Professional Documents

Culture Documents

Preparing A Quality Manual: Guide

Preparing A Quality Manual: Guide

Uploaded by

Revathy GunaseelanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Preparing A Quality Manual: Guide

Preparing A Quality Manual: Guide

Uploaded by

Revathy GunaseelanCopyright:

Available Formats

NABL 160

NABL

NATIONAL ACCREDITATION

BOARD FOR TESTING AND

CALIBRATION LABORATORIES

GUIDE

for PREPARING

A QUALITY MANUAL

ISSUE NO. : 05 AMENDMENT NO : 00

ISSUE DATE: 27.06.2012 AMENDMENT DATE: --

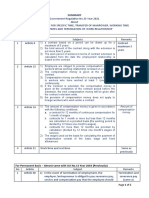

Amendment Sheet

Sl Page Clause Date of Amendment made Reasons Signature Signature

No. No. Amendment QO Director

1

10

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 1/ 59

Contents

Sl. Contents Page No.

Amendment sheet 1

Contents 2

1. Introduction 3

2. Process for preparing a Quality Manual 4

3. Structure and format of Quality Manual 7

4. Management Requirements 18

4.1 Organisation 18

4.2 Management system 21

4.3 Document control 24

4.4 Review of requests, tenders and contracts 26

4.5 Subcontracting of tests and calibrations 27

4.6 Purchasing, services and supplies 28

4.7 Service to the customer 29

4.8 Complaints 30

4.9 Control of nonconforming testing and/ or calibration work 31

4.10 Improvements 32

4.11 Corrective action 33

4.12 Preventive action 34

4.13 Control of records 35

4.14 Internal audit 36

4.15 Management review 38

5. Technical Requirements 40

5.1 General 40

5.2 Personnel 41

5.3 Accommodation and environmental conditions 43

5.4 Test and calibration methods and method validation 45

5.5 Equipment 49

5.6 Measurement traceability and calibration 51

5.7 Sampling 54

5.8 Handling of calibration and test items 55

5.9 Assuring the quality of test and calibration results 56

5.10 Reporting the results 58

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 2/ 59

1. Introduction

Testing and Calibration laboratories are required to comply with the

requirements of ISO/IEC 17025:2005 ‘General Requirements for the

Competence of Testing and Calibration Laboratories’ and Medical Testing

laboratories have to comply with the requirements of ISO 15189:2007

‘Medical laboratories – Particular requirements for quality and

competence’.

One of the pre-requisite for seeking NABL Accreditation is that applicant

laboratory shall submit its Quality Manual, describing its policies, the

structure of management system documentation and compliance to

ISO/IEC 17025 or ISO 15189, as applicable & relevant NABL Specific

Criteria.

In preparing the Quality Manual, it should not be restricted to the contents

of this guide. However, all elements of ISO/IEC 17025 or ISO 15189 as

applicable must be addressed in the intended Quality Manual. As an

illustration this document provides guidance to Testing and Calibration

laboratories for addressing the requirements of ISO/IEC 17025 in their

Quality Manual. Similarly, the requirements of ISO 15189 can be

addressed by Medical Testing laboratories in their Quality Manual.

The amount of details to be provided in the manual will vary depending

upon the size, field of activities, and nature of testing / calibration

performed by the laboratory. The Quality Manual shall include or make

reference to other documents such operational procedures, work

instructions, forms etc.

For preparing the Quality Manual, the laboratory may also get its technical

personnel trained in NABL’s training program on management system for

laboratory personnel. A calendar of such training courses is regularly

published in the NABL News/ web-site.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 3/ 59

2. Process of preparing a Quality Manual

The management should nominate individuals from one or more functional

area/ section of the laboratory and a Quality Manager, having a

background of Management Systems. This group should get fully

acquainted with all NABL documents and understand the assessment

procedure & methodology of making an application. Relevant requirements

for NABL accreditation should be discussed amongst concerned staff of

the laboratory. The team should collectively make the effort to prepare the

Quality Manual with the guidance of the Quality Manager.

Laboratory needs to ascertain the status of its existing management

system and its competence. For that all existing policies, objectives,

procedures, work instruction whether documented or otherwise are

required to be listed and compared with the requirements of ISO/IEC

17025 or ISO 15189 as applicable, relevant NABL Specific criteria and

other requirements.

The laboratory should examine that the existing management system is

appropriate or it needs modification or it needs to be built from scratch.

The laboratory will be able to decide. However, it is advisable that the

laboratory writes the manual afresh, as the elements of ISO/ IEC 17025 or

ISO 15189 are quite different from other Quality Management System

standards, even though the system elements are similar.

It must be remembered that Quality Manual is a policy document, which

has to be supplemented by a set of other documents like procedure

manuals, work instructions, forms, reports etc. to align the management

system in accordance with ISO/IEC 17025 or ISO 15189, as applicable

and relevant NABL specific criteria. Therefore, the management system of

the laboratory needs to be structured.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 4/ 59

The management system of the laboratory can be structured in many

ways. A typical structure of management system document hierarchy,

generally followed, is given below:

Quality

Manual

(Level A)

Management system

Procedures

(Level B)

Other quality documents

(W ork instructions, forms, reports, etc.)

(Level C)

The order of development of a hierarchy for an individual laboratory

usually starts with the development of the laboratory’s Quality Policy &

objectives followed by the implementation plan of the various elements of

ISO/IEC 17025 or ISO 15189 as applicable in brief. This is the apex

document or Level A document termed as the ‘Quality Manual’.

The Quality Manual has to be supplemented by a set of management

system procedures, Level B documents, which describe the detailed

procedures of the activities of individual function units needed to

implement the management system. All procedures are cross referred in

the Quality Manual.

Management system procedures may further be supplemented with

detailed work instructions, forms, reports etc. termed as Level C

documents. In some hierarchy systems, forms and reports may be grouped

as Level D documents.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 5/ 59

The quantity of documented procedures, work instructions, forms, reports

etc. and the nature of their format and presentation are to be determined

by the individual functional units. However, it is preferred that each of

these set of documents are arranged in the same structure and format so

that the users become familiar with the consistent approach applied to

each requirement and to improve the likelihood of systematic compliance

with ISO/IEC 17025 or ISO 15189 as applicable.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 6/ 59

3. Structure and Format of Quality Manual

There is no required structure or format for a Quality Manual. However,

any Quality Manual should convey accurately, completely and concisely

the Quality Policy, objectives, address or reference to the next level of

documentation and management responsibilities of the laboratory. One of

the methods of assuring that the subject matter is adequately addressed

and located would be to align the sections of the Quality Manual to the

elements of the ISO/IEC 17025 or ISO 15189 as applicable. Other

approaches, such as structuring the manual to reflect the nature of the

laboratory or nature of work carried out by the laboratory are equally

acceptable.

This guide is not intended to define a unique structure, format, content or

method of presentation for the Quality Manual, which can be applied to all

(or even some) laboratories. It is unique to each laboratory. However, it is

recommended that the first few pages of the Quality Manual should

address to the sections of general information like title, authority under

which it is issued, scope of the Quality Manual, amendment record of the

manual, contents of the manual, references to other documents,

definitions and abbreviations used, distribution record, brief description of

the laboratory and the management system.

After these pages, should place the section on ‘Quality Policy and

Objectives’ of the laboratory. The Quality Policy is required to be stated

under clause 4.2 of management requirements. It is preferred that it is

placed after the introductory pages, since this is the basic objective, the

laboratory’s management system is designed to meet. The remaining

sections of the Quality Manual should describe all applicable elements of

the ISO/IEC 17025 or ISO 15189. The description of these sections of the

Quality Manual should be in a sequence similar to that of ISO/IEC 17025

or ISO 15189, as applicable. Other sequencing or cross-referencing, as

appropriate to the laboratory, is acceptable.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 7/ 59

Thereafter the list of documents, records and forms maintained by the

laboratory should be placed. Any supportive data, to be provided should

be annexed at the last.

A brief explanation of these sections has been given below. These

sections, should preferably be sequenced in the manner as given below:

Title

The title of the Quality Manual should clearly indicate the name of the

laboratory to which the manual belongs. It should also indicate the issue

number, issue date, holders name and the copy number. A typical ‘title

page’ is shown at page 11.

Release Authorisation

The section on ‘release authorisation’ should indicate the authority under

which the Quality Manual has been released. The management

responsible for the implementation of Quality Manual, normally the Head

of the laboratory should authorise its release for usage. Each copy should

bear evidence of this release. A typical ‘release authorisation’ is shown at

page 12.

Table of contents

The table of contents of a Quality Manual should show the titles of the

sections within it and how they can be located. The numbering system of

sections, subsections, pages, figures, exhibits, diagrams, tables, etc.,

should be clear and logical. A typical ‘table of contents’ is shown at

page 14.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 8/ 59

Scope and field of application

This section of the Quality Manual should clearly mention the compliance

to the applicable standard(s) and NABL documents. It should also define

the field(s)/ discipline(s)/ area(s) and the section(s)/ division(s)

department(s) of the laboratory, to which the Quality Manual is applicable.

To ensure clarity and avoid confusion, the use of disclaimers (eg. what is

not covered by the Quality Manual and situations where it should not be

applied) may also be mentioned.

Use of references

Wherever appropriate, and to avoid unnecessary document volume,

reference to existing recognised standards or documents available with

the Quality Manual user should be incorporated.

Definitions

Although it is recommended, when practical, to use standard definitions

and terms which are referenced in recognised quality terminology

documents or in general dictionary usage, this section of the Quality

Manual should contain the definitions of terms and concepts that are

uniquely used within the Quality Manual.

The use of references to existing concepts, terminology, definitions and

standards (eg. ISO 8402) is highly recommended.

Abbreviations

Whenever the abbreviations are used, its expanded form should be

defined in this section.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 9/ 59

Distribution of the manual

The method of distribution of the authorised manual should provide

assurance that all users have appropriate access. Proper distribution and

control can be aided, for example, by serialisation of copies for recipients.

Management should ensure that individuals are familiar with those

contents of the manual appropriate to each user within the laboratory. A

typical ‘distribution record’ is shown at page 15.

Introduction

The introductory pages of a Quality Manual should provide general

information about the laboratory concerned and the Quality Manual itself.

The minimum information about the laboratory should be its name, site,

location and means of communication. Additional information about the

laboratory, such as its line of business, a brief description of its

background, history or size, may also be included.

The information about the Quality Manual itself should include:

a The current issue number, date of issue and identification of

amended contents

b A brief description of how the Quality Manual is revised and

maintained, who reviews its content and how often, who is authorised

to change the Quality Manual, and who is authorised to approve it,

this information may also be give under the system element

concerned; a method for determining the history of any change in

procedure may be included, if appropriate

c A brief description of the documented procedures used to identify the

status and to control the distribution of the Quality Manual, whether

or not is contains confidential information, whether it is used only for

the laboratory’s internal purposes, or whether it can be made

available externally

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 10/ 59

d Evidence of approval by those responsible for authorisation of the

contents of the Quality Manual.

Quality Policy and Objectives

This section of a Quality Manual should state the laboratory’s Quality

Policy and objectives, which should be in line with the requirements of

clause 4.2 of ISO/IEC 17025 or ISO 15189, as applicable. This is where

the laboratory commitment to quality is presented and where the

laboratory’s objectives for quality are outlines. This section should also

describe how the Quality Policy is made known to, and understood by, all

employees and how it is implemented and maintained at all levels.

Elements of the Management system

The subsequent sections of the Quality Manual should describe all the

elements of the ISO/IEC 17025 or ISO 15189 as applicable.

The format or method of presentation for the description of management

system elements, which can be applied, is unique to each laboratory.

However it is recommended that the description of the elements of the

management system be in a sequence similar to that of ISO/IEC 17025 or

ISO 15189, as applicable.

Further the description of each element should be divided into logical

sub-sections revealing a well-coordinated management system. This may

be done by inclusion of policy and objectives with respect to the element

or reference to the policy, scope, person(s)/ position responsible for

executing that policy, documented management system procedures and

reference to records for each element.

The management system procedure of each element of Quality Manual,

wherever applicable, should be briefly outlined, covering the major aspects

of respective clause of ISO/IEC 17025 or ISO 15189. The actual process/

procedure may be covered in separate procedure document and cross

referred in the Quality Manual.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 11/ 59

List of documents, records and forms

All documents which are maintained by the laboratory and the records &

forms, which are used by the laboratory should be listed in these sections.

These must find reference in the Quality Manual or the associated

document.

Annexure for supportive information

Whenever it appears in this document, that supportive data has to be

provided, it should be attached as an annexure at the end.

Page Footer

It is recommended that to facilitate ease of handling and updating of the

Quality Manual, each page within the manual should have a page footer,

similar to the given on the typical pages shown in the next few pages.

Page footer shows the Issue status, amendment status, page no. etc. As

and when the manual is amended, the relevant pages where amendment

takes place are replaced by new pages and is cross referred in the

amendment record. A typical ‘amendment record’ is shown at page 13. It

also gives the copy number. As and when each holder is issued a Quality

Manual, a copy no. is allotted to him/ her and this is indicated in the

distribution record, page 15. The signatures of the persons/ position who

have prepared, approved and issued the Quality Manual are also placed in

the page footer.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 12/ 59

TITLE PAGE

The title page of the Quality Manual should normally contain the following:

QUALITY MANUAL

of

(Name & Address of Laboratory)

Issue No. :

Issue Date :

Copy No. :

Holder’s Name :

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 13/ 59

QUALITY MANUAL RELEASE AUTHORISATION

Immediately after the title page, this page should be placed. A typical authorization

should normally contain the following:

RELEASE AUTHORISATION

This Quality Manual is released under the authority of

(name and designation of the Head of the laboratory)

and is the property of

(name of the laboratory with address).

(Signature, Name & Designation)

Name of Laboratory:

Document No.: Document Name: Quality Manual

Issue No.: Issue Date: Copy No.: Section No. Page No.:

Amend No.: Amend Date Prepared by: Approved by: Issued by:

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 14/ 59

AMENDMENT PAGE

An amendment page should be inserted immediately after the title page. Specific

instructions to each holder of the Quality Manual as to the amendment procedure to

be followed to maintain each copy upto date should be included. To ensure that

each copy of the Quality Manual contains a complete record of amendments, this

amendment page should be updated and issued with each set of amended/ new

pages of the Quality Manual.

A typical amendment page should normally contain the following:

AMENDMENT RECORD

Sl Page Section/ Clause/ Date of Amendment made Reasons of Signature of

No. Para/ line Amendment Amendment person

(a s a p p l ic a bl e ) authorising

Amendment

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Name of Laboratory:

Document No.: Document Name: Quality Manual

Issue No.: Issue Date: Copy No.: Section No. Page No.:

Amend No.: Amend Date Prepared by: Approved by: Issued by:

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 15/ 59

CONTENT PAGE

For the ease of reference, the manual should contain a table of contents listing the

major sections, sub-sections and their page numbers. A list of the Annexures should

also be included.

A typical table of contents should normally contain the following:

CONTENTS

Section Contents Page

Quality Manual release authorisation

Amendment sheet

Contents

Scope

References (if any)

Definitions (if any)

Abbreviations (if any)

Distribution List

Introduction ( B ri ef de scripti on of the Laboratory & management s yste m )

Quality Policy and Objectives

Management Requirements

Organisation

Management system

Document Control

Technical Requirements

General

Personnel

List of all documents maintained by the laboratory

List of all records

List of all forms

Annexures (if any)

Name of Laboratory:

Document No.: Document Name: Quality Manual

Issue No.: Issue Date: Copy No.: Section No. Page No.:

Amend No.: Amend Date Prepared by: Approved by: Issued by:

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 16/ 59

DISTRIBUTION LIST

The distribution record should list the holders of the controlled copies of Quality

Manual with their allotted copy numbers. Copies of Quality Manual distributed as

uncontrolled copies, should not be listed.

A typical distribution list should normally contain the following:

DISTRIBUTION LIST

The following are the authorised holders of the controlled copy of Quality Manual.

Controlled copy No. Name/ Designation of the holder of controlled copy

Name of Laboratory:

Document No.: Document Name: Quality Manual

Issue No.: Issue Date: Copy No.: Section No. Page No.:

Amend No.: Amend Date Prepared by: Approved by: Issued by:

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 17/ 59

4. Management Requirements

4.1 Organisation

4.1.1 Give the name, address, type of corporate structure and whether or not an

affiliate of a larger organisation and any other information required to

identify the laboratory, including its legal status, such as Government, a

registered society or under company’s act. The date of incorporation may

also be mentioned.

4.1.2 The laboratory shall make a compliance statement that it carries out its

testing/ calibration activities in accordance with the requirements of

ISO/IEC 17025:2005, the needs of its customer, the regulatory authorities

or the organisations providing recognition, at all times. The names and

details of the regulatory bodies and the organisations providing recognition

may also be mentioned.

4.1.3 Describe the laboratory and its operations to convey a true picture of the

organisation such as location, size, whether permanent/ part of

permanent/ independent site/ mobile, branches, type of services offered,

major fields of activity etc.

4.1.4 If the laboratory is a part of larger organisation which also performs other

activities, other than testing and/ or calibration, the responsibility of the

key personnel in the organisation that have an involvement or influence on

the testing and/ or calibration activities such as production, commercial,

marketing or finance shall be clearly defined in order to identify the

potential conflict of interest with the laboratory personnel, which might

adversely effect the judgement & integrity of staff and quality of work.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 18/ 59

4.1.5 a A statement that the laboratory has adequate number of staff both

managerial and technical, appropriate to the scope of work being

carried out.

Define the duties/ responsibilities of the managerial and technical

personnel to carry out their duties and to identify the occurrence of

departures from management system or procedures.

b Describe the procedure that is followed to ensure that the

laboratory’s management and personnel are free from any undue

internal and external commercial, financial and other pressures which

might influence their technical judgement.

c Describe the procedure which the laboratory uses to protect the

proprietary right and confidential information of the customer.

Under no circumstances the results of test and/ or calibration be made known to

any third party without the written consent of the customer. No reports should be

send by fax without customers prior permission.

d State policy and describe procedure that the laboratory is not

engaged in any activity that may diminish its trust in its independence

of judgement, competence, impartiality and integrity in relation to its

testing and/ or calibration.

e Describe the organisation and management structure of the

laboratory with the help of a chart showing Quality Management,

Technical Management and other support services alongwith their

linkages. The relationship with its parent organisation (if any) should

be stated.

f Describe the arrangement whereby written instructions and

information are given to members of staff to ensure that every

employee is aware of the extent and limitations of his areas of

responsibility and authority. Provide an organisation chart to show

the interrelationship of the laboratory staff.

Copies of job descriptions be issued to all personnel to ensure that they are aware

of both their responsibility and authority.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 19/ 59

g State the laboratory’s arrangement for providing supervision to

laboratory staff.

The supervision has to be provided by persons familiar with methods and

procedures, purpose of each test and/ or calibration and assessment of the test

and/ or calibration results.

h Include a statement that the Technical Manager (however named)

has an overall responsibility of technical operations of the laboratory

as a whole or its sub-section their off and provision of resources to

ensure the required quality.

i Include a statement that the Quality Manager (however named) is

responsible for ensuring that the management system related to

quality is implemented and followed, at all times.

Also include a statement that the Quality Manager has direct access

to the highest level of management at which decisions are made for

laboratory policy and resources, commensurate with the organisation

chart.

j Describe arrangements in the event of absence of key laboratory

staff, including Quality Manager and Technical Manager.

k Describe arrangements to ensure that laboratory personnel are aware

of the relevance and importance of their activities and how they

contribute to the achievements of the objectives of the management

system.

4.1.6 Describe the arrangement whereby top management ensures that

appropriate communication process are established within the laboratory

and that communication takes place regarding the effectiveness of the

management system.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 20/ 59

4.2 Management System

4.2.1 General

Describe the documentation, implementation and maintenance of the

management system of the laboratory. Include a statement that the

management system is appropriate to the scope of its activities and in

accordance with ISO/IEC 17025:2005 and NABL documents.

A statement also to be made that the management system documentation

of the laboratory is communicated to, understood by, available with and

implemented by those personnel who are responsible for maintaining the

quality of test and/ or calibration results.

The Quality Manual of a laboratory is the basic document to describe its management

system. Associated documents like operating procedures, work instructions, forms,

report etc. also form a part of the management system. The management system of the

laboratory need not be complex. Much will depend on the size of the laboratory and the

scope of testing/ calibration requiring accreditation.

4.2.2 Quality Policy

The laboratory must define its management system policies related to

quality, including Quality Policy statement and objectives, preferably in the

beginning of the Quality Manual. The quality policy statement shall be

signed by the Chief Executive or any person of the top management who

takes decisions on the laboratory’s policy and resources. The statement

must include atleast the following:

a commitment of the laboratory management in relation to quality of its

testing and calibration services and to provide its customers at all

times with a service complying with recognised standards of practice

b standard of services given to its customers

c the purpose of the management system related to Quality

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 21/ 59

d all staff shall familiarise themselves with the content of the Quality

Manual and comply with the Policies and Procedures laid down in the

Manual and associated documentation, at all times

e commitment to compliance with ISO/IEC 17025:2005 and to

continually improve the effectiveness the management.

The quality policy statement should be concise and may include the requirement that

tests and/ or calibrations shall always be carried out in accordance with stated methods

and customers requirements. It may also include that the laboratory gives emphasis in

producing reliable and accurate tests and/ or calibration results. When test and/ or

calibration laboratory is part of a larger organisation, some quality policy elements may

be in other documents.

4.2.3 Describe arrangements that top management provides evidence of

commitment to the development and implementation of the management

system and continually improving its effectiveness.

4.2.4 Describe arrangements that top management communicates to the

organisation the importance of meeting customer as well as statutory and

regulatory requirements.

4.2.5 Documentation Structure

Describe the structure of documentation used in the management system.

It shall include or make reference to the supporting procedures, including

technical procedures, i.e., reference to supporting documents such as

operating procedures etc. Pyramid structure for documentation may also

be described here or referred. It shall include or make references to the

supporting documents such as operating procedures, work instructions,

forms, reports etc. This may also be described by a pyramid structure of

management system document hierarchy.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 22/ 59

4.2.6 Responsibility

The person(s)/ position responsible for implementing and monitoring

programs and policies to achieve laboratory’s quality objectives shall be

identified. The role and responsibility of the Technical Management and

the Quality Manager for ensuring compliance to ISO/IEC 17025:2005,

should be clearly defined.

Generally the responsibilities of key personnel are defined in Quality Manual and others

having different responsibilities within the management system at appropriate position,

in the second/ third level of documentation.

4.2.7 Describe arrangements that top management ensures that the integrity of

the management system is maintained when changes to the management

system are planned and implemented.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 23/ 59

4.3 Document Control

4.3.1 General

Describe the system to uniquely identify all documents generated by the

laboratory and the procedure to control these documents

The laboratory must list all documents that form part of its management system, both

internally generated or from external source such as policy statements, procedures,

specification, calibration tables, charts, text books, posters, notices, memoranda,

software, drawings, plans, regulations, standards and other normative documents etc.

and maintain a master list or equivalent document control procedure, which identifies the

revision status and distribution.

All documents generated by the laboratory shall be uniquely identified, which shall

include document number, issue number, date of issue, amendment/ revision number,

date of amendment/ revision, page numbering, total number of pages, approving

authority and issuing authority.

4.3.2 Document approval and issue

Procedure

Describe the document approval and issue procedure. It shall atleast

include the following information:

a availability of authorised edition of appropriate documents at all

locations

b periodic review of documents

c removal of obsolete documents from all locations

d retention of a copy of obsolete document.

Responsibility

The person(s)/ position responsible for review and approval of documents

shall be identified for all level of documentation.

The laboratory shall ensure that all documents are reviewed and approved by authorised

personnel prior to issue.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 24/ 59

4.3.3 Document changes

Procedure

The laboratory shall state the procedure to identify the altered or new text,

in the amended document.

Where documentation control system allows the amendments of

documents by hand pending re-issue, the procedure and authority for such

amendment shall be defined.

Where the laboratory maintains the amendments to documents in a

computerised system, procedures to describe the changes and its control

shall be defined.

Policy with respect to all above may be given in Quality Manual and the actual process

may be covered in a separate procedure referred in the Quality Manual.

Responsibility

The person(s)/ position authorised to review and approve changes/

amendments shall be identified.

It should be preferably be the same person who performed the original review.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 25/ 59

4.4 Review of requests, tenders and contracts

Policy

State the laboratory’s policy for the review of requests, tenders and

contracts including subcontracted work.

Responsibility

The person(s)/ position responsible for review of request/ indent of new,

repetitive/ routine, special work, tenders and contracts may be identified.

Procedure

Briefly outline the procedure for review of requests and tenders which

shall include:

a defining, documenting and understanding customer requirements

before commencing work

b assessment of laboratory’s capability and resources

c appropriate method selection

d work that is subcontracted by the laboratory.

The details of how the review is actually done, may be covered separately

in a procedure cross referred herein.

Records

Make a reference to the document, where the records are maintained.

The records of reviews, any significant changes, pertinent discussions with the customer

etc., during the execution of contract and during the amendment to the contract shall be

maintained.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 26/ 59

4.5 Subcontracting of tests and calibrations

Policy

State the laboratory’s policy for subcontracting of test and/ or calibration

work.

The NABL policy for subcontracting by the laboratories is that the work shall be placed

with an accredited laboratory.

Responsibility

The person(s)/ position responsible for subcontracting the works may be

identified.

Procedure

Briefly outline the procedure for subcontracting, which should include

advising customer of such arrangements in writing, seeking customers’

approval and accepting the responsibility for the subcontracted work. The

actual process may be covered in a separate procedure cross referred in

the Quality Manual.

Records

Make a reference to the document, where the records are maintained.

Records of all subcontractors that are used and record of evidence of compliance with

ISO/IEC 17025:2005 for the work in question, shall be maintained.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 27/ 59

4.6 Purchasing, services and supplies

Policy

State the laboratory’s policy for purchasing, services and supplies which

affect the quality of test and/ or calibration.

Responsibility

The person(s)/ position responsible for authorising purchases may be

identified.

Procedure

Briefly outline the procedure for the selection and purchase of services

and supplies, evaluation of suppliers of critical items, receipt and storage

of reagents/ consumables, inspection & verification.

Also briefly outline the procedure for review and approval of purchase

documents for technical contents. The actual process may be covered in

separate procedure cross referred in the Quality Manual.

The description in the purchase document may include types, class, grade, precise

identification, specification, drawings, inspection instructions, other technical data

including approval of test results, the quality required and the management system

standard under which they were made.

Where assurance of quality of outside support services or supplies is unavailable, the

laboratory’s policy of using the items may be stated (i.e. whether they should be

inspected or otherwise verified for adequate quality).

Records

Make a reference to the document, where the records are maintained.

The records of evaluation of supplies of critical consumables & services and the list of

those approved shall be maintained. The records of action taken to check the

compliance of supplies/ services used with specified requirements shall also be

maintained. The records like purchasing documents may also be maintained.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 28/ 59

4.7 Service to the customer

Policy

State the laboratory’s policy for service to the customer. The policy may

address to the following:

a maintenance of good communication

b to clarify their request

c monitor the laboratory’s performance in relation to the work

performed

d provide reasonable access to relevant areas of the laboratory for the

witnessing of test(s)/ calibration(s) performed for the customer

e preparation, packaging and despatch of test(s)/ calibration(s) items

f advice and guidance in technical matters

g opinion and interpretation based on results

h to maintain confidentiality to other customers during the monitoring

i delays or major deviations in the performance of test(s)/

calibration(s).

Responsibility

The person(s)/ position responsible for authorising the customers for these

services, if required shall be identified.

Procedure

Briefly outline the procedure for implementation. It may also include the

procedure for obtaining feedback from the customers on laboratory’s

quality of services. The actual process may be documented separately and

cross referred in the Quality Manual.

Records

Make a reference to the document, where the records are maintained.

The records of the customer feedback, both positive and negative from the customers

shall be maintained.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 29/ 59

4.8 Complaints

Policy

State the laboratory’s policy on resolution of complaints to improve the

quality of services provided.

Responsibility

The person(s)/ position responsible for resolution of complaints shall be

identified.

Procedure

Briefly outline the procedure for resolution of complaints received from

customers or other parties. The procedure shall have a provision of

promptly auditing those aspects, which are indicated by the complainant

and conveying it for management review. The actual process may be

documented separately and cross referred in the Quality Manual.

Records

Make a reference to the document, where the records are maintained.

The records of all complaints written or verbal shall be maintained. The records shall

also, include the complainant’s name/ organisation, the investigations carried out and

the corrective action taken by the laboratory, shall be maintained.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 30/ 59

4.9 Control of nonconforming testing and/ or calibration work

Policy

State the laboratory’s policy on control of nonconforming work, when any

work and results do not confirm to its own procedures or the agreed

requirements of the customers.

Responsibility

The person(s)/ position responsible for management of nonconforming

work and actions such as halting of work, withholding of test reports/

calibration certificates & resumption of work shall be identified.

Procedure

Briefly outline the procedure for control of nonconforming work, which

shall include:

a authority for halt of work, if necessary

b an evaluation of the significance of the non-conforming work

c Corrections and decision about the acceptability of nonconforming

work to be taken

d notification to the customer and work recall, if necessary

e authorising the resumption of work

f action taken to prevent future occurrence.

The actual process may be covered in a separate procedure cross referred

in the Quality Manual.

Records

Make a reference to the document, where the records are maintained.

Records of all non-conformities and action taken for correcting the non-conformities shall

be maintained.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 31/ 59

4.10 Improvements

Policy

State the laboratory’s policy on improvement of the effectiveness of its,

management system.

The policy may include use of quality policy, quality objectives, audit

results, analysis of data, corrective and preventive actions and

management reviews.

Responsibility

Designate the management persons(s)/ position responsible for

improvements shall be identified.

Procedure

Briefly outline the procedure of identification, implementation and

monitoring the improvements.

The actual process may be covered in a separate procedure cross referred

in the Quality Manual.

Records

Make a reference to the document, where the records are maintained.

Records of all improvements implemented shall be maintained.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 32/ 59

4.11 Corrective action

Policy

State the laboratory’s policy on corrective action when nonconforming

work or departures from policies and procedures in the management

system or technical operations are identified.

Responsibility

The person(s)/ position responsible for planning, implementing and

monitoring appropriate corrective action shall be identified.

Procedure

Briefly outline the procedure for implementing corrective action which shall

include:

a sources of information for identification of problems

b cause analysis

c selection and implementation of corrective actions

d monitoring of corrective actions

e additional audits where non-conformities/ departures cast doubt.

The actual process may be covered in a separate procedure cross referred

in the Quality Manual.

Records

Make a reference to the document, where the records are maintained.

Records of all corrective actions taken shall be maintained.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 33/ 59

4.12 Preventive action

Policy

State the laboratory’s policy on preventive actions for needed

improvements and identification of potential sources of non-conformities,

technical as well as concerning the management system.

Responsibility

The person(s)/ position responsible for taking preventive actions shall be

identified.

Procedure

Briefly outline the procedure for preventive action and action plan to

implement & monitor to reduce the likelihood of the occurrence of non-

conformities.

The procedure for preventive action shall include initiation of such actions

and application of controls to ensure they are effective.

The sources for identification of areas for implementing preventive action

may include feedback from staff and customers, internal quality checks,

management review, proficiency testing, results, customer feedback,

analysis of data, trend/ risk analysis, etc. Such feedback serves as

controls and based on these an action plan to identify the potential

sources of non-conformities and required improvement & preventive

measures can be drawn for implementation.

The actual process may be covered in a separate procedure cross referred

in the Quality Manual.

Records

Make a reference to the document, where the records are maintained.

Records of identification of potential sources of non-conformities, investigations carried

out, required improvements and preventive measures taken shall be maintained.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 34/ 59

4.13 Control of records

Policy

State the laboratory’s policy to maintain and control record pertaining to

quality and technical activities. Also state policy on confidentiality,

protection and security of records, especially computer records.

Scope

List all quality and technical records maintained by the laboratory and give

a unique identification record number.

Responsibility

State the person(s) responsible for maintaining and controlling each

record.

Procedure

Briefly outline the procedure for identification, collection, indexing, access,

filing, storage, maintenance and disposal of quality and technical records.

The quality records shall include reports of internal audit, management review,

corrective action, preventive action etc. The technical records shall include original

observations, derived data, calibration records, staff records, a copy of each test report

or calibration certificate, personnel responsible for sampling, participation in proficiency

testing etc.

Briefly describe the procedure for control and time period for retention of

records, especially the test and/ or calibration worksheet, raw data and

test report/ calibration certificate.

Briefly describe the procedure for corrections, if mistakes occur.

The actual process may be covered in a separate procedure cross referred

in the Quality Manual.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 35/ 59

4.14 Internal Audit

Policy

State the laboratory’s policy in respect to conduct internal audit of all

activities to verify that the operations continue to comply with the

requirements of laboratory’s management system and ISO/IEC

17025:2005.

Scope

State the activities of the management system including testing and/ or

calibration activities, which will be audited to cover all elements of the

laboratory’s management system and ISO/IEC 17025:2005.

Responsibility

State the person/ position responsible for planning, organising internal

audits and coordinating the corrective action.

Normally this activity is the responsibility of the Quality Manager.

Procedure

Briefly outline the procedure for conduct of internal audit. The procedure

shall take account of:

a the frequency of conducting the internal audit at regular intervals

b training and qualification criteria of personnel conducting the internal

audit, that they are independent of the activity to be audited to the

extent possible.

The procedure shall also include the procedure for the corrective action(s)

to be taken and its verification including notifying customers in writing, if

the findings of internal audit cast doubt on the effectiveness of operations

or on the correctness/ validity of test and/ or calibration results. The

detailed process may be covered in a separate procedure cross referred in

the Quality Manual.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 36/ 59

Records

Make a reference to the document, where the records are maintained.

The records of the activities covered; the audit findings including the areas audited,

records verified, objective evidence gathered for verifying compliance with the

requirements of ISO/IEC 17025:2005 & the laboratory’s management system and the

gaps/ non conformities observed if any; corrective actions that arise from them,

implementation, its verification and the effectiveness of the corrective action taken shall

be recorded.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 37/ 59

4.15 Management review

Policy

State laboratory’s policy for the conduct of Management Review to ensure

the continuing suitability and effectiveness of laboratory’s management

system and its testing and/ or calibration activities and to introduce

necessary changes and improvements.

It is expected that the top management (chief executive) of the laboratory who has the

executive responsibility for running the laboratory, undertakes the management review.

The members of senior management having overall responsibility for design and

implementation of laboratory’s management system for the Technical Management, may

also be involved in the management review.

Scope

State the activities, the Management Review shall take account of,

however they should not be limited to the following:

a the suitability of policies and procedures

b reports from managerial and supervisory personnel

c the outcome of recent internal audits

d corrective and preventive actions

e assessments by external bodies

f the results of inter-laboratory comparisons or proficiency testing

g changes in the volume and type of the work

h customer feedback

i complaints

j recommendations for improvement

k other relevant factors, such as quality control activities, resources

and staff training.

Responsibility

State the person/ position responsible to convene the Management Review

meeting and the person who shall implement the decisions of the meeting.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 38/ 59

Procedure

Briefly outline the procedure for conduct of the Management Review

covering all the aspects stated above and the frequency at which it is

conducted.

The procedure shall also include that any action identified during the

review, is implemented within the agreed time limit. The detailed

processes may be covered in a separate procedure cross referred in the

Quality Manual.

Records

Make a reference to the document, where the records are maintained.

Records of all management review, and the actions that arise from them shall be

recorded. Records should also identify the personnel responsible for the actions and

agreed time frame. It should also include report on the actions of previous reviews.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 39/ 59

5. Technical Requirements

5.1 General

State the factors that determine the correctness and reliability of the tests/

calibrations performed by the laboratory. These factors should not be

limited to:

a human factors

b accommodation and environmental conditions

c test and calibration methods and method validation

d equipment

e measurement traceability

f sampling

g the handling of test and calibration items.

The laboratory shall take account of the factors in developing the test and/ or calibration

methods and procedures, in the training and qualification of personnel and in the

selection and calibration of the equipment it uses.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 40/ 59

5.2 Personnel

Policy

State the laboratory’s policy on ensuring personnel competence and with

regard to training needs, relevant to the present and anticipated tasks of

the laboratory. Formulate and state goals with respect to education,

training and skills of the laboratory personnel.

Job Description

Provide job description of the laboratory staff which shall include atleast

the following:

a name

b qualification

c training attended

d management duties

e expertise

f responsibilities

g further expertise/ training required.

This data may be maintained by the personnel department and be also annexed with the

procedural manual of relevant sections.

Supervision of Personnel

Provide for each technical operating department/ section, information of

the number of supervisory & non-supervisory personnel and the

procedures used to ensure adequacy of supervision.

Include a statement that department/ section laboratory managers ensure

that only staff members who have been assessed and found competent to

perform a test and/ or calibration are allowed to perform only that test and/

or calibration independently.

Other staff members may only assist in performing that test under close supervision of a

competent staff member.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 41/ 59

Training and Assessment of Competence

Describe the procedure for identifying the training needs and providing

training of personnel, relevant to the present and anticipated tasks of the

laboratory. A procedure for assessing the competence/ skills of the

personnel should also be described.

Also describe the evaluation procedure for the effectiveness of the training

actions taken.

The details of the training and assessment program of each section may be contained in

the Training Manual of that section. Each sectional laboratory manager may be

responsible to maintain the manual and plan the training schedule of his section to

satisfy these requirements.

Records

Make a reference to the document, where the records are maintained.

The personnel competence requirements with respect to different task undertaken by

laboratory shall be maintained. The laboratory shall also maintain records of persons

who are competent/ authorised including date of authorization, to perform specific tasks

such as sampling, test and/ or calibration, issue of test report & calibration certificate, to

give opinion and interpretations and to operate particular types of equipment. Also the

records of their educational & professional qualification, training, skills and experience

shall be maintained.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 42/ 59

5.3 Accommodation and Environmental Conditions

Policy

State the laboratory’s policy with respect to accommodation and

environments facilitate correct performance of the tests and/ or

calibrations.

Accommodation

Briefly describe the building facilities, location, construction features,

energy & water sources and lighting. A layout plan may be included.

Describe measures to control access to any particular area of the

laboratory and procedures to ensure laboratory security. If necessary, give

a table listing the staff that is permitted access to the various areas and

the position of staff responsible for security.

Is there effective separation between neighboring areas in which there are

incompatible activities? What measures have been taken to prevent cross

contamination?

Give instructions for laboratory staff to maintain good house keeping.

Prepare/ document special procedures for specific areas, if necessary.

Environmental Conditions

Give a brief description of the environmental conditions such as

temperature and humidity, in the various sections of the laboratory, as

required by particular category of calibration or tests (giving a list if

necessary).

In addition to temperature and humidity, laboratories performing biological

measurements shall specify biological sterility as environmental factor to

be controlled and electo-technical laboratories shall monitor the mains

voltage.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 43/ 59

Give a brief description of how to achieve the control of these

environmental conditions. What if they break down? Briefly outline the

procedure to monitor the environmental conditions.

Records

Make a reference to the document, where the records are maintained.

The records of environmental conditions such as temperature and humidity, wherever

relevant, shall be maintained.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 44/ 59

5.4 Test and Calibration Methods and method validation

Policy

State laboratory’s policy with respect to selecting any particular test and/

or calibration method i.e. whether prescribed in national or international

standards, published in reputed journals, text books, equipment

operational manuals or laboratory developed methods etc. to meet the

customer’s requirements.

The methods published in national or international standards with latest valid edition

shall be used. Methods published in journals, text books, equipment manuals and

laboratory developed methods or non-standard methods suggested by the customer,

shall be validated.

Test and Calibration Methods

Briefly describe the procedure and instruction for use of appropriate

methods and procedures for all tests and/ or calibrations within its scope.

This should include sampling, handling, transport, storage and preparation

of items to be tested and/ or calibrated, and where appropriate, an

estimation of measurement uncertainty as well as statistical techniques for

analysis of tests and/ or calibration data.

Describe the general arrangements for issuing, amending, updating,

retrieving, reviewing and approving of test and calibration methods.

Designate the staff responsible for the above task.

Describe the procedure for writing laboratory developed and non-standard

methods. The procedure should include that in-house methods shall be

validated and approved before issue.

Each test or calibration procedure shall contain at least the following information:

a appropriate identification

b scope

c description of the type of item to be tested or calibrated

d parameters or quantities and ranges to be determined

e apparatus and equipment, including technical performance requirements

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 45/ 59

f reference standards and reference materials required

g environmental condition required and any stabilization period needed

h description of the procedure, including

- affixing of identification marks, handling, transporting, storing and preparation

of items

- checks to be made before the work is started

- checks that the equipment is working properly and, where required, calibration

and adjustment of the equipment before each use

- the method of recording the observations and results

- any safety measures to be observed

i criteria and/ or requirements for approval/ rejection

j data to be recorded and method of analysis and presentation

k the uncertainty or the procedure for estimating uncertainty.

For in-house methods, guidance should be provided for amplifying standard

specifications to make a step-by-step procedure, which is unambiguous to the staff

concerned.

Procedure Manuals

List the various categories of test and/ or calibration methods employed

and make a cross-reference to the Test and/ or Calibration Procedure

Manual(s) in the Quality Manual.

International, Regional or National Standard that contain sufficient and concise

information on how to perform the tests and/ or calibrations do not need to be

supplemented or rewritten as internal procedures if these standards are written in a way

that they can be used as published by the operating staff in the laboratory. It may be

necessary to provide additional documentation for optional steps in the method or

addition details.

Standard Specifications

State the laboratory’s policy for referring to latest standards as the basis

for test and/ or calibration methods, whenever possible.

List the relevant standard specifications on which the test and/ or

calibration procedures are based.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 46/ 59

Validation of Methods

Where the laboratory is using the laboratory developed or non-standard

methods, the laboratory shall confirm the techniques used for the

determination of the performance of a method.

One or combination of the following techniques may be used for the determination of

performance of a method.

a calibration using reference standards or reference materials

b comparison of results achieved with other methods

c Inter-laboratory comparisons

d systematic assessment of the factors influencing the result

e assessment of the uncertainty of the results based on scientific understanding of

the theoretical principals of the method and practical experience

f any other technique.

Estimation of Uncertainty of Measurement

The laboratory shall state the procedure applied to estimate the

uncertainty of measurement for all types/ ranges of calibration.

When estimating the uncertainty of measurement, all uncertainty components which are

of importance in the given situation shall be taken into account, which shall include but

not be limiting to:

a reference standards and reference materials with reported uncertainty in the

calibration certificate

b method employed

c equipment used with reported uncertainty in the calibration certificate

d environmental conditions

e properties and condition of the item being tested/ calibrated.

For calibration laboratories and testing laboratories performing their own calibrations

shall estimate the uncertainty of measurement for all calibrations and types/ range of

calibrations.

For testing laboratories availing the services from calibration laboratories, shall identify

all the components of uncertainty and make a reasonable estimation for all test

parameters, and shall ensure that the form of reporting of the result does not give a

wrong impression of the uncertainty. The degree of rigor needed in an estimation of

uncertainty of measurement depends on the requirements of test method, requirements

of customer and the existence of narrow limits on which decisions on conformance to a

specification are based.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 47/ 59

Control of Data

Describe the arrangement to ensure that all data transfer are subjected to

appropriate checking by responsible staff.

Describe the procedure to protect the integrity, confidentiality and security

of data, particularly when using computer processing, including software

validation.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 48/ 59

5.5 Equipment

Policy

State laboratory’s policy on use of equipment and reference materials for

complying to required specifications and capable of achieving the desired

accuracy.

Procedures for test and calibration equipment

Make a cross reference to the document where a list of major equipment

are maintained and also make a statement to the effect that it has all the

necessary equipment and reference material for meeting the stated policy.

List the range of major test and/ or calibration equipment, reference standards and

materials required by the laboratory.

Describe the procedure for commissioning new equipment including the

criteria for acceptance and safeguarding from adjustments.

The laboratory shall confirm that all equipment under the control of

laboratory requiring calibration are identified and labeled to indicate the

status of calibration, date of last calibration and date of next calibration.

Describe a procedure for intermediate checks to maintain confidence

status of the equipment.

Describe the procedure for safe handling, transport, storage, use and

planned maintenance of measuring equipment to ensure proper

functioning and prevent contamination or deterioration.

Describe the procedure for safeguarding tests and/ or calibration

equipment, including both hardware and software for adjustment

invalidating the results.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 49/ 59

Describe the procedure for equipment subjected to overloading or

mishandling, giving suspected results or the equipment is declared

defective or when equipment goes outside the direct control of laboratory

and a procedure when it is repaired and brought back/ returned to service.

Describe the procedure to ensure that copies (eg. in computer software)

are correctly updated, where calibrations give rise to set of correction

factors.

Equipment Records

Make a reference to the document, where the records are maintained.

The laboratory shall maintain records of all major test and/ or calibration equipment.

For each equipment atleast the following data should be included:

a the identity of the item of equipment and its software

b the manufacturer’s name, type identification, and a serial number or other unique

identification

c checks that equipment complies with the specification

d current location, where appropriate

e the manufacturer’s instructions, if available, or reference to their location

f dates, results and copies of reports and certificates of all calibrations,

adjustments, acceptance criteria, and the due date of next calibration

g the maintenance plan, where appropriate, and maintenance carried out to date

h any damage, malfunction, modification or repair to the equipment.

The records for authorization of the technical staff for handling/ operating the

equipments shall also be maintained.

The laboratory shall also maintain records of all test and/ or calibration equipment,

reference standards and reference materials requiring calibration which shall atleast

include equipment name, calibration status, date of the calibration and due date of next

calibration.

For chemical reference materials, the expiry date should be indicated. A record of their

usage should be included.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 50/ 59

5.6 Measurement Traceability and Calibration

Policy

The laboratory shall make a commitment to implement NABL policy on

measurement traceability and calibration, given in NABL 142.

The laboratory shall also make a commitment to use the services of

accredited laboratories for external calibrations, to provide traceability to

national/ international standards.

Where traceability to national/ international standards is not practicable,

how does the laboratory provide the satisfactory evidence about the

reliability of the measurement of result.

A calibration certificate bearing an accreditation body symbol from a calibration

laboratory accredited in accordance with ISO/IEC 17025:2005, for the calibration

concerned is sufficient evidence of traceability of the calibration data reported.

Calibration program

Describe the calibration program operative in the laboratory which

includes the scheduling & fixing of calibration due dates and fulfills the

requirements of NABL 142. The program shall cover all measuring

instrument/ equipment, reference standards and reference materials.

For internal calibration, describe calibration procedure including

estimation of uncertainties of measurement and traceability to national/

international standards and acceptance criteria.

A detailed procedure for calibration may be given in a separate document

and cross referred in the Quality Manual.

National Accreditation Board for Testing and Calibration Laboratories

Doc. No: NABL 160 Guide for Preparing a Quality Manual

Issue No: 05 Issue Date: 27.06.2012 Amend No: 00 Amend Date: -- Page No: 51/ 59

The overall program of calibration and verification and validation of an equipment shall