Professional Documents

Culture Documents

SRF Limited: Typical Properties of Tufnyl Rms 1 Steel Grey

Uploaded by

ரஞ்சன் ஞானயோளி0 ratings0% found this document useful (0 votes)

149 views1 pageDatasheet

Original Title

Poly Amide Data

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDatasheet

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

149 views1 pageSRF Limited: Typical Properties of Tufnyl Rms 1 Steel Grey

Uploaded by

ரஞ்சன் ஞானயோளிDatasheet

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

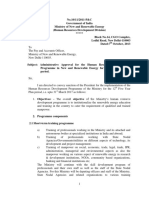

SRF LIMITED

ENGINEERING PLASTICS BUSINESS

Typical Properties of

TUFNYL RMS 1 STEEL GREY

All Properties measured at 23 Deg. / 50% RH on dry-as-molded test specimens.

Only typical data for material selection purposes only. Users has to establish material suitability.

ASTM

PROPERTY METHOD UNIT VALUE

Tensile Strength D-638 Mpa 80

Elongation @ break D-638 % 15.0

Flexural Strength D-790 Mpa 130

Flexural Modulus D-790 Mpa 2800

Impact Strength, Izod D-256A Kg.cm/cm 7.0

Rockwell Hardness D- 785 M scale 80

R Scale 115

Mold Shrinkage (Along the D-955 % 1.5~1.8

flow on 3 MM Thickness)

Specific Gravity D-792 - 1.14

Melting Point D-2117 Deg C 260

Heat Deflection Temperature D-648 Deg C

At 18.5Kgf Load 75

At 4.6 Kgf Load 145

It is recommended to pre dry the Nylon granules in vacuum / air

circulated ovens at 100/80Deg.c for 2 - 4 hrs. Using perforated trays.

Injection Moulding Parameters: Temperature setting in Deg.C

Feed Compression Melting Nozzle Melt Mould

250 270 285 280 265 –280 80 -100

Plant: Manali Industrial Area, Manali, Chennai – 600 068, INDIA

Phone: +91-44-2594 6206 Fax: +91-44-2594 3073 Email: dbalaji@srf.com

Corporate office: Unitech Crest, Block C, Plot 946, Sector 45, Gurgaon, Haryana-122 003

Registered office: Express Building, 9-10, Bahadur Shah Zafar Marg, New Delhi-110 002

You might also like

- Rgf33 Natural New - Nominal PropDocument1 pageRgf33 Natural New - Nominal PropRanjan GnanaoliNo ratings yet

- Zylar 631: Methyl Methacrylate Butadiene Styrene (MBS)Document3 pagesZylar 631: Methyl Methacrylate Butadiene Styrene (MBS)Fernando Garcia HiguitaNo ratings yet

- Technical Data Sheet: Heavy Duty GreaseDocument1 pageTechnical Data Sheet: Heavy Duty GreaseDon HowardNo ratings yet

- Gulf EP Lubricant SY - PAODocument1 pageGulf EP Lubricant SY - PAOatripathi2009No ratings yet

- Durolon HFR 1910Document2 pagesDurolon HFR 1910elrolo3000No ratings yet

- PDS CSG-100 (ENG) - s-11521Document1 pagePDS CSG-100 (ENG) - s-11521huongktbNo ratings yet

- PVDF Material Properties Data Sheet: Kynar Hylar Mechanical Property ASTM Method Unit 1000 HD MP-10Document1 pagePVDF Material Properties Data Sheet: Kynar Hylar Mechanical Property ASTM Method Unit 1000 HD MP-10JorgeLuisRiveraNo ratings yet

- Product Data Sheet: Gulfsea Gear Oil SeriesDocument2 pagesProduct Data Sheet: Gulfsea Gear Oil SeriesObydur RahmanNo ratings yet

- Ptfe 25 GF 25 CF PDFDocument1 pagePtfe 25 GF 25 CF PDFseeralan_1986No ratings yet

- Corrapol Clear Corrugated Sheet Ranges Technical GuideDocument8 pagesCorrapol Clear Corrugated Sheet Ranges Technical GuideDavid Galvis VelozaNo ratings yet

- MolykoteDocument2 pagesMolykoteRafael FrançaNo ratings yet

- Compound Specification Sheet: CSP-938 Diesel Grade, Vinyl Ester, Gray SMCDocument1 pageCompound Specification Sheet: CSP-938 Diesel Grade, Vinyl Ester, Gray SMCBrian García AguirreNo ratings yet

- Mapex An0920sn 1Document1 pageMapex An0920sn 1Muhd IzzurinNo ratings yet

- Pghsaw33 01BKDocument2 pagesPghsaw33 01BKRanjan GnanaoliNo ratings yet

- Mapex AN0320SN PDFDocument1 pageMapex AN0320SN PDFDiegoTierradentroNo ratings yet

- TecamidDocument2 pagesTecamidTejas HuddarNo ratings yet

- PP - Braskem - CP 442 XP PDFDocument1 pagePP - Braskem - CP 442 XP PDFAdemilson Alves Dos SantosNo ratings yet

- Equate EMDA 6200Document2 pagesEquate EMDA 6200HichamSalamaNo ratings yet

- Matrix EP and TK TDS 2035Document1 pageMatrix EP and TK TDS 2035Don HowardNo ratings yet

- SM750Document2 pagesSM750Gantungan KulkasNo ratings yet

- Brosur DTL 051 (English)Document2 pagesBrosur DTL 051 (English)Deltalube TangerangNo ratings yet

- Hoja Tecnica - OmnilithDocument1 pageHoja Tecnica - OmnilithJhosbrield Pacheco ZegarraNo ratings yet

- Styrolution PS 1290/1291: General Purpose Polystyrene (GPPS)Document2 pagesStyrolution PS 1290/1291: General Purpose Polystyrene (GPPS)DiegoTierradentroNo ratings yet

- Gulf Geartek - Hd-Sept2021 - 20211102102844Document1 pageGulf Geartek - Hd-Sept2021 - 20211102102844magadali7814No ratings yet

- Gearmate 1000 ICT TDS 3041Document1 pageGearmate 1000 ICT TDS 3041Don HowardNo ratings yet

- 6210GCFNC1 英文物性表 20161122Document1 page6210GCFNC1 英文物性表 20161122Sơn Nguyễn ĐắcNo ratings yet

- 3 NEPROPLAST CPVC PipesFlowGuard EmailDocument12 pages3 NEPROPLAST CPVC PipesFlowGuard EmailperezismaelNo ratings yet

- ALATHON L5005 y CERTENE 122DDocument4 pagesALATHON L5005 y CERTENE 122DJuan Carlos Otero JaramilloNo ratings yet

- Ekran Resmi 2024-01-06 - Gece 9.58.56Document1 pageEkran Resmi 2024-01-06 - Gece 9.58.56tahmasebi.hadi2017No ratings yet

- Ficha Técnica - FRAYÖL GEAR S 2 EP - 680Document2 pagesFicha Técnica - FRAYÖL GEAR S 2 EP - 680Julio Oliveira Goncalves JuniorNo ratings yet

- Pghsim33 01NCDocument2 pagesPghsim33 01NCRanjan GnanaoliNo ratings yet

- CSP SMC 40774 Data Sheet 2012 PDFDocument1 pageCSP SMC 40774 Data Sheet 2012 PDFBrian García AguirreNo ratings yet

- Gulf Synthetic Gear Oil - PAGDocument1 pageGulf Synthetic Gear Oil - PAGatripathi2009No ratings yet

- TDS Drag Cable LubricantDocument2 pagesTDS Drag Cable LubricantDaniel ColinsNo ratings yet

- iNVENTA 515UL Material: Properties Values (Metric) Values (English) Test MethodDocument1 pageiNVENTA 515UL Material: Properties Values (Metric) Values (English) Test Methodsatheez3251No ratings yet

- Preserv 1 300 K2DDocument4 pagesPreserv 1 300 K2DamitabhsrivastavaNo ratings yet

- Molykote D-321R DowCorning DatasheetDocument2 pagesMolykote D-321R DowCorning DatasheetalbertoNo ratings yet

- Tds Ral 7037 Haa Hfhr02s8Document1 pageTds Ral 7037 Haa Hfhr02s8Jaskaran SinghNo ratings yet

- LLDPE - Lotrene Q1018N PDFDocument2 pagesLLDPE - Lotrene Q1018N PDFNilay TanrıverNo ratings yet

- Estane 58887Document2 pagesEstane 58887M J VoraNo ratings yet

- CP 191-enUS-ASTMDocument1 pageCP 191-enUS-ASTMAndersonNo ratings yet

- TOTAL Polystyrene 1441: Material DatasheetDocument3 pagesTOTAL Polystyrene 1441: Material DatasheetAlbert FortunatoNo ratings yet

- Dow Elite 5400G TDSDocument2 pagesDow Elite 5400G TDSAli RazuNo ratings yet

- VM835-75 For Aerospace Applications: O-Ring DivisionDocument2 pagesVM835-75 For Aerospace Applications: O-Ring Divisionluis hernandezNo ratings yet

- Lldpe 22501aa22501kjDocument2 pagesLldpe 22501aa22501kj李万福No ratings yet

- EPX RangeDocument2 pagesEPX RangecarmaNo ratings yet

- Property ASTM or UL Test Extruded NYLON 6/6 Cast Nylon Physical MechanicalDocument1 pageProperty ASTM or UL Test Extruded NYLON 6/6 Cast Nylon Physical MechanicalEktor RamirzNo ratings yet

- Solmax - HDPE REFLECTIVE IMPERIALDocument6 pagesSolmax - HDPE REFLECTIVE IMPERIALchipnowNo ratings yet

- Whitmore BMG-6000 Open Gear LubricantDocument1 pageWhitmore BMG-6000 Open Gear LubricantDon HowardNo ratings yet

- Gulf EP Lubricant HDDocument1 pageGulf EP Lubricant HDatripathi2009No ratings yet

- EP 440L-enUS-ASTMDocument1 pageEP 440L-enUS-ASTMAndersonNo ratings yet

- Technical Data Sheet: Wire Rope OilDocument1 pageTechnical Data Sheet: Wire Rope OilDon HowardNo ratings yet

- S1005 TairiproDocument1 pageS1005 TairiproJacquelin DelgadoNo ratings yet

- PRB 0131-enUS-ASTMDocument1 pagePRB 0131-enUS-ASTMquanghoang10986No ratings yet

- MSS PJ PJMaterialsDataSheetDocument2 pagesMSS PJ PJMaterialsDataSheetAndreNo ratings yet

- Brosur Lubline Hi-Temp MC 2495 XRT (English)Document1 pageBrosur Lubline Hi-Temp MC 2495 XRT (English)Deltalube Tangerang100% (1)

- Giant 3030 15W40Document1 pageGiant 3030 15W40ibrahim maulanaNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- GATE BooksDocument1 pageGATE Booksரஞ்சன் ஞானயோளிNo ratings yet

- CH 27.8 PlasticsDocument95 pagesCH 27.8 PlasticsSmruti Ranjan PattanayakNo ratings yet

- NCERT Class 12 Political Science Part 2 PDFDocument197 pagesNCERT Class 12 Political Science Part 2 PDFManikanta LalkotaNo ratings yet

- HRD Programme 12thplan PDFDocument32 pagesHRD Programme 12thplan PDFரஞ்சன் ஞானயோளிNo ratings yet

- UPSC EXAM Calendar 2014Document5 pagesUPSC EXAM Calendar 2014ரஞ்சன் ஞானயோளிNo ratings yet

- GATE Mechanical 1999 PaperDocument16 pagesGATE Mechanical 1999 PaperTapadev DasNo ratings yet

- HRD Programme 12thplan PDFDocument32 pagesHRD Programme 12thplan PDFரஞ்சன் ஞானயோளிNo ratings yet

- Annual Calendar 2018 EnglDocument1 pageAnnual Calendar 2018 EnglSaketNo ratings yet

- General Studies and Engineering Aptitude: T.B.C.: SKP-U-DSTDocument16 pagesGeneral Studies and Engineering Aptitude: T.B.C.: SKP-U-DSTரஞ்சன் ஞானயோளிNo ratings yet

- GS DDocument16 pagesGS Dரஞ்சன் ஞானயோளிNo ratings yet

- General Studies and Engineering Aptitude: T.B.C.: SKP-U-DSTDocument16 pagesGeneral Studies and Engineering Aptitude: T.B.C.: SKP-U-DSTரஞ்சன் ஞானயோளிNo ratings yet

- Ese 18 Ga Set ADocument65 pagesEse 18 Ga Set Aரஞ்சன் ஞானயோளிNo ratings yet

- Mechanical-Engineering Gate2016.InfoDocument3 pagesMechanical-Engineering Gate2016.InfoHenryNo ratings yet

- Test Booklet General Studies and Engineering Aptitude: T.B.C.: SKP-U-DSTDocument16 pagesTest Booklet General Studies and Engineering Aptitude: T.B.C.: SKP-U-DSTரஞ்சன் ஞானயோளிNo ratings yet

- Example of Design FMEA WorksheetDocument5 pagesExample of Design FMEA Worksheetரஞ்சன் ஞானயோளிNo ratings yet

- NASA Lunar Sampling System Design Chall... Ineering & Design Challenges - GrabCADDocument7 pagesNASA Lunar Sampling System Design Chall... Ineering & Design Challenges - GrabCADரஞ்சன் ஞானயோளிNo ratings yet

- Post Session Assignments 3Document2 pagesPost Session Assignments 3ரஞ்சன் ஞானயோளிNo ratings yet

- CAD Storm PresentationDocument7 pagesCAD Storm Presentationரஞ்சன் ஞானயோளிNo ratings yet

- Mechanical-Engineering Gate2016.InfoDocument3 pagesMechanical-Engineering Gate2016.InfoHenryNo ratings yet

- CatiaDocument20 pagesCatiaரஞ்சன் ஞானயோளிNo ratings yet

- Jed 426Document4 pagesJed 426ரஞ்சன் ஞானயோளிNo ratings yet

- Daily Activity MonitorDocument402 pagesDaily Activity Monitorரஞ்சன் ஞானயோளிNo ratings yet

- ResumeDocument3 pagesResumeரஞ்சன் ஞானயோளிNo ratings yet

- Product Brochuer-Two Stage Compressor 02Document2 pagesProduct Brochuer-Two Stage Compressor 02Ranjan GnanaoliNo ratings yet

- 528 JED Specification JED-612 008 en BDocument5 pages528 JED Specification JED-612 008 en Bரஞ்சன் ஞானயோளிNo ratings yet

- Example of Design FMEA WorksheetDocument5 pagesExample of Design FMEA Worksheetரஞ்சன் ஞானயோளிNo ratings yet

- 528 JED Specification JED-005M 008 GDocument4 pages528 JED Specification JED-005M 008 Gரஞ்சன் ஞானயோளிNo ratings yet

- 1 Scope: SpecificationDocument5 pages1 Scope: Specificationரஞ்சன் ஞானயோளிNo ratings yet

- Roy MechDocument6 pagesRoy Mechரஞ்சன் ஞானயோளிNo ratings yet

- Elastollan Verarbeitung enDocument28 pagesElastollan Verarbeitung enwoongs73No ratings yet