Professional Documents

Culture Documents

Knife Gate Valve: Product Description

Uploaded by

Tamil SelvanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Knife Gate Valve: Product Description

Uploaded by

Tamil SelvanCopyright:

Available Formats

ET KNIFE GATE VALVE

The ET model knife gate valve is a lug type valve designed according to MSS SP-81 and TAPPI TIS 405-8 for general

industrial service applications. The design of the body and seat assures nonclogging shut off on suspended solids in

industries such as Pulp & Paper, Power Plants, Mining, Chemical Plants, Wastewater Treatment Plants, Food &

Beverage, etc

Product description:

• Uni-directional lug type knife gate valve

• Size range of DN50-900 (larger sizes upon request). See Dimension Charts for pressure rating

• Rising stem as standard. Non-rising stem also available

• Standard flange connection: DIN PN10 (EN 1092-2) and ANSI B16.5 (class 150)

Others available upon request

• Manual (handwheel, chainwheel, lever and bevel gear), pneumatic (single and

double-acting), electric and hydraulic actuation options available

• Directives: 2006/42/EC (MACHINES), 2014/68/EU (PED) Fluid: Group 1(b), 2 (Cat. I. mod. A)

and 2014/34/EU (ATEX)

Features:

• Lug type one piece cast stainless steel body with internal cast-in gate wedges and guides

• Port design as per the MSS SP-81 and TAPPI TIS 405-8 standards

• Stainless steel gate polished both sides to avoid jamming and seat damage

• Standard EPDM resilient seat. Metal-to-metal seat, as well as high performance rings and

deflection cones available

• Long life PTFE impregnated synthetic fibre plus EPDM o-ring packing with easy access

and adjustable gland follower. Wide range of packing materials available

• RAL-5015 blue epoxy-coating on all cast iron/carbon steel components

• Automated valves provided with gate guards in accordance with EU Safety Standards

• Other options: bonnets, V-ports, flush ports, special materials, fabricated valves, etc.

• Actuation accessories: limit & proximity switches, mechanical stops, positioners, solenoid

valves, manual overrides, locking devices, fail safe systems, stem extensions and floor stands

STANDARD PARTS LIST

METAL - METAL

Part Stainless Steel:

1 Body CF8M

2 Gate AISI 316

3 Seat Metal/Metal, EPDM

4 Packing PTFE impreg. synth. fibre and EPDM o-ring

5 Gland Follower CF8M

RESILIENT TYPE "A"

6 Stem AISI 430

7 Stem Nut Brass

8 Yoke AISI 304 / Epoxy-coated carbon steel

9 Seat Retainer Ring AISI 316

10 Handwheel GJS400 (GGG40)

11 Cap Plastic

RESILIENT TYPE "B"

12 Stem Protector Epoxy-coated carbon steel

13 Friction Washer Brass

14 Nut Zinc-plated carbon steel

DEFLECTION CONE "C"

www.orbinox.com OBX Rev. 3 - 01/2018

Reserves the right to change specifications without notice

ET KNIFE GATE VALVE

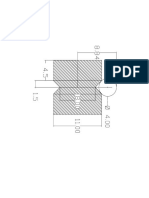

DIMENSIONS (mm) Handwheel Rising Stem

DN Pressure N A B C D E F ØG H Weight (kg.)

50 10 bar 50 48 124 100 98 136 47 225 420 8

80 10 bar 80 51 149 100 119 162 47 225 470 10

100 10 bar 97 51 169 100 139 187 47 225 519 12,5

125 10 bar 117 57 169 100 150 223 47 225 613 16

150 10 bar 140 57 197 100 165 237 47 225 642 20

200 10 bar 184 70 247 122 203 309 67 310 820 32

250 10 bar 230 70 298 122 233 345 67 310 986 47

300 10 bar 275 76 349 122 273 390 69 410 1071 65

350 10 bar 305 76 391 193 312 433 66 410 1245 95

400 10 bar 351,6 89 439 193 347 478 66 410 1325 122

450 10 bar 390 89 483 197 415 552 67 550 1510 160

500 10 bar 435 114 542 197 450 611 67 550 1617 202

600 10 bar 522 114 637 197 501 697 67 550 1883 290

DIMENSIONS (mm) Pneumatic Actuator (D/A)

DN Pressure N A B C D E F G H Weight (kg.) Standard Cyl. Connect.

50 10 bar 50 48 124 100 98 136 178 115 412 10 C100/62 ¼”G

80 10 bar 80 51 149 100 119 162 211 115 492 12 C100/95 ¼”G

100 10 bar 97 51 169 100 139 187 231 115 557 15 C100/115 ¼”G

125 10 bar 117 57 169 100 150 223 271 140 644 21 C125/143 ¼”G

150 10 bar 140 57 197 100 165 237 296 140 698 27 C125/168 ¼”G

200 10 bar 184 70 247 122 203 309 358 175 870 46 C160/220 ¼”G

250 10 bar 230 70 298 122 233 345 428 220 1006 70 C200/270 3/8”G

300 10 bar 275 76 349 122 273 390 478 220 1141 89 C200/320 3/8”G

350 10 bar 305 76 391 193 312 459 549 277 1320 135 C250/375 3/8”G

400 10 bar 351,6 89 439 193 347 478 599 277 1424 162 C250/425 3/8”G

450 10 bar 390 89 483 197 415 552 680 382 1647 212 C300/475 1/2”G

500 10 bar 435 114 542 197 450 611 730 382 1791 290 C300/525 1/2”G

600 10 bar 522 114 637 197 501 697 830 382 2028 375 C300/625 1/2”G

750 7 bar 670 117 842 320 624 940 985 444 2549 645 C350/730 3/4”G

900 7 bar 810 117 970 320 775 1100 1202 515 3077 780 C400/930 3/4”G

DIMENSIONS (mm) Electric Actuator Rising Stem

Stem Ø Torque

DN Pressure N A B C D E F ØG H I J L M X pich (Nm)

50 10 bar 50 48 124 100 98 136 377 160 454 265 249 62 238 20x4 10

80 10 bar 80 51 149 100 119 162 424 160 501 265 249 62 238 20x4 10

100 10 bar 97 51 169 100 139 187 469 160 546 265 249 62 238 20x4 10

125 10 bar 117 57 169 100 150 223 516 160 593 265 249 62 238 20x4 15

150 10 bar 140 57 197 100 165 237 545 160 1122 265 249 62 238 20x4 20

200 10 bar 184 70 247 122 203 309 667 160 1255 265 249 62 238 24x5 30

250 10 bar 230 70 298 122 233 345 733 160 1321 265 249 62 238 24x5 45

300 10 bar 275 76 349 122 273 390 793 200 1381 283 254 65 248 24x5 70

350 10 bar 305 76 391 193 312 433 875 200 1463 283 254 65 248 36x6 110

400 10 bar 351,6 89 439 193 347 478 955 315 1543 389 336 91 286 36x6 160

450 10 bar 390 89 483 270 415 552 1142 315 1870 389 336 91 286 36x6 190

500 10 bar 435 114 542 270 450 611 1222 400 1950 389 339 91 286 36x6 270

600 10 bar 522 114 637 270 501 697 1444 400 2172 389 339 91 286 40x7 450

750 7 bar 670 117 842 320 624 883 1779 500 2832 430 365 117 303 50x8 550

900 7 bar 810 117 970 320 779 1046 2035 500 3080 430 365 117 303 60x9 850

www.orbinox.com OBX Rev. 3 - 01/2018

Reserves the right to change specifications without notice

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Knife Gate Valve: Product DescriptionDocument2 pagesKnife Gate Valve: Product Descriptionviki851No ratings yet

- EX Knife Gate Valve GuideDocument2 pagesEX Knife Gate Valve GuideRio PurnamaNo ratings yet

- Knife Gate Valve: Product DescriptionDocument2 pagesKnife Gate Valve: Product DescriptionVinay Kumar SahuNo ratings yet

- Econ Ball Valves Carbon Steel Stainless Steel 3 Way Port: Full Bore Blow-Out Proof StemDocument1 pageEcon Ball Valves Carbon Steel Stainless Steel 3 Way Port: Full Bore Blow-Out Proof StemChristianGuerreroNo ratings yet

- Series 20 Knife Gate Valve: Product DescriptionDocument2 pagesSeries 20 Knife Gate Valve: Product DescriptionDhananjay BhaldandNo ratings yet

- EP1 Materials ListDocument2 pagesEP1 Materials ListGrover Miranda VallejosNo ratings yet

- Wafer Butterfly Valve Specification for JIS B2239 10K/16K Flange MountingDocument3 pagesWafer Butterfly Valve Specification for JIS B2239 10K/16K Flange MountingJf OngNo ratings yet

- Butterfly Valves EgeplastDocument4 pagesButterfly Valves EgeplastdsyashankaNo ratings yet

- VALVULA CHECK OSCILANTE HakohavDocument1 pageVALVULA CHECK OSCILANTE HakohavDanny VenturaNo ratings yet

- Ball Valve Weight For Nutech Control ValveDocument11 pagesBall Valve Weight For Nutech Control Valveanandbhanushali1541991No ratings yet

- Ductile Iron Gate Valve Acc - To BS Flanged PN 16Document2 pagesDuctile Iron Gate Valve Acc - To BS Flanged PN 16khai ruleNo ratings yet

- Flowcom - Bridada y BridadaDocument1 pageFlowcom - Bridada y BridadaErickNo ratings yet

- ART 231 PN16 Rev1Document1 pageART 231 PN16 Rev1Amadou MokshaNo ratings yet

- Valves 1234Document13 pagesValves 1234Goutham KSNo ratings yet

- Cast Iron Swing Check Valves With Counter Weight and Lever PN 10 and 16Document2 pagesCast Iron Swing Check Valves With Counter Weight and Lever PN 10 and 16Baskaran RathinamNo ratings yet

- 2309+QT04 - Gala-Motorized Butterfly ValveDocument4 pages2309+QT04 - Gala-Motorized Butterfly ValveNam Đỗ100% (1)

- GAER Double Disc Check Valve EngDocument2 pagesGAER Double Disc Check Valve EngCarlos Rovello GandoNo ratings yet

- Soft Seated Gate Valves in Ductile Iron, PN 10 and 16Document2 pagesSoft Seated Gate Valves in Ductile Iron, PN 10 and 16Mohamed RaafatNo ratings yet

- Flowcom - Ranurada y BridadaDocument1 pageFlowcom - Ranurada y BridadaErickNo ratings yet

- Kingston Model 115: Kingston Safety & Relief ValvesDocument2 pagesKingston Model 115: Kingston Safety & Relief ValvesAntonio SerranoNo ratings yet

- BAC SDB Ball Valves 3 or 4 Way Port Full Bore ANSI Class 150Document1 pageBAC SDB Ball Valves 3 or 4 Way Port Full Bore ANSI Class 150ChristianNo ratings yet

- Econ Ball Valves Nodular Cast Iron 3 Way Port Fig. 7327: Full Bore Blow-Out Proof StemDocument1 pageEcon Ball Valves Nodular Cast Iron 3 Way Port Fig. 7327: Full Bore Blow-Out Proof StemChristianGuerreroNo ratings yet

- Valvula de Compuerta Crane 2.5Document1 pageValvula de Compuerta Crane 2.5Juan Arturo Hernandez RuizNo ratings yet

- Brass CR Ball Float Valve: Comply With Bs1212: Part1: 1990Document1 pageBrass CR Ball Float Valve: Comply With Bs1212: Part1: 1990mbgprsmsNo ratings yet

- CDCV-W (Group) (V1116)Document1 pageCDCV-W (Group) (V1116)ismi iqhwan ihsanNo ratings yet

- JFS Dual Flapper CV 3 (Catalogo Valvula Check)Document12 pagesJFS Dual Flapper CV 3 (Catalogo Valvula Check)fernando cordova zegarraNo ratings yet

- Econ Gate Valve Cast Iron Bronze Trim ANSI Class 125 Fig. 1800Document1 pageEcon Gate Valve Cast Iron Bronze Trim ANSI Class 125 Fig. 1800ChristianGuerreroNo ratings yet

- Zhejiang Linuo Flow Control Technology Co.,Ltd: Flanged Three-Way Ball ValveDocument5 pagesZhejiang Linuo Flow Control Technology Co.,Ltd: Flanged Three-Way Ball ValvesafirioNo ratings yet

- Tozen ValveDocument43 pagesTozen ValveSeh YongNo ratings yet

- Isv B50Document5 pagesIsv B50deborazoletNo ratings yet

- RPRRL21SPD500-Pressure Reducer and Flow Control Valve Type E2114-02Document13 pagesRPRRL21SPD500-Pressure Reducer and Flow Control Valve Type E2114-02Marinos GounaridisNo ratings yet

- SB41Document1 pageSB41bhaaskarNo ratings yet

- DS-786 FIG.Z 16 TTTGV CL150 Valve SpecsDocument1 pageDS-786 FIG.Z 16 TTTGV CL150 Valve SpecsYerson JuarezNo ratings yet

- Weflo Swing Check Valve F0311-300-Data-SheetDocument1 pageWeflo Swing Check Valve F0311-300-Data-Sheetachmad.zs7827No ratings yet

- CLASS 150: AWWA C504 Double Flanged Butterfly ValveDocument1 pageCLASS 150: AWWA C504 Double Flanged Butterfly ValveAnnie De WildeNo ratings yet

- Gate Cast Steel Astm A216 WCB Class 150: Pressure Temperature RatingsDocument2 pagesGate Cast Steel Astm A216 WCB Class 150: Pressure Temperature RatingsJavier Hinojosa Garrido LeccaNo ratings yet

- Technical Data: Globe Valve - AngleDocument1 pageTechnical Data: Globe Valve - Angledona gangulyNo ratings yet

- National Fire Equipment Ltd. OS&Y Gate Valve Spec SheetDocument1 pageNational Fire Equipment Ltd. OS&Y Gate Valve Spec SheetAhmed HassanNo ratings yet

- 41 22GSDocument2 pages41 22GSmathewgprsNo ratings yet

- Flowcom - Ranurada y RanuradaDocument1 pageFlowcom - Ranurada y RanuradaErickNo ratings yet

- Flexible Connectors Flanged - PCSSF Series: Features Standard MaterialsDocument1 pageFlexible Connectors Flanged - PCSSF Series: Features Standard MaterialsRamon De los ReyesNo ratings yet

- V Anular - SGP (Eng)Document8 pagesV Anular - SGP (Eng)John lercariNo ratings yet

- Gate Cast Steel A216 WCB Class 150 Mod. XXXXX: Pressure Temperature RatingsDocument2 pagesGate Cast Steel A216 WCB Class 150 Mod. XXXXX: Pressure Temperature Ratingsjaponesito01No ratings yet

- Knife Gate Valve: Product DescriptionDocument2 pagesKnife Gate Valve: Product DescriptionAyman RiyadhNo ratings yet

- F0111 300 Data SheetDocument1 pageF0111 300 Data SheetSehoon OhNo ratings yet

- BAC LD Butterfly Valves Lugged Type Carbon Steel/stainless Steel ANSI Class 150 and 300Document1 pageBAC LD Butterfly Valves Lugged Type Carbon Steel/stainless Steel ANSI Class 150 and 300ChristianNo ratings yet

- Filvalco PRVDocument1 pageFilvalco PRVForhad AhmedNo ratings yet

- SG41Document1 pageSG41bhaaskarNo ratings yet

- Ball Valve PN63 ErhardDocument1 pageBall Valve PN63 ErhardM MNo ratings yet

- Data SheetDocument1 pageData SheetMathi Vinoth PillaiNo ratings yet

- BV224 Series DSDocument1 pageBV224 Series DSFAIYAZ AHMEDNo ratings yet

- Butterfly ValveDocument2 pagesButterfly ValveKELVIN TECHNOLOGIESNo ratings yet

- Wafer Type Butterfly Valve SpecificationDocument2 pagesWafer Type Butterfly Valve SpecificationAzwan SunlineNo ratings yet

- Mech Van Catalogue PDFDocument26 pagesMech Van Catalogue PDFVan Nguyen Huu VanNo ratings yet

- Wafer Cast Steel Check Valve150Lb/300Lb: Applicable Standards: Design DescriptionsDocument2 pagesWafer Cast Steel Check Valve150Lb/300Lb: Applicable Standards: Design Descriptionsmigaspro energiaNo ratings yet

- Cast Steel Cylindrical Body Gate Valves Outside Screw and Yoke, PN 100Document2 pagesCast Steel Cylindrical Body Gate Valves Outside Screw and Yoke, PN 100Seymur AkbarovNo ratings yet

- Flowjet Valves Product BrochureDocument18 pagesFlowjet Valves Product BrochureUday GokhaleNo ratings yet

- 1078 Butter y Valve (Wafer Type) PN 16 With S.G Iron Disc: Salient FeaturesDocument17 pages1078 Butter y Valve (Wafer Type) PN 16 With S.G Iron Disc: Salient FeaturesSanket PhatangareNo ratings yet

- Home Modl R BroachDocument9 pagesHome Modl R BroachTamil SelvanNo ratings yet

- Manage machine shop maintenance with CBMDocument14 pagesManage machine shop maintenance with CBMTamil SelvanNo ratings yet

- A BEGINNER'S GUIDE TO SELLING ON AMAZON.INDocument17 pagesA BEGINNER'S GUIDE TO SELLING ON AMAZON.INSanthoshini BhaskaranNo ratings yet

- Drafting Systems Product Brochure ENDocument28 pagesDrafting Systems Product Brochure ENTamil SelvanNo ratings yet

- Cut-Offs and The Measurement of Surface Roughness PDFDocument8 pagesCut-Offs and The Measurement of Surface Roughness PDFLOGANATHAN VNo ratings yet

- How Calculate The Press Fit ForceDocument3 pagesHow Calculate The Press Fit ForceAuloma Holding Industrial AutomationNo ratings yet

- AUEligibilityDocument22 pagesAUEligibilitySadagopan RajaNo ratings yet

- Angle Grinding ModelDocument1 pageAngle Grinding ModelTamil SelvanNo ratings yet

- PressFitPressureCalculator-English UnitsDocument5 pagesPressFitPressureCalculator-English UnitsTamil SelvanNo ratings yet

- Non WovenDocument3 pagesNon WovenTamil SelvanNo ratings yet

- A Freecad ManualDocument181 pagesA Freecad ManualCleber_Rocha_Santos88% (8)

- ExtDocument1 pageExtTamil SelvanNo ratings yet

- Carborundum Advice On How To Sharpen Wood-Working ToolsDocument40 pagesCarborundum Advice On How To Sharpen Wood-Working ToolsTamil SelvanNo ratings yet

- UsimDocument17 pagesUsimTamil SelvanNo ratings yet

- ENGDocument28 pagesENGTamil Selvan100% (1)

- 2012 August EatonCare LEAN SolutionsDocument57 pages2012 August EatonCare LEAN SolutionsTamil SelvanNo ratings yet

- Mountainboard Stumdent WB 2011 ENGDocument550 pagesMountainboard Stumdent WB 2011 ENGyoung4912No ratings yet

- Chastotnii Preobrazovatel Sunfar E300 Manual enDocument17 pagesChastotnii Preobrazovatel Sunfar E300 Manual enTamil SelvanNo ratings yet

- Wheels and DiscsDocument2 pagesWheels and DiscsTamil SelvanNo ratings yet

- Measurement: Path To PreciseDocument12 pagesMeasurement: Path To PreciseTamil SelvanNo ratings yet

- GSG Compacttechnical09Document267 pagesGSG Compacttechnical09Tamil SelvanNo ratings yet

- AlgorithmsNotesForProfessionals PDFDocument257 pagesAlgorithmsNotesForProfessionals PDFqwer plmNo ratings yet

- User Manual, Tesa BPX Twin-Station en de FRDocument1 pageUser Manual, Tesa BPX Twin-Station en de FRTamil SelvanNo ratings yet

- Arthritis Booklet Vol 1 PDFDocument29 pagesArthritis Booklet Vol 1 PDFTamil SelvanNo ratings yet

- Chastotnii Preobrazovatel Sunfar E300 Manual enDocument42 pagesChastotnii Preobrazovatel Sunfar E300 Manual enPhan Giang ChâuNo ratings yet

- Hydralic Noise PDFDocument16 pagesHydralic Noise PDFTamil SelvanNo ratings yet

- Carborundum Advice On How To Sharpen Wood-Working ToolsDocument40 pagesCarborundum Advice On How To Sharpen Wood-Working ToolsTamil SelvanNo ratings yet

- Mikuni VM Roundslide Parts DiagramDocument19 pagesMikuni VM Roundslide Parts DiagramTamil Selvan100% (2)

- Catalog ProbeDocument76 pagesCatalog ProbeTamil SelvanNo ratings yet

- SolarBright MaxBreeze Solar Roof Fan Brochure Web 1022Document4 pagesSolarBright MaxBreeze Solar Roof Fan Brochure Web 1022kewiso7811No ratings yet

- CHEMICAL ANALYSIS OF WATER SAMPLEDocument5 pagesCHEMICAL ANALYSIS OF WATER SAMPLEAiron Fuentes EresNo ratings yet

- BOQ - Hearts & Arrows Office 04sep2023Document15 pagesBOQ - Hearts & Arrows Office 04sep2023ChristianNo ratings yet

- 2010-12 600 800 Rush Switchback RMK Service Manual PDFDocument430 pages2010-12 600 800 Rush Switchback RMK Service Manual PDFBrianCook73% (11)

- PBS-P100 Facilities Standards GuideDocument327 pagesPBS-P100 Facilities Standards Guidecessna5538cNo ratings yet

- Scientology Abridged Dictionary 1973Document21 pagesScientology Abridged Dictionary 1973Cristiano Manzzini100% (2)

- Phaseo Abl7 Abl8 Abl8rps24100Document9 pagesPhaseo Abl7 Abl8 Abl8rps24100Magda DiazNo ratings yet

- Banu Maaruf of The LevantDocument6 pagesBanu Maaruf of The LevantMotiwala AbbasNo ratings yet

- Guillermo Estrella TolentinoDocument15 pagesGuillermo Estrella TolentinoJessale JoieNo ratings yet

- 10 Tips To Support ChildrenDocument20 pages10 Tips To Support ChildrenRhe jane AbucejoNo ratings yet

- Load Frequency Control of Hydro and Nuclear Power System by PI & GA ControllerDocument6 pagesLoad Frequency Control of Hydro and Nuclear Power System by PI & GA Controllerijsret100% (1)

- Hisar CFC - Approved DPRDocument126 pagesHisar CFC - Approved DPRSATYAM KUMARNo ratings yet

- Pharma TestDocument2 pagesPharma TestMuhammad AdilNo ratings yet

- Kennedy 1945 Bibliography of Indonesian Peoples and CulturesDocument12 pagesKennedy 1945 Bibliography of Indonesian Peoples and CulturesJennifer Williams NourseNo ratings yet

- Earth Life Science Module 9 Second Quarter 1Document25 pagesEarth Life Science Module 9 Second Quarter 1Milo CatNo ratings yet

- Multivariate Analysis Homework QuestionsDocument2 pagesMultivariate Analysis Homework Questions歐怡君No ratings yet

- Muv PDFDocument6 pagesMuv PDFDenisse PxndithxNo ratings yet

- Durand Et Al JHRC 1997 Experimental Design Optimization of The Analysis of Gasoline by Capillary Gas ChromatographyDocument6 pagesDurand Et Al JHRC 1997 Experimental Design Optimization of The Analysis of Gasoline by Capillary Gas ChromatographyCatalinaSalamancaNo ratings yet

- AWS Cloud Practicioner Exam Examples 0Document110 pagesAWS Cloud Practicioner Exam Examples 0AnataTumonglo100% (3)

- Best Way To LearnDocument3 pagesBest Way To LearnRAMIZKHAN124No ratings yet

- 2 5 Marking ScheduleDocument6 pages2 5 Marking Scheduleapi-218511741No ratings yet

- Timber, PVCu and aluminium window and door hardware systemsDocument24 pagesTimber, PVCu and aluminium window and door hardware systemsOmul Fara NumeNo ratings yet

- TNTCL Cost Data 2021 22Document95 pagesTNTCL Cost Data 2021 22Akd DeshmukhNo ratings yet

- QP P1 APR 2023Document16 pagesQP P1 APR 2023Gil legaspiNo ratings yet

- Philippine LiteratureDocument82 pagesPhilippine LiteratureLovelene Chrizze100% (5)

- Project Report On Evaporative CoolerDocument12 pagesProject Report On Evaporative Coolersourabh singh tomerNo ratings yet

- FM 5130Document66 pagesFM 5130Aswini Kr KarmakarNo ratings yet

- PediculosisDocument14 pagesPediculosisREYMARK HACOSTA100% (1)

- Analysis and Design of Multi Storey Building by Using STAAD ProDocument5 pagesAnalysis and Design of Multi Storey Building by Using STAAD Prolikith rockNo ratings yet

- (PDF) Biochemistry and Molecular Biology of Plants: Book DetailsDocument1 page(PDF) Biochemistry and Molecular Biology of Plants: Book DetailsArchana PatraNo ratings yet