Professional Documents

Culture Documents

Partial-Stroke Testing of Block Valves

Partial-Stroke Testing of Block Valves

Uploaded by

fraihafraihaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Partial-Stroke Testing of Block Valves

Partial-Stroke Testing of Block Valves

Uploaded by

fraihafraihaCopyright:

Available Formats

PARTIAL-STROKE TESTING OF BLOCK VALVES

Angela E. Summers, Ph.D., P.E., President, SIS-TECH Solutions, LP

“Partial Stroke Testing of Valves,” Control Engineering, November 2000.

“Partial Stroke Testing of Block Valves,” ISA EXPO 2001, Houston, Texas, September 2001.

Successful implementation of the safety lifecycle model, associated with ANSI/ISA 84.01-1996 (ISA 84)

and IEC 61508, hinges on one design constraint---the safety integrity level (SIL). The SIL is a numerical

benchmark, related to the probability of failure on demand (PFD). SIL is affected by the design robustness,

e.g., device integrity, voting, and common cause faults. It is also affected by the operation and

maintenance strategy, e.g., diagnostics and testing interval.

For many operating companies, the most difficult part of SIL compliance is the testing of final elements,

especially emergency block valves. Traditionally, emergency block valves have been tested at unit

turnaround, using a full-stroke test to demonstrate performance. Thirty years ago, turnarounds were every

two to three years. Due to mechanical reliability and preventive maintenance programs, companies are

now extending unit turnarounds to every five to six years. Extended turnarounds yield great economic

returns through increased production. Extended turnaround intervals also mean that emergency block

valves are expected to go longer between function tests, yet still achieve the same performance. This is

not possible.

Partial-stroke testing can be used to supplement full-stroke testing to reduce the block valve PFD. The

amount of the reduction is dependent on the valve and its application environment. This paper will discuss

how to determine the actual impact of the partial-stroke test on PFD. It will also present a discussion of the

three partial-stroke testing methodologies that are currently being evaluated and used by industry.

SIL VERIFICATION FOR BLOCK VALVES

The probability to fail on demand (PFD) can be calculated using the dangerous failure rate (λD) and the

testing interval (TI). The mathematical relationship, assuming that systematic failures are minimized

through design practice, is as follows:

PFD = λD * TI/2

The equation shows that the relationship between PFD and TI is linear. Longer test intervals yield larger

PFDs. The OREDA database has data for various valve types and sizes. For the purposes of illustration, a

dangerous failure rate of 3.03E-06 failures per hour will be used. The valve failure rate varies with type,

size, and operating environment (e.g., process chemicals, deposition, polymerization, etc.). The reader

should determine the appropriate failure rate for the specific application.

12621 Featherwood Drive • Suite 120 • Houston, Texas 77034

Tel: (281) 922-8324 • Fax: (281) 922-4362

www.SIS-Tech.com

June 15, 2007

Page 2 of 8

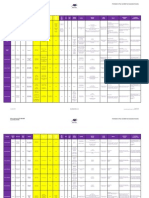

The PFD, based on the 3.03E-06 per hour failure rate, is shown in Table 1 for various testing frequencies.

As expected, the valve performance at a 5-year testing interval is not the same as the valve performance at

a 2-year testing interval. Reliability data for operating equipment provided justification to extend the

turnaround period, in many cases by a factor of three or more. However, the impact of longer testing

intervals on standby devices, such as block valves, was not evaluated. Longer turnaround intervals result

in improved financial performance. The side effect is increased risk of an incident due to lower

performance of safety critical devices, such as the SIS final elements.

Table 1. PFDavg for a Typical Block Valve as a Function of Testing Interval (λ=3.03E-06)

Testing Interval PFDavg

1 year 1.33E-02

2 years 2.65E-02

3 years 3.98E-02

4 years 5.31E-02

5 years 6.64E-02

6 years 7.96E-02

Due to the degraded performance at longer testing intervals, many companies have found that they must

test the block valves on-line. Once facilities for on-line testing are installed, full-stroke testing can easily be

performed. However, since a full-stroke test involves full contact of the valve seating members, frequent

stroking can cause excessive wear to the block valve seat. This is a serious concern for soft-seated

valves. Increased testing may achieve a higher integrity, but cause damage to the valve seat, leading to

earlier valve failure.

Another major concern is that the plant is unprotected while the block valve is in bypass for testing. The

fraction of the time that the valve is in bypass must be considered in the PFD calculation. If the valve is

bypassed every six months for testing and the test takes 1-hour, the PFD is increased by 2.3E-04. For

longer bypass periods or more frequent testing, the impact on the PFD is even more significant. To

maintain safety, operating procedures must include a list of the actions to be taken when the valve is in

bypass, such as reducing production rates, monitoring certain process variables, or executing shutdown.

An option to a full-stroke test is a partial-stroke test. The test involves moving the valve a minimum of 15

percent, which tests a portion of the valve failure modes. The remainder of the failure modes are tested

using a full-stroke test. The main purpose of the partial-stroke test is to reduce the required full-stroke

testing frequency.

Partial-stroke testing does not eliminate the need for a full flow bypass. If the valve is partial-stroke tested

and determined to be non-functional, maintenance will need a bypass or the process will have to be

shutdown for valve repair. Since the bypass is not required for testing, there is no loss of safety integrity.

The bypass is only used during valve maintenance.

12621 Featherwood Drive, Suite 120

Houston, Texas 77034

June 15, 2007

Page 3 of 8

How does partial-stroke testing affect the PFD? A complete functional test of the valve can be viewed as

consisting of two parts: the partial-stroke (PS) and the full-stroke (FS). For the calculation, the dangerous

failure rate, λD, must be divided into what can be tested at the partial-stroke (λDPS) and what can only be

tested with a full-stroke (λDFS). The resulting equation for the PFD is as follows:

PFD = λDPS * TIPS/2 + λDFS * TIFS/2

The division of λD into parts requires an evaluation of the failure modes of the valve. Table 2 provides a

listing of typical dangerous failure modes for block valves and the corresponding effect of these failure

modes. The test strategy indicates whether the failure mode can be detected by partial-stroke testing or

only by full-stroke testing.

Table 2. Dangerous Failure Modes and Effects with Associated Test Strategy

Failure Modes Effects Test Strategy

Actuator sizing is insufficient to Valve fails to close (or open) Not tested

actuate valve in emergency

conditions

Valve packing is seized Valve fails to close (or open) Test valve – Partial or full-stroke

Valve packing is tight Valve is slow to move to closed or Not tested unless speed of closure is

open position monitored.

Air line to actuator crimped Valve is slow to move to closed or Not tested unless speed of closure is

open position monitored. Physical inspection

Air line to actuator blocked Valve fails to move to closed or Test valve – Partial or full-stroke

open position

Valve stem sticks Valve fails to close (or open) Test valve – Partial or full-stroke

Valve seat is scarred Valve fails to seal off Full-stroke test with leak test

Valve seat contains debris Valve fails to seal off Full-stroke test

Valve seat plugged due to Valve fails to seal off Full-stroke test

deposition or polymerization

The failure modes listed in Table 2 can be compared to the failure mode distributions presented in the

Offshore Reliability Data Handbook (OREDA) for various valve types and sizes. Based on the OREDA

data, the maximum percentage of the failures that can be detected by a partial-stroke test is 70%. The

remaining 30% of the failures can only be detected using a full-stroke test.

The reader is cautioned that this breakdown is based on average valve performance in off-shore

installations and may not represent the breakdown for the reader’s application. This evaluation should be

done for each valve type, based on the application environment and the shutoff requirements. If the

service is erosive, corrosive, or plugging, the failure rate and failure mode breakdown will be different from

12621 Featherwood Drive, Suite 120

Houston, Texas 77034

June 15, 2007

Page 4 of 8

that shown in this paper. If the valve is specified as tight-shutoff, the contribution of minor seat deformation

or scarring will be more significant than shown in this paper. For these reasons, it is recommended that

partial-stroke testing not used as a substitute for full-stroke testing for a single block valve application when:

a. the valve has been shown to fail in the service due to process deposition or plugging,

b. the valve is specified as tight-shutoff for safety reasons,

c. valve leakage can generate a hazardous incident.

Using 70% as the breakdown of the dangerous failure rate, λD, the equation for the PFD can be written as

follows:

PFD = 0.7λD * TIPS/2 + 0.3λD * TIFS/2

Using a dangerous failure rate of 3.03E-06 per hour, Figure 1 shows the PFD when the test procedure

requires removing the valve from service during the test. As expected, the partial-stroke testing does

improve the PFD performance of the valve. The star illustrates the point where the partial-stroke testing

interval and full-stroke testing interval are both at 8760 hours (1 year). This corresponds to the results for a

1 year full-stroke test, as shown in Table 1.

Figure 1. Relationship Between Partial-stroke Testing Interval and PFD – Valve is Unavailable During the

Test

PARTIAL STROKE TESTING IMPACT ON PFD

VALVE IS UNAVAILABLE DURING PARTIAL STROKE TEST

0.001

CALCULATION ASSUMES THAT 70% OF THE VALVE FAILURES FULL STROKE AT 1 YR

ARE TESTED AT THE PARTIAL STROKE TESTING INTERVAL FULL STROKE AT 2 YRS

AND THAT 30% OF THE VALVE FAILURES ARE TESTED AT THE

FULL STROKE AT 3 YRS

PROBABILITY TO FAIL ON DEMAND (PFD)

FULL STROKE TESTING INTERVAL. THE VALVE IS

UNAVAILABLE FOR SHUTDOWN DURING THE PARTIAL STROKE FULL STROKE AT 4 YRS

TEST. FULL STROKE AT 5 YRS

0.01

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

0.1

PARTIAL STROKE TESTING INTERVAL (HRS)

12621 Featherwood Drive, Suite 120

Houston, Texas 77034

June 15, 2007

Page 5 of 8

The downward trend of the curves for very frequent partial-stroke testing is due to the valve being removed

from service during the test. This removal results in the valve not being available for the fraction of time

that the valve is being tested. The calculation assumes that the total test time is 30 minutes. If the actual

test time is longer, the effect will be more pronounced.

Figure 2 shows the PFD when the test procedure allows the valve to remain in service during the test. Very

frequent partial-stroke tests improve the PFD substantially, because there is no loss of functionality during

the test. Again, the star illustrates the point where the partial-stroke testing interval and full-stroke testing

interval are both at 8760 hours (1 year).

Figure 2. Relationship Between Partial-stroke Testing Interval and PFD – Valve is Available During the

Test

PARTIAL STROKE TESTING IMPACT ON PFD

VALVE IS AVAILABLE DURING TEST

0.001

CALCULATION ASSUMES THAT 70% OF THE VALVE FAILURES ARE FULL STROKE AT 1 YR

TESTED AT THE PARTIAL STROKE TESTING INTERVAL AND THAT 30%

OF THE VALVE FAILURES ARE TESTED AT THE FULL STROKE TESTING FULL STROKE AT 2 YRS

INTERVAL. THE VALVE IS AVAILABLE FOR SHUTDOWN DURING THE FULL STROKE AT 3 YRS

PARTIAL STROKE TEST.

PROBABILITY TO FAIL ON DEMAND (PFD)

FULL STROKE AT 4 YRS

FULL STROKE AT 5 YRS

0.01

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

0.1

PARTIAL STROKE TESTING INTERVAL (HRS)

For both test procedures, partial-stroke testing does improve the valve performance. For example, 5-year

full-stroke testing achieved a PFD of 6.64E-02 (Table 1). A 5 year full-stroke test supplemented with a 6-

month (4380 hours) partial stroke test achieved a PFD of 2.46E-02, which is a 37% reduction in PFD. In

the cases of 1-year and 2-year full-stroke testing, a single block valve can potentially achieve SIL 2

performance when supplemented with frequent partial-stroke tests. For longer full-stroke testing intervals,

the valve performance can increase from low SIL 1 to high SIL 1, depending on the partial-stroke testing

interval. From the graphs, it is easy to see that no amount of partial-stroke testing is going to allow a single

valve to achieve high SIL 2 performance, let alone SIL 3 performance, at full-stroke testing intervals of 1

year or more.

12621 Featherwood Drive, Suite 120

Houston, Texas 77034

June 15, 2007

Page 6 of 8

PARTIAL-STROKE TEST METHODOLOGY

There are three basic types of partial-stroke test equipment: mechanical limiting, position control, and

solenoids. Each type involves different levels of sophistication and risk. Consequently, each type will be

discussed separately.

Mechanical Limiting

Mechanical limiting methods involve the installation of a mechanical device to limit the degree of valve

travel. When mechanical limiting methods are used, the valve is not available for process shutdown (see

Figure 1).

The mechanical devices used for partial stroke testing include collars, valve jacks, and jammers.

9 Valve collars are slotted pipes that are placed around the valve stem of a rising stem valve.

The collar prevents the valve from traveling any farther than the top of the collar. Any

fabrication shop can build a valve collar, suitable for test use.

9 A valve jack is a screw that is turned until it reaches a set position. The valve jack limits the

actuator movement to the screw set position. The valve jack is ordered from the valve

manufacturer when the valve is purchased. Valve jacks work with both rising stem valves and

rotary valves.

9 Mechanical jammers are integrated into the rotary valve design. They are essentially slotted

rods that limit valve rotation when placed in position using an external key switch. Since the

jammer is integrated into the rotary valve, the jammer must be purchased from a valve

manufacturer. A contact can be provided for the key switch to allow annunciation in the control

room whenever the key is used.

Mechanical limiting methods are inexpensive in terms of capital and installation costs. These methods are

manually initiated in the field and are manpower intensive.

A limit switch or visual inspection is used to confirm valve movement. Successful implementation and

return to normal operational status are completely procedure driven. For valve collars and jacks, bypass

notification to the control room is entirely procedural. For the jammer, automatic notification using the key

switch contact can be provided.

One of the biggest drawbacks to these methods is the lack of assurance that the valve is in or has been

returned to normal status. There is no way to know for certain that the jack or jammer has been completely

retracted without actuating the valve. Furthermore, unauthorized use of the valve jack or jammer cannot be

determined by casual inspection. This means that the valve could potentially be out of service with

operations personnel unaware of the situation.

12621 Featherwood Drive, Suite 120

Houston, Texas 77034

June 15, 2007

Page 7 of 8

These methods do not add to the normal operating spurious trip rate. However, there is the potential for a

spurious trip during the partial-stroke test. For valve collars, the main culprit of spurious trips is improper

installation, causing the collar to pop off the stem when the valve begins to move. Jacks and jammers must

be placed in service by the technician; so procedural mistakes can result in the valve closing completely

rather than just partially. Therefore, these methods are really only as good as the written procedures and

technician training.

Position Control

Position control uses a positioner to move the valve to a pre-determined point. This method can be used

on rising stem and rotary valves. Since most emergency block valves are not installed with a positioner,

this method does require installation of additional hardware. Positioner operation also requires an analog

output, which is typically not installed in SIS applications. Consequently, cost is a major drawback for the

position control method.

A limit switch or position transmitter can be used to determine and document the successful completion of

the tests. If a smart positioner is used for the position control, a HART maintenance station can collect the

test information and generate test documentation. Of course, the use of a smart positioner and

maintenance station further increases the capital cost.

Some vendors have promoted the use of the positioner in lieu of a solenoid for valve actuation. However,

most positioners do not have a large enough vent port (Cv) for rapid valve closure. Consequently, a

solenoid should still be used for valve actuation. This solenoid valve must be installed between the

positioner and the actuator.

The positioner does contribute to the spurious trip rate during normal operation, since the positioner can fail

and vent the air from the valve. When a solenoid is installed between the positioner and the actuator, the

safety functionality is never lost during the partial-stroke test (See Figure 2). De-energizing the solenoid

will shut the valve regardless of the positioner action.

Solenoid

A partial-stroke test can be accomplished by pulsing a solenoid valve. The solenoid can be the same

solenoid used for valve actuation, resulting in a low capital and installation costs for the method. If the

actuation solenoid valve is used, this method will also test the solenoid valve functionality.

The time of the pulse must be adjusted for each valve and solenoid pair to achieve the desired valve travel.

Valve travel confirmation is accomplished by a limit switch or position transmitter, allowing automatic

documentation of test status. Since a serious failure of the valve may result in more movement of the valve

during the pulse than desired, the pulse timer should be voted with the limit switch or position transmitter. If

the valve reaches its desired travel point before the pulse timer is finished, the solenoid valve should be

12621 Featherwood Drive, Suite 120

Houston, Texas 77034

June 15, 2007

Page 8 of 8

reset. The test can be programmed in the SIS logic solver with the test being implemented automatically

based on a programmed cycle time or initiated by the operator on a maintenance schedule.

Since the valve is never bypassed or disabled, the valve remains available for shutdown during the test

(see Figure 2). As with the other partial-stroke testing methods, a maintenance bypass is required to allow

maintenance to be performed on-line without a process shutdown.

Spurious trips during testing can be a problem, if non-redundant solenoids are used for valve actuation.

After all, the solenoid is being de-energized for the test and re-energized to stop the test. If the solenoid

valve does not reset, the test becomes a trip. The use of redundant solenoids can seriously reduce the

probability of the spurious trip.

CONCLUSION

Partial-stroke testing does provide measurable improvement of the PFD over full-stroke testing alone. The

amount of improvement is dependent on the specification, configuration, and application environment. The

three partial-stroke testing methodologies offer choices between manual and automated testing.

Whichever method is selected, procedures must be written to ensure that the block valve is not tripped

during testing, the test is properly carried out, incorrect valve performance is documented, and

maintenance is performed to return valve to fully functional status. This means that the documentation

requirements for the partial-stroke test are the same as for the full-stroke test. Since a bypass is still

required for maintenance, facilities and procedures must be in place to ensure that use of the bypass valve

is restricted. The main benefit is that partial stroke testing can reduce the full-stroke testing interval

required to achieve the SIL.

REFERENCES

1. “Application of Safety Instrumented Systems for the Process Industries,” ANSI/ISA-ISA 84.01-1996,

ISA, Research Triangle Park, NC (1996).

2. “Functional safety of electrical/electronic/programmable electronic safety related systems,” IEC 61508,

International Electrotechnical Commission, Geneva, Switzerland (1999).

3. Summers, A.E., “Understanding Safety Integrity Levels,” Control Engineering website (February 2000).

4. “OREDA: Offshore Reliability Data Handbook,” 3rd Edition, Det Norske Veritas Industri Norge as DNV

Technica, Norway, 1997.

12621 Featherwood Drive, Suite 120

Houston, Texas 77034

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Play Based Learning PresentationDocument14 pagesPlay Based Learning PresentationNajwaCacen100% (23)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Developmental Psychology From Infancy To Adulthood (1988)Document149 pagesDevelopmental Psychology From Infancy To Adulthood (1988)MilosNo ratings yet

- 0843 0856 PDFDocument14 pages0843 0856 PDFArun BabuNo ratings yet

- Title: Seismic Functional Qualification of Active Mechanical and Electrical Component Based On Shaking Table TestingDocument123 pagesTitle: Seismic Functional Qualification of Active Mechanical and Electrical Component Based On Shaking Table TestingArun BabuNo ratings yet

- 2011 - 1 - Daimler Supplier Magazine - EngDocument64 pages2011 - 1 - Daimler Supplier Magazine - EngArun BabuNo ratings yet

- Armalit АСО: JSC Actuator Control GmbhDocument2 pagesArmalit АСО: JSC Actuator Control GmbhArun BabuNo ratings yet

- Simvac Speciality Boards & Shapes: CharacteristicsDocument1 pageSimvac Speciality Boards & Shapes: CharacteristicsArun BabuNo ratings yet

- VALCO Air Separation Valves ENGDocument15 pagesVALCO Air Separation Valves ENGArun BabuNo ratings yet

- IMI Critical Engineering Brochure DownloadDocument24 pagesIMI Critical Engineering Brochure DownloadArun Babu0% (1)

- Auma Marine Actuator SeriesDocument45 pagesAuma Marine Actuator SeriesArun BabuNo ratings yet

- Rigid Rod SystemDocument9 pagesRigid Rod SystemArun BabuNo ratings yet

- Type 01262 - Bellow Sealed Globe Valve: Fire Safe ValvesDocument1 pageType 01262 - Bellow Sealed Globe Valve: Fire Safe ValvesArun BabuNo ratings yet

- Velan View Spring 2011scrDocument32 pagesVelan View Spring 2011scrArun BabuNo ratings yet

- Dart PDFDocument12 pagesDart PDFArun BabuNo ratings yet

- 26 289a2267-100Document8 pages26 289a2267-100Arun BabuNo ratings yet

- Basics Leak DetectionDocument23 pagesBasics Leak DetectionArun BabuNo ratings yet

- EU Directive 94/9/EC - Equipment and Protective Systems Intended For Use in Potentially Explosive Atmospheres (ATEX)Document6 pagesEU Directive 94/9/EC - Equipment and Protective Systems Intended For Use in Potentially Explosive Atmospheres (ATEX)Arun BabuNo ratings yet

- Cee Based ControllerDocument47 pagesCee Based ControllerJohn HowardNo ratings yet

- Rotating Magnet Ranging System: Long Distance Magnetic RangingDocument2 pagesRotating Magnet Ranging System: Long Distance Magnetic RangingHendri HaryantoNo ratings yet

- Complete The Following Equation: Exercise 3.2 Balancing Nuclear ReactionsDocument2 pagesComplete The Following Equation: Exercise 3.2 Balancing Nuclear ReactionsRinalyn AsuncionNo ratings yet

- Caustic Soda Evaporator PDFDocument2 pagesCaustic Soda Evaporator PDFwitker2008No ratings yet

- Body Composition and Optimal HealthDocument2 pagesBody Composition and Optimal HealthcjgeeNo ratings yet

- Present Panchayati Raj SystemDocument2 pagesPresent Panchayati Raj SystemArundeep sidhuNo ratings yet

- Besar Grinding OrtoDocument5 pagesBesar Grinding OrtoBramita Beta ArnandaNo ratings yet

- Hospital List For Ayushman Bharat YojnaDocument6 pagesHospital List For Ayushman Bharat Yojnadadan vishwakarma100% (1)

- Detailed List of Items Exempted From Value Added Tax 9701Document21 pagesDetailed List of Items Exempted From Value Added Tax 9701Guitar SubashNo ratings yet

- Catalogue - Sunclean LightingDocument33 pagesCatalogue - Sunclean LightingJ Alberto GiglioNo ratings yet

- KFCDocument38 pagesKFCArchit Katoch100% (1)

- 1.fundamentals of nutrition-BHMDocument47 pages1.fundamentals of nutrition-BHMBakhtawarNo ratings yet

- NCM 114 Care of Older AdultsDocument47 pagesNCM 114 Care of Older Adultsbrilliant dumayNo ratings yet

- Core Acceptance - Injection PumpDocument9 pagesCore Acceptance - Injection PumpGersonNo ratings yet

- History of NarraDocument4 pagesHistory of NarraArmand Caleb Delos ReyesNo ratings yet

- Prescolite Panorama Outdoor Lighting Catalog P-1 1966Document20 pagesPrescolite Panorama Outdoor Lighting Catalog P-1 1966Alan MastersNo ratings yet

- Fisiologi Sistem Pencernaan: Kristanti, DRDocument64 pagesFisiologi Sistem Pencernaan: Kristanti, DRFeny Maharani100% (1)

- 9990 Scheme of Work (For Examination From 2020)Document96 pages9990 Scheme of Work (For Examination From 2020)AyaNo ratings yet

- Asma Khan Saffron Chicken Korma With Indian Flatbreads Recipe - BBC FoodDocument3 pagesAsma Khan Saffron Chicken Korma With Indian Flatbreads Recipe - BBC FoodbohemianNo ratings yet

- SCMHRD SM-1Document43 pagesSCMHRD SM-1ShivanirahejaNo ratings yet

- Grouting in Difficult DamDocument68 pagesGrouting in Difficult DamTam Eng Sun67% (3)

- Design and Implementation of Seeding Agricultural RobotDocument6 pagesDesign and Implementation of Seeding Agricultural RobotKathir Vel100% (1)

- Analy Food Colour Uv-VisDocument13 pagesAnaly Food Colour Uv-VisNoor Zarif100% (1)

- Introduction Part Assessment 2Document27 pagesIntroduction Part Assessment 2SagarNo ratings yet

- OCHEM Practice FinalDocument24 pagesOCHEM Practice FinalNoleNo ratings yet

- Software Project Management (Unit 9) PDFDocument56 pagesSoftware Project Management (Unit 9) PDFIshan TimilsinaNo ratings yet

- Excel FormatDocument38 pagesExcel FormatSaad QureshiNo ratings yet

- Safety Valves For Industrial ApplicationDocument164 pagesSafety Valves For Industrial ApplicationJOHNNo ratings yet

- SKB Racking BrochureDocument22 pagesSKB Racking BrochureMuhammad Ibad AlamNo ratings yet