Professional Documents

Culture Documents

DCM PDF

Uploaded by

vasava dipakOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DCM PDF

Uploaded by

vasava dipakCopyright:

Available Formats

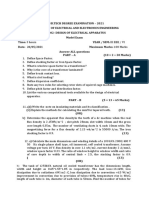

Seat No.: ________ Enrolment No.

___________

GUJARAT TECHNOLOGICAL UNIVERSITY

BE - SEMESTER–VI (NEW) - EXAMINATION – SUMMER 2018

Subject Code: 2160912 Date: 28/04/2018

Subject Name: Design of DC Machines and Transformer

Time: 10:30 AM to 01:30 PM Total Marks: 70

Instructions:

1. Attempt all questions.

2. Make suitable assumptions wherever necessary.

3. Figures to the right indicate full marks.

Q.1 (a) Define: (1) Specific Electric Loading (2) Specific Magnetic Loading 03

(b) Explain design difference between power transformer and distribution 04

transformer.

(c) Write a short note on classification of insulating materials. 07

Q.2 (a) Why circular coils are preferred in transformer winding? 03

(b) Explain: (1) Window space factor (2) Stacking factor. 04

(c) Derive the output equation of a 3-phase core type transformer. 07

OR

(c) Determine the dimensions of core and yoke for a 200 kVA, 50 Hz single 07

phase core type transformer. A cruciform core is used with distance between

adjacent limbs equal to 1.6 times the width of core laminations. Assume

voltage per turn 14 V, maximum flux density 1.1 Wb/m2, Window space

factor 0.32, current density 3 A/mm2 and stacking factor = 0.9. The net iron

area is 0.56 d2 in a cruciform core where d is the diameter of circumscribing

circle. Also the width of largest stamping is 0.85 d.

Q.3 (a) Explain: Bracing in transformer winding. 03

(b) Explain: Significance of mitred joints in transformer. 04

(c) What is design optimization? Derive the condition for maximum efficiency 07

of a transformer.

OR

Q.3 (a) Give technical reason for low flux density for yoke of a three phase 03

transformer.

(b) Explain effect of change in frequency on losses of transformer. 04

(c) Derive the expression of leakage reactance of a 3-phase core type distribution 07

transformer.

Q.4 (a) Discuss the factors to be considered when selecting a suitable value of core 03

length of a D.C. machine.

(b) Explain any two factors while deciding the length of air gap in the design of 04

a D.C. machine.

(c) A design is required for a 50 kW, 4 pole, 600 r.p.m. D.C. shunt generator, 07

the full load terminal voltage being 220 V. If the maximum gap density is

0.83 Wb/m2 and the armature ampere conductors per meter are 30,000,

calculate suitable dimensions of armature core to give a square pole face.

Assume that the full load armature voltage drop is 3 percent of the rated

terminal voltage, and that the field current is 1 percent of rated full load

current. Ratio of pole arc to pole pitch is 0.67.

OR

Q.4 (a) State factor to be consider for selection of specific loading. 03

(b) Derive output equation of a D.C. machine. 04

(c) Explain guideline used for the selection of number of armature slots in D.C. 07

machine design.

1

Q.5 (a) Explain the losses at commutator surface. 03

(b) How to reduce the cross magnetizing effect of armature reaction in a D.C. 04

machine?

(c) Explain steps to design shunt field winding of a D.C. machine. 07

OR

Q.5 (a) How inter pole improves commutation in D.C. machine? 03

(b) Explain: Staggering of Brushes in a D.C. machine. 04

(c) Explain various factors affecting selection of number of poles for D.C. 07

machine.

*************

You might also like

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHet ShahNo ratings yet

- Be Winter 2022Document2 pagesBe Winter 2022Ele052 Patel MilanNo ratings yet

- Be Winter 2021Document2 pagesBe Winter 2021tushar fataniyaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityPalak AriwalaNo ratings yet

- DamDocument2 pagesDamkaran sathvaraNo ratings yet

- Eed Winter 2017 PDFDocument2 pagesEed Winter 2017 PDFY DNo ratings yet

- Gujarat Technological University: Subject Code: 2170909 Date: Subject Name: Design of AC Machines Time: Total Marks: 70Document2 pagesGujarat Technological University: Subject Code: 2170909 Date: Subject Name: Design of AC Machines Time: Total Marks: 70Abhishek PatelNo ratings yet

- DamDocument2 pagesDamAbhishek PatelNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityKathit VasavadaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityPalak AriwalaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversitydileshNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityPalak AriwalaNo ratings yet

- Btech Ee 6 Sem Conventional and Cad of Electrical Machines Nee 023 2016 17Document2 pagesBtech Ee 6 Sem Conventional and Cad of Electrical Machines Nee 023 2016 17Tanisha ShahNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityyicef37689No ratings yet

- Be Winter 2015Document2 pagesBe Winter 2015babaf79912No ratings yet

- Instructions:: Gujarat Technological UniversityDocument2 pagesInstructions:: Gujarat Technological UniversityPalak AriwalaNo ratings yet

- Be Winter 2016Document2 pagesBe Winter 2016babaf79912No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityPalak AriwalaNo ratings yet

- Gtu PaperDocument2 pagesGtu PaperUtsav PanchalNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological UniversityKathit VasavadaNo ratings yet

- SummerDocument2 pagesSummerPiyush ckNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityjijo123408No ratings yet

- DC MACHINE DESIGNDocument6 pagesDC MACHINE DESIGNrubyviswanathanNo ratings yet

- Ee 1403 - Design of Electrical ApparatusDocument9 pagesEe 1403 - Design of Electrical ApparatusskrtamilNo ratings yet

- Be Summer 2016Document2 pagesBe Summer 2016babaf79912No ratings yet

- Paper 2023Document2 pagesPaper 2023sohaliyasahil49No ratings yet

- DEM ModelDocument2 pagesDEM ModelAnonymous IT2ouJqQNo ratings yet

- QPDocument4 pagesQPnandhakumarmeNo ratings yet

- Electrical Machine Design QBDocument9 pagesElectrical Machine Design QBPrince Janesh UniqueNo ratings yet

- Ee 1403 Design of Electrical ApparatusDocument9 pagesEe 1403 Design of Electrical Apparatusdoo123oodNo ratings yet

- Be Winter 2022Document2 pagesBe Winter 2022shivamparmartechNo ratings yet

- Wi 19Document2 pagesWi 19patodaNo ratings yet

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.ABISHEK AJAYNo ratings yet

- Ee 8002 - DeaDocument2 pagesEe 8002 - DeaJerome ColinNo ratings yet

- Ee 1403 - Design of Electrical ApparatusDocument3 pagesEe 1403 - Design of Electrical ApparatussubhazNo ratings yet

- Electrical Machine Design - Department of Electrical and Electronics EngineeringDocument8 pagesElectrical Machine Design - Department of Electrical and Electronics Engineeringni60No ratings yet

- Be Winter 2022Document3 pagesBe Winter 2022Karan SheladiyaNo ratings yet

- Total Pages: 2: Answer Any Three Full Questions, Each Carries 10 MarksDocument2 pagesTotal Pages: 2: Answer Any Three Full Questions, Each Carries 10 MarksJangoNo ratings yet

- Question Bank: Ee 1403 - Design of Electrical ApparatusDocument11 pagesQuestion Bank: Ee 1403 - Design of Electrical ApparatussuriyasureshNo ratings yet

- Question Bank For Emd-1Document5 pagesQuestion Bank For Emd-1the_ray004No ratings yet

- Question About MachinnesDocument3 pagesQuestion About MachinnesJoshua HicksNo ratings yet

- Dayananda Sagar College of Engineering Electrical and Electronics Engineering Question BankDocument15 pagesDayananda Sagar College of Engineering Electrical and Electronics Engineering Question BankshashikumarNo ratings yet

- PDFDocument3 pagesPDFVatsal PatelNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universitysameerpatel15770No ratings yet

- 2131006Document3 pages2131006Janak TrivediNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universitysmartboynitish01No ratings yet

- Be Summer 2012Document2 pagesBe Summer 2012babaf79912No ratings yet

- Name: Reg - No. Sixth Semester B.Tech Degree Examination, JUNE 2009Document2 pagesName: Reg - No. Sixth Semester B.Tech Degree Examination, JUNE 2009maniNo ratings yet

- Be Summer 2018Document1 pageBe Summer 2018babaf79912No ratings yet

- Be Summer 2014Document2 pagesBe Summer 2014babaf79912No ratings yet

- DEADocument4 pagesDEAKavitha BaluNo ratings yet

- Be Summer 2016Document2 pagesBe Summer 2016babaf79912No ratings yet

- Conventional and CAD of Electrical Machines EEE023Document3 pagesConventional and CAD of Electrical Machines EEE023Dheeraj KumarNo ratings yet

- KTU EDC Previous Question PapersDocument12 pagesKTU EDC Previous Question PapersVarun DevNo ratings yet

- L-4ff-l/EEE Date: 06/07/2013Document42 pagesL-4ff-l/EEE Date: 06/07/2013HolloGramNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological UniversityJANVI PANCHALNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityVijayNo ratings yet

- 3 Marks Questio-WPS OfficeDocument2 pages3 Marks Questio-WPS OfficeYogesh KarlekarNo ratings yet

- Dme Gtu PaperDocument5 pagesDme Gtu PaperManav HnNo ratings yet

- Characteristic Modes: Theory and Applications in Antenna EngineeringFrom EverandCharacteristic Modes: Theory and Applications in Antenna EngineeringNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityvasava dipakNo ratings yet

- Hve PDFDocument2 pagesHve PDFvasava dipakNo ratings yet

- Ice Dyso-Dy Mam-Mock Test PaperDocument73 pagesIce Dyso-Dy Mam-Mock Test Papervasava dipakNo ratings yet

- Rules of ReassesmentDocument1 pageRules of ReassesmentAamirMansuriNo ratings yet

- Online Applications (Through Website of ESIC at (: WWW - Esic.nic - inDocument17 pagesOnline Applications (Through Website of ESIC at (: WWW - Esic.nic - invasava dipakNo ratings yet

- Ice Dyso-Dy Mam-Mock Test PaperDocument73 pagesIce Dyso-Dy Mam-Mock Test Papervasava dipakNo ratings yet

- Pressure-Controlled Pumps CascadeDocument2 pagesPressure-Controlled Pumps Cascadecc_bauNo ratings yet

- RENR81310001Document11 pagesRENR81310001Guido VillafuerteNo ratings yet

- Section 6 PDFDocument84 pagesSection 6 PDFVaziKvaziNo ratings yet

- Abb Artu 2014Document404 pagesAbb Artu 2014haldrik5966No ratings yet

- 0l1500 B SMM ModuleDocument2 pages0l1500 B SMM ModulereinaldomdNo ratings yet

- Buk453 100aDocument7 pagesBuk453 100amicrowave440No ratings yet

- Dsa0066344 PDFDocument6 pagesDsa0066344 PDFJosé AdelinoNo ratings yet

- Analysis of DT Linear Invariant Systems Using ConvolutionDocument51 pagesAnalysis of DT Linear Invariant Systems Using ConvolutionReddy BabuNo ratings yet

- Exponential Moving AverageDocument7 pagesExponential Moving Averagehamid aslanovNo ratings yet

- SC TNS - CompleteDocument89 pagesSC TNS - CompleteJohn Cristouv CortezNo ratings yet

- A 266 PDFDocument312 pagesA 266 PDFwilfran villegasNo ratings yet

- Standard Control PanelDocument2 pagesStandard Control PaneldaneNo ratings yet

- CablesDocument94 pagesCablesMrudulaNo ratings yet

- The Arduino: This Presentation Made by Thingerbit's PDFDocument23 pagesThe Arduino: This Presentation Made by Thingerbit's PDFscience for lifeNo ratings yet

- L297Document12 pagesL297wtn2013No ratings yet

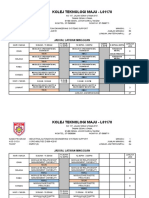

- Jadual Latihan Meka L4 Noss 2016Document129 pagesJadual Latihan Meka L4 Noss 2016Al Ameer SultanNo ratings yet

- Logic Guide Texas InstrumentsDocument20 pagesLogic Guide Texas InstrumentsCristian RoblesNo ratings yet

- Efficient Multi Controller for Hitachi CompressorsDocument6 pagesEfficient Multi Controller for Hitachi CompressorsDikaAnindyajatiNo ratings yet

- Arsenal Stadium Acoustics ReportDocument22 pagesArsenal Stadium Acoustics ReportBhargav Bhat100% (1)

- Uniten Arsepe 08 L2Document87 pagesUniten Arsepe 08 L2amin_bravoNo ratings yet

- 4274GV50 5v Regulator PDFDocument13 pages4274GV50 5v Regulator PDFvanadium0No ratings yet

- Combicom: GB INSTRUCTION MANUAL USB Serial ConverterDocument12 pagesCombicom: GB INSTRUCTION MANUAL USB Serial ConverterFet hiNo ratings yet

- Centric 50 KvaDocument85 pagesCentric 50 KvaAntónio BarrosNo ratings yet

- Design Studio: Shin Yang Development SDN BHDDocument1 pageDesign Studio: Shin Yang Development SDN BHDcRi SocietyNo ratings yet

- Lecture 1: Introduction To CS-541 and Wireless Sensor NetworksDocument30 pagesLecture 1: Introduction To CS-541 and Wireless Sensor NetworksKumar SarthakNo ratings yet

- ZVS High Voltage Power SupplyDocument13 pagesZVS High Voltage Power Supplysaran gulNo ratings yet

- DGS 8800eDocument82 pagesDGS 8800eDmNo ratings yet

- Detailed SolutionsDocument76 pagesDetailed SolutionsDuppalapudi SainadhNo ratings yet

- Ground Penetrating Radar Improving Sensing and Imaging Through Numerical ModelingDocument346 pagesGround Penetrating Radar Improving Sensing and Imaging Through Numerical ModelingIsmaelMinjarezSosa100% (2)

- NGR Sizing 11kVDocument4 pagesNGR Sizing 11kVSantoshNo ratings yet