Professional Documents

Culture Documents

Manual

Uploaded by

Emilio RochaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual

Uploaded by

Emilio RochaCopyright:

Available Formats

Rolling (metalworking). Составитель : Захарова Г.Ф.

Rolling as a branch of engineering is a fabricating process in which the metal, plastic, paper, glass

etc. is passed through a pair (or pairs) of rolls. There are two types of rolling processes - flat and

profile rolling. In flat rolling shape of the product is either classed as sheet (thickness less than 3

mm) or plate (thickness more than 3 mm ). In profile rolling the final product may be round rod

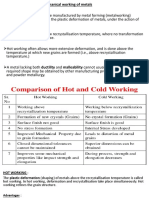

or other shaped bar. Rolling is also classified according to the temperature of the metal rolled. If

the temperature of the metal is above its recrystallization temperature, then the process is termed

as hot rolling. If the temperature is below - then cold rolling.

The first rolling mill was designed by Leonardo da Vinci. And later, in 1779, during the industrial

revolution a rolling mill was created in Hampshire by Henry Cort, who developed ideas for

rolling processes. In 1783 Cort received a patent for his groove rolling process.

Now I’d like to tell you about hot rolling. It’s a hot metalworking process where large pieces of

metal, such as slabs or billets, are heated above their recrystallization temperature. Then they are

deformed between rolls to form thinner cross-section. Hot rolling produces thinner cross-section

than cold rolling processes with the same number of stages. Hot rolling is used mainly to produce

sheet metal or simple cross-sections as rail road bars from billets.

It should be noted that there are many types of hot rolling mills. They are: hot strip mills, plate

mills, billet mills, structural mills, merchant and bar mills, slab and bloom mills. All of them are

currently available in industrial engineering.

The essential parts of every rolling mill are rolls, working stands, a manipulator provided just

before each working stand and an induction motor.

Rolls can be classified as small working rolls, which do the actual rolling and two large backing

rolls , which serve to give support to the smaller ones. The drive is taken directly to the smaller

rolls.

The rolls may be either of steel or cast iron consisting of a body or barrel and the neck. The body

of the roll may be a simple cylinder or may be grooved , if a piece is to be rolled to a definite

shape.

In conclusion it should be said that one of the main advantages of rolling is that large pieces of

metal can be rolled on rolling mills.

You might also like

- Forging Operations - Machine Forging, Forging Dies and Special Forging OperationsFrom EverandForging Operations - Machine Forging, Forging Dies and Special Forging OperationsNo ratings yet

- Rolling (Metalworking)Document10 pagesRolling (Metalworking)sideralmccNo ratings yet

- Mensuration for Sheet Metal Workers - As Applied in Working Ordinary Problems in Shop PracticeFrom EverandMensuration for Sheet Metal Workers - As Applied in Working Ordinary Problems in Shop PracticeNo ratings yet

- Rolling (Metalworking) : From Wikipedia, The Free EncyclopediaDocument12 pagesRolling (Metalworking) : From Wikipedia, The Free Encyclopediarhajtv100% (1)

- Rolling (Metalworking) : Roller MillDocument45 pagesRolling (Metalworking) : Roller MilldnyaneshwarNo ratings yet

- Cold Forming of MetalsDocument9 pagesCold Forming of Metalsanakngtukneneyahoo.comNo ratings yet

- Rolling FinalDocument7 pagesRolling FinalHaroon Karim BalochNo ratings yet

- Report On Material Used For Making Dies For Pressure Die Casting of Alluminium Alloys.2Document21 pagesReport On Material Used For Making Dies For Pressure Die Casting of Alluminium Alloys.2Maroof Alam100% (2)

- RollingDocument54 pagesRollingavutu_kunduru100% (1)

- Rolling FundamentalsDocument20 pagesRolling FundamentalsJo100% (6)

- Introduction To Bulk-Forming ProcessesDocument9 pagesIntroduction To Bulk-Forming ProcesseslelixNo ratings yet

- Design of Dies - Unit 4Document149 pagesDesign of Dies - Unit 4210 SureshNo ratings yet

- Hot Rolling: Plate MillsDocument4 pagesHot Rolling: Plate MillsMohammed Abu SufianNo ratings yet

- Module 2 Activity No. 1Document6 pagesModule 2 Activity No. 1Benz DyNo ratings yet

- Mechanical Working of Metals MaterialDocument40 pagesMechanical Working of Metals MaterialRoyalmechNo ratings yet

- RollingDocument24 pagesRollingAd Man GeTigNo ratings yet

- Olen Sampson, Ariel Needham - Know All About Jewelry Making, Jewelry Designing and Metal Working (2012, World Technologies) - Min - Parça10Document15 pagesOlen Sampson, Ariel Needham - Know All About Jewelry Making, Jewelry Designing and Metal Working (2012, World Technologies) - Min - Parça10mare_sierraNo ratings yet

- Q2. What Is Rolling and Recrystallization Temperature. Explain The Methods of Rolling Steel and Highlight The Major DifferencesDocument6 pagesQ2. What Is Rolling and Recrystallization Temperature. Explain The Methods of Rolling Steel and Highlight The Major DifferencesArslan RaoNo ratings yet

- Forging Methods: 18 Gear Solutions - May 2006Document6 pagesForging Methods: 18 Gear Solutions - May 2006Santosh NarvekarNo ratings yet

- Mechanical Working of MetalsDocument53 pagesMechanical Working of Metalsmurari100% (3)

- Die CastingDocument4 pagesDie Castingthasarathanr1993_939No ratings yet

- DV03PUB23 Study GuideDocument4 pagesDV03PUB23 Study GuidesobheysaidNo ratings yet

- Laboratory 5Document10 pagesLaboratory 5Andy BirdieNo ratings yet

- AMT-Forming (Compatibility Mode)Document15 pagesAMT-Forming (Compatibility Mode)Abdulhmeed MutalatNo ratings yet

- Hot Working Processes Rolling Drawing Forging Extruding Piercing SpinningDocument26 pagesHot Working Processes Rolling Drawing Forging Extruding Piercing SpinningSarojKumarSinghNo ratings yet

- Unit IV OrigionalDocument25 pagesUnit IV OrigionalPrakash SinghNo ratings yet

- BME B Project Armaan SinghDocument16 pagesBME B Project Armaan Singharmaansingh 2K20B1220No ratings yet

- Forging FundamentalsDocument23 pagesForging FundamentalsJoNo ratings yet

- SH Metal Chapter 01-Sheet MetalDocument9 pagesSH Metal Chapter 01-Sheet MetalAnonymous PIqdeNp8No ratings yet

- Extrusion: Cross-Sectional Die Compressive ShearDocument10 pagesExtrusion: Cross-Sectional Die Compressive ShearCarlos BustamanteNo ratings yet

- Unit - IIIDocument13 pagesUnit - IIIMechanicalNo ratings yet

- ME - 32021 Chapter (3) Hard Mold Casting ProcessesDocument26 pagesME - 32021 Chapter (3) Hard Mold Casting ProcessesWILYNo ratings yet

- Die Casting - Wikipedia, The Free EncyclopediaDocument10 pagesDie Casting - Wikipedia, The Free EncyclopediaSantanu MondalNo ratings yet

- Metal Forming and Casting Processes GuideDocument31 pagesMetal Forming and Casting Processes GuideSHAIK BAJI50% (2)

- Rolling (Metalworking) : From Wikipedia, The Free EncyclopediaDocument15 pagesRolling (Metalworking) : From Wikipedia, The Free EncyclopediaVatsal DubeNo ratings yet

- Unit - Iii: Metal Forming ProcessesDocument63 pagesUnit - Iii: Metal Forming ProcessesRohith RoNo ratings yet

- ME6301 MANUFACTURING TECHNOLOGY - 1 - UNIT 3 - 2marksDocument5 pagesME6301 MANUFACTURING TECHNOLOGY - 1 - UNIT 3 - 2marksrajakumaresanNo ratings yet

- Continuous Casting: Equipment and ProcessDocument8 pagesContinuous Casting: Equipment and ProcessErickman Simorangkir100% (1)

- Forging Is ADocument5 pagesForging Is ASahilNo ratings yet

- Presentation. RedaDocument34 pagesPresentation. RedaRedaNo ratings yet

- February 16, 2013Document18 pagesFebruary 16, 2013Partha MishraNo ratings yet

- Extrusion: Navigation SearchDocument12 pagesExtrusion: Navigation SearchAbdullah Syfq DaudNo ratings yet

- Seminae Report On-Rolling Method Presented by Dwitikrishna Sahoo Branch-Mechanical Regd No-L17152004007 Semester-6thDocument22 pagesSeminae Report On-Rolling Method Presented by Dwitikrishna Sahoo Branch-Mechanical Regd No-L17152004007 Semester-6thSid Bro SidNo ratings yet

- Metal Rolling: An Essential Manufacturing ProcessDocument17 pagesMetal Rolling: An Essential Manufacturing ProcesskxalxoNo ratings yet

- MT 2nd AssignmentDocument72 pagesMT 2nd AssignmentDixitNo ratings yet

- A Foundry Is Found ADocument11 pagesA Foundry Is Found AJackson SichingaNo ratings yet

- Manufacturing Process of C PurlinsDocument17 pagesManufacturing Process of C PurlinsJOHNEDERSON PABLONo ratings yet

- ForgingDocument38 pagesForgingapi-2636010075% (4)

- Pressure Die PPT InPDFDocument84 pagesPressure Die PPT InPDFSree RamichettyNo ratings yet

- ExtrusionDocument9 pagesExtrusionOdebiyi StephenNo ratings yet

- Experiment 6Document3 pagesExperiment 6Subhasis BiswalNo ratings yet

- 4.0 Manufacturing Process Roll FormingDocument4 pages4.0 Manufacturing Process Roll FormingMuhd NadzriNo ratings yet

- An Introduction To Rolling of MetalsDocument1 pageAn Introduction To Rolling of MetalsvijayakumarNo ratings yet

- Rolling Process Explained: Hot vs Cold Rolling and UsesDocument3 pagesRolling Process Explained: Hot vs Cold Rolling and UsesMuhammad YasirNo ratings yet

- Metal FormingDocument20 pagesMetal FormingPrashant ShreshthaNo ratings yet

- Hot Working: Forming Can Be Divided Into Two CategoriesDocument9 pagesHot Working: Forming Can Be Divided Into Two CategoriesNelson AlvarezNo ratings yet

- IronDocument91 pagesIronManish KumarNo ratings yet

- Rolling (Bulk Deformation Process)Document27 pagesRolling (Bulk Deformation Process)Kazal ArefinNo ratings yet

- Aluminum Extrusion Process ExplainedDocument6 pagesAluminum Extrusion Process ExplainedEaswaran NampoothiriNo ratings yet

- PP PP PP PPDocument37 pagesPP PP PP PPJagdish Kolte100% (1)

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiFrom Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiRating: 5 out of 5 stars5/5 (2)

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiFrom EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiRating: 4 out of 5 stars4/5 (3)

- House Rules: How to Decorate for Every Home, Style, and BudgetFrom EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNo ratings yet

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastFrom EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastRating: 5 out of 5 stars5/5 (1)

- Coloring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesFrom EverandColoring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesRating: 2 out of 5 stars2/5 (12)

- Radical Sewing: Pattern-Free, Sustainable Fashions for All BodiesFrom EverandRadical Sewing: Pattern-Free, Sustainable Fashions for All BodiesNo ratings yet

- Crochet Impkins: Over a million possible combinations! Yes, really!From EverandCrochet Impkins: Over a million possible combinations! Yes, really!Rating: 4.5 out of 5 stars4.5/5 (10)

- Martha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeFrom EverandMartha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeNo ratings yet

- A Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionFrom EverandA Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionRating: 4.5 out of 5 stars4.5/5 (23)

- Modern Granny Stitch Crochet: Make clothes and accessories using the granny stitchFrom EverandModern Granny Stitch Crochet: Make clothes and accessories using the granny stitchRating: 5 out of 5 stars5/5 (1)

- Origami: The Ultimate Origami Guide - Master Origami in 2 hours. Learn Origami with 20 Step by Step Projects that Inspire YouFrom EverandOrigami: The Ultimate Origami Guide - Master Origami in 2 hours. Learn Origami with 20 Step by Step Projects that Inspire YouRating: 3 out of 5 stars3/5 (15)

- Sew Bags: The Practical Guide to Making Purses, Totes, Clutches & More; 13 Skill-Building ProjectsFrom EverandSew Bags: The Practical Guide to Making Purses, Totes, Clutches & More; 13 Skill-Building ProjectsRating: 5 out of 5 stars5/5 (3)

- Two Simple Shapes = 26 Crocheted Cardigans, Tops & Sweaters: If you can crochet a square and rectangle, you can make these easy-to-wear designs!From EverandTwo Simple Shapes = 26 Crocheted Cardigans, Tops & Sweaters: If you can crochet a square and rectangle, you can make these easy-to-wear designs!Rating: 3 out of 5 stars3/5 (2)

- Delicate Crochet: 23 Light and Pretty Designs for Shawls, Tops and MoreFrom EverandDelicate Crochet: 23 Light and Pretty Designs for Shawls, Tops and MoreRating: 4 out of 5 stars4/5 (11)

- The Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsFrom EverandThe Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsRating: 4.5 out of 5 stars4.5/5 (2)

- Kawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreFrom EverandKawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreRating: 5 out of 5 stars5/5 (5)

- Friends: The One with the Crochet: The Official Crochet Pattern BookFrom EverandFriends: The One with the Crochet: The Official Crochet Pattern BookRating: 5 out of 5 stars5/5 (1)

- Siren's Atlas US Terms Edition: An Ocean of Granny Squares to CrochetFrom EverandSiren's Atlas US Terms Edition: An Ocean of Granny Squares to CrochetRating: 5 out of 5 stars5/5 (3)

- Crochet Lace: Techniques, Patterns, and ProjectsFrom EverandCrochet Lace: Techniques, Patterns, and ProjectsRating: 3.5 out of 5 stars3.5/5 (3)

- Big Book of Pretty & Playful Appliqué: 150+ Designs, 4 Quilt Projects Cats & Dogs at Play, Gardens in Bloom, Feathered Friends & MoreFrom EverandBig Book of Pretty & Playful Appliqué: 150+ Designs, 4 Quilt Projects Cats & Dogs at Play, Gardens in Bloom, Feathered Friends & MoreRating: 4.5 out of 5 stars4.5/5 (3)

- The Art of Tinkering: Meet 150+ Makers Working at the Intersection of Art, Science & TechnologyFrom EverandThe Art of Tinkering: Meet 150+ Makers Working at the Intersection of Art, Science & TechnologyRating: 4 out of 5 stars4/5 (11)

- Modern Crochet Bible: Over 100 Contemporary Crochet Techniques and StitchesFrom EverandModern Crochet Bible: Over 100 Contemporary Crochet Techniques and StitchesRating: 5 out of 5 stars5/5 (13)

- Too Cute Amigurumi: 30 Crochet Patterns for Adorable Animals, Playful Plants, Sweet Treats and MoreFrom EverandToo Cute Amigurumi: 30 Crochet Patterns for Adorable Animals, Playful Plants, Sweet Treats and MoreRating: 5 out of 5 stars5/5 (2)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsFrom EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsRating: 4.5 out of 5 stars4.5/5 (10)