Professional Documents

Culture Documents

1.sieve Analysis of Fine Aggregates

Uploaded by

Rahul SharmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.sieve Analysis of Fine Aggregates

Uploaded by

Rahul SharmaCopyright:

Available Formats

EXPERIMENT NO: -

Date:

TITLE: Sieve analysis of coarse aggregates.

AIM: To find fineness modulus of the course aggregates by sieve analysis.

APPARATUS: Sieve of various sizes 20 mm, 10 mm, 4.75 mm, 2.36 mm, sieve brush ,

trays, balance of 5 gm sensitivity, weights etc.

THEORY: The sieve analysis of coarse aggregates may be done by standard sizes of sieve

20 mm, 10 mm, 4.75 mm, 2.36 mm. Sieve analysis consists of shaking the aggregate sample

through a set of sieve. The percentage of aggregate retained on each sieve and therefore

percentage finer than any other particle sizes are found and grain size distribution curve for

the aggregates are drawn on the graph. It helps in predicting if the aggregate mix is well

graded or poorly graded.

Fineness Modulus: The fineness modulus is the numerical index of fineness giving some

idea about mean size of particles present in the entire mix of aggregates. The fineness

modulus can be regarded as weighted average size of sieve on which material is retained.

PROCEDURE: Sieve of different sizes are taken and cleaned. About 5 kg of the given

sample is taken. It was sieved through the sieves of 20 mm, 10 mm, 4.75 mm, 2.36 mm.

Weigh the weight of aggregates retained on each sieve.

FORMULA: Fineness modulus of coarse aggregate = total cumulative % weight retained/

100

OBSERVATION AND CALCULATIONS

Weight of sample of aggregate =

Sieve size in Weight retained % Weight Cumulative % weight % Weight

mm in grams retained retained passing

40

20

10

4.75

2.36

1.18

600 microns

300 microns

150 microns

Total

CALCULATION:

Fineness Modulus =

GRAPH: Draw the particle size distribution/ gradation curve on semi log graph paper taking

sieve size on X-axis and % passing on Y- axis.

RESULT: Fineness modulus of the course aggregates was found to be=

CONCLUSION:

PRECAUTIONS

1. No aggregates should be pushed through the sieve opening.

2. No aggregate should be lost during sieving.

3. The aggregate should be dry.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- List of OC-HM Courses W-2017Document1 pageList of OC-HM Courses W-2017Rahul SharmaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hostel Fees 2017-18Document2 pagesHostel Fees 2017-18Rahul SharmaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

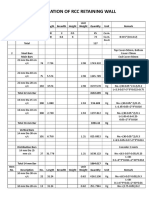

- Estimation of RCC Retaining WallDocument2 pagesEstimation of RCC Retaining WallRahul SharmaNo ratings yet

- Envo Sess 2 Notes.Document11 pagesEnvo Sess 2 Notes.Rahul SharmaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Survey2 Sess2 PDFDocument59 pagesSurvey2 Sess2 PDFRahul SharmaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Event Meets Apr 2017-Week 2Document3 pagesEvent Meets Apr 2017-Week 2Rahul SharmaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Winter 2017 Fees Notice ACADDocument1 pageWinter 2017 Fees Notice ACADRahul SharmaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Concrete Lecture 7Document88 pagesConcrete Lecture 7Rahul SharmaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Event Meetings Schedule: Date Time Events Venue ContactDocument3 pagesEvent Meetings Schedule: Date Time Events Venue ContactRahul SharmaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- FM Open ChannelDocument62 pagesFM Open ChannelRahul SharmaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Testing of AggregatesDocument22 pagesTesting of AggregatesRahul SharmaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Airport Engineering - 2 - Runway Length and Its OrientationDocument40 pagesAirport Engineering - 2 - Runway Length and Its Orientationraghav VarmaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Airport Engineering - 2b - Wind Rose and Runway LengthDocument20 pagesAirport Engineering - 2b - Wind Rose and Runway LengthRahul SharmaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Concrete Lecture 6Document10 pagesConcrete Lecture 6Rahul SharmaNo ratings yet

- 11.initial and Final Setting TimeDocument2 pages11.initial and Final Setting TimeRahul SharmaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Compacting Factor TestDocument3 pagesCompacting Factor TestRahul SharmaNo ratings yet

- 11.initial and Final Setting TimeDocument2 pages11.initial and Final Setting TimeRahul SharmaNo ratings yet

- Grades of Concrete: Group Ordinary Concrete Standard Concrete High Strength ConcreteDocument16 pagesGrades of Concrete: Group Ordinary Concrete Standard Concrete High Strength ConcreteRahul SharmaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- 9.strength Test On Cement Sand Mortar CubesDocument3 pages9.strength Test On Cement Sand Mortar CubesRahul SharmaNo ratings yet

- Compacting Factor TestDocument3 pagesCompacting Factor TestRahul SharmaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- 5.fineness of CementDocument2 pages5.fineness of CementRahul Sharma100% (1)

- 9.strength Test On Cement Sand Mortar CubesDocument3 pages9.strength Test On Cement Sand Mortar CubesRahul SharmaNo ratings yet

- 4.bulk Density of AggregatesDocument3 pages4.bulk Density of AggregatesRahul SharmaNo ratings yet

- Experiment No:: Date: TITLE: Soundness Test On Cement. AIM: To Verify The Soundness of Given Sample of Cement. TheoryDocument2 pagesExperiment No:: Date: TITLE: Soundness Test On Cement. AIM: To Verify The Soundness of Given Sample of Cement. TheoryRahul SharmaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 7.specific Gravity and Water AbsorptionDocument4 pages7.specific Gravity and Water AbsorptionRahul Sharma50% (2)

- 8.standard ConsistencyDocument2 pages8.standard ConsistencyRahul SharmaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)