Professional Documents

Culture Documents

Valvula Compuerta CS R

Uploaded by

JULIO CESAR LANDINEZ RAMIREZCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Valvula Compuerta CS R

Uploaded by

JULIO CESAR LANDINEZ RAMIREZCopyright:

Available Formats

MODEL CS-R

Cast Body Reverse Acting Slab Gate Valves for Actuation

Cast Body Gate Valves

FEATURES

Adaptability

Model CS-R valves are designed to accept pneumatic, hydraulic or electric actuators from

any manufacturer. Omni will provide interface drawings upon request. Omni has a com-

plete line of pneumatic and hydraulic actuators and can deliver CS-R valves with actuators

already mounted, ready for immediate deployment.

Operating Temperatures

Model CS-R valves are available with API 6A Temperature ratings of L (-50 F) through X

(350 F). Valves for API Temperature rating X are pressure de-rated as required per Annex

G of API 6A 20th Edition.

Reverse Acting Slab Gate

The reverse acting slab gate has the conduit opening on the upper portion of the gate.

This means that the valve will be open when the gate is in the down position. The gate is

moved to the down position by application of adequate control pressure to the actuator.

Upon loss of control pressure, pressure acting on the gate and stem will cause the valve

to close automatically Under zero bore pressure conditions, valve closure is assisted by a

spring contained in the actuator/bonnet assembly.

Full Through Conduit Bore

The full through conduit bore provides for smooth flow with minimal turbulence. It also

provides an unobstructed passage for well intervention tools.

All Model CS-R valves are drift tested in accordance with API 6A 20th Edition requirements.

Seat Designs

INTRO The standard gate to seat and seat to body sealing interface is a slip-fit design, assisted

Omni Model CS-R cast-body reverse acting slab gate valves are designed to by inserts in the face and o-rings in the rear of each seat. Metal-to-metal gate to seat and

be used as surface safety valves for oil and natural gas wellhead, manifold pressed-fit seat to body sealing is used for high-temp valves and is otherwise available

upon request..

or other critical service applications with operating pressures from 2,000 to

5,000 psi. An appropriate pneumatic, hydraulic or electric actuator is re- Grease Fittings

quired in conjunction with the Model CS-R. The valve body may be lubricated through the grease fittings provided in the valve body.

All fittings meet the requirements of NACE MR0175.

All Model CS-R reverse acting slab gate valves are API 6A 20th Edition mono- Exposed Bolting

grammed equipment and are available in bore sizes rangingfrom 2 1⁄16”

All exposed bolting meets the requirements of NACE MR0175.

through 7 1⁄16”.

© 2015 Omni Valve | TB-CS-R Rev: 1.1 1

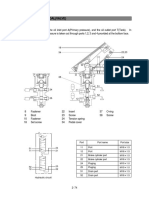

INTERNAL CONFIGURATION

Valve depicted with one flanged and one threaded end.

Internal components are identical.

Cast Body Gate Valves

3

1 2

4

5

Component Description Qty 10

1 Valve Body 1 6

9

2 Nut 8

3 Stud 8

4 Bonnet Seal Ring 1 (VRK)

5 Gate Guide 2 (VRK)

6 Gate Nut 1 (VRK)

7 Reverse Acting Slab Gate 1 (VRK)

8 Seat 2 (VRK)

9 Seat Seal 2 (VRK)

10 Stem Pin 1 (VRK)

7

(VRK) = Valve Redress Kit Item 8

OMNI GATE VALVES PREPARED FOR ACTUATOR:

Omni offers a complete line of pneumatic and hydraulic actuators for manifold and safety shutdown applications that can easily be provided in conjunction

with Omni Model CS-R valves. All Omni actuators can be provided as actuated valve assemblies ready to be put into service or as actuators adapted to

mount on valves from any valve manufacturer. Model CS-R valves are also designed to accept actuators from other manufacturers.

Full Assembly

Component Description

DX Pneumatic Diaphragm Actuator (Fail Safe)

PX Pneumatic Piston Actuator (Fail Safe, Removable Manual Override)

PMX Pneumatic Piston Actuator (Fail Safe, Integrated Manual Override)

HX Hydraulic Piston Actuator (Fail Safe)

HWX Hydraulic Piston Actuator (Fail Safe)

HDX Hydraulic Piston Actuator (Fail Safe)

© 2015 Omni Valve | TB-CS-R Rev: 1.1 2

FAIL-SAFE OPERATION

Fail “closed” operation is depicted

Fail “open” operation is available upon request

Cast Body Gate Valves

Control Pressure Control Pressure

When no control pressure is applied to Upon application of adequate control pressure With continued application of adequate control

actuator, valve is in closed position to the actuator, valve begins to open pressure, valve moves to the fully open position

(gate all the way up) (gate moves down) (gate all the way down)

Control Pressure Control Pressure

Valve remains in fully open position as long Upon loss of control pressure, valve begins Valve fully closes and remains closed until

as adequate control pressure is present to close (gate moves up) application of control pressure to the actuator

(gate all the way down) (gate all the way up)

© 2015 Omni Valve | TB-CS-R Rev: 1.1 3

DIMENSIONAL DATA

Cast Body Gate Valves

Flanged Threaded

(RTJ) (LP, 8RD)

D D

Common Dimensions Flanged Threaded

Valve Working API

A B C Stroke D Weight D Weight

Bore Pressure Ring

Size (psi) # in mm in mm in mm in mm in mm lbs kgs in mm lbs kgs

2 1⁄16” 2,000 R23 2.06 52 4.81 122 4.84 123 2.57 65 11.62 295 85 39 9.62 244 57 26

3-5,000 R24 2.06 52 5.06 128 4.84 123 2.57 65 14.62 371 127 58 9.62 244 79 36

2 9⁄16” 2,000 R26 2.56 65 5.62 142 5.62 143 3.08 78 13.12 333 159 72 10.25 260 95 43

3-5,000 R27 2.56 65 5.93 150 5.62 143 3.08 78 16.62 422 194 88 10.25 260 122 55

3 1⁄8” 2,000 R31 3.12 79 6.93 176 7.12 181 3.8 97 14.12 358 171 78 11.38 289 137 62

3,000 R31 3.12 79 7.31 185 7.12 181 3.8 97 17.12 434 234 106 11.38 289 166 75

5,000 R35 3.12 79 7.31 185 7.12 181 3.8 97 18.62 437 265 120 11.38 289 166 75

4 1⁄16” 2,000 R37 4.06 103 8.62 219 8.32 211 4.8 122 17.12 435 342 155 13 330 278 126

3,000 R37 4.06 103 9.06 230 8.32 211 4.8 122 20.12 511 414 188 13 330 315 143

5,000 R39 4.06 103 9.06 230 8.32 211 4.8 122 21.62 549 446 202 13 330 315 143

5 ⁄8”

1

2,000 R41 5.12 130 11.62 295 10.04 255 5.97 152 22.12 562 617 280

3,000 R41 5.12 130 11.62 295 10.04 255 5.97 152 24.12 613 694 315

5,000 R44 5.12 130 11.62 295 10.04 255 5.97 152 28.62 727 756 343

N/A

7 1⁄16” 2,000 R45 7.06 179 13.87 352 12.86 327 7.69 195 26.12 663 703 319

3,000 R45 7.06 179 13.87 352 12.86 327 7.69 195 28.12 714 769 349

5,000 R46 7.06 179 13.87 352 12.86 327 7.69 195 32 813 962 436

© 2015 Omni Valve | TB-CS-R Rev: 1.1 4

TRIM CHART

Cast Body Gate Valves

Materials of construction listed below are as provided in Omni’s standard valve configurations.

Alternate materials are available upon customer request.

NON-NACE TRIMS NACE TRIMS

API Mat’l Class AA BB CC DD-NL EE-0,5 EE-1,5 EE-NL FF-0,5 FF-1,5 FF-NL

Service General General General Sour Sour Sour Sour Sour Sour Sour

Trim Standard SS Trim Full SS Standard SS Trim SS Trim SS Trim Ful SS Full SS Full SS

Corrosive No Slightly Moderate No Moderate Moderate Moderate Highly Highly Highly

Avail API Temp L to Y L to Y P to Y L to Y L to Y L to Y L to Y P to Y P to Y P to Y

COMPONENTS

ASTM A217 ASTM A217 ASTM A217 ASTM A217

ASTM A487 ASTM A487 ASTM A487 ASTM A487 ASTM A487 ASTM A487

or A487 or A487 or A487 or A487

Body CL 4 60K CL 4 60K CL 4 60K CL 4 60K CL 4 60K CL 4 60K

CA-15 CA-15 CA-15 CA-15

ALLOY ALLOY ALLOY ALLOY ALLOY ALLOY

60K SS 60K SS 60K SS 60K SS

AISI 4130 AISI 410 SS AISI 410 SS AISI 4130 AISI 410 SS AISI 410 SS AISI 410 SS AISI 410 SS AISI 410 SS AISI 410 SS

Gate 75K 75K 75K 75K 75K 75K 75K 75K 75K 75K

NITRIDED NITRIDED NITRIDED NITRIDED NITRIDED NITRIDED NITRIDED NITRIDED NITRIDED NITRIDED

AISI 4130 AISI 410 SS AISI 410 SS AISI 4130 AISI 410 SS AISI 410 SS AISI 410 SS AISI 410 SS AISI 410 SS AISI 410 SS

Seats 75K 75K 75K 75K 75K 75K 75K 75K 75K 75K

NITRIDED NITRIDED NITRIDED NITRIDED NITRIDED NITRIDED NITRIDED NITRIDED NITRIDED NITRIDED

AISI AISI AISI AISI AISI AISI AISI AISI AISI AISI

Bonnet Seal Ring

1018/1020 316 SS 316 SS 1018/1020 316 SS 316 SS 316 SS 316 SS 316 SS 316 SS

ASTM A193 ASTM A193 ASTM A193 ASTM A193 ASTM A193 ASTM A193 ASTM A193 ASTM A193 ASTM A193 ASTM A193

GR B7 or GR B7 or GR B7 or GR B7M or GR B7M or GR B7M or GR B7M or GR B7M or GR B7M or GR B7M or

Studs

ASTM A320 ASTM A320 ASTM A320 ASTM A320 ASTM A320 ASTM A320 ASTM A320 ASTM A320 ASTM A320 ASTM A320

GR L7 GR L7 GR L7 GR L7M GR L7M GR L7M GR L7M GR L7M GR L7M GR L7M

ASTM A194 ASTM A194 ASTM A194 ASTM A194 ASTM A194 ASTM A194 ASTM A194 ASTM A194 ASTM A194 ASTM A194

Nuts

GR 2H GR 2H GR 2H GR 2HM GR 2HM GR 2HM GR 2HM GR 2HM GR 2HM GR 2HM

NOTES

1 Nitriding is standard on all gates and seats. Tungsten Carbide, HF6 or other hardfacing techniques are also available.

2 Teflon inserts on seat faces are standard in Omni valves. Metal-to-metal seats are available upon request.

3 Charpy impact test results are provided as required by API according to the temperature rating and material class.

4 Materials for sour service trims conform to lastest edition of NACE MR0175. Explanation for suffixes used for sour trims:

0,5 = 0.5 psi maximum partial pressure of hydrogen sulfide

1,5 = 1.5 psi maximum partial pressure of hydrogen sulfide

NL = No limit to hydrogen sulfide exposure.

5 Omni reserves the right to use material class ZZ when customers request materials of construction that do not comply with

current NACE MR0175/ISO standards.

All Model CS-R valves are available in API PSL-1 or PSL-2, PR-1 or PR-2. Please specify at time of order.

© 2015 Omni Valve | TB-CS-R Rev: 1.1 5

MODEL CS-R

Product Warranty

Cast Body Gate Valves

LIMITED PRODUCT WARRANTY

All products manufactured or sold by Omni are warranted against defects of material and workmanship for a period of twelve (12) months from the date of installation or

eighteen (18) months from date of shipment, whichever period first expires, when all such products are used in the service and within the pressure range for which they were

manufactured.

In the case of products or parts not wholly of Omni’s manufacture, Omni’s liability shall be limited to the extent of Omni’s recovery from the original manufacturer of such

products or parts under its warranty or liability to Omni.

Any repair work performed by Omni is warranted for one year from completion of such repairs and applies

only to work performed. If, within these specified periods, Omni receives notice from Buyer of any alleged

defect in or nonconformance of any product or repair and if in Omni’s sole judgment the product or repair

does not conform or is found to be defective in material or workmanship, then, Buyer shall, at Omni’s request,

return the part or product F.O.B. to Omni’s designated plant or service location.

Omni has no liability for removal or reinstallation of products or equipment. Omni, at its option and expense,

shall repair or replace the defective part or product, or repay to Buyer the full price paid by Buyer for such

defective part, repair or product. Any repayment of purchase price shall be without interest.

Omni’s warranty liability, including defects caused by Omni’s negligence, shall be limited to such repair, re-

placement or refund, and shall not include claims for labor costs, expenses of Buyer resulting from such

defects, recovery under general tort law or strict liability or for damages resulting from delays, loss of use, or

other direct, indirect, incidental or consequential damages of any kind.

Omni will not be responsible for failures of products which have been in any way tampered with or altered

by anyone other than an authorized representative of Omni, failures due to lack of compliance with recom-

mended maintenance procedures or products which have been repaired or altered in such a way (in Omni’s

judgment) as to affect the products adversely.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS, STATUTORY OR IMPLIED, INCLUDING THE WARRANTY OF MERCHANTABILITY AND FITNESS FOR

PARTICULAR PURPOSE WHICH EXCEED THE FOREGOING WARRANTY.

If you have questions regarding this warranty or if you would like information about other Omni products and services please contact us at the address and phone numbers below.

TECNOSTEEL S.A. de C.V.

API Certified 6A-1344

Dr. Jose Ma. Cantu 312 |Reynosa, Tams. 88690 | MEX

(52)899-995-4040

ventas@tecnos teel .c om .m x

www.tecnosteel.com.mx

omnivalve.com/certs

© 2015 Omni Valve | TB-CS-R Rev: 1.1 6

You might also like

- Valvula Compuerta FS RDocument6 pagesValvula Compuerta FS RAngie LondoñoNo ratings yet

- Oil Pump Type Ale Gear Sizes 35-55: ALE Oil Pump Incorporates A Blocking Solenoid Valve Fitted With A Built-InDocument2 pagesOil Pump Type Ale Gear Sizes 35-55: ALE Oil Pump Incorporates A Blocking Solenoid Valve Fitted With A Built-Inmochammad RezaNo ratings yet

- Mento - Katalog API 6A Valves & Manifolds - 21.06.21 - Rev18Document46 pagesMento - Katalog API 6A Valves & Manifolds - 21.06.21 - Rev18DIEGO CONCEIÇÃO DE OLIVEIRANo ratings yet

- Expansion Devices: TXV in ControlDocument2 pagesExpansion Devices: TXV in ControlRajat JunejaNo ratings yet

- " - 12" Circuit Balancing Valves: File No.: Date: Supersedes: DateDocument8 pages" - 12" Circuit Balancing Valves: File No.: Date: Supersedes: DateNorman GarduñoNo ratings yet

- Aot Om2700aDocument9 pagesAot Om2700aModestyNo ratings yet

- CVS Control ValveDocument24 pagesCVS Control ValvehdrNo ratings yet

- Installation, Operation and Maintenance Manual For Model WG-HLA Hydraulic ActuatorDocument15 pagesInstallation, Operation and Maintenance Manual For Model WG-HLA Hydraulic ActuatorNeilton Junior100% (1)

- SC-700-800 Valvulas de Convercion de AireDocument100 pagesSC-700-800 Valvulas de Convercion de AireFlorencio MaximilianoNo ratings yet

- Aquestia OCV TERMINALDocument12 pagesAquestia OCV TERMINALSony Nd AshaNo ratings yet

- PCT 4152034Document50 pagesPCT 4152034Felipe Doria RibeiroNo ratings yet

- CLA-VAl Float ValveDocument4 pagesCLA-VAl Float ValveEntor EntorNo ratings yet

- Datasheet 2Document3 pagesDatasheet 2Ahmed NasserNo ratings yet

- Universal Service Pump Type Au V - Gear Size 47Document2 pagesUniversal Service Pump Type Au V - Gear Size 47mochammad RezaNo ratings yet

- Catalog Functional Safety Solutions Asco en 5084612Document16 pagesCatalog Functional Safety Solutions Asco en 5084612alejomariana03No ratings yet

- R Series Valves PDFDocument3 pagesR Series Valves PDFRonald LlerenaNo ratings yet

- Phase Out: Series R5V General Description Technical InformationDocument6 pagesPhase Out: Series R5V General Description Technical InformationkuncoroNo ratings yet

- 10 ValvesDocument23 pages10 ValvesPower PlantNo ratings yet

- Electric Expansion Valves Type AKVA 10, AKVA 15 and AKVA 20: Data SheetDocument19 pagesElectric Expansion Valves Type AKVA 10, AKVA 15 and AKVA 20: Data SheetRoberto pascualNo ratings yet

- F51 450 FP AccessoriesDocument4 pagesF51 450 FP AccessoriesFayez Al-ahmadiNo ratings yet

- Petrochemichal Catalogue PDFDocument112 pagesPetrochemichal Catalogue PDFbagastcNo ratings yet

- VOLK Valves API 6D CatalogDocument20 pagesVOLK Valves API 6D CatalogJuan PabloNo ratings yet

- A Pilotair ValvesDocument33 pagesA Pilotair ValvesZMCONTROL100% (1)

- Ful Flo A SeriesDocument10 pagesFul Flo A Seriesrodruren01No ratings yet

- 2017 Price List PDFDocument40 pages2017 Price List PDFJOHNNY CALERONo ratings yet

- E4036Document2 pagesE4036Pablo Cardenas SandovalNo ratings yet

- E30C - Globe Valves NewDocument20 pagesE30C - Globe Valves NewTaha FaNo ratings yet

- Design CAV4 Control ValveDocument10 pagesDesign CAV4 Control ValveDatt NguyenNo ratings yet

- YCMS35 - ITEM 3-21 CATALOGUE - 65SC-Model-SheetDocument2 pagesYCMS35 - ITEM 3-21 CATALOGUE - 65SC-Model-SheetChinhNo ratings yet

- Company Profile (ACE VALVE)Document20 pagesCompany Profile (ACE VALVE)DDFSFNo ratings yet

- DelugeDocument12 pagesDelugeHaitham MohammadNo ratings yet

- Bfe API 6a ValvesDocument32 pagesBfe API 6a ValvesAldo P WicaksanaNo ratings yet

- Preset Valve Ocv Model Sheet 115 - 25 Aviation 2020Document2 pagesPreset Valve Ocv Model Sheet 115 - 25 Aviation 2020varadarajck893No ratings yet

- BHEL Valves PDFDocument135 pagesBHEL Valves PDFNitin Aggarwal100% (1)

- A2VKDocument10 pagesA2VKsalelg1980No ratings yet

- A2vk PDFDocument10 pagesA2vk PDFMohar SinghNo ratings yet

- A2vk PDFDocument10 pagesA2vk PDFMohar SinghNo ratings yet

- Art - castEL 6 Motorized Ball ValvesDocument1 pageArt - castEL 6 Motorized Ball ValvesHenryNo ratings yet

- Type A Air Valves (WABCO) AVENTICSDocument32 pagesType A Air Valves (WABCO) AVENTICSWILLIAM ROMERO100% (1)

- JSV C500 Metal Gate Solid Wedge 8pg 01122020 7 MSGV SpecificationDocument1 pageJSV C500 Metal Gate Solid Wedge 8pg 01122020 7 MSGV SpecificationRhandell DionisioNo ratings yet

- Series Features: Two-Stage Preset ValveDocument2 pagesSeries Features: Two-Stage Preset Valvefernando.juarezpetroserviciosNo ratings yet

- Propotional Relief ValveDocument2 pagesPropotional Relief ValveaungaungoomanualNo ratings yet

- PCT 1246314Document44 pagesPCT 1246314Felipe Doria RibeiroNo ratings yet

- Oilgear CartridgeDocument12 pagesOilgear Cartridgesuresh muthuramanNo ratings yet

- Instrument Engineer's Handbook For DURCO Quarter-Turn Control ValvesDocument77 pagesInstrument Engineer's Handbook For DURCO Quarter-Turn Control ValvesVarsha ChawdaNo ratings yet

- ALgbDocument2 pagesALgbOlivier MontagueNo ratings yet

- Vav Pid 5 CDocument28 pagesVav Pid 5 Csiva anandNo ratings yet

- Valvulas GresensvDocument92 pagesValvulas GresensvAnonymous j6WnEH5No ratings yet

- Float Valve: (Sizes 1/2"-6") (Sizes 3"-8")Document4 pagesFloat Valve: (Sizes 1/2"-6") (Sizes 3"-8")Abubakar Ashraf AnjumNo ratings yet

- Val Aliv 0.75-20881504aDocument4 pagesVal Aliv 0.75-20881504aJulio VizacarraNo ratings yet

- PrysDocument40 pagesPrysteddy tavaresNo ratings yet

- Hydrant Pit ValveDocument8 pagesHydrant Pit ValvepfeNo ratings yet

- Handbook For Durco Quarter Turn Control ValveDocument72 pagesHandbook For Durco Quarter Turn Control Valverieza_fNo ratings yet

- Screw Pumps Series SPF: Application Shaft SealingDocument16 pagesScrew Pumps Series SPF: Application Shaft Sealingmsh16000No ratings yet

- Rate of Flow and Fuel Shut Off Valve: ModelDocument2 pagesRate of Flow and Fuel Shut Off Valve: Modelanon_867776278No ratings yet

- Series HPX and HPAXDocument20 pagesSeries HPX and HPAXJairo andres Guarnizo SuarezNo ratings yet

- Cla ValDocument4 pagesCla ValBanupriya BalasubramanianNo ratings yet

- Dorot S100Document36 pagesDorot S100joseph katongoNo ratings yet

- Samson Cryogenic Globe ValveDocument8 pagesSamson Cryogenic Globe ValveShaheen HydrosNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- GSX SeriesDocument33 pagesGSX SeriesCristian MamaniNo ratings yet

- Design Experiment 1: Pneumatic ControlDocument5 pagesDesign Experiment 1: Pneumatic ControlKim Angelo GonzalesNo ratings yet

- Basic Tools 1Document48 pagesBasic Tools 1palaniNo ratings yet

- Matco's Presentation 2Document34 pagesMatco's Presentation 2Mohamad Nasuthion MakkasauNo ratings yet

- Cost Conscious Coker Unheading Valve Hydraulic System Design Cammy Blac DCU Mumbai 2016 PDFDocument24 pagesCost Conscious Coker Unheading Valve Hydraulic System Design Cammy Blac DCU Mumbai 2016 PDFFayaz MohammedNo ratings yet

- APV X SPXDocument52 pagesAPV X SPXFabio Jose LarocaNo ratings yet

- ACTAIR - NG240 To NG700 DYNACTAIR - NG120 To NG350Document48 pagesACTAIR - NG240 To NG700 DYNACTAIR - NG120 To NG350tommyNo ratings yet

- Fieldvue DVC5000 Series Digital Valve ControllerDocument10 pagesFieldvue DVC5000 Series Digital Valve Controllerhocine1No ratings yet

- Manual Part HTH622B-PC10045Document196 pagesManual Part HTH622B-PC10045Alex PerezNo ratings yet

- TRG Control ValveDocument13 pagesTRG Control Valvemilton1987No ratings yet

- 1 - Operation Instruction SSC15Document6 pages1 - Operation Instruction SSC15sumanta_2008dredifmaNo ratings yet

- Cat 950g Trans, Hyd Heui & EuiDocument125 pagesCat 950g Trans, Hyd Heui & Euiguta wondemu mamoNo ratings yet

- HyundaiDocument3 pagesHyundaiМанук ЗурначянNo ratings yet

- Air Actuators: For Pneumatic ApplicationsDocument12 pagesAir Actuators: For Pneumatic ApplicationsAna NedeljkovicNo ratings yet

- Bulletins TVCDocument4 pagesBulletins TVCrodruren01No ratings yet

- TYCO - Pre-Action Deluge ValveDocument16 pagesTYCO - Pre-Action Deluge Valvelance boxNo ratings yet

- Engineering Materials, PPTDocument42 pagesEngineering Materials, PPTKemal Getiso100% (1)

- Faisal HJ Ali, Md. Zahidul Islam Bhuiyan and Firas SalmanDocument8 pagesFaisal HJ Ali, Md. Zahidul Islam Bhuiyan and Firas SalmanZahid BhuiyanNo ratings yet

- Swaco Disc Choke Console Manual 9090080 (E) PDFDocument166 pagesSwaco Disc Choke Console Manual 9090080 (E) PDFguoss10673100% (1)

- 3516BDocument392 pages3516Bmuhammad arif95% (22)

- Directional Seat ValvesDocument4 pagesDirectional Seat ValvesMiron GabrielNo ratings yet

- Gruner 227S enDocument22 pagesGruner 227S enErdinç Eşref UsluNo ratings yet

- Wabco Automated Manual Transmission (AMT) : Aftermarket Solutions For Gearbox Control Units For ZF TransmissionsDocument7 pagesWabco Automated Manual Transmission (AMT) : Aftermarket Solutions For Gearbox Control Units For ZF TransmissionsDieselk0% (1)

- VHB Presentation (Compatibility Mode) PDFDocument21 pagesVHB Presentation (Compatibility Mode) PDFhirenkumar patelNo ratings yet

- Series 74 Positioner ManualDocument25 pagesSeries 74 Positioner ManualhcalderonmarinNo ratings yet

- Aft-Catalog - s8 - Sec - WINCH AND MOTOR VALVESDocument37 pagesAft-Catalog - s8 - Sec - WINCH AND MOTOR VALVESAmcaNo ratings yet

- Electrical Actuator (227SOL)Document2 pagesElectrical Actuator (227SOL)nastyn-1No ratings yet

- Butterfly Valves enDocument37 pagesButterfly Valves enMolitorisz AndorNo ratings yet

- TS20C (02250184-783) User ManualDocument124 pagesTS20C (02250184-783) User ManualMarcos CabreraNo ratings yet

- CV BQDocument2 pagesCV BQBram StyawanNo ratings yet