Professional Documents

Culture Documents

Valve Seat Selection

Uploaded by

Pamela Coleman0 ratings0% found this document useful (0 votes)

8 views4 pagesBy Flowcontrols

Copyright

© © All Rights Reserved

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document0 ratings0% found this document useful (0 votes)

8 views4 pagesValve Seat Selection

Uploaded by

Pamela ColemanYou are on page 1of 4

Special Section: Valves & Actuators

Valve stem seal selection criteria

Consider service specifications, bonnet design and more.

By K.S. Patil, Jaisingh Jadhav & Ram Viswanathan, LAT Valves

tion fits all” approach exists when

it comes to sealing technology.

Selection depends on a myriad of fac:

tors such as the media to which the

seals are exposed, temperature, pros-

sure and the leakage tightness required.

In a process plant, several failure modes

for valves are possible, including bonnet

and flange leaks and leaks through the

seat, but 77 percent of them are caused

by stem packing leaks.* Therefore, valve

sealing solutions must be tailored to

meet the specific application require-

ments. The solutions can range from

selecting the right vahe type and cus:

tomizing bonnet design to installing the

valve in a specific onentation

L the world of valves, no “one solu-

Valve seal selection criteria

Service-specific selection

Fugitive emission service — “Fugitive

emission” can be defined as a chemical

(or mixture of chemicals, in any physical

fot, which represents an unanticipated

or spurious leak from equipment on an

industrial site and can be broadly classi

fied as a volatile organic compound and

hazardous air pollutant. The American

Petroleum Institute's API 622 is the

‘ype test standard for qualifying process

valve packing for fugitive emissions,

Many valve type test standards exist

for fugitive emissions such as API 624,

API 641 and ISO 15848-1, These stan-

dards specify the performance criteria

for the vave qualified such as number

‘of mechanical cycles, thermal cycles,

temperature and pressure and leakage

tightness achieved,

Hydrogen service — Hydrogen is an

nstablled and combustible gas often

used in combination with other hydro-

carbons. Any media containing hydro-

gen gas with @ partial pressure of 7

Ber and above will be considered as

hydrogen service. Because hydrogen

is very permeable, hybrid packings are

preferred with live-loading. Reducing

leakage by impregnating graphite with

polytetrafluoroethylene (PTFE) is unac-

ceptable since PTFE can evaporate in a

fire with disastrous result.

‘Steam service — Valves used in com-

bined cycle and supercritical power

plants pose unique challenges to the

stem seal selection. Combined cycle

power plants involve high temperatures,

high pressures, high Delta Ps and fre-

quent “cycling” of valves because of

load variations for plants that are not

purely base-load plants. In coal-based

power plants, plants operating above 24

millipascals (mPa) (3,480 psi/S93°C

(2,100°F) are regarded as ultra-super-

critical (USC), and those operating

below 24 mPa (3,480 psi) as sub-

critical” For these applications, graphite

packings without PTFE and binders are

‘most suitable, These graphite packings

could also have an oxidation inhibitor

‘and, optionally, be live-loaded to com-

ppensate for frequent thermal cycling.

wth heat

eae rie

reel

kage class

100 ppm

Methane

Table 1 Fugitive emisions standar

Oxygen service — When designing a

valve for oxygen senice, itis important

to identify potential sources of ignition

and the factors that aggravate propaga-

tion because all three elements — oxy-

gen, fuel and heat (source of ignition)

— are required to start and propagate

a fire. AS nonmetals forn an important

Partin the kindling chain in an oxygen

system, gland packings and other non-

metalic seals are chosen for design

temperature-pressure conditions based

on tests conducted for autogenous igni-

tion temperature, aging resistance, igni-

tion sensitvty to gaseous omygen and

liguid oxygen impacts.

‘Temperature & pressure

As per API RP 615,* high-temperature

service is typically defined as a service

with a temperature higher than 205°C

(400'F) for soft-seated valves and

400°C (750°F) for metal-seated valves.

Low-temperature service is generally

defined in the process industry as ser-

Vices that range from -196°C (-320°F)

to -30°C (-21°F). These services include

liquefied natural gas liquefaction and

gasification, natural gas liquid produc-

tion and ethylene production. While

temperature determines the thresholds

for the use of nonmetals/metals as

seals, pressure determines the perme-

ability and extrusion behavior of seals

over time. Graphite packings are rei

forced with Inconel to ge the biowout

proof strength.

Leakage tightness.

Extemal leakage tightness can either be

expressed in parts per million (ppm) or

flow rate. Different standards specify

leak tightness for valves. API 624 and

APL 644 are standards for 100 ppm

{ugttive emissions for rising and rotating

er ers

100 ppm

Methane

50, 100, 500 pom (Methane)

Glass AH, BH, CH (Holi)

stem valves, respectively. ISO 15848

has methane and helium leakage class-

es and can be extended to isolation and

control valves. Valve stem seal selec-

tion depends on whether the intended

leakage class is Class AH, BH or CH.

Ina rising stem valve, Class AH would

require a metal bellows while Class BH

Would require a live-loaded low fugitive

emissions packing.

Customized bonnet

designs

Extended bonnet design

For lower or higher temperature ser-

vices, the bonnet arrangemenvinstal-

lation could be changed to ensure that

conventional graphite packing system

works for the desired temperature and

pressure. The heat dissipation length

has two functions: to clear the lagging

and to have sufficient length outside

the lagging to dissipate the heat so

the graphite-packing skin temperature

remains in an operable range.

Extended bonnet lengths for low tem-

perature are covered in standards such

as BS 6364 and MSS SP-134 that

address low-temperature/cryogenic

applications. Shell MESC SPE 77/212

'S a specification that covers “valves in

high-temperature senices.” This speci-

fication suggests that for vahes for

temperatures above 450°C (842°F) the

length of the extension shall be suf-

ficient to maintain the stem packing

at a temperature less than or equal to

400°C (750°F) to minimize the potential

{or the oxidization of graphite, which can

affect the valve's performance.

Other bonnet arrangements

* A lantem ring could be used in

conjunction with compression

packings for cooling the packing or

acting as an injection chamber for

a sealant or as a water sealing con-

nection for vacuum service.

Jacketed valves can be installed for

cooling or heating. When a cooling

medium is circulated, the jacketing

is concentrated around the bon-

net so the packing temperature is

reduced sufficiently.

In high-temperature services, it can

be effective to install the bonnet

below the vate. If the bonnet is

below the valve, no convection

‘occurs and the heat from process

fluid is transferred by conduction in

‘the bonnet wall only.

Special cooling arrangements such

as a stem cooling arrangement

‘could be used where liquid sodium

or water can be used to cool the

valve stem and consequently the

sealing system.

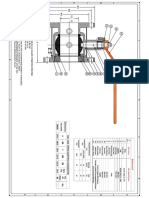

Bellows-sealed gate & globe valve

A bellows-sealed valve Is designed with

‘a metal bellows that expands or con-

tracts with the linear stroke of the valve

while providing a solid, permanent bar-

rier between the fluid medium in the

body and any potential leak paths to

the atmosphere. The purpose of a bel-

lows seal is to provide @ metal bartier

botween the stom at its point of entry

through the pressure boundary and the

process fluid within the valve to elimi-

nate stem leakage,

Alternate & complementary

sealing materials

‘At present, graphite is a popular packing,

material for all general sealing applica-

tions in the form of gasket and packing

rings. The service temperature limit of

‘graphite packing rings has precluded

its application for high-temperature ser-

Vices above 450°C (842°F) in oxidizing

‘atmospheres. Conventionally in such

high-temperature applications, bonnet

extensions are provided in valves that

ensure the temperature at the packing,

remains below 450°C (842°F). However,

the use of bonnet extensions becomes

prohibitive in some cases where end

Users want compact piping layouts.

The packing material/configuration

selected would have to be stable at high

temperatures without any deterioration

jn the chemical properties and still

achieve sealabilty at elevated tempera-

‘tures. Following are the sealing mate-

fials considered for high-temperature

applications:

* High-purity graphite (greater than 29

percent) with oxidation inhibitor

‘can be used at temperatures up to

550°C (1,022 °F).

+ Packings made from Vermiculte, @

natural mineral that expands with

the application of heat, are resis-

tant to temperatures up to 1,050°C

(1,922°F) but are hygroscopic in

ature.

+ Packings made from silica fibers are

resistant to high temperature and

pressure, but silica packings tend to

hharden at high temperatures.

* Glass wool-based packings are

Co —

Ceara

Ball, Plug, Sutertly

Thermoplat

Table 2. amples of multbarier seals in ves

porous but resistant to tempera-

tures up to 1,000°C (1,832°F).

+ Mica-based packings can be used at

temperatures up to 1,000°C

(,832°P, are panty hygroscopic and

Can be used for wv pressures only.

Spring-energized metal seals made from

Inconel can work up to 700°C

(1,292°F), though the finish and hard

ness requirements of the stuffing

ox and stem could be demanding.

Se sar ne

Ce

+ graphite packing

Pe

lip seal + graphite packing

od

‘Multibarrier seals

In valves, the concept of independent

sealing barriers has been in use for a

long time. Primary and secondary stem

seals were first used in plug valves and

later in ball valves where the primary

seal is responsible for leak tightness

while the secondary seal is merely a fre-

safe seal when used in process applica-

tions. However, with the demands for

Jow-emission valves, or Low-E valves,

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- List of HSN CODE Used in Valve IndustryDocument1 pageList of HSN CODE Used in Valve IndustryPamela ColemanNo ratings yet

- IqaDocument3 pagesIqaPamela ColemanNo ratings yet

- Tc-Er410 Tig 127Document1 pageTc-Er410 Tig 127Pamela ColemanNo ratings yet

- GA BAll Valve JackettedDocument1 pageGA BAll Valve JackettedPamela ColemanNo ratings yet

- Manual Overlay WeldingDocument8 pagesManual Overlay Weldingcarlmac6183% (6)

- Comparison: Venturi Vs TD TrapDocument1 pageComparison: Venturi Vs TD TrapPamela ColemanNo ratings yet

- Neweacideplant Neweasteamldistributionlnetwork For: Client Rayalseemalhi-Strengthnhypowlimited-KurnoolDocument1 pageNeweacideplant Neweasteamldistributionlnetwork For: Client Rayalseemalhi-Strengthnhypowlimited-KurnoolPamela ColemanNo ratings yet

- Thrust Bearing DimensionsDocument8 pagesThrust Bearing DimensionsPamela ColemanNo ratings yet

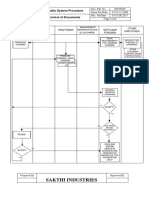

- Control of Documents-Flow ProcessDocument1 pageControl of Documents-Flow ProcessPamela ColemanNo ratings yet

- 1 12 1Document7 pages1 12 1Chandrasekhar SonarNo ratings yet

- Flange Bolting Guide PDFDocument12 pagesFlange Bolting Guide PDFPamela ColemanNo ratings yet

- 1 12 1Document7 pages1 12 1Chandrasekhar SonarNo ratings yet

- Float ValveDocument1 pageFloat ValvePamela ColemanNo ratings yet

- BLV Seat 15mm Ptfe DesignDocument1 pageBLV Seat 15mm Ptfe DesignPamela ColemanNo ratings yet

- 3 Piece Design Triclover End Ball ValveDocument1 page3 Piece Design Triclover End Ball ValvePamela ColemanNo ratings yet

- En 10204-2004 Metallic Products - Types of Inspection DocumentsDocument10 pagesEn 10204-2004 Metallic Products - Types of Inspection DocumentsDalamagas KwnstantinosNo ratings yet

- Design Trends Globe Valve Upload VersionDocument11 pagesDesign Trends Globe Valve Upload Versionvijay_gnanaNo ratings yet

- Machining Symbol 1Document8 pagesMachining Symbol 1Prasanna RajaNo ratings yet

- Air Vent ValvesDocument1 pageAir Vent ValvesPamela ColemanNo ratings yet

- Valve Size ManualDocument43 pagesValve Size Manualarthur_toafkNo ratings yet

- Computational Study of Poppet Valves On Flow FieldsDocument103 pagesComputational Study of Poppet Valves On Flow FieldsPamela ColemanNo ratings yet

- PTFE SpecificationsDocument1 pagePTFE SpecificationsPamela ColemanNo ratings yet

- Dimensional Tolerance ChartDocument1 pageDimensional Tolerance Chartpushkar_k123No ratings yet

- Valve Material EquivalentsDocument3 pagesValve Material EquivalentsAndre Villegas Romero100% (1)

- Final Inspection ProcedureDocument1 pageFinal Inspection ProcedurePamela ColemanNo ratings yet

- P&ID SymbolDocument18 pagesP&ID SymbolBagus Okti100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)