Professional Documents

Culture Documents

Short Circuit

Uploaded by

ReneCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Short Circuit

Uploaded by

ReneCopyright:

Available Formats

IEEE

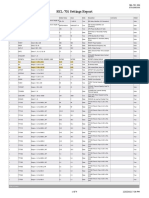

Std 551-2006 CHAPTER 9

Table 9-1—Rotating equipment reactances per IEEE Std C37.010 and

IEEE Std C37.13—Induction motor X" = 16.7% (continued)

Reactance for

Medium- and single

Low-voltage

high-voltage multivoltage

Source type network per

network IEEE system IEEE Std

IEEE Std C37.13

Std C37.010 C37.010/IEEE

Std C37.13

Above 1000 HP X" X" X"

Above 250 HP, 3600 r/min X" X" X"

Medium induction motors

All others, 50 Hp and above 1.2 X" 1.2 X" 1.2 X"

(see Note 1)

Small induction motors

All smaller than 50 hp × X" 1.67 X"

(see Note 2)

Interrupting time calculations, 1.5–5 cycles

Utility Xs N/A Xs

Synchronous machines

All turbo alternators, hydro X"d N/A X"d

with dampers and

synchronous condensers

Hydro without dampers 0.75 X"d N/A

Synchronous motor 1.5 X"d N/A 1.5 X"d

Large induction motors

Above 1000 hp 1.5 X" N/A 1.5 X"

(see Note 3)

Above 250 hp, 3600 r/min 1.5 X" N/A 1.5 X"

(see Note 3)

Medium induction motors

All others 50 hp and above 3.0 X" N/A 3.0 X"

Small induction motors

All smaller than 50 hp × N/A ×

202 Copyright © 2006 IEEE. All rights reserved.

CALCULATING AC SHORT-CIRCUIT CURRENTS IEEE

IN ACCORDANCE WITH ANSI-APPROVED STANDARDS Std 551-2006

Table 9-1—Rotating equipment reactances per IEEE Std C37.010 and

IEEE Std C37.13—Induction motor X" = 16.7% (continued)

Reactance for

Medium- and single

Low-voltage

high-voltage multivoltage

Source type network per

network IEEE system IEEE Std

IEEE Std C37.13

Std C37.010 C37.010/IEEE

Std C37.13

NOTE 1—For larger size low-voltage induction motors, described as “medium > 50 hp, etc.”

using a contribution of “4.8 times rated current,” attributed in IEEE Std C37.13 to synchronous

motors and considered also applicable to these induction motors, determines a 20.8% reactance.

This is effectively the same as multiplying the 16.7% assumed reactance by approximately 1.2 as

shown in column 2 of Table 9-1. For this motor group, therefore, there is reasonable

correspondence of low and medium-voltage procedures.a

NOTE 2—For a typical induction motor, the subtransient reactance of 16.7% is determined by

the initial magnitude of symmetrical root-mean-square (rms) current contributed to a terminal

short circuit, assumed to contribute six times rated current. For smaller induction motors, “small

< 50 hp” per Table 9-1, a conservative fault current estimate, according to IEEE Std C37.13 is

“3.6 times rated current” (equivalent of 0.278 per-unit reactance). This is effectively the same as

multiplying the 16.7% subtransient reactance by 1.67 as shown in column 3 of Table 9-1.

NOTE 3—Large induction motors (> 1000 hp, 4-poles or more and >250 hp, 2-poles) are

assumed to contribute six times their rated current to a terminal short circuit, when better data is

not available. The corresponding 16.7% reactance is modified, per Table 9-1, depending on the

calculation time. The same multipliers, however, apply if motor reactance data is known. For

example, a 500 hp, 900-r/min motor with a known locked-rotor reactance of 15% would have a

first cycle reactance of 18% or an interrupting time reactance 45%, (three times 15%).

aNotes in text, tables, and figures are given for information only and do not contain requirements needed to

implement the standard.

Using the approach of a single multivoltage level network, as outlined in Table 9-1, first

cycle duty calculations for circuit breakers and fuses at both low and high voltages can be

made with one set of network impedances.

It is important to emphasize at this point that accurate induction motor data for short cir-

cuit are paramount for simulation accuracy, particularly for industrial systems featuring a

large content of induction motor loads. Motor data accuracy requirements are, as a rule, a

function of the motor size. The best possible data should be sought for larger motors

which also have the highest influence on calculated short-circuit duties. For small motor

groups using first cycle reactance of 28% (0.28 p.u.) as typical is probably sufficiently

conservative. Individual representation of large and medium motors (or separate groups of

medium motors) is normally justified and increases confidence in the obtained results. It is

recommended to consult the manufacturer for accurate locked-rotor current data (or first

cycle reactances), whenever possible, to properly establish first cycle impedances before

applying the impedance correction multipliers shown in Table 9-1 for interrupting duty

simulations. For the cases in which induction motor contributions are critically important,

additional data pertinent to motor time constants reflecting more exactly ac decrement

characteristics for every machine may be justified. Higher-efficiency motors also feature

Copyright © 2006 IEEE. All rights reserved. 203

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Best Laptop For AutoCAD (Summer August 2017 Update!)Document12 pagesBest Laptop For AutoCAD (Summer August 2017 Update!)ReneNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Architectural SpecificationsDocument13 pagesArchitectural Specificationschan abejoNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- IEEE PowerDeliveryDocument9 pagesIEEE PowerDeliveryReneNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- RIBA Plan of WorkDocument68 pagesRIBA Plan of WorkRene100% (2)

- 7 Electrical Load Study: 7.1 TerminologyDocument2 pages7 Electrical Load Study: 7.1 TerminologyReneNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The 5S and Kaizen Concept For Overall ImprovementDocument20 pagesThe 5S and Kaizen Concept For Overall ImprovementRene100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Root Causes of Construction Project FailureDocument38 pagesRoot Causes of Construction Project FailureReneNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Sample Essay Turabian StyleDocument3 pagesSample Essay Turabian StyleReneNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Stainless Steel Grade PDFDocument1 pageStainless Steel Grade PDFReneNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- RME ReviewerDocument354 pagesRME ReviewerRene100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Candidate Evaluation FormDocument1 pageCandidate Evaluation FormReneNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- RDS 1275kva Gen DwgsDocument6 pagesRDS 1275kva Gen DwgsReneNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Short Circuit Calculation GuideDocument5 pagesShort Circuit Calculation Guideashok203No ratings yet

- 8.7/15kV RFOU, 8.7/15kV RFBU: No. mm EA mm mm mm mm mm mm mm mm ±mm Ω/km V/5min. kg/kmDocument7 pages8.7/15kV RFOU, 8.7/15kV RFBU: No. mm EA mm mm mm mm mm mm mm mm ±mm Ω/km V/5min. kg/kmReneNo ratings yet

- 2004 Nissan X Trail 52344Document48 pages2004 Nissan X Trail 52344ReneNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Sample Essay Turabian Style PDFDocument10 pagesSample Essay Turabian Style PDFReneNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Technical Analysis: PDF Generated At: Wed, 02 Feb 2011 16:50:34 UTCDocument183 pagesTechnical Analysis: PDF Generated At: Wed, 02 Feb 2011 16:50:34 UTCb87208582100% (12)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Estimates Table ConstructionDocument3 pagesEstimates Table ConstructionReneNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- WVSU Student Center Construction ProjectDocument6 pagesWVSU Student Center Construction ProjectAlmira RoblesNo ratings yet

- Best Laptop For AutoCAD (Summer August 2017 Update!)Document12 pagesBest Laptop For AutoCAD (Summer August 2017 Update!)ReneNo ratings yet

- GUIDELINES FOR THE PEE LICENSURE EXAMDocument42 pagesGUIDELINES FOR THE PEE LICENSURE EXAMJukjuk ManlangitNo ratings yet

- Revised National Plumbing Code of The PhilippinesDocument225 pagesRevised National Plumbing Code of The PhilippinesGizelle Ambasan91% (85)

- High Voltage Circuit Breaker PDFDocument4 pagesHigh Voltage Circuit Breaker PDFA.K.A. HajiNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- HV CB TestingDocument38 pagesHV CB Testingsujendranarayana100% (1)

- TrancientDocument3 pagesTrancientReneNo ratings yet

- Arc Flash - Program ScheduleDocument1 pageArc Flash - Program ScheduleReneNo ratings yet

- Revised National Plumbing Code of The PhilippinesDocument225 pagesRevised National Plumbing Code of The PhilippinesGizelle Ambasan91% (85)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Types of System EarthingDocument1 pageTypes of System EarthingReneNo ratings yet

- Physics ProjectDocument23 pagesPhysics ProjectGNag R'Varma100% (1)

- Process Design QuestionnaireDocument30 pagesProcess Design QuestionnaireNguyen Anh TungNo ratings yet

- Production of Biodiesel From Used Vegetable OilDocument4 pagesProduction of Biodiesel From Used Vegetable OilEmmanuelNo ratings yet

- TheNewEducationortheOneHundredPointsofCharacter 10799976Document241 pagesTheNewEducationortheOneHundredPointsofCharacter 10799976Mr FNo ratings yet

- Standard, Hot Smoke, Atex and Ex: Zerax® Axial Flow FansDocument32 pagesStandard, Hot Smoke, Atex and Ex: Zerax® Axial Flow FansYorlevy J. Chirinos M.No ratings yet

- RPS Design Manual GuideDocument29 pagesRPS Design Manual GuideAdriana HernandezNo ratings yet

- SOMDocument431 pagesSOMPradeepvenugopalNo ratings yet

- Wiring Instructions For 10, 16 & 20 Function, 92 & 93 Series, FET ReceiversDocument3 pagesWiring Instructions For 10, 16 & 20 Function, 92 & 93 Series, FET ReceiversGerardNo ratings yet

- Free WRE PM Practice ProblemsDocument45 pagesFree WRE PM Practice ProblemsKahui LimNo ratings yet

- Catalogo ToshibaDocument43 pagesCatalogo Toshibapepitito22100% (1)

- Aits 2021 FT Vii Jeea Paper 2Document11 pagesAits 2021 FT Vii Jeea Paper 2Manideep ReddyNo ratings yet

- Section 7. Ultrasonic InspectionDocument11 pagesSection 7. Ultrasonic InspectionblackhawkNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- NZ Building Code HandbookDocument220 pagesNZ Building Code HandbookDUELEONI100% (2)

- Case Study Scavenge FireDocument4 pagesCase Study Scavenge FirepoetoetNo ratings yet

- 313GC - Specalog APD - PEDJ0867-01 EmailDocument12 pages313GC - Specalog APD - PEDJ0867-01 EmailJoneil RanidoNo ratings yet

- Service Manual: International HS 2.8LDocument130 pagesService Manual: International HS 2.8LGarriga JDew100% (1)

- HVAC Brochure Rev No 12Document66 pagesHVAC Brochure Rev No 12steve@air-innovations.co.zaNo ratings yet

- OHSAS 18001 Work Instruction and SOPsDocument5 pagesOHSAS 18001 Work Instruction and SOPsAlina Walace0% (1)

- OTCQB Company ListDocument119 pagesOTCQB Company ListtbconantNo ratings yet

- Wind Turbines - Protective Measures - Requirements For Design, Operation and MaintenanceDocument28 pagesWind Turbines - Protective Measures - Requirements For Design, Operation and Maintenancexcv100% (4)

- Jura Impressa S7, S9 DiagramDocument19 pagesJura Impressa S7, S9 DiagrampolyfaxNo ratings yet

- Natural and Forced Convection Experiments-2Document12 pagesNatural and Forced Convection Experiments-2Dare AdeoyeNo ratings yet

- UNIT 5 - Special MachinesDocument33 pagesUNIT 5 - Special MachinesKapilachander ThangavelNo ratings yet

- 8 INHE SD NF2 OM MTR002 A Three Phase Smart Meter Operation Manual FRDocument154 pages8 INHE SD NF2 OM MTR002 A Three Phase Smart Meter Operation Manual FRHous Sam100% (2)

- SEL-701 Settings ReportDocument9 pagesSEL-701 Settings ReportJosé AntonioNo ratings yet

- Positively Innovative: Instructions For Use and HandlingDocument16 pagesPositively Innovative: Instructions For Use and HandlingNelson MartinsNo ratings yet

- Page 1 of 4: Design & Calculation Drawing Results Viva-Voce Record Total 30 40 10 10 10 100Document4 pagesPage 1 of 4: Design & Calculation Drawing Results Viva-Voce Record Total 30 40 10 10 10 100UthraNo ratings yet

- Bazooka November 2023 CompressedDocument152 pagesBazooka November 2023 Compressedanjus5sudha5vinu5No ratings yet

- Electronics For YouDocument94 pagesElectronics For Youpre freeda100% (5)