Professional Documents

Culture Documents

Model ICB 100-800 HP Boilers: Table A4-14. Model ICB Steam Boiler Safety Valve Outlet Size

Model ICB 100-800 HP Boilers: Table A4-14. Model ICB Steam Boiler Safety Valve Outlet Size

Uploaded by

sebaversaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model ICB 100-800 HP Boilers: Table A4-14. Model ICB Steam Boiler Safety Valve Outlet Size

Model ICB 100-800 HP Boilers: Table A4-14. Model ICB Steam Boiler Safety Valve Outlet Size

Uploaded by

sebaversaCopyright:

Available Formats

Model ICB 100-800 HP Boilers

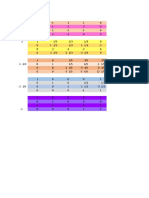

Table A4-14. Model ICB Steam Boiler Safety Valve Outlet Size

VALVE

15 PSIG STEAM 150 PSIG STEAM 200 PSIG STEAM 250 PSIG STEAM

SETTING

NO. OF NO. OF NO. OF NO. OF

OUTLET OUTLET OUTLET OUTLET

BOILER HP VALVES VALVES VALVES VALVES

SIZE (IN.) SIZE (IN.) SIZE (IN.) SIZE (IN.)

REQ’D REQ’D REQ’D REQ’D

100 1 2-1/2 1 1-1/2 1 1-1/2 1 1-1/4

125 1 2-1/2 1 2 1 (1) 1-1/2 1 1 1/2

(1) 1-1/2 1-1/4

150 1 3 2 2 2 1

(1) 1-1/4 (1) 1

(1) 2-1/2 (1) 1-1/2

200 2 2 1-1/2 2 2 1-1/4

(1) 2 (1) 1-1/4

(1) 2 1-1/2 (1) 1-1/2

250 2 (2) 2-1/2 2 2 2

(1) 1-1/2 (1) 1-1/4 (1) 1-1/4

3 (1) 2 (1) 1-1/2

300 2 2 2 (2) 1-1/2 2

(1) 2-1/2 (1) 1-1/2 (1) 1-1/4

(1) 2-1/2 2 (1) 1-1/2

350 2 (2) 3 2 2 2

(1) 2 (1) 1-1/2 (1) 2

(1) 2-1/2 2

400 2 (2) 3 2 2 2 (2) 1-1/2

(1) 2 (1) 1-1/2

(2)3 (1) 2-1/2 (1) 2-1/2 2

500 3 2 2 2

(1) 2-1/2 (1) 2 (1) 2 (1) 1-1/2

(1) 2-1/2

600 3 (3) 3 2 (2) 2-1/2 2 2 2

(1) 2

(2) 2-1/2 (1) 2-1/2

700 4 (4) 3 3 2 2-1/2 2

(1) 2 (1) 2

(3) 3 (2) 2

800 5 3 2-1/2 3 2 2-1/2

(2) 2-1/2 (1) 2-1/2

NOTE: Valve manufacturers are Kunkle, Consolidated or Conbraco, depending on availability.

Table A4-15. Model ICB Hot Water Boiler Relief Valve Outlet Size

VALVE SETTING 30 PSIG HW 125 PSIG HW 150 PSIG HW

NO. OF NO. OF NO. OF

OUTLET SIZE OUTLET SIZE OUTLET SIZE

BOILER HP VALVES VALVES VALVES

(IN.) (IN.) (IN.)

REQ’D REQ’D REQ’D

100 1 2 1 1 12

(1) 1-1/2

125 1 2-1/2 1 1-1/4 2

(1) 2

(1) 1-1/2

150 1 2-1/2 1 1-1/4 2

(1) 2

(1) 2-1/2

200 2 2 1 22

(1) 1

(1) 1-1/4 (1) 2

250 2 1 2 2

(1) 2-1/2 (1) 2-1/2

(1) 2-1/2 (1) 1-1/2

300 2 1 2 2

(1) 2 (1) 2

350 2 2-1/2 1 2-1/2 2 (2) 2-1/2

(1) 1 (1) 2-1/2

400 3 1 2-1/2 2

(2) 2-1/2 (1) 3

(1) 2 (1) 3

500 4 1 2-1/2 2

(2) 2-1/2 (1) 2-1/2

(1) 1

600 3 2-1/2 2 2 3

(1) 2-1/2

(1) 2-1/2 (2) 3

700 4 (4) 2-1/2 2 3

(1) 1-1/4 (1) 2-1/2

(1) 1 (1) 2-1/2

800 5 2 3 3

(4) 2-1/2 (1) 2

NOTE: Relief valve is Kunkle #537 for 30# & 125#(Section IV) boiler and is Kunkle #927 for 150# HTHW (Section I) boiler.

Section A4-22 Rev. 02-08

Model ICB 100-800 HP Boilers

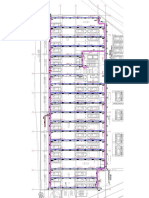

Table A4-16. Model ICB Recommended Steam Nozzle Size

OPERATING

BOILER HP

PRESSURE

PSIG 100 125 150 200 250 300 350 400 500 600 700 800

15 8 8 8 10 10 12 12 12 12 12 12 12

30 6 6 6888 10 10 10 12 12 12

40 6 6 66888 10 10 10 12 12

50 4 6 666888 10 10 10 12

75 4 4 46668888 10 10

100 4 4 466666888 10

125 4 4 4466668888

150 2.5 3 3446666688

200 2.5 2.5 3 444466666

250 2 2.5 3 344446666

NOTES:

1. Steam nozzle sizes given in inches.

2. Recommended steam nozzle sizes based on 4000 to 5000 fpm steam velocity.

3. All standard steam nozzle sizes for 150 psig design pressure or greater are the same

as 125 psig operating pressure on the above table. To increase or decrease the standard

size, request the change with your local Cleaver-Brooks authorized representative.

4. Shaded area denotes special surge load baffles must be installed to avoid possible

water carryover.

5. For incremental operating pressure, see Table I3-1 Steam System Fundamentals.

Table A4-17. Model ICB Recommended Non-Return Valve Size

BOILER BOILER CAPACITY OPERATING PRESSURE (PSIG)

HP (LBS/HR) 50 75 100 125 150 175 200 250

100 3450 2-1/2 2-1/2 NA NA NA NA NA NA

125 4313 3 2-1/2 2-1/2 2-1/2 NA NA NA NA

150 5175 3 3 2-1/2 2-1/2 2-1/2 2-1/2 NA NA

200 6900 3* 3 3 3 3 2-1/2 2-1/2 2-1/2

250 8625 4 3* 3 3 3 3 33

300 10350 4 4 4 3* 3 3 33

350 12025 4 4 4 4 4 3* 3 3

400 13800 5 4 4 4 4 4 4 3*

500 17210 6 5 5 4 4 4 44

600 20700 6 6 5 5 5 4 44

700 24150 6 6 6 5 5 5 54

800 27600 6 6 6 6 6 5 55

NOTE:

Valve sizes (300# flanges) given in inches).

Standard non-return valve selections limited to a maximum 2 to 1 turndown (50% of full boiler output);

selection based on typical valve sizing recommendations. For final valve selection contact your authorized

C-B representative. For high turndown applications see Boiler Book Section I3, Table I3-3.

*Indicates pressure drop of less than 7.5 psig. All other selections are less than 6 psig pressure drop.

Section A4-23 Rev. 02-08

Model ICB 100-800 HP Boilers

Table A4-18. Model ICB Blowdown Tank Sizing Information

BOILER HP WATER (GAL)

100 75

125 94

150 102

200 135

250 125

300 150

350 174

400 191

500 206

600 248

700 266

800 297

NOTE: Quantity of water removed from boiler by lowering normal water line 4"

Table A4-19. Altitude Correction for Gas

ALTITUDE (FT.) CORRECTION FACTOR ALTITUDE (FT.) CORRECTION FACTOR

1000 1.04 6000 1.25

2000 1.07 7000 1.3

3000 1.11 8000 1.35

4000 1.16 9000 1.4

5000 1.21 — —

NOTE: To obtain minimum required gas pressure at altitudes above 700 feet, multiply the pressure

by the listed factors: Inches WC x 0.577 = oz/sq.-in.

oz/sq.-in x 1.732 = Inches WC.

Inches WC x 0.0361 = psig.

oz/sq.-in x 0.0625 = psig.

psig x 27.71 = Inches WC.

psig x 16.0 = oz/sq.-in.

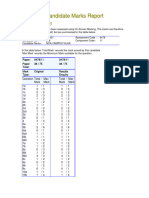

Table A4-20. Sound Levels in dBA for 4-Pass ICB Boilers at High Fire

Sound Level — dBA

BHP

ICB

100 80.0

125 84.5

150 84.5

200 84.5

250 84.5

300 91.0

350 94.0

400 91.5

500 93.5

600 93.5

700 93.7

800 93.7

Section A4-24 Rev. 02-08

Model ICB 100-800 HP Boilers

Table A4-21. Model ICB, Standard Emissions, Minimum Required Gas Pressure

at Entrance to Standard, FM & IRI Gas Trains (Upstream of Gas Pressure Regulator)

STD PIPE PRESSURE REQUIRED, PRESSURE REQUIRED,

BOILER 3-PASS ("WC) 4-PASS ("WC)

SIZE

HP

(Inches) GPR* Minimum Maximum GPR* Minimum Maximum

100 2 RV91 8.5 27.7 RV91 10.5 27.7

125 2 RV91 13.5 27.7 RV91 16 27.7

150 2 RV91 17 27.7 RV91 21 27.7

200 2-1/2 RV111 20 27.7 210G 26 277

250 2-1/2 210G 32.5 277 210G 33 277

300 2-1/2 210G 45 277 210G 45.5 277

350 3 210G 46 277 210G 46.5 277

1.5-2 S 133 208 S 133 208

2-2.5 S 91 133 S 94 133

400

2.5 S 64 91 S 66 94

3 S 39 64 S 42 66

1.5-2.5 S 191 277 S 183 277

2-2.5 S 139 191 S 133 183

500

2.5 S 94 139 S 89 133

3 S 55 94 S 53 89

2-1.5-2.5 S 249 277 S 244 277

2-2.5 S 191 249 S 188 244

600 2.5 S 130 191 S 133 188

2.5-3 S 108 130 S 111 133

3 S 66 108 S 72 111

2-3 S 233 277 S 230 277

2.5-3 S 141 233 S 141 230

700

3 S 91 141 S 91 141

4 S 58 91 S 64 91

2.5-3 S 177 277 S 175 277

800 3 S 114 177 S 114 175

4 S 72 114 S 72 114

NOTE: Where multiple gas train sizes are shown, the shaded row indicates standard size. For altitudes above 700 feet,

contact your local Cleaver-Brooks authorized representative.

* GPR Gas Pressure Regulator

S-Siemens regulating actuator.

Section A4-25 Rev. 02-08

You might also like

- Model CBLE 125-800 HP Boilers: Table A1-14. Steam Boiler Safety Valve OpeningsDocument4 pagesModel CBLE 125-800 HP Boilers: Table A1-14. Steam Boiler Safety Valve OpeningssebaversaNo ratings yet

- Model 4WG 100 - 800 HP Boilers: Table A3-13. Model 4WG Hot Water Relief Valve Outlet SizeDocument4 pagesModel 4WG 100 - 800 HP Boilers: Table A3-13. Model 4WG Hot Water Relief Valve Outlet SizesebaversaNo ratings yet

- CA Pipe SizingDocument1 pageCA Pipe SizingTiến Hà VũNo ratings yet

- Air Line Pipe Size: Length of Run - FeetDocument1 pageAir Line Pipe Size: Length of Run - FeetbiondavNo ratings yet

- Sistemas Con El Método GaussDocument11 pagesSistemas Con El Método GaussRuby RamírezNo ratings yet

- Plano Taler Sotano 2Document1 pagePlano Taler Sotano 2jaime hernandezNo ratings yet

- 8.13 - Glycol Heat Tracing 11Document1 page8.13 - Glycol Heat Tracing 11Greg EverettNo ratings yet

- ABSENDocument3 pagesABSENyassirNo ratings yet

- Lower Beads - Single Digit: (Picture Abacus)Document1 pageLower Beads - Single Digit: (Picture Abacus)mayna2010No ratings yet

- Head To HeadDocument1 pageHead To Headapi-536574900No ratings yet

- Provide The Coordinates For Each PointDocument2 pagesProvide The Coordinates For Each PointMurugaNo ratings yet

- Warfarin Dosing PDFDocument3 pagesWarfarin Dosing PDFOMGStudyNo ratings yet

- 2. 18 07 24 01 დევნილთა სამეწარმეო საქმიანობის ხელშეწყობა 1Document11 pages2. 18 07 24 01 დევნილთა სამეწარმეო საქმიანობის ხელშეწყობა 14w6cszvpdcNo ratings yet

- OLIVER Y BENJI TROMPETA SibDocument1 pageOLIVER Y BENJI TROMPETA SibItsLUNATIC19No ratings yet

- Orario Ufficiale 2022 CICLODocument5 pagesOrario Ufficiale 2022 CICLOana liliaNo ratings yet

- Pset Number 5Document6 pagesPset Number 5Paul Winston RegaladoNo ratings yet

- MSDS TCS TrichlorosilaneDocument4 pagesMSDS TCS Trichlorosilanemoku_mokuNo ratings yet

- Ats RCN Daily SCH Feb10Document54 pagesAts RCN Daily SCH Feb10Faisal KhanNo ratings yet

- wb308 Pergola PDFDocument4 pageswb308 Pergola PDFtbpageNo ratings yet

- Ansi Valve DimensionsDocument1 pageAnsi Valve Dimensionsbkm dizaynNo ratings yet

- Mech Ranu UL Conex Fierro NegrogalvaDocument14 pagesMech Ranu UL Conex Fierro NegrogalvaPatricia MoranNo ratings yet

- Activity 4 7X7 Determinant Using Gauss JordanDocument8 pagesActivity 4 7X7 Determinant Using Gauss Jordanjlnadua23No ratings yet

- Asynchronous Task 4 MusicDocument3 pagesAsynchronous Task 4 MusicJohn Iverson AdajarNo ratings yet

- Baron Suite in CDocument7 pagesBaron Suite in CjrewingheroNo ratings yet

- Abhishek Yadav RAS Paper 4th 128 MarksDocument46 pagesAbhishek Yadav RAS Paper 4th 128 MarksYOGENDRANo ratings yet

- Ats RCN Daily SCH Dec09Document52 pagesAts RCN Daily SCH Dec09Faisal KhanNo ratings yet

- Metode GrafikDocument4 pagesMetode GrafikDemitria Dini AriyaniNo ratings yet

- Principio de Exclusión de PauliDocument2 pagesPrincipio de Exclusión de PauliGalileaNo ratings yet

- SRR CT 008Document30 pagesSRR CT 008César Agustín Acevedo CornejoNo ratings yet

- List of FormulaDocument1 pageList of FormulaMuhammad Fauzan Ansari Bin AzizNo ratings yet

- Captura de Pantalla 2023-09-21 A La(s) 5.32.58 P.M.Document2 pagesCaptura de Pantalla 2023-09-21 A La(s) 5.32.58 P.M.Richard CarvajalNo ratings yet

- 19j BNG SwimDocument1 page19j BNG SwimAnonymous Ue6YScYAlNo ratings yet

- Kondisi Tempat Tidur Ruang PerawatanDocument4 pagesKondisi Tempat Tidur Ruang PerawatanElvi VaniaNo ratings yet

- Matriz Inversa - Gauss JordanDocument4 pagesMatriz Inversa - Gauss JordanKevinrichard MendozayunesNo ratings yet

- 8J BNG SwimDocument1 page8J BNG SwimRajivNo ratings yet

- Etiquetas PCDocument2 pagesEtiquetas PCsoporte1.itcmcNo ratings yet

- UntitledDocument1 pageUntitledHersy Marie Azores GarayNo ratings yet

- Charts & Tables: (9.5) Lock-On ChartDocument2 pagesCharts & Tables: (9.5) Lock-On ChartВлад «Befly» МирошниченкоNo ratings yet

- MPSC Civil Services NMK Recruitment 2024Document14 pagesMPSC Civil Services NMK Recruitment 2024tipu10598No ratings yet

- 爱途牌MT05I电喷诊断系统服务手册Document13 pages爱途牌MT05I电喷诊断系统服务手册张连杉No ratings yet

- Es631 Cos 1354608 0500 11 268Document17 pagesEs631 Cos 1354608 0500 11 268noacamposvilar1No ratings yet

- Pen Ny Lane, Thereis A Bar Ber Showing Pho To Graphs of Ev 'Ry Head He's Had The Plea Sure To - KnowDocument3 pagesPen Ny Lane, Thereis A Bar Ber Showing Pho To Graphs of Ev 'Ry Head He's Had The Plea Sure To - KnowjrewingheroNo ratings yet

- Accesorio Marca MECH-UL ApprovalDocument9 pagesAccesorio Marca MECH-UL Approvalsaul rengifoNo ratings yet

- Responses - 30Document7 pagesResponses - 30musharib.11701No ratings yet

- I. Leadership and Governance Level 1 Level 2 Level 3: School-Based Management Scoring Sheet Per PrincipleDocument6 pagesI. Leadership and Governance Level 1 Level 2 Level 3: School-Based Management Scoring Sheet Per Principlecristina maquintoNo ratings yet

- Gini AlgorithmDocument7 pagesGini AlgorithmShams PushanNo ratings yet

- N Sub Tingkat L Elektron Dalam Sub Tingat Elektron Dalam Sub UtamaDocument3 pagesN Sub Tingkat L Elektron Dalam Sub Tingat Elektron Dalam Sub UtamamasuddinNo ratings yet

- CU AL Ampacity Chart FinalDocument1 pageCU AL Ampacity Chart FinalRobertoHerediaJacoboNo ratings yet

- NS Prueba 2 Muestra C Con MarcasDocument28 pagesNS Prueba 2 Muestra C Con MarcasMarlon VásquezNo ratings yet

- Escala de La Mayor CompletaDocument1 pageEscala de La Mayor CompletawdonaNo ratings yet

- Es631 Cos 1354606 0478 11 268Document14 pagesEs631 Cos 1354606 0478 11 268noacamposvilar1No ratings yet

- 2 Centri-Thrift+Series+SpecificationsDocument4 pages2 Centri-Thrift+Series+SpecificationsArio BharataNo ratings yet

- Monthly Manpower AprDocument8 pagesMonthly Manpower AprJim Brady FerranNo ratings yet

- MECH - Conexiones Roscada ULDocument8 pagesMECH - Conexiones Roscada ULDiego VaronaNo ratings yet

- 5 - Centri-Thrift SeriesDocument4 pages5 - Centri-Thrift SeriesErick ContrerasNo ratings yet

- AmoxilDocument1 pageAmoxilKimiemichNo ratings yet

- 17 BG SwimDocument1 page17 BG SwimRajivNo ratings yet

- 중국문화 중간 정리Document365 pages중국문화 중간 정리asad6325783No ratings yet

- 20j Mum SwimDocument1 page20j Mum SwimRajivNo ratings yet

- Model CB 15-100 HP Boilers: LightsDocument5 pagesModel CB 15-100 HP Boilers: LightssebaversaNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Sound LevelDocument5 pagesModel CB 15-100 HP Boilers: Sound LevelsebaversaNo ratings yet

- Model CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)Document5 pagesModel CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)sebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDocument5 pagesModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaNo ratings yet

- Section A5: Model CBL 900-1800 HP BoilersDocument5 pagesSection A5: Model CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocument5 pagesModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaNo ratings yet

- Features and Benefits: Model CB 15-100 HP BoilersDocument5 pagesFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP BoilersDocument5 pagesModel CBR 125-800 HP BoilerssebaversaNo ratings yet

- Model CBL: 900 - 1800 HP Steam Wet-Back Package BurnerDocument5 pagesModel CBL: 900 - 1800 HP Steam Wet-Back Package BurnersebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDocument5 pagesModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDocument5 pagesModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaNo ratings yet

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Engineering DataDocument5 pagesModel CBL 900-1800 HP Boilers: Engineering DatasebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Document6 pagesModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 pagesModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNo ratings yet

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDocument5 pagesModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocument5 pagesModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- General: Model ICB 100-800 HP BoilersDocument4 pagesGeneral: Model ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimDocument4 pagesModel ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimsebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EDocument5 pagesModel CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EsebaversaNo ratings yet

- Research ArticleDocument9 pagesResearch ArticlesebaversaNo ratings yet

- Model ICB 100-800 HP Boilers: Performance DataDocument4 pagesModel ICB 100-800 HP Boilers: Performance DatasebaversaNo ratings yet

- Closed Crankcase Ventilation Filtration Systems Technical InformationDocument12 pagesClosed Crankcase Ventilation Filtration Systems Technical InformationDwiko RiyonoNo ratings yet

- W20845C V K3fah3b2000016 08062020Document931 pagesW20845C V K3fah3b2000016 08062020eng samiNo ratings yet

- Operation and Maintenance - CP2100 - 2015 - 4812316022Document109 pagesOperation and Maintenance - CP2100 - 2015 - 4812316022Alexander LopezNo ratings yet

- Yamaha PW 80 Parts List WWW - Manualedereparatie.infoDocument41 pagesYamaha PW 80 Parts List WWW - Manualedereparatie.infoMickNo ratings yet

- Housing Designs & Seal Options PDFDocument27 pagesHousing Designs & Seal Options PDFmimi_chan_17100% (1)

- Analogy Between The Electromagnetic and Hydrodynamic Equations - Application To TurbulenceDocument60 pagesAnalogy Between The Electromagnetic and Hydrodynamic Equations - Application To Turbulencesunil481No ratings yet

- ME304 Spring2016 HW3Document3 pagesME304 Spring2016 HW3Steve KrodaNo ratings yet

- Wastewater Treatment Plants-Part 1: General Construction PrinciplesDocument16 pagesWastewater Treatment Plants-Part 1: General Construction Principlesdaprc100% (1)

- Fluids in Rigid Body MotionDocument34 pagesFluids in Rigid Body Motionandreina100% (1)

- Completions - Catalog - BE - Web - CopieDocument56 pagesCompletions - Catalog - BE - Web - CopieArmel HamidouNo ratings yet

- LIST PARTS GM 4-71 00245963 (Maret 10)Document3 pagesLIST PARTS GM 4-71 00245963 (Maret 10)Ahmad Abdulah HasaniNo ratings yet

- Design, Fabrication and Control of Soft RobotsDocument24 pagesDesign, Fabrication and Control of Soft RobotsSagar JoshiNo ratings yet

- Göttgens Forged Steel Valves GADocument88 pagesGöttgens Forged Steel Valves GAludaNo ratings yet

- ME AMC Civil-SE - FinalDocument69 pagesME AMC Civil-SE - FinalACOE P-INo ratings yet

- A Literature Review On Automated Manual Transmission (AMT) : M. S. Kumbhar Proffessor Dr. D. R PanchagadeDocument4 pagesA Literature Review On Automated Manual Transmission (AMT) : M. S. Kumbhar Proffessor Dr. D. R PanchagadeIndia In NewsNo ratings yet

- Method Statement Hot InsulationDocument14 pagesMethod Statement Hot InsulationSaleem AkhtarNo ratings yet

- Pre Stressed Concrete ReportDocument21 pagesPre Stressed Concrete ReportVincent John MendezNo ratings yet

- BS 2995-1966 PDFDocument15 pagesBS 2995-1966 PDF윤규섭No ratings yet

- 9.1 Wind Loads Using ASCE Standard 7-93 PDFDocument9 pages9.1 Wind Loads Using ASCE Standard 7-93 PDFIan DalisayNo ratings yet

- Drive Shaft Literature SurveyDocument12 pagesDrive Shaft Literature SurveyNitin SkNo ratings yet

- Table of Comparative Qualities of Cast Irons: EngineDocument2 pagesTable of Comparative Qualities of Cast Irons: EngineAmber ShrivastavaNo ratings yet

- DB4Document2 pagesDB4gangrukaNo ratings yet

- Sample Problem 3.4Document13 pagesSample Problem 3.4WaleedNo ratings yet

- 12 Samss 018Document4 pages12 Samss 018Dhaval PatelNo ratings yet

- 2014 690 SMC R EuDocument248 pages2014 690 SMC R EuJacopo Lo ConteNo ratings yet

- EN 253 Pre-InsulatedDocument4 pagesEN 253 Pre-Insulatedlela84kNo ratings yet

- By: Meet Shah & Arpit ThumarDocument27 pagesBy: Meet Shah & Arpit ThumarArpit ThumarNo ratings yet

- Jawaban Fisika Irodov Bab 1.3Document3 pagesJawaban Fisika Irodov Bab 1.3Anak SerawaiNo ratings yet

- Samala Phani Kumar - Am AssignmentDocument7 pagesSamala Phani Kumar - Am AssignmentSASI PHANI KUMARNo ratings yet

- Fcu 10Document1 pageFcu 10mohansafNo ratings yet