Professional Documents

Culture Documents

Compact and versatile low profile cylinders for confined spaces

Uploaded by

laluOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compact and versatile low profile cylinders for confined spaces

Uploaded by

laluCopyright:

Available Formats

LOW PROFILE

IDEAL FOR CONFINED AREAS

RLS Series FROM 1-5/8” TO 4” CLEARANCE.

5-150 Ton • Cylinder body, piston and gland nut “Power

Tech” treated for corrosion and abrasion

Single-Acting, Spring Return resistance (see page 8).

• Standard domed piston rod

(5-30 ton) or swivel cap (50-

150 ton) minimize effects of

off-center loading.

CYLINDERS

• Unique heavy duty spring

provides fast piston return.

• A 9796 3/8” NPTF female half

coupler is standard with each cylinder

(the RLS50 has a 3/8” coupler which is

not angled). Oil ports are 3/8” NPTF.

• Couplers on all cylinders, except RLS50, are

angled upward for extra clearance.

RLS100

ASME B30.1

10,000 PSI

RLS1000S

Z

Y Base Mounting Holes

See Page 233

C1 X

W

C2

H 0-10° offset

B A

F

A B C1 & C2 F H W X Y Z

Re- Ex- Base Piston Int. Tons

Cyl. Oil tracted tended Outside to Rod Prod. Bore Cyl. Eff. Press. at Prod.

Cap. Stroke Order Cap. Height Height Dia. Port Dia. Mounting Hole Location Dia. Area at Cap. 10,000 Wt.

(tons) (in.) No. (cu. in.) (in.) (in.) (in.) (in.) (in.) (in.) (in.) (sq. in.) (psi) psi (lbs.)

5 9/16 RLS50 .62 15/8 23/16 15/8 x 29/16 3/4 5/8 3/4 11/8 1/

4 1 11/8 .994 10,061 4.97 2.2

10 7/16 RLS100 1.0 13/4 23/16 23/16 x 31/4 5/8 3/4 11/16 17/16 3/

8 15/16 111/16 2.236 8,943 11.18 3.3

20 7/

16 RLS200 2.0 2 27/16 3x4 21/

32 11/8 23/32 115/16 17/32 19/16 23/8 4.430 9,029 22.15 5.6

30 1/

2 RLS300 3.2 2 /16 213/16

5 3 /4 x 4 /2 23/32

3 1 13/8 13/16 21 /16 27/32 13/4 27/8 6.492 9,242 32.46 8.6

50 5/

8 RLS500S 6.0 25/8 31/4 41/2 x 51/2 27/32 13/4 15/16 25/8 15/16 21/8 31/2 9.621 10,394 48.10 14.0

75 5/

8 RLS750S 9.9 31/8 33/4 517/32 x 61/2 1 21/8 15/16 3 117/64 219/32 41/2 15.904 9,431 79.52 23.3

100 5/ RLS1000S

8 12.3 33/8 4 6x7 1 21/2 13/16 3 11/2 213/16 5 19.635 10,186 98.17 30.0

150 9/ RLS1500S

16 17.2 4 49/16 71/2 x 81/2 15/16 3 1 /16 4 /8 17/16

5 5 31/8 61/4 30.680 9,778 153.39 52.0

18

You might also like

- BudgetingForecastingCoursePresentation 1547839506611Document91 pagesBudgetingForecastingCoursePresentation 1547839506611ikakkos100% (2)

- Pivot Table TutorialDocument47 pagesPivot Table TutoriallaluNo ratings yet

- Captiva 2013 Systema Electric 3.0Document13 pagesCaptiva 2013 Systema Electric 3.0carlos martinez50% (2)

- MO - NO. H11/504: Manufacturing Instructions MHKXTLS607X5Document1 pageMO - NO. H11/504: Manufacturing Instructions MHKXTLS607X5maruti_gbNo ratings yet

- API Documentation Alpha VantageDocument55 pagesAPI Documentation Alpha VantageFun WorldNo ratings yet

- Rolling Contact BearingsDocument26 pagesRolling Contact BearingsHariharan HemarajanNo ratings yet

- Philippine Legal CitationDocument72 pagesPhilippine Legal CitationArwella GregorioNo ratings yet

- Howden PDFDocument24 pagesHowden PDFskb2550% (2)

- Vastu House PlanDocument187 pagesVastu House Planshilpa shahNo ratings yet

- Reciprocating Gas Compressors: TP SeriesDocument11 pagesReciprocating Gas Compressors: TP SeriesAlfonso Alberto ArguelloNo ratings yet

- Aa2fm Model CodeDocument27 pagesAa2fm Model CodeCristianNo ratings yet

- Seismic Example For PhilippinesDocument85 pagesSeismic Example For Philippineswawen03No ratings yet

- Power Team RLS-Series Cylinders - CatalogDocument1 pagePower Team RLS-Series Cylinders - CatalogTitanplyNo ratings yet

- Power Team RA-Series Cylinders - CatalogDocument1 pagePower Team RA-Series Cylinders - CatalogTitanplyNo ratings yet

- Power Team RH-Series S/A Cylinders - CatalogDocument1 pagePower Team RH-Series S/A Cylinders - CatalogTitanplyNo ratings yet

- PowerteamDocument1 pagePowerteamShaik MajeedNo ratings yet

- Series 1000: Hydraulic Cable Winches - Standard FeaturesDocument7 pagesSeries 1000: Hydraulic Cable Winches - Standard FeaturesJader LeyvaNo ratings yet

- Compact Cylinders for Confined Spaces RSS SeriesDocument1 pageCompact Cylinders for Confined Spaces RSS SerieslaluNo ratings yet

- High Tonnage: R SeriesDocument2 pagesHigh Tonnage: R Seriesmkt mechoceanNo ratings yet

- ArchDocument4 pagesArchCarlos Torres OliverosNo ratings yet

- NC Rotary Tables: Standard TypeDocument2 pagesNC Rotary Tables: Standard TypeNathan ChenNo ratings yet

- TC21Document2 pagesTC21Pierrat0% (1)

- Re 91401Document16 pagesRe 91401Jamin SmtpngNo ratings yet

- Section3 1Document43 pagesSection3 1adil_farooq_6No ratings yet

- Ytg PDFDocument2 pagesYtg PDFHarshitShuklaNo ratings yet

- Hvac3 Tubing Copper InsulationDocument7 pagesHvac3 Tubing Copper InsulationmaheshNo ratings yet

- Series 800: Hydraulic Cable Winches - Standard FeaturesDocument6 pagesSeries 800: Hydraulic Cable Winches - Standard Featurespaolita_mahecha1265No ratings yet

- Parker - Compact EHA 3-09Document4 pagesParker - Compact EHA 3-09Mehmet Sencer KarakuşNo ratings yet

- Bombas Control HidraulicoDocument2 pagesBombas Control HidraulicoLenin CórdovaNo ratings yet

- A2fm eDocument28 pagesA2fm eSaubatul IslamiyahNo ratings yet

- Butterfly Valve GRWDocument8 pagesButterfly Valve GRWilkinNo ratings yet

- Eaton Remanufactured Clutches Brochure enDocument2 pagesEaton Remanufactured Clutches Brochure enJMgomez1974No ratings yet

- Power Team RH-Series D/A Cylinders - CatalogDocument1 pagePower Team RH-Series D/A Cylinders - CatalogTitanplyNo ratings yet

- RC SeriesDocument1 pageRC SeriesXuan Khanh maNo ratings yet

- On Off Data Sheet For 9,12,18 &24KDocument2 pagesOn Off Data Sheet For 9,12,18 &24KcharbelNo ratings yet

- VICKERS V200 Series BrochureDocument4 pagesVICKERS V200 Series BrochureMari BGNo ratings yet

- Flow-Tek Part Number Selection GuideDocument18 pagesFlow-Tek Part Number Selection GuideAmanda50% (2)

- W.S. Darley & Co.: Installation of Type Ag, HM, JMP, KSP, LSP, PSP, & Other Pto Driven Pumps Warning!Document26 pagesW.S. Darley & Co.: Installation of Type Ag, HM, JMP, KSP, LSP, PSP, & Other Pto Driven Pumps Warning!Mohamed KaremNo ratings yet

- Pentair VM FIG GRW y GRL - MTJE KEYSTONE PDFDocument8 pagesPentair VM FIG GRW y GRL - MTJE KEYSTONE PDFFlavio Garcia ValenteNo ratings yet

- Air Cooled Condensing Unit: Shandong Vicot Air Conditioning Co.,LtdDocument8 pagesAir Cooled Condensing Unit: Shandong Vicot Air Conditioning Co.,LtdPATRICKNo ratings yet

- Trorfiro: Drive Shaft Phase AnglesDocument31 pagesTrorfiro: Drive Shaft Phase AnglesSonthi MooljindaNo ratings yet

- COLUMN SCHEDULE (FC' 4,000 Psi, Fy 60,000 Psi) : Reinforcement OF Column Column Up To Egl EGL TO + 3550Document14 pagesCOLUMN SCHEDULE (FC' 4,000 Psi, Fy 60,000 Psi) : Reinforcement OF Column Column Up To Egl EGL TO + 3550Engr. Sheikh AnikNo ratings yet

- Adjustments, Clearances and Wear Limits GuideDocument4 pagesAdjustments, Clearances and Wear Limits GuideAwliya TaqwaNo ratings yet

- PDP Series Positive Displacement Plunger Dosing Pump Technical SpecsDocument12 pagesPDP Series Positive Displacement Plunger Dosing Pump Technical SpecsTrungGVNo ratings yet

- Av-760 NC Rotary Rne-200rDocument12 pagesAv-760 NC Rotary Rne-200rsunhuynhNo ratings yet

- Goulds 3885 WE CatalogoDocument8 pagesGoulds 3885 WE CatalogoToleditos y masNo ratings yet

- RCC52 Column Chart GenerationDocument8 pagesRCC52 Column Chart Generationchristi SNo ratings yet

- R410 UNIT SPECIFICATIONSDocument2 pagesR410 UNIT SPECIFICATIONSKello jamesNo ratings yet

- Lampiran A Spesifikasi Alat Muat ExcavatorDocument9 pagesLampiran A Spesifikasi Alat Muat ExcavatorDoro MoreiraNo ratings yet

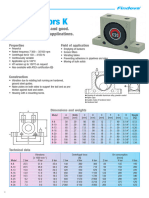

- Technical Data K-Ball VibratorDocument1 pageTechnical Data K-Ball VibratorautomatizacionNo ratings yet

- Kolmeks Pump Catalogue Low PDFDocument260 pagesKolmeks Pump Catalogue Low PDFsriguruprasathsNo ratings yet

- Bearing Fit ChartDocument6 pagesBearing Fit ChartAvinash MamillapalliNo ratings yet

- AA SelecionadoDocument3 pagesAA SelecionadoJosé Luis ColmenarezNo ratings yet

- Schedule of Technical Data For Belt Conveyors: Description Unit BC-001 BC-002Document3 pagesSchedule of Technical Data For Belt Conveyors: Description Unit BC-001 BC-002anon_440745729No ratings yet

- Power Team C-Series CylindersDocument2 pagesPower Team C-Series CylindersTitanplyNo ratings yet

- Helical gear motors and gearboxes buying guideDocument26 pagesHelical gear motors and gearboxes buying guideTilak RajNo ratings yet

- Valvoline 6Document2 pagesValvoline 6munh100% (1)

- S. No Discription Type Qty U. Price T.PriceDocument1 pageS. No Discription Type Qty U. Price T.PriceOSAMANo ratings yet

- Manual ICE 170 Vibratory HammerDocument12 pagesManual ICE 170 Vibratory HammerhaythamNo ratings yet

- Technical Specifications Premium 5-1/2" OD Heavy-Weight Drill Pipe, 1340, TT-550 Conn's. NewDocument2 pagesTechnical Specifications Premium 5-1/2" OD Heavy-Weight Drill Pipe, 1340, TT-550 Conn's. NewbkprodhNo ratings yet

- 1000series - Hyd. WinchDocument7 pages1000series - Hyd. Winchadrianram1No ratings yet

- AUMA ActuatorsDocument116 pagesAUMA Actuatorsbalajiprasanna.kNo ratings yet

- Motores de Rotación ParkerDocument26 pagesMotores de Rotación ParkerSam MarmorNo ratings yet

- Quick Release Snap Type CouplingDocument1 pageQuick Release Snap Type Couplingpeters petersNo ratings yet

- DSBF 1216 LHDVDocument19 pagesDSBF 1216 LHDVNikolay KapitanovNo ratings yet

- 06 Casquillos de Agujas Sin Fondo Clutch SimilarDocument98 pages06 Casquillos de Agujas Sin Fondo Clutch SimilarSara Sarmiento EcheverryNo ratings yet

- Parker TC-SeriesDocument18 pagesParker TC-SeriesSam MarmorNo ratings yet

- Analisis Lateral Movement JantiDocument10 pagesAnalisis Lateral Movement JantilaluNo ratings yet

- Compact Cylinders for Confined Spaces RSS SeriesDocument1 pageCompact Cylinders for Confined Spaces RSS SerieslaluNo ratings yet

- Compact Cylinders for Confined Spaces RSS SeriesDocument1 pageCompact Cylinders for Confined Spaces RSS SerieslaluNo ratings yet

- Adaboost With Totally Corrective Updates For Fast Face DetectionDocument6 pagesAdaboost With Totally Corrective Updates For Fast Face DetectionNguyen Quoc TrieuNo ratings yet

- Guide To Equilibrium DialysisDocument29 pagesGuide To Equilibrium DialysisHaripriya SantoshNo ratings yet

- Electric Machine Design 01 Electric Machine DesignDocument10 pagesElectric Machine Design 01 Electric Machine Designkhodabandelou100% (1)

- Technical Report Writing For Ca2 ExaminationDocument6 pagesTechnical Report Writing For Ca2 ExaminationAishee DuttaNo ratings yet

- A4931 DatasheetDocument12 pagesA4931 DatasheetDiego HernandezNo ratings yet

- Sta. Rosa, Lapu-Lapu City, Cebu PhilippinesDocument8 pagesSta. Rosa, Lapu-Lapu City, Cebu PhilippinesMet XiiNo ratings yet

- MSC Dissertation Gantt ChartDocument6 pagesMSC Dissertation Gantt ChartProfessionalPaperWritingServiceUK100% (1)

- MR Explorer: Magnetic Resonance Logging ServiceDocument7 pagesMR Explorer: Magnetic Resonance Logging ServiceRoberto DominguezNo ratings yet

- Ooplabmanual 150412132629 Conversion Gate01 PDFDocument146 pagesOoplabmanual 150412132629 Conversion Gate01 PDFyawerjs33% (6)

- 11.1 Exam Practice 30 U11Document6 pages11.1 Exam Practice 30 U11Đỗ LoanNo ratings yet

- IAS Mains Electrical Engineering 1994Document10 pagesIAS Mains Electrical Engineering 1994rameshaarya99No ratings yet

- Welder Training in SMAW, GTAW & GMAW Welding Engineering & NDT Consultancy Welding Engineering Related TrainingDocument4 pagesWelder Training in SMAW, GTAW & GMAW Welding Engineering & NDT Consultancy Welding Engineering Related TrainingKavin PrakashNo ratings yet

- Get Lucky LetraDocument1 pageGet Lucky LetraDante Jhonatan Kamt GarciaNo ratings yet

- PassionForProcesse en 04-13Document20 pagesPassionForProcesse en 04-13Mutas MattaNo ratings yet

- Executive CommitteeDocument7 pagesExecutive CommitteeMansur ShaikhNo ratings yet

- Herbarium Specimen Preparation and Preservation GuideDocument9 pagesHerbarium Specimen Preparation and Preservation GuideJa sala DasNo ratings yet

- P0880 TCM Power Circuit InspectionDocument5 pagesP0880 TCM Power Circuit InspectionLojan Coronel José HumbertoNo ratings yet

- Experiences in The OperationDocument7 pagesExperiences in The OperationUsama Bin SabirNo ratings yet

- QP 7721-Sobha-B+g+8-2town-Pahse IiDocument2 pagesQP 7721-Sobha-B+g+8-2town-Pahse IirajatNo ratings yet

- Variety of Living Organisms WorksheetDocument7 pagesVariety of Living Organisms WorksheetSenuNo ratings yet

- The Practice of Medicinal Chemistry, 4th EditionDocument2 pagesThe Practice of Medicinal Chemistry, 4th Editionlibrary25400% (1)

- Java Pattern Programming AssignmentsDocument9 pagesJava Pattern Programming Assignmentstamj tamjNo ratings yet

- Module 4.Document16 pagesModule 4.Sania MaqsoodNo ratings yet

- Ac and DC MeasurementsDocument29 pagesAc and DC MeasurementsRudra ChauhanNo ratings yet