Professional Documents

Culture Documents

Features and Benefits: Model CB 15-100 HP Boilers

Uploaded by

sebaversaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Features and Benefits: Model CB 15-100 HP Boilers

Uploaded by

sebaversaCopyright:

Available Formats

Model CB 15-100 HP Boilers

FEATURES AND BENEFITS

In addition to the features provided on all Cleaver-Brooks Firetube Boilers, the following

features apply specifically to Model CB Firetube Boilers. The CB four-pass dryback boiler

is the premium firetube boiler design available.

Four-Pass Dryback Design:

• Four-pass design provides high flue gas velocities and low stack temperature for

guaranteed maximum efficiency.

• Dryback design provides full access to boiler tubes, tube sheet, and furnace for ease

of maintenance.

• Dryback design includes single rear tube sheet construction, providing reduced tube

sheet stresses.

Five Square Feet of Heating Surface per Boiler hp:

• Maximum heat transfer with minimum thermal stresses provide guaranteed efficiency

and long boiler life.

• Highest guaranteed fuel-to-steam efficiencies.

Low Furnace Location

• Furnace located well below water level with generous clearance from bottom of

boiler, allowing proper circulation.

• Low furnace provides additional safety margin between furnace and water level.

• Reduces water carryover, producing drier steam.

Hinged or Davited Front and Rear Doors:

• Provides full access to front and rear tube sheet and furnace.

• Reduces maintenance costs.

High Turndown Burner:

• 4:1 turndown (gas and oil) is standard.

• Advanced burner design provides maximum combustion efficiencies and high

turndown.

• Reduced boiler cycling and maintenance.

• Boiler stays on line during low load conditions for optimum efficiency and

performance.

Gas, No. 2 Oil, No. 6 Oil, and Combination Gas and Oil Burners Available:

• High radiant multi-port gas burner designed for high gas velocities and complete

fuel/air mixing, providing maximum combustion efficiencies.

• Air atomizing oil burner available for proper oil atomization, maximum combustion

efficiency, and low maintenance requirements.

• Air atomizing compressor provided with the boiler package for clean oil burning and

ease of maintenance.

• Combination gas/oil burners provide quick fuel changeover without re- adjustment of

the burner.

• Fuel oil controller eliminates the need for over 40 connections, combining gauges,

valves, and regulators into a single casting.

• Retractable oil nozzle provides easy access and cleaning and eliminates coking of oil

and nozzle tip when firing gas.

Section A6-3 Rev. 07-10

Model CB 15-100 HP Boilers

PRODUCT OFFERING

Model CB Firetube Boilers are available in low pressure steam, high pressure steam, and

hot water designs. Burners are available to fire natural gas, light oil, heavy oil, or a

combination of oil and gas. Optional alternate fuel burners are also available.

Model CB Boilers include:

• Four-pass dryback design.

• 15 hp through 100 hp.

• 150 psig - 350 psig high pressure steam.

• 15 psig low pressure steam.

• 30 psig or 125 psig hot water.

• Natural gas, light oil, or heavy oil firing.

The Model CB Boiler is the premium firetube product offering providing maximum boiler

efficiency, the widest range of size and pressures, and premium control packages.

Available options: For option details, contact your Cleaver-Brooks authorized

representative. Options include the following:

Boiler Options

• Auxiliary low water cut-off (standard on steam boilers).

• Drain valves.

• Additional screwed or flanged tappings.

• Special design pressures.

• Surge load baffles.

• Seismic design.

• Internal hot water coils.

• Blowdown valves.

• Non-return valves.

• Feedwater valves and regulators.

• Special doors, davited, hinged, left swing.

• Special base rails.

• Surface blowdown systems.

• Combustion relief door.

• Weather-proofing.

• Blend pump.

Burner/Control Options

• Special modulation controls.

• Optional flame safeguard controller.

• Lead/lag system.

• High altitude design, up to 12,000 ft.

• Special insurance and code requirements (e.g. FM, ASME CSD-1).

• Alarm bell/silence switch.

Section A6-4 Rev. 07-10

Model CB 15-100 HP Boilers

• Special motor requirements (TEFC, high efficiency).

• Remote contacts.

• Special purpose indicator lights.

• Main disconnect.

• Elapsed time meter.

• Voltmeter/micro-ammeter.

• NEMA enclosures.

• Low fire hold controls.

• Remote emergency shut-off (115V).

• Circuit breaker.

• Day/night controls.

• Special power requirements.

Fuel Options

• Automatic fuel changeover.

• Special gas pressure regulator.

• Oversized/undersized gas trains.

• Gas strainer.

• Special fuel shut-off valves.

• Special pilot.

• Alternate fuel firing (propane, digester gas, etc.).

• Special oil pumps.

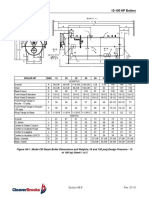

DIMENSIONS AND RATINGS

• Dimensions and ratings for the Model CB boilers are shown in the following tables

and illustrations:

• Table A6-1. Model CB Steam Boiler Ratings (15 thru 100 hp)

• Table A6-2. Model CB Hot Water Boiler Ratings (15 thru 100 hp)

• Table A6-3. Safety Valve Openings

• Table A6-4. Relief Valve Openings

• Figure A6-1. Model CB Steam Boiler Dimensions (15 and 150 lb design pressure) (15

thru 100 hp)

• Figure A6-2 Model CB Hot Water Boiler Dimensions (15 and 150 lb design pressure)

(15 thru 100 hp)

• Figure A6-3. Space Required to Open Rear Head on Model CB Boilers Equipped

with Davits

• Figure A6-4. Model CB Boiler Mounting Piers

• Figure A6-5. Lifting Lug Locations, Model CB Boilers

Section A6-5 Rev. 07-10

Model CB 15-100 HP Boilers

Table A6-1. Model CB Steam Boiler Ratings (15 - 100 hp)

BOILER HP 15C 20C 30C 40C 50 60 70 80 100

RATINGS - SEA LEVEL TO 3000 FT

Rated Cap. (lbs steam/hr @ 212°F) 518 690 1035 1380 1725 2070 2415 2760 3450

Btu Output (1000 Btu/hr) 502 670 1004 1339 1674 2009 2343 2678 3348

APPROXIMATE FUEL CONSUMPTION AT RATED CAPACITY

Light Oil (gph)A 4.5 6.0 9.0 12.0 15.0 18.0 21.0 24.0 30.0

Heavy Oil (gph)B - - - - 14.0 16.5 19.5 22.5 28.0

Gas (cfh) 1000 Btu-Nat 625 835 1255 1675 2095 2510 2930 3350 4185

Gas (Therm/hr) 6.3 8.4 12.6 16.8 21.0 25.1 29.3 33.5 41.9

POWER REQUIREMENTS - SEA LEVEL TO 3000 FT, 60 HZ

Blower Motor hp (except gas) 1 1 1-1/2 2 2 2 2 2D 3

Gas Models (only) 1 1 1-1/2 2 222 2D 3

Oil Pump Motor, hp No. 2 Oil Belt-Driven From Blower 1/3 1/3 1/3 1/3 1/3

Oil Pump Motor, hp No. 6 Oil - - - - 1/3 1/3 1/3 1/3 1/3

Oil Heater kW No. 6 Oil - - - - 5 5 5 5 5

Air Compressor Motor hp Air Compressor Belt-Driven from

2 2222

(Oil firing Only) Blower Motor

NOTES:

1. For altitudes above 3000 ft, contact your local Cleaver-Brooks authorized representative for verification of

blower motor hp.

A. Based on 140,000 Btu/gal.

B. Based on 150,000 Btu/gal.

C. No. 6 Oil not available in 15-40 hp range.

D. 3 hp above 2000 ft.

Table A6-2. Model CB Hot Water Boiler Ratings (15 - 100 hp)

BOILER HP 15 C 20 C 30 C 40 C 50 60 70 80 100

RATINGS - SEA LEVEL TO 3000 FT

Rated Cap Btu Output (1000

502 670 1004 1339 1674 2009 2343 2678 3348

Btu/hr)

APPROXIMATE FUEL CONSUMPTION AT RATED CAPCITY

Light Oil (gph)A 4.5 6.0 9.0 12.0 15.0 18.0 21.0 24.0 30.0

Heavy Oil (gph)B - - - - 14.0 16.5 19.5 22.5 28.0

Gas (cfh) MBtu- nat 625 835 1255 1675 2095 2510 2930 3350 4185

Gas (Therm/hr) 6.3 8.4 12.6 16.8 21.0 25.1 29.3 33.5 41.9

POWER REQUIREMENTS - SEA LEVEL TO 3000 FT, 60 HZ

Blower Motor hp (except gas) 1 1 1-1/2 2 2 2 2 2D 3

Gas Models (only) 1 1 1-1/2 2 2 2 2 2D 3

Oil Pump Motor, hp No. 2 Oil Belt-Driven From Blower 1/3 1/3 1/3 1/3 1/3

Oil Pump Motor, hp No. 6 Oil - - - - 1/3 1/3 1/3 1/3 1/3

Oil Heater kW No. 6 Oil - - - - 5 5 5 5 5

Air Compressor Motor hp Air Compressor Belt-Driven

2 2 2 2 2

(Oil firing Only) from Blower Motor

NOTES:

1. For altitudes above 3000 ft, contact your local Cleaver-Brooks authorized representative for

verification of blower motor hp.

A. Based on 140,000 Btu/gal.

B. Based on 150,000 Btu/gal.

C. No. 6 Oil not available in 15-40 hp range.

D. 3 hp above 2000 ft.

Section A6-6 Rev. 07-10

Model CB 15-100 HP Boilers

Table A6-3. Steam Boiler Safety Valve Openings

VALVE 15 PSIG STEAM 100 PSIG STEAM 125 PSIG STEAM 150 PSIG STEAM 200 PSIG STEAM 250 PSIG STEAM

SETTING

BOILER NO. OF OUTLET NO. OF OUTLET NO. OF OUTLET NO. OF OUTLET NO. OF OUTLET NO. OF OUTLET

HP VALVES SIZE VALVES SIZE VALVES SIZE VALVES SIZE VALVES SIZE VALVES SIZE

REQ'D (IN.) REQ'D (IN.) REQ'D (IN.) REQ'D (IN.) REQ'D (IN.) REQ'D (IN.)

15 1 1-1/2 1 1 1 3/4 1 3/4 1 3/4 1 3/4

20 1 1-1/2 1 1 1 1 1 3/4 1 3/4 1 3/4

25 1 2 1 1 1 1 1 1 1 3/4 1 3/4

30 1 2 1 1-1/4 1 1 1 1 1 3/4 1 3/4

40 1 2-1/2 1 1-1/4 1 1-1/4 1 1 1 1 1 1

50 1 2-1/2 1 1-1/2 1 1-1/2 1 1-1/4 1 1 1 1

60 1 2 1 1-1/2 1 1-1/2 1 1-1/4 1 1 1 1

70 1 2 1 2 1 1-1/2 1 1-1/2 1 1-1/4 1 1

80 1 2-1/2 1 2 1 1-1/2 1 1-1/2 1 1-1/4 1 1-1/4

100 1 2-1/2 1 2 1 2 1 1-1/2 1 1-1/2 1 1-1/4

Table A6-4. Hot Water Boiler Relief Valve Openings

VALVE 30 PSIG HW 60 PSIG HW 100 PSIG HW 125 PSIG HW

SETTING

BOILER NO. OF OUTLET NO. OF OUTLET NO. OF OUTLET NO. OF OUTLET

HP VALVES SIZE VALVES SIZE VALVES SIZE VALVES SIZE

REQ'D (IN.) REQ'D (IN.) REQ'D (IN.) REQ'D (IN.)

15 1 1 1 1 1 1 1 1

20 1 1 1 1 1 1 1 1

25 1 1-1/4 1 1 1 1 1 1

30 1 1-1/4 1 1 1 1 1 1

40 1 1-1/4 1 1 1 1 1 1

50 1 2 1 1-1/4 1 1 1 1

60 1 2 1 1-1/4 1 1 1 1

70 1 2 1 2 1 1-1/4 1 1

80 1 2 1 2 1 1-1/4 1 1-1/4

100 1 2-1/2 1 2 1 1-1/4 1 1-1/4

NOTES:

1.Hot water relief valves are Kunkle #537.

2. BHP followed by “A” designates hot water boilers furnished in a smaller vessel size with additional tubes in the

upper portion of the vessel.

A6-7 Rev. 07-10

You might also like

- Gasoline and Oil Stoves, "New Process" and "Standard." 1901From EverandGasoline and Oil Stoves, "New Process" and "Standard." 1901No ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Model ICB 100-800 HP Boilers: IllustrationsDocument4 pagesModel ICB 100-800 HP Boilers: IllustrationssebaversaNo ratings yet

- General Boiler Information on Low-Emission Firetube ModelsDocument10 pagesGeneral Boiler Information on Low-Emission Firetube Modelsnecio77No ratings yet

- TPL Boiler Fundamentals 10th JuneDocument51 pagesTPL Boiler Fundamentals 10th Junepratosh1313No ratings yet

- 2009 Ajax CatalogDocument88 pages2009 Ajax Cataloglemiis93No ratings yet

- BFS Boiler Book PDFDocument4 pagesBFS Boiler Book PDFfauzi endraNo ratings yet

- Boiler Book CBEX Premium 100-800Document19 pagesBoiler Book CBEX Premium 100-800fauzi endraNo ratings yet

- Gas fired condensing boilers technical documentationDocument24 pagesGas fired condensing boilers technical documentationGheorghiu GheorgheNo ratings yet

- Efficient KramerSaver Air Cooled Condensing UnitsDocument8 pagesEfficient KramerSaver Air Cooled Condensing UnitsErixon RamírezNo ratings yet

- IntegralDocument4 pagesIntegralprasenjitsayantanNo ratings yet

- Boiler Fundamental Read ItDocument119 pagesBoiler Fundamental Read ItRajanish BiswasNo ratings yet

- Introduction To Boilers: Submitted To: Dr. Vivekananda Vivekananda Submitted By: Archee Gupta Kartik SinoliyaDocument23 pagesIntroduction To Boilers: Submitted To: Dr. Vivekananda Vivekananda Submitted By: Archee Gupta Kartik SinoliyaKARTIK SINOLIYANo ratings yet

- Black Gold Vegetable Oil HeaterDocument8 pagesBlack Gold Vegetable Oil HeateraaposxtoloNo ratings yet

- Types of Reformer Design ExplainedDocument59 pagesTypes of Reformer Design ExplainedMary Scott100% (1)

- The Boiler BookDocument1,140 pagesThe Boiler BookJose Lorenzo ToralNo ratings yet

- Boiler BasicsDocument61 pagesBoiler Basicsfferla100% (1)

- High Pressure Boilers 1238Document41 pagesHigh Pressure Boilers 1238rajushamla9927No ratings yet

- Combustion ChambersDocument81 pagesCombustion ChambersRavikumar Ningachar0% (1)

- Boiler InterviewDocument16 pagesBoiler InterviewSachin PatelNo ratings yet

- Oilfield Compression 101Document49 pagesOilfield Compression 101Aizaz MuhammadNo ratings yet

- BakerSPD Choke Tech Handbook 5-9-06 PDFDocument14 pagesBakerSPD Choke Tech Handbook 5-9-06 PDFTg TarroNo ratings yet

- Boiler Book 2005 PDFDocument1,014 pagesBoiler Book 2005 PDFYul Ramon Paradas HernandezNo ratings yet

- Thermax IR-CFBC Conference Rajavel - DistributionDocument32 pagesThermax IR-CFBC Conference Rajavel - Distributionchada1971100% (4)

- BB5-Barrel Pumps-To Be or Not To BeDocument31 pagesBB5-Barrel Pumps-To Be or Not To Beanon_437384288No ratings yet

- Once Through BoilerDocument16 pagesOnce Through BoilerYousuf Ali100% (1)

- CB-OS Boiler BookDocument20 pagesCB-OS Boiler Bookfauzi endraNo ratings yet

- BHEL PAPER Super CriticalDocument29 pagesBHEL PAPER Super CriticalalokntpcNo ratings yet

- CBEX Elite 100-800 HPDocument4 pagesCBEX Elite 100-800 HPsebaversaNo ratings yet

- Boiler With Mountings and AccessoriesDocument67 pagesBoiler With Mountings and AccessoriesYashvir Singh100% (1)

- Fire Tube Boilers PDFDocument16 pagesFire Tube Boilers PDFG.SWAMI67% (3)

- Cheema Boiler Limited: Presented To: MR - Deepak Bhandari (Document32 pagesCheema Boiler Limited: Presented To: MR - Deepak Bhandari (angenious100% (1)

- BoilersDocument76 pagesBoilersDeekshith raiNo ratings yet

- Boiler FundamentalsDocument73 pagesBoiler Fundamentalsmasoodism100% (1)

- Role of Maintenance in Boiler Energy ConservationDocument125 pagesRole of Maintenance in Boiler Energy ConservationkkannanmtpsNo ratings yet

- AOS Cyclone Mxi BTH English CANCG10210 - 0920 - CompressedDocument6 pagesAOS Cyclone Mxi BTH English CANCG10210 - 0920 - CompressedMatteo TorresNo ratings yet

- High Temperature Hot Water BoilersDocument4 pagesHigh Temperature Hot Water BoilersRibhi HamdanNo ratings yet

- Boiler and AuxiliariesDocument29 pagesBoiler and Auxiliariesnsarav100% (1)

- Thermal Engineering Unit-IiDocument67 pagesThermal Engineering Unit-IiAyush SinghalNo ratings yet

- Can KDocument12 pagesCan KSergio RinconNo ratings yet

- Op Eff 16 12 2023Document45 pagesOp Eff 16 12 2023Sharath BogaNo ratings yet

- Super Critical Technology in NTPCDocument24 pagesSuper Critical Technology in NTPCLakshminarayanNo ratings yet

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocument5 pagesModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaNo ratings yet

- Coal MillDocument40 pagesCoal MillRaja VigneshNo ratings yet

- Unit 2: BoilersDocument43 pagesUnit 2: Boilersommech2020No ratings yet

- Steam Turbine Solutions Steam Turbine SolutionsDocument8 pagesSteam Turbine Solutions Steam Turbine SolutionsramakantinamdarNo ratings yet

- Factors in P.F. Boiler DesignDocument147 pagesFactors in P.F. Boiler DesignAnil Palamwar100% (3)

- Auxiliary Boiler Construction Details: BY Mohammed Arif M Mechanical Engineer 41256Document81 pagesAuxiliary Boiler Construction Details: BY Mohammed Arif M Mechanical Engineer 41256Arif MechanicalNo ratings yet

- VTG Bro 121108XrfDocument8 pagesVTG Bro 121108Xrfultron2099ultronNo ratings yet

- Steam Boiler Basics Guide: Types, Components & Best PracticesDocument77 pagesSteam Boiler Basics Guide: Types, Components & Best Practicesaddy2645100% (1)

- Boiler TrainingDocument40 pagesBoiler TrainingHarry Ansari100% (1)

- Coal To Biomass Conversion: Adam Nicholson Ceng Fimeche 19 February 2019Document47 pagesCoal To Biomass Conversion: Adam Nicholson Ceng Fimeche 19 February 2019Diego Martínez FernándezNo ratings yet

- Condensate Storage Tanks GuideDocument4 pagesCondensate Storage Tanks Guidefauzi endraNo ratings yet

- CalderaDocument44 pagesCalderaIvan SanchezNo ratings yet

- Steam Boilers, MountingsDocument63 pagesSteam Boilers, Mountingsswarg patelNo ratings yet

- Boiler OverviewDocument35 pagesBoiler Overviewshashank dasNo ratings yet

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Sound LevelDocument5 pagesModel CB 15-100 HP Boilers: Sound LevelsebaversaNo ratings yet

- 900-1800 HP Boiler SpecsDocument5 pages900-1800 HP Boiler SpecssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDocument5 pagesModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaNo ratings yet

- Section A5: Model CBL 900-1800 HP BoilersDocument5 pagesSection A5: Model CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaNo ratings yet

- Efficient 15-100 HP Boilers for BuildingsDocument5 pagesEfficient 15-100 HP Boilers for BuildingssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocument5 pagesModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaNo ratings yet

- 15-100 HP Boilers Dimensions SpecsDocument5 pages15-100 HP Boilers Dimensions SpecssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDocument5 pagesModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Engineering DataDocument5 pagesModel CBL 900-1800 HP Boilers: Engineering DatasebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDocument5 pagesModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaNo ratings yet

- Model CBR 125-800 HP BoilersDocument5 pagesModel CBR 125-800 HP BoilerssebaversaNo ratings yet

- 900-1800 HP Steam Boilers: Features, Dimensions and Engineering DataDocument5 pages900-1800 HP Steam Boilers: Features, Dimensions and Engineering DatasebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 pagesModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNo ratings yet

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaNo ratings yet

- 81Document5 pages81sebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocument5 pagesModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaNo ratings yet

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDocument5 pages125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDocument5 pagesModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaNo ratings yet

- 75Document5 pages75sebaversaNo ratings yet

- 78Document5 pages78sebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Document6 pagesModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaNo ratings yet

- General: Model ICB 100-800 HP BoilersDocument4 pagesGeneral: Model ICB 100-800 HP BoilerssebaversaNo ratings yet

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDocument5 pages125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- High-efficiency boiler specifications for 100-800 HP modelsDocument4 pagesHigh-efficiency boiler specifications for 100-800 HP modelssebaversaNo ratings yet

- Final PROJECT ReportDocument38 pagesFinal PROJECT ReportElakkiya100% (1)

- Lennox G26Document53 pagesLennox G26Kyle ZielinskiNo ratings yet

- Basic Mechanical Engineering All Units Question BankDocument39 pagesBasic Mechanical Engineering All Units Question BankKshitij SalaveNo ratings yet

- Surya Roshni Annual Report 2012-13Document80 pagesSurya Roshni Annual Report 2012-13vinayakraaoNo ratings yet

- Group-B & C Combatised (Non Gazetted-Non Ministerial) Posts in The Border Security Force, SMT WKSPDocument39 pagesGroup-B & C Combatised (Non Gazetted-Non Ministerial) Posts in The Border Security Force, SMT WKSPKaisgNo ratings yet

- Brochure Range Rover 2010Document44 pagesBrochure Range Rover 2010Beepin JeNo ratings yet

- Super Chargers and Turbo Chargers: 3.1 Introduction To Naturally Aspirated EngineDocument28 pagesSuper Chargers and Turbo Chargers: 3.1 Introduction To Naturally Aspirated EngineRohan PattarNo ratings yet

- UseMaintanceManual NEF MechInjection L31900018E Apr06 PDFDocument41 pagesUseMaintanceManual NEF MechInjection L31900018E Apr06 PDFmanuel segoviaNo ratings yet

- MANUAL UV-5153 - DetronicDocument71 pagesMANUAL UV-5153 - DetronicTiago TorresNo ratings yet

- IceDocument83 pagesIceAJ BantayNo ratings yet

- Supercharger Kits For Honda Civic at Andy's Auto SportDocument8 pagesSupercharger Kits For Honda Civic at Andy's Auto Sportedson.acordiNo ratings yet

- Snowblower ManualDocument39 pagesSnowblower ManualMichaelSewallNo ratings yet

- Man Diesel EngineDocument325 pagesMan Diesel Engineepicnote100% (10)

- Operating and Maintenance Instructions for Paxman Diesel Valenta (RP200) EngineDocument437 pagesOperating and Maintenance Instructions for Paxman Diesel Valenta (RP200) EnginesxturboNo ratings yet

- Piggyback TuningDocument11 pagesPiggyback TuningNilesh YengantiNo ratings yet

- Moteur Briggs 127802Document18 pagesMoteur Briggs 127802tosquallerNo ratings yet

- Understand Diesel Locomotive Shed OperationsDocument30 pagesUnderstand Diesel Locomotive Shed OperationsHimanshu Rawat100% (1)

- Pipe 2Document349 pagesPipe 2Herson Fronda BucadNo ratings yet

- Demu NotesDocument102 pagesDemu NotesHANUMA REDDY100% (2)

- Códigos de Diagnóstico Mack MixersDocument110 pagesCódigos de Diagnóstico Mack Mixersdaniilo agudeloNo ratings yet

- Turbair Vacuum SystemsDocument6 pagesTurbair Vacuum SystemsKerim ŠenderovićNo ratings yet

- Lista Comandos WindowsDocument6 pagesLista Comandos Windowsdiogenes torresNo ratings yet

- Rotary dryer most common dryer usedDocument352 pagesRotary dryer most common dryer usedWati KaNo ratings yet

- Wing ConfigurationDocument15 pagesWing ConfigurationKarenNo ratings yet

- EPC Plant Lubricating Oil AVAILABLE QUANTITYDocument6 pagesEPC Plant Lubricating Oil AVAILABLE QUANTITYSiraj AhmedNo ratings yet

- Pump FMEADocument241 pagesPump FMEAAnonymous g5nzwGICJ100% (6)

- Different Types of ENGINEDocument31 pagesDifferent Types of ENGINEKarnal 0388No ratings yet

- Turbocharger Analysis: October 2017Document8 pagesTurbocharger Analysis: October 2017Wai YanNo ratings yet

- Ic Engines PDFDocument18 pagesIc Engines PDFChaitanya Kishore ChitikenaNo ratings yet

- Books for race car engineering and performanceDocument8 pagesBooks for race car engineering and performanceRohit Tokas100% (3)