M8207E

Copyright c 2010 by the American Society of Mechanical Engineers.

No reproduction may be made of this material without written consent of ASME.

Table 32 Thread Ring Gages — Range No. 0 to and Including 43⁄4 in.; Also Fine-Pitch Instrument Thread Ring Gages,

No. 0 to and Including No. 12 (Cont’d)

Decimal General Dimensions

Nominal Range, U

Ring Ring Range, Above Drill Size,

Ream, S Pitch Diameter

Size Assembly Inclusive, and M N P Drill Size,

No. No. No. or in. Including A B C D E F H J K L ± 1⁄64 ± 1⁄64 (No. or in.) R Min. Max. Size Min. Max. V W

1 1 5 5 5 7 5 1 11 1

1-T 1 No. 0 to 0.059– 1 ⁄4 ... ... ... ⁄32 ⁄16 ⁄32 ⁄16 ⁄32 ⁄32 ⁄16 No. 41 ⁄64 0.1370 0.1373 0.164-36 0.1400 0.1478 0.010 ⁄32

6 (1) 0.230 (0.0960) (0.1719) (2)

1 5 3 11 5 1 7 3 3 11 1 1 7 1

2-T 2 ⁄4– ⁄16 0.230– 1 ⁄8 ⁄32 ... ... ⁄32 ⁄32 ⁄16 ⁄16 ⁄8 ⁄32 ⁄4 ⁄8 No. 31 ⁄32 0.1810 0.1813 0.216-28 0.1928 0.1950 1⁄32 ⁄16

0.365 (0.1200) (0.2187)

3 7 3 3 19 1 15 1 3 3 17 1 3

3-T 3 ⁄8–1⁄2 0.365– 13⁄4 ⁄16 ... ... ⁄16 ⁄64 ⁄32 ⁄4 ⁄32 ⁄2 ⁄8 ⁄16 No. 25 ⁄64 0.2150 0.2153 0.250-28 0.2268 0.2290 ⁄32 ⁄32

0.510 (0.1495) (0.2656)

9 9 3 11 1 3 5 11 17 13 7 21 1 3

4-T 4 ⁄16–3⁄4 0.510– 23⁄16 ⁄16 ⁄4 11⁄16 ⁄32 ⁄16 ⁄4 ⁄16 ⁄16 ⁄32 ⁄32 ⁄32 No. 7 ⁄64 0.2720 0.2723 0.3125-24 0.2854 0.2878 ⁄16 ⁄32

0.825 (0.2010) (0.3281)

1 11 15 9 1 31 5 7 17 13 9 25 1 3

5-T 5 ⁄8–11⁄8 0.825– 25⁄8 ⁄16 ⁄16 11⁄2 ⁄16 ⁄16 ⁄32 ⁄16 ⁄8 ⁄32 ⁄32 ⁄32 No. 1 ⁄64 0.3340 0.3344 0.375-24 0.3479 0.3503 ⁄16 ⁄32

1.135 (0.2280) (0.3906)

3 27 1 3 5 7 5 17 29 1 3

6-T 6 11⁄4–11⁄2 1.135– 31⁄4 ⁄4 11⁄8 17⁄8 ⁄32 ⁄16 13⁄16 ⁄8 11⁄8 ⁄8 ⁄16 ⁄16 ⁄64 ⁄64 0.3890 0.3894 0.4375-20 0.4050 0.4076 ⁄16 ⁄32

1.510 (0.2656) (0.4531)

13 3 3 5 7 5 17 29 1 1

7-T 6 15⁄8–2 1.510– 33⁄4 ⁄16 11⁄4 23⁄8 13⁄16 ⁄32 17⁄16 ⁄8 13⁄8 ⁄8 ⁄16 ⁄16 ⁄64 ⁄64 0.3890 0.3894 0.4375-20 0.4050 0.4076 ⁄16 ⁄8

2.010 (0.2656) (0.4531)

7 3 7 13 9 7 21 33 3 1

8-T 7 21⁄8–21⁄2 2.010– 41⁄2 ⁄8 15⁄16 27⁄8 119⁄32 ⁄32 13⁄4 ⁄16 111⁄16 ⁄16 ⁄16 ⁄16 ⁄64 ⁄64 0.4510 0.4515 0.500-20 0.4675 0.4701 ⁄32 ⁄8

2.510 (0.3281) (0.5156)

7 3 7 13 9 7 21 33 3 1

9-T 7 25⁄8–3 2.510– 5 ⁄8 13⁄8 33⁄8 2 ⁄32 2 ⁄16 115⁄16 ⁄16 ⁄16 ⁄16 ⁄64 ⁄64 0.4510 0.4515 0.500-20 0.4675 0.4701 ⁄32 ⁄8

3.010 (0.3281) (0.5156)

15 3 7 13 9 7 21 33 3 1

10-T 7 31⁄8–31⁄2 3.010– 51⁄2 ⁄16 17⁄16 37⁄8 27⁄16 ⁄32 27⁄32 ⁄16 23⁄16 ⁄16 ⁄16 ⁄16 ⁄64 ⁄64 0.4510 0.4515 0.500-20 0.4675 0.4701 ⁄32 ⁄8

3.510 (0.3281) (0.5156)

15 3 1 3 5 13 41 3 1

11-T 8 35⁄8–4 3.510– 63⁄8 ⁄16 11⁄2 45⁄8 215⁄16 ⁄32 25⁄8 ⁄2 29⁄16 1 ⁄4 ⁄8 ⁄32 ⁄64 0.5710 0.5715 0.625-18 0.5889 0.5919 ⁄32 ⁄8

4.010 (0.4062) (0.6406)

3 1 3 5 13 41 3 1

12-T 8 41⁄8–43⁄4 4.010– 71⁄4 1 11⁄2 53⁄8 33⁄8 ⁄32 31⁄32 ⁄2 3 1 ⁄4 ⁄8 ⁄32 ⁄64 0.5710 0.5715 0.625–18 0.5880 0.5919 ⁄32 ⁄8

4.760 (0.4062) (0.6406)

GENERAL NOTES:

Copyright c 2010 by the American Society of Mechanical Engineers.

(a) All dimensions are in inches.

(b) Thin gage blanks are to be used for all NOT GO thread ring gages. For GO thread ring gages, use thin or thick blanks as follows.

No reproduction may be made of this material without written consent of ASME.

Diameter, in. Thin Blank Thick Blank

From No. 0 to 1⁄2, inclusive All pitches ...

Above 1⁄2 to 11⁄8, inclusive Pitches 12 TPI and finer except 9⁄16–12 Pitches coarser than 12 TPI

Above 11⁄8 Pitches 10 TPI and finer Pitches coarser than 10 TPI

(c) Screws and sleeves are not shown.

(d) Special thicker blanks are sometimes required for checking long lengths of engagement or exceptionally coarse pitch threads.

(e) Solid working thread ring gages are of similar standard thickness and furnished without adjustment feature. Outside diameter of solid ring blanks may be smaller to suit particular

requirements. See Table 39 for solid setting and master thread ring gage blanks.

NOTES:

(1) Blanks for the range Nos. 0 to 12, inclusive, may be either counterbored or milled, as shown in illustration for Table 32.

(2) Approximate.

Copyrighted material licensed to Stanford University by Thomson Scientific (www.techstreet.com), downloaded on Oct-05-2010 by Stanford University User. No further reproduction or distribution is permitted. Uncontrolled wh

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Ensat Self Tapping Inserts 302 Series ImperialDocument1 pageEnsat Self Tapping Inserts 302 Series ImperialAce Industrial SuppliesNo ratings yet

- Power ProductDocument6 pagesPower ProductJOSEALBERICHNo ratings yet

- Hexagon Socket-Head Shoulder Screws: Fit: f9 Bare Steel 012.9Document1 pageHexagon Socket-Head Shoulder Screws: Fit: f9 Bare Steel 012.9Bo WangNo ratings yet

- Drill Bits - Burrs - Cutting Discs: Assorted ToolsDocument16 pagesDrill Bits - Burrs - Cutting Discs: Assorted Toolsمرتضی فراهانیNo ratings yet

- ADDISON Drills Price List MC 45-MergedDocument116 pagesADDISON Drills Price List MC 45-MergedVenkateshan VenuNo ratings yet

- Guide To Screwthread Sizes - Page 1Document6 pagesGuide To Screwthread Sizes - Page 1squanerNo ratings yet

- 09-Hardox Tool Recommendations For Hardox Wear PlateDocument4 pages09-Hardox Tool Recommendations For Hardox Wear PlateAnonymous c8uPXQW7No ratings yet

- Iso 68 1Document10 pagesIso 68 1Kapil Enterprises BigboltnutNo ratings yet

- Grease Nipples Data Sheet ENDocument36 pagesGrease Nipples Data Sheet ENTinkku PatelNo ratings yet

- ANSI Thread Series DesignationsDocument1 pageANSI Thread Series DesignationsAbby BurchNo ratings yet

- Drill Size For Form Tap PDFDocument2 pagesDrill Size For Form Tap PDFGirish KulkarniNo ratings yet

- 1 Cutting Tools KDocument358 pages1 Cutting Tools Kchitzulanu100% (1)

- Details For Screw Jack DesignDocument22 pagesDetails For Screw Jack DesignHesoyam SirNo ratings yet

- 031 DG Pi05 0301 0Document28 pages031 DG Pi05 0301 0powerclean ctgNo ratings yet

- Screw Size ChartDocument1 pageScrew Size ChartEngineering005No ratings yet

- Ansi Screw Clearance HolesDocument1 pageAnsi Screw Clearance HoleswilliaqNo ratings yet

- DrillchartDocument5 pagesDrillchartcc6689No ratings yet

- Machinery Canada - DC Swiss Taps-Sti-EgDocument11 pagesMachinery Canada - DC Swiss Taps-Sti-EgmachineCanNo ratings yet

- Hex Socket Head Cap Screws Partially / Fully Threaded, With UNC Thread BN 13Document3 pagesHex Socket Head Cap Screws Partially / Fully Threaded, With UNC Thread BN 13razvan65No ratings yet

- Racoreria Manghidraulica BosadoDocument59 pagesRacoreria Manghidraulica BosadoOdicoNo ratings yet

- RYCO Thread ID Booklet PDFDocument80 pagesRYCO Thread ID Booklet PDFWesNo ratings yet

- Inch Series Thread ToleranceDocument5 pagesInch Series Thread Tolerancemangesh sandavNo ratings yet

- Manual de Roscas EstandaresDocument136 pagesManual de Roscas EstandaresDavid AgNo ratings yet

- MS35275BDocument4 pagesMS35275BmahNo ratings yet

- Asme B1.13M-2005Document84 pagesAsme B1.13M-2005Anuj Garg100% (1)

- ThreadTables PDFDocument1 pageThreadTables PDFRichard HockleyNo ratings yet

- Bolts and Nuts PricesDocument3 pagesBolts and Nuts PricesRenalyn AndradeNo ratings yet

- Asme B18.2.3.4M 1999Document14 pagesAsme B18.2.3.4M 1999Jesse ChenNo ratings yet

- DrillDocument4 pagesDrillPsg GrtNo ratings yet

- Speeds & Feeds: Drilling & Reaming Surface Feet Per Minute (SFM)Document6 pagesSpeeds & Feeds: Drilling & Reaming Surface Feet Per Minute (SFM)naninoNo ratings yet