100% found this document useful (1 vote)

723 views45 pagesGE Digital Twin Overview and Tutorial - RRI v3 PDF

Uploaded by

Ssheshan PugazhendhiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

723 views45 pagesGE Digital Twin Overview and Tutorial - RRI v3 PDF

Uploaded by

Ssheshan PugazhendhiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

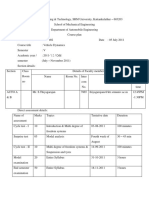

- Introduction: Introduces the presentation with information about the speaker and the focus on Digital Twin technology.

- Outline: An overview of the topics discussed in the presentation, including the path to Digital Twin, its impact, and a tutorial for building one.

- The Path to Digital Twin: Chronicles the evolution of GE's Digital Twin technology from its inception to the present, highlighting key developments and chronological advancements.

- Digital Twin Defined and Explained: Explains the concept of Digital Twin and its primary components, comparing physical assets with digital models.

- 5 Criteria for Analytic to be Digital Twin: Defines the five essential criteria that characterize an analytic as a Digital Twin, detailing GE's application of these characteristics.

- Digital Twin Impact at GE: Discusses the impact of Digital Twin technology on GE's operations, emphasizing its support for industrial assets.

- Being Digital – Solving Problems, Building Solutions: Presents case studies demonstrating how Digital Twin technology solves real-world issues at GE, with examples across various applications.

- Tutorial: How to Build a Digital Twin: A step-by-step tutorial for constructing a Digital Twin, from determining goals to validating and operating the model.