Professional Documents

Culture Documents

Brinell Test IOM PDF

Brinell Test IOM PDF

Uploaded by

AjimKe'en0 ratings0% found this document useful (0 votes)

13 views29 pagesOriginal Title

Brinell Test IOM.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views29 pagesBrinell Test IOM PDF

Brinell Test IOM PDF

Uploaded by

AjimKe'enCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 29

PHB-3000

HYDRAULIC BRINELL

HARDNESS TESTER

Contents

1. Introduction:

2. Features:

3. Technical Parameters:

4. Principle & Structures:

5. Operations+.+++

5.1 Preparation:

5.2 Operation

6. Introduction of Main Parts--

6.1 Indent

6.2 Gauge

6.3 Pressure Lever-

6.4 Pressure Release Lever--

6.5 Control Valve--

6.6 Oil Cylinder:

6.7 Test Head Carriagarssss+ssssssssssns

7. Standard Package"

8. Optional Accessorie: “8

Appendix 1: Maintenance Manual

Appendix 2: Packing & Transportation

Appendix 3: Warranty

Table 1: Brinell Hardness Table

Table 2: Testing Accuracy of Brinell Hardness Testers

Table 3: Testing Conditions for Brinell Hardness Testers

Table 4: Selection of Testing Conditions for Brinell Hardness Testers

Table 5: Conversion of Brinell Hardness and Tensile Strength

PHB~3000 Hydraulic Brinell Hardness Tester 1

1, Introduction

PHB-3000 portable Brinell hardness tester has the same structure as King Brinell

hardness tester. It is the unique portable hardness tester in the world which applies

test condition with 3000kg test force on a 10mm carbide indenter. The large

indentation resulted by the tester can reflect the average value of combined influence

affected by all the compositions of large materials. It is unaffected by certain

composition of materials or partial nonuniform distribution and very suitable for

testing nonuniform materials made of large crystal particle. The testing result of this

instrument is tue and accurate with good repeatability and it has a good

correspondence with tensile strength. Itis the best mechanical property tester which

can be used on site. The test condition and accuracy meet the requirements of ISO

6506 and ASTM E110 and can be used to test rough castings, forgings, nonferrous

metals and semi-finished products after tempering heat treatment.

2. Features

2.1 On-site testing, without sampling

Itis a portable instrument suitable to use in the plant. It is easy to operate and

convenient to carry, So it can be used to test the large workpiece, fixed workpiece

without sampling and to test the large workpiece in any direction (ike upside,

underside, side face or inversion) on site.

2.2 Permanent indentation, easy reinspection

By applying 3000kg test force and 10mm ball indenter, the permanent indentation

can be reinspected at any time after testing. In addition, the existence of the

indention shows that the workpiece has been tested

2.3 Accurate testing, real result

Testing according to the real principle of Brinell hardness testing, PHB-3000

applies the same principle as the bench type Brinell hardness tester. Thus the result

is totally different from the inaccurate cenversion value that other portable hardness

testers (eg. Leeb hardness tester) get. The calibration accuracy of the test force is

0.5%, The accuracy of hardness testing is the same as bench type hardness tester.

2.4 Optional test condition, wide testing range

The tester has various testing forces and indenters so that it can test all kinds of

materials and its testing range can be up to 16-G50HBW.

2.5 High technique, high cost performance

The parts machining and assembling quality of this instrument are much better

than King Brinell hardness tester. Itis free of the problem of oil leak of the hydraulic

system and gear jamming of the jacking system, so it has a higher cost performance.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- AS 1100 Part 301 Architectural DrawingDocument24 pagesAS 1100 Part 301 Architectural DrawingHao Much100% (3)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Flow Chart For Handling Incoming DocumentsDocument1 pageFlow Chart For Handling Incoming Documentsmusaismail8863No ratings yet

- Material Specification Sheet Saarstahl - C40E (Ck40)Document2 pagesMaterial Specification Sheet Saarstahl - C40E (Ck40)musaismail8863No ratings yet

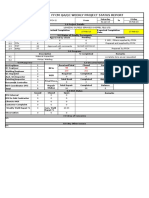

- FFCM-MSI QAQC Weekly Project Status Report (07.02. 15-13 02 15)Document1 pageFFCM-MSI QAQC Weekly Project Status Report (07.02. 15-13 02 15)musaismail8863100% (1)

- 02 MechanicalDocument44 pages02 Mechanicalmusaismail8863No ratings yet

- Abs Guide Rules For Fpso ConversionDocument1 pageAbs Guide Rules For Fpso Conversionmusaismail8863No ratings yet

- Risks in Facility Build Quality and Project Handover: What Happened?Document3 pagesRisks in Facility Build Quality and Project Handover: What Happened?musaismail8863No ratings yet

- MDR NDT Drawing Tembikai As of 08.11.2014Document1 pageMDR NDT Drawing Tembikai As of 08.11.2014musaismail8863100% (1)

- 232 50Document2 pages232 50musaismail8863No ratings yet

- Instruction Manual - Dial Thickness Gauge Kit How Replica Tape WorksDocument6 pagesInstruction Manual - Dial Thickness Gauge Kit How Replica Tape Worksmusaismail8863No ratings yet