Professional Documents

Culture Documents

Methods of Manufacture

Uploaded by

rosinni0 ratings0% found this document useful (0 votes)

7 views1 pagemethods of manufacture

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentmethods of manufacture

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views1 pageMethods of Manufacture

Uploaded by

rosinnimethods of manufacture

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

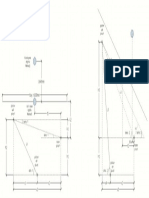

Table 1 — Methods of manufacture

Bended and

Made | ,, Machined | | ciectric welded |, Pressed

free rat | 10m rolled or | Form pars. seo._|from welded

Type of Flange and Collar Forged *|Casted lforged bars and! “lor [or seamless,

products| tional steel or

(plates) forged sectional strip pipes or flat

fp steel ae products

07 (Plate flange for welding) yes | no | yes yes yes no.

(02 (Loose piate flange for Types 32—37) | yes | no | yes es 25 no.

(04 (Loose piate flange for Type 34) yes_| no | yes yes yes no.

05 (Blind flange) yes | no | yes yes no no.

11 (Weld-neck flange) yes | no | no yes yes, for no.

2 DN 700

12 (Hubbed slip-on flange for welding) yes| no | no yes no. no.

13 (Hubbed threaded flange) yes_| no | no yes no. no.

21_(Integral flange) yes_| yes | no yes no no.

32 (Weldon plate collar) yes | no | yes yes yes no.

33 (Lapped end pipe) yes_| no | yes yes yes yes

34 (Weld-neck collar) yes_| yes | no yes yes no.

35 (Welding neck) yes_| no | yes yes yes no.

'36_(Pressed collar with long neck) yes_| no | no no yes yes

37_(Pressed collar) yes [ro | yes no yes yes

Seamless rolled, pressed, forged,

© Only one radial weld is allowed under DN 1800

© Forwelding see 5.11

4 Welded flanges allowed only for an application up to 370 °C in conformance with EN 13480-3:2002, 0.4.4,

© In case flanges are made by cold forming of a base material e.g. lat product, some mechanical properties, lke elongation after fracture

(A) and impact energy (KV), will be impaired due to cold forming without subsequently heat treatment

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Pipe Flow - Liters Per SecondDocument1 pagePipe Flow - Liters Per SecondrosinniNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Chemische Industrie EN DS KsDocument10 pagesChemische Industrie EN DS KsrosinniNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- CB7480SA Purple 2in1 Heated Straightening Brush ManualDocument2 pagesCB7480SA Purple 2in1 Heated Straightening Brush ManualrosinniNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- User Manual - 1050 EBS - 080808Document20 pagesUser Manual - 1050 EBS - 080808rosinniNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Astm A320 l7 GradeDocument1 pageAstm A320 l7 GraderosinniNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- 6110 L06 Economic Pipe Selection MethodDocument0 pages6110 L06 Economic Pipe Selection Methodemye237627No ratings yet

- Compressor Room DWGDocument1 pageCompressor Room DWGrosinniNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Gelisim Forged Valves TR IngDocument12 pagesGelisim Forged Valves TR IngrosinniNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Chemische Industrie EN DS KsDocument10 pagesChemische Industrie EN DS KsrosinniNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Astm A53 A53mDocument23 pagesAstm A53 A53mRaviprakash Chauhan100% (2)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Acfm To SCFM FormulaDocument1 pageAcfm To SCFM FormularosinniNo ratings yet

- ASME B46.1 2009 Standard: Introduction To ASME B46.1-2009 Donald K. Cohen, Ph.D. 3/17/2011Document16 pagesASME B46.1 2009 Standard: Introduction To ASME B46.1-2009 Donald K. Cohen, Ph.D. 3/17/2011Sowmen ChakrobortyNo ratings yet

- Expansion Loop For A Steel PipeDocument1 pageExpansion Loop For A Steel PiperosinniNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Cooling TowerDocument1 pageCooling TowerrosinniNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Water HammerDocument1 pageWater HammerrosinniNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- CFD of PumpDocument180 pagesCFD of PumpFarCfdNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Pipe Rack 2Document1 pagePipe Rack 2rosinniNo ratings yet

- Pipe Spacing ChartDocument1 pagePipe Spacing ChartAhmad Dzulfiqar RahmanNo ratings yet

- Advance Steel 2017 - Essentials Metric - Training GuideDocument426 pagesAdvance Steel 2017 - Essentials Metric - Training GuideEdinson Navarro100% (11)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- KaroqDocument1 pageKaroqrosinniNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Thermal Conductivity of Various MetalsDocument1 pageThermal Conductivity of Various MetalsrosinniNo ratings yet

- Pipe Rack 1Document1 pagePipe Rack 1rosinniNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Asme Section I & Section Viii Fundamentals: Pdhonline Course M398 (3 PDH)Document1 pageAsme Section I & Section Viii Fundamentals: Pdhonline Course M398 (3 PDH)rosinniNo ratings yet

- Pipe Rack 3Document1 pagePipe Rack 3rosinniNo ratings yet

- Unloading PlatformDocument1 pageUnloading PlatformrosinniNo ratings yet

- Kalmar 3d ViewDocument3 pagesKalmar 3d ViewrosinniNo ratings yet

- HSD SteelDocument1 pageHSD SteelrosinniNo ratings yet

- Plate SectionDocument1 pagePlate SectionrosinniNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Einstein SayingDocument1 pageEinstein SayingrosinniNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)