Professional Documents

Culture Documents

Klinger Gasket Factors

Uploaded by

George TanasescuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Klinger Gasket Factors

Uploaded by

George TanasescuCopyright:

Available Formats

KLINGER® GASKET FACTORS trusted. worldwide.

Fibre Reinforced Gasket Materials

DIN 28090/DIN 28091 ASME ELECTRICAL AND THERMAL FACTORS

Average

Average Average Average Average

Thick- specific Thermal

σVO σVu/0.1 σBO (7.2.2) surface dielectric power dielectric

ness volume conductivity

resistance strength factor coefficient

resistance

mm MPa MPa MPa MPa MPa MPa "m" "y" stress ρO ρD ΕD 50 Hz 50 Hz λ

25 °C 25 °C 50 °C 100 °C 200 °C 300 °C factor MPa Ω Ω cm kV/mm tan δ εr W/mK

KLINGERSIL® C-4300 1.0 200 15 151 79 45 - 1.3 15 - - - - - -

2.0 200 18 69 45 34 - 3.0 15 2.2x10E12 1.2x10E12 10.0 0.082 7.4 0.39

3.0 61 20 48 35 22 - 4.0 15 - - - - - -

KLINGERSIL® C-4324 1.0 200 12 189 64 40 - 2.2 15 - - - - - -

2.0 200 14 60 38 29 - 2.6 15 1.0x10E13 4.3x10E11 12.0 0.109 9.0 0.50

3.0 60 20 34 25 21 - 4.1 15 - - - - - -

KLINGERSIL C-4400

®

1.0 200 18 195 95 50 38 1.2 15 - - - - - -

2.0 200 23 110 80 42 30 1.6 15 1.4x10E12 1.2x10E12 21.6 0.131 9.2 0.42

3.0 63 24 53 41 24 - 4.0 15 - - - - - -

KLINGERSIL C-4409

®

1.0 240 39 215 176 120 80 3.0 30 - - - - - -

2.0 230 43 110 80 42 30 3.2 30 - - - - - -

3.0 - - - - - - 3.8 30 - - - - - -

KLINGERSIL® C-4430 1.0 >240 22 >240 145 81 65 1.1 20 - - - - - -

2.0 200 29 200 120 73 56 1.6 20 4.1x10E13 4.5x10E12 21.3 0.030 6.7 0.38

3.0 133 29 97 65 40 31 2.2 20 - - - - - -

KLINGERSIL C-4430 plus

®

1.0 >240 22 >240 145 81 65 1.1 20 - - - - - -

2.0 230 29 230 120 73 56 1.6 20 4.1x10E13 4.5x10E12 21.3 0.030 6.7 0.38

3.0 133 29 97 65 40 31 2.2 20 - - - - - -

KLINGERSIL C-4500

®

1.0 220 23 195 120 68 51 1.0 20 - - - - - -

2.0 180 26 110 110 59 43 1.6 20 n.a. 8.0x10E04 n.a. n.a. n.a. 0.43

3.0 100 28 80 55 33 23 2.0 20 - - - - - -

KLINGER® GASKET FACTORS trusted. worldwide.

Fibre Reinforced Gasket Materials

DIN 28090/DIN 28091 ASME ELECTRICAL AND THERMAL FACTORS

Average

Average Average Average Average

Thick- specific Thermal

σVO σVu/0.1 σBO (7.2.2) surface dielectric power dielectric

ness volume conductivity

resistance strength factor coefficient

resistance

mm MPa MPa MPa MPa MPa MPa "m" "y" stress ρO ρD ΕD 50 Hz 50 Hz λ

25 °C 25 °C 50 °C 100 °C 200 °C 300 °C factor MPa Ω Ω cm kV/mm tan δ εr W/mK

KLINGERSIL® C-4509 1.0 >240 24 195 140 120 97 3.1 30 - - - - - -

2.0 180 28 110 110 59 43 4.4 30 - - - - - -

3.0 - - - - - - 6.0 30 - - - - - -

KLINGERSIL C-8200

®

1.0 225 17 160 70 44 - 2.1 20 - - - - - -

2.0 150 19 110 53 34 - 3.0 20 5.8x10E11 4.1x10E12 17.0 0.228 9.4 -

3.0 75 21 55 26 17 - 6.2 20 - - - - - -

KLINGER Quantum

®

1.0 230 19 120 86 62 48 1.1 15 - - - - - -

2.0 158 22 68 56 39 32 2.5 15 7.7x10E12 4.7x10E12 18.5 0.064 6.8 0.44

3.0 130 25 55 42 33 27 3.8 15 - - - - - -

KLINGER top-sil ML1

®

1.0 >240 16 240 150 70 55 1.5 15 - - - - - -

2.0 160 21 150 80 60 50 2.2 15 9.3x10E12 3.8x10E12 18.8 0.048 7.3 0.36

3.0 150 23 110 70 50 30 4.0 15 - - - - - -

KLINGER top-graph 2000

®

1.0 - - - - - - 2.4 20 - - - - - -

2.0 >160 25 120 80 70 60 4.2 20 n.a. 6.7x10E3 n.a. n.a. n.a. 0.69

3.0 - - - - - - 6.7 20 - - - - - -

KLINGER CompenSil

®

1.0 230 9 125 55 36 - 1.0 10 - - - - - -

2.0 95 13 43 28 18 - 2.9 10 - - - - - -

3.0 70 15 30 25 17 - 3.3 10 - - - - - -

KLINGER® GASKET FACTORS trusted. worldwide.

PTFE Gasket materials

DIN 28090/DIN 28091 ASME ELECTRICAL AND THERMAL FACTORS

Average

Average Average Average Average

Thick- specific Thermal

σVO σVu/0.1 σBO (7.2.2) surface dielectric power dielectric

ness volume conductivity

resistance strength factor coefficient

resistance

mm MPa MPa MPa MPa MPa MPa "m" "y" stress ρO ρD ΕD 50 Hz 50 Hz λ

25 °C 25 °C 50 °C 100 °C 200 °C 250 °C factor MPa Ω Ω cm kV/mm tan δ εr W/mK

KLINGER®top-chem 2000 1.0 - - - - - - 2.8 12 - - - - - -

2.0 200 21 185 150 125 50 3.2 15 6.9x10E12 2.2x10E12 3.6 0.166 10.6 0.60

3.0 - - - - - - 3.8 18 - - - - - -

KLINGER®top-chem 2003 1.0 - - - - - - 2.0 8 - - - - - -

2.0 80 13 60 28 15 10 2.7 8 9.0x10E12 2.6x10E12 16.7 0.085 2.8 0.18

3.0 - - - - - - 3.6 10 - - - - - -

KLINGER top-chem 2005

®

1.0 - - - - - - 2.2 10 - - - - - -

2.0 100 28 50 35 20 15 2.8 12 3.1x10E13 3.2x10E13 23.8 0.071 3.2 0.42

3.0 - - - - - - 3.8 12 - - - - - -

KLINGER top-chem 2006

®

1.0 - - - - - - 2.0 12 - - - - - -

2.0 60 10 50 39 25 12 3.1 12 1.0x10E13 1.2x10E13 16.7 0.083 4.2 0.40

3.0 - - - - - - 3.8 15 - - - - - -

KLINGER®top-chem 2000soft 1.0 - - - - - - - - - - - - - -

2.0 200 21 149 113 68 49 2.6 15 - - - - - -

3.0 - - - - - - - - - - - - - -

In general gasket factors provide indicators for the performance of gasket materials for several aspects of physical properties. Above given chart summarizes some of the most common factors

used in sealing technology. Figures given as for σVu indicate minimum required gasket stress to achieve a tightness level of 0.1 [mg/s*m] at an internal pressure of 40bar nitrogen for room temperature.

The columns σVO and σBO show the maximum surface pressure with which the gasket material may be loaded, depending on the operating temperature and thickness of the gasket. In contrast to Qsmax

according to EN 13555, the surface pressures specified here are based on a maximum permissible reduction in thickness. The above given m and y factors are related to a tightness level of 0.1 [mg/s*m].

The test is carried out at ambient temperature and nitrogen is being used as the test media.

You might also like

- APC materials piezoelectric propertiesDocument1 pageAPC materials piezoelectric propertiesnamyefNo ratings yet

- Description and Application: 100%CO /80%ar - 20%CO EN ISO 17632-A-T 46 3 P C/M 1 H5 AWS A5.20 E71T-1C/1M,-9C/9MDocument1 pageDescription and Application: 100%CO /80%ar - 20%CO EN ISO 17632-A-T 46 3 P C/M 1 H5 AWS A5.20 E71T-1C/1M,-9C/9Mamit singhNo ratings yet

- SBCW 12311Document5 pagesSBCW 12311Johnrenald SuelloNo ratings yet

- Physical and Piezoelectric Properties of APC Materials ChartDocument2 pagesPhysical and Piezoelectric Properties of APC Materials ChartTrương Anh DuyNo ratings yet

- Tds - Macgrid BiaxialDocument1 pageTds - Macgrid BiaxialLiliana Ribeiro100% (2)

- Geodren PEITDocument1 pageGeodren PEITMikolajBojarskiNo ratings yet

- Dichtungskennwerte e PDFDocument3 pagesDichtungskennwerte e PDFАндрей ИнгельбергNo ratings yet

- Cold-Rolled Steel CoilsDocument28 pagesCold-Rolled Steel CoilsX800XLNo ratings yet

- Gasket Factors: KlingersilDocument3 pagesGasket Factors: KlingersilsNo ratings yet

- Moldex PVC-U Pressure Mains Pipes and Fittings for Potable Water SystemsDocument2 pagesMoldex PVC-U Pressure Mains Pipes and Fittings for Potable Water SystemsJim Paul MendozaNo ratings yet

- TDS - Nimrod C276KSDocument1 pageTDS - Nimrod C276KSImmalatulhusnaNo ratings yet

- Metso Dust Hood DetailsDocument9 pagesMetso Dust Hood DetailsmbaalaajeNo ratings yet

- Sarafil CFL101 Grade Clear Polyester Film Is Designed As Base Film For High Clarity Industrial Applications LikeDocument2 pagesSarafil CFL101 Grade Clear Polyester Film Is Designed As Base Film For High Clarity Industrial Applications LikeJay AhmadNo ratings yet

- Nema Contactor SizeDocument8 pagesNema Contactor SizeSubrat DasNo ratings yet

- Clasificación NEMA-IEC-ControlDocument1 pageClasificación NEMA-IEC-ControlAlejandro TrejoNo ratings yet

- Datasheet Nema23Document1 pageDatasheet Nema23Juan De La TorreNo ratings yet

- Shear Box Test ASTM D3080: R e Sults Summa RyDocument2 pagesShear Box Test ASTM D3080: R e Sults Summa Rywafikmh4No ratings yet

- EDS Heavy Duty Disconnect SwitchDocument2 pagesEDS Heavy Duty Disconnect SwitchMuhamad PriyatnaNo ratings yet

- DBEC DATA Sheet SpecificationsDocument1 pageDBEC DATA Sheet SpecificationsMohd FarhanNo ratings yet

- Manufacturing tolerances for moulded and extruded rubberDocument1 pageManufacturing tolerances for moulded and extruded rubberStephenNo ratings yet

- MMDX SMMDX Series-1661233Document12 pagesMMDX SMMDX Series-1661233Pușcă MartinNo ratings yet

- Technical Data Sheet Nonwoven Polyester (Pet) : Pt. Hilon IndonesiaDocument2 pagesTechnical Data Sheet Nonwoven Polyester (Pet) : Pt. Hilon IndonesiaG Nurhidayat ANo ratings yet

- M4II Family Operation Manual SpanishDocument1 pageM4II Family Operation Manual SpanishLanco SANo ratings yet

- 40W Single Output Industrial DIN Rail Power Supply: SeriesDocument3 pages40W Single Output Industrial DIN Rail Power Supply: Seriesanand sundharNo ratings yet

- CW603NDocument1 pageCW603NPatrik RingdahlNo ratings yet

- MMDX - SMMDX SeriesDocument11 pagesMMDX - SMMDX SeriesPușcă MartinNo ratings yet

- 1.4466 (310L Ug)Document4 pages1.4466 (310L Ug)ramramjeyNo ratings yet

- Klinger - Gasket FactorsDocument1 pageKlinger - Gasket FactorsAnonymous q2HC0zyfa2No ratings yet

- TCC15 Resistance of Retaining Members XLDocument8 pagesTCC15 Resistance of Retaining Members XLalexanderNo ratings yet

- Classification: AWS A5.22 E310T0-1 AWS A5.22 E310T0-4: All-Weld-Metal (100%CO) 1-1. Chemical CompositionDocument2 pagesClassification: AWS A5.22 E310T0-1 AWS A5.22 E310T0-4: All-Weld-Metal (100%CO) 1-1. Chemical Compositionmohamed AdelNo ratings yet

- Description and Application: 80%ar - 20%CO / 100%CO EN ISO 17633-A T 19 9 L P C1/M21 1 AWS A5.22 E308LT1-1/4 EN 1.4316Document1 pageDescription and Application: 80%ar - 20%CO / 100%CO EN ISO 17633-A T 19 9 L P C1/M21 1 AWS A5.22 E308LT1-1/4 EN 1.4316amit singhNo ratings yet

- AUTODESK STRUCTURAL BRIDGE DESIGN PROGRAM VerificationDocument12 pagesAUTODESK STRUCTURAL BRIDGE DESIGN PROGRAM VerificationMohammed Haitham ElShafieNo ratings yet

- 02 Wear ChartDocument2 pages02 Wear ChartRIAN NOFENDRINo ratings yet

- Weldclad WLDC 3Document1 pageWeldclad WLDC 3furiousgaulNo ratings yet

- Indreptar Pentru Calcule HidrauliceDocument2 pagesIndreptar Pentru Calcule HidrauliceIon MateiNo ratings yet

- Design D and DA Control ValvesDocument12 pagesDesign D and DA Control Valvesluis rodriguezNo ratings yet

- Air Duct Sizing - SI & Imperial UnitsDocument4 pagesAir Duct Sizing - SI & Imperial UnitsDarshan Patel100% (1)

- 1vap428831-Db SCBDocument4 pages1vap428831-Db SCBHoon MiewJieNo ratings yet

- Geotextiles Technical SpecificationsDocument2 pagesGeotextiles Technical SpecificationsElber Ramiro Olivares BareñoNo ratings yet

- Chromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelDocument2 pagesChromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelVVan TanNo ratings yet

- 1.0SMB SeriesDocument6 pages1.0SMB SeriesPablo AllosiaNo ratings yet

- Series: Brushless DC Fans & BlowersDocument5 pagesSeries: Brushless DC Fans & BlowersDawood AhmedNo ratings yet

- Fibertex Geotextiles: Product Data SheetDocument2 pagesFibertex Geotextiles: Product Data Sheetmanuel agostinhoNo ratings yet

- CLC 17-12-2ti: A Ti Stabilized 18Cr-11Ni-2Mo Austenitic Stainless Steel (316ti Grade)Document4 pagesCLC 17-12-2ti: A Ti Stabilized 18Cr-11Ni-2Mo Austenitic Stainless Steel (316ti Grade)PeterWayNo ratings yet

- MLV Telecom Series: SMD VaristorsDocument5 pagesMLV Telecom Series: SMD VaristorsIgor PNo ratings yet

- CLC 17-13-5LN - High corrosion resistant austenitic stainless steelDocument4 pagesCLC 17-13-5LN - High corrosion resistant austenitic stainless steelPeterWayNo ratings yet

- 1.0 EBSRAY EMVI CatalogDocument16 pages1.0 EBSRAY EMVI Catalogckyee88-1No ratings yet

- 无齿轮MDX26M: 1200公斤主轴静载无齿轮电机技术参数Document4 pages无齿轮MDX26M: 1200公斤主轴静载无齿轮电机技术参数Andres GonzalezNo ratings yet

- Specification: Constant Current Discharge Characteristics Unit:A (25, 77)Document2 pagesSpecification: Constant Current Discharge Characteristics Unit:A (25, 77)Dhani DmjNo ratings yet

- Ordering Details 25 A, AC-1/AC-7a, AC/DC Operated: EN25..N Installation Contactors - Manually/automatic OperatedDocument3 pagesOrdering Details 25 A, AC-1/AC-7a, AC/DC Operated: EN25..N Installation Contactors - Manually/automatic OperatedMohammed SaleemNo ratings yet

- Oemer DC Motors QCCDocument21 pagesOemer DC Motors QCCTroformasNo ratings yet

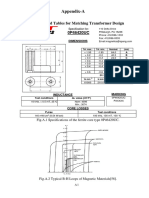

- Matching Transformer Design Specification and Core Loss DataDocument3 pagesMatching Transformer Design Specification and Core Loss DataNaeemo IraqiNo ratings yet

- Multiple Conditions Datasheet: Condition # 1 2 3 4 5 6 7 8Document2 pagesMultiple Conditions Datasheet: Condition # 1 2 3 4 5 6 7 8Guillermo GuzmánNo ratings yet

- Alloy 2319 welding data sheetDocument2 pagesAlloy 2319 welding data sheetSyam NathNo ratings yet

- Find Bare Copper Class 2 ConductorDocument1 pageFind Bare Copper Class 2 ConductorKmnzmnNo ratings yet

- Bare Copper Class 2 Conductor Bs en 13602Document1 pageBare Copper Class 2 Conductor Bs en 13602Hridya PradeepNo ratings yet

- Duct AcDocument4 pagesDuct Acjoelaloshius1212No ratings yet

- Maida Catalog Specifications Standard SeriesDocument16 pagesMaida Catalog Specifications Standard SeriesRetanaMaferNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- WHO Monographs On Selected Medicinal Plants3Document390 pagesWHO Monographs On Selected Medicinal Plants3George TanasescuNo ratings yet

- LK - Manual Smartcomfort-Pc3Document2 pagesLK - Manual Smartcomfort-Pc3George TanasescuNo ratings yet

- Readme !!! LeggimiDocument6 pagesReadme !!! LeggimiGeorge TanasescuNo ratings yet

- 1137 - Oferta Chiller TraneDocument3 pages1137 - Oferta Chiller TraneGeorge TanasescuNo ratings yet

- DSG 02e SSP - 308 PDFDocument64 pagesDSG 02e SSP - 308 PDFcataroxi100% (1)

- Flowserve Pump Division PresentationDocument20 pagesFlowserve Pump Division PresentationGeorge Tanasescu100% (1)

- CoalescerDocument18 pagesCoalescer112dharmesh0% (1)

- CoalescerDocument18 pagesCoalescer112dharmesh0% (1)

- Waste Heat Recovery Steam TurbinesDocument29 pagesWaste Heat Recovery Steam TurbinesGeorge TanasescuNo ratings yet

- Nicad Vs Lead Acid Batteries Tech BulletinDocument4 pagesNicad Vs Lead Acid Batteries Tech BulletinMuruganandhan DurairajNo ratings yet

- Heliyon: N.G. Mbewana-Ntshanka, M.J. Moloto, P.K. MubiayiDocument8 pagesHeliyon: N.G. Mbewana-Ntshanka, M.J. Moloto, P.K. MubiayijaiemNo ratings yet

- Lecture 2: Physical Operation of Diodes.: SiliconDocument10 pagesLecture 2: Physical Operation of Diodes.: Silicon9013227246No ratings yet

- PCA-Soil Cement Construction Handbook 1Document11 pagesPCA-Soil Cement Construction Handbook 1Carlos Guillermo Somoza AlvarengaNo ratings yet

- Torsional Shear StrengthDocument7 pagesTorsional Shear Strengthkc olidanNo ratings yet

- Department of Thermal Power Engineering: Visvesvaraya Technological UniversityDocument26 pagesDepartment of Thermal Power Engineering: Visvesvaraya Technological UniversityRaju SubediNo ratings yet

- ASTM E132-04 - V - Poisson's Ratio at Room Temperature1Document4 pagesASTM E132-04 - V - Poisson's Ratio at Room Temperature1Mehdi Gouader100% (1)

- Ansys 18.2: Transient Analysis On The BridgeDocument7 pagesAnsys 18.2: Transient Analysis On The BridgeUsman Khalil50% (2)

- سنوات سابقة خواصDocument64 pagesسنوات سابقة خواصmechanical depNo ratings yet

- Quantum Dot Laser Full ReportDocument38 pagesQuantum Dot Laser Full ReportRajeev Sndhr50% (2)

- ASTM D5528 - 2013 Fracture Toughness Mode IDocument13 pagesASTM D5528 - 2013 Fracture Toughness Mode IPablo OrtegaNo ratings yet

- Evaluation of AISI 4140 Steel Repair Without Post-WeldDocument8 pagesEvaluation of AISI 4140 Steel Repair Without Post-WeldVidaurriNo ratings yet

- Self Cleaning GlassDocument2 pagesSelf Cleaning GlassAnOnYmOuS_1995No ratings yet

- BeerMOM GE C07-P001-P169Document190 pagesBeerMOM GE C07-P001-P169Kaoru AmaneNo ratings yet

- Acetal (POM) Molding and Extrusion Materials: Standard Classification ForDocument9 pagesAcetal (POM) Molding and Extrusion Materials: Standard Classification ForraulNo ratings yet

- IES CONV Mechanical Engineering 1991Document7 pagesIES CONV Mechanical Engineering 1991GURURAJ CNo ratings yet

- Introduction To PolymerDocument9 pagesIntroduction To PolymerDr. Stan Wardel BA, MA, MChem, MBA, DPhil, DSc.No ratings yet

- Sustarinc ds2012Document2 pagesSustarinc ds2012Berno Muishond KohlmeyerNo ratings yet

- In Class Exercise CH 6 GlassDocument4 pagesIn Class Exercise CH 6 GlassPreethpalNo ratings yet

- Properties of Concrete For Use in Eurocode 2Document59 pagesProperties of Concrete For Use in Eurocode 2oqusousNo ratings yet

- Cells and BatteriesDocument3 pagesCells and BatteriesmelissaNo ratings yet

- Limit State of Collapse in ShearDocument21 pagesLimit State of Collapse in ShearNavi RengarajanNo ratings yet

- SLHT Sci 8 Q3 Wk3Document7 pagesSLHT Sci 8 Q3 Wk3Jim Alesther LapinaNo ratings yet

- Steel Making - Nptel PDFDocument214 pagesSteel Making - Nptel PDFanurag3069100% (3)

- Metal FormingDocument33 pagesMetal FormingSamir KhNo ratings yet

- Safely Design Thermal Fluid Heat Transfer SystemsDocument8 pagesSafely Design Thermal Fluid Heat Transfer SystemsGarry BernzNo ratings yet

- Essay Material SelectionDocument6 pagesEssay Material Selectionashams492No ratings yet

- Maharashtra State Board of Technical Education Mumbai. (M.S.)Document9 pagesMaharashtra State Board of Technical Education Mumbai. (M.S.)ythNo ratings yet

- Combined Footing NUNNA Bldg. R0Document6 pagesCombined Footing NUNNA Bldg. R0prabhat_iitdNo ratings yet

- 1-Heat & Temp - Set 1 - SolnDocument6 pages1-Heat & Temp - Set 1 - SolnBibhash SinghNo ratings yet

- Static and Dynamic Analysis of Storage Tanks Considering Soil-Structure InteractionDocument18 pagesStatic and Dynamic Analysis of Storage Tanks Considering Soil-Structure InteractionRashma JomoNo ratings yet