Professional Documents

Culture Documents

Nedal Alloy Datasheet EN AW 6082 PDF

Uploaded by

Rohit SharmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nedal Alloy Datasheet EN AW 6082 PDF

Uploaded by

Rohit SharmaCopyright:

Available Formats

Type:

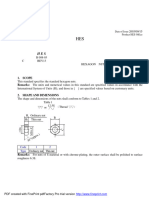

ALLOY DATA SHEET High strength

EN AW-6082 [AlSi1MgMn] structural alloy

The alloy EN AW-6082 is a high strength alloy for highly loaded structural

applications. Typical applications are scaffolding elements, rail coach parts, offshore

constructions, containers, machine building and mobile cranes. Due to the fine

grained structure this alloy exhibits a good resistance to dynamic loading conditions.

EN AW-6082 is certified for use in marine applications.

Chemical composition according to EN573-3 (weight%, remainder Al)

Si Fe Cu Mn Mg Cr Zn Ti remarks others

each total

0.7 – max. max. 0.40 – 0.6 – max max max max max

1.3 0.50 0.10 1.0 1.2 0.25 0.20 0.10 0.05 0.15

Mechanical properties according to EN755-2

Temper* Wallthickness Yield stress Tensile strength Elongation Hardness**

e*** Rp0.2 Rm A A50mm HB

[MPa] [MPa] [%] [%]

T4 e 25 110 205 14 12 65

T5 e 5 230 270 8 6 80

e 5 250 290 8 6 95

T6

5 < e 25 260 310 10 8 95

*Temper designation according to EN515: T4-Naturally aged to a stable condition, T5-cooled from an elevated temperature

forming operation and artificially aged, T6-Solution heat treated, quenched and artificially aged (T6 properties can be achieved

by press quenching)

** Hardness values are for indication only

***For different wall thicknesses within one profile, the lowest specified properties shall be considered as valid for the whole

profile cross section

Physical properties (approximate values, 20°C)

Density Melting range Electrical Thermal Co-efficient of Modulus of

conductivity conductivity thermal expansion elasticity

3 -6

[kg/m ] [°C] [MS/m] [W/m.K] 10 /K [GPa]

2700 585-650 24-32 170-220 23.4 ~70

Weldability1

Gas: 3 TIG: 2 MIG: 1 Resistance welding: 3 Spot welding: 2

Typical filler materials (EN ISO18273): AlMg5Cr(A), AlMg4.5Mn0.7(A) or AlSi5. Due

to the heat input during welding the mechanical properties will be reduced by

approximately 50% (ref. EN1999-1).

Machining characteristics1:

T4 temper: 4 T5 and T6 temper: 2

Corrosion resistance1

General: 2 Marine: 2

Coating properties1

Hard/protective anodising: 2 Bright/colour anodising: 3

1

Relative qualification ranging from 1-very good to 6 – unsuitable

Nedal Aluminium Alloy data sheet jun-2005

P.O.-Box 2020 EN AW-6082

NL-3500 GA Utrecht, The Netherlands rev.00

T. +31 30 2925711 F. +31 30 2939512

sales@nedal.nl www.nedal.com

You might also like

- SAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentDocument2 pagesSAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentAnush Swaminathan100% (1)

- Metallurgical and Weldability Aspects of The New-Generation Martensitic Stainless Steels: A Case StudyDocument19 pagesMetallurgical and Weldability Aspects of The New-Generation Martensitic Stainless Steels: A Case Studyvasea100% (1)

- BS en 10025-3Document28 pagesBS en 10025-3yasser awadallhNo ratings yet

- S For Quenching D Tentpering-: SteelDocument28 pagesS For Quenching D Tentpering-: SteelDidier LZNo ratings yet

- Iso 2320 2008 FR en PDFDocument8 pagesIso 2320 2008 FR en PDFAmirtharaaj VijayanNo ratings yet

- 42 CR Mo 4Document4 pages42 CR Mo 4eduardomanar1224No ratings yet

- Iso 15614-13Document24 pagesIso 15614-13Marija IvanovskaNo ratings yet

- Hot Rolled Carbon Steel Sheet, Plate and Strip According To IS 1079:2017Document8 pagesHot Rolled Carbon Steel Sheet, Plate and Strip According To IS 1079:2017raghavendragouda patilNo ratings yet

- Norma Ps Fiat 50116Document6 pagesNorma Ps Fiat 50116Hatada FelipeNo ratings yet

- Material Specification: Specification: Revision Date: Revision LevelDocument2 pagesMaterial Specification: Specification: Revision Date: Revision LevelReginaldo Santos100% (1)

- NES-M2032 - 2021 - (ColdRoll-High Tensile)Document13 pagesNES-M2032 - 2021 - (ColdRoll-High Tensile)dpfloresNo ratings yet

- Application DIN 2303Document8 pagesApplication DIN 2303Marcelle Poll100% (1)

- Din en 10083 3 2007 Alloy SteelsDocument58 pagesDin en 10083 3 2007 Alloy SteelsThang Do100% (1)

- BS-970!3!1991-Specification For Wrought Steels For Mechanical and Allied Engineering PurposesDocument38 pagesBS-970!3!1991-Specification For Wrought Steels For Mechanical and Allied Engineering PurposesEric Mellier100% (1)

- Cen TR 14633 (E)Document9 pagesCen TR 14633 (E)consssNo ratings yet

- 3455 1971 Reff2020Document17 pages3455 1971 Reff2020Ashish DubeyNo ratings yet

- Iso 9445 2 2009Document9 pagesIso 9445 2 2009Kerem ErtemNo ratings yet

- Equivalent MaterialDocument1 pageEquivalent MaterialRajput PratiksinghNo ratings yet

- Metrode ER110S-G FillerDocument6 pagesMetrode ER110S-G FillerBernie SimcsNo ratings yet

- FiatDocument10 pagesFiatrgi178100% (1)

- BS en 00755-5-2008Document17 pagesBS en 00755-5-2008Luis SierraNo ratings yet

- En 10088 Steel NumberDocument3 pagesEn 10088 Steel Numberrvieira659No ratings yet

- Tolerante en 10029Document1 pageTolerante en 10029r3loop100% (1)

- Comparison of BS and BSEN For Steel Simplified VersionDocument28 pagesComparison of BS and BSEN For Steel Simplified VersiondpkguptNo ratings yet

- EN 755 - Part 3Document2 pagesEN 755 - Part 3myusernameatscribdNo ratings yet

- ISO-15792-1-2000. Test Vật Liệu HànDocument9 pagesISO-15792-1-2000. Test Vật Liệu HànLã Hải ĐăngNo ratings yet

- JIS G3452 PipeDocument0 pagesJIS G3452 PipefaridyeniNo ratings yet

- ISO 10684 Hot Dip Galvanized Fasteners PDFDocument27 pagesISO 10684 Hot Dip Galvanized Fasteners PDFOzan AtıcıNo ratings yet

- Ford-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgDocument9 pagesFord-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgdpfloresNo ratings yet

- ISO 15510 - Part 1Document5 pagesISO 15510 - Part 1Zdenko MahacekNo ratings yet

- IS 5517 - 1993-Hardening & Tempering GradesDocument15 pagesIS 5517 - 1993-Hardening & Tempering GradesMohanrajMJ100% (1)

- Hes B008-03 Hexagon NutsDocument5 pagesHes B008-03 Hexagon NutsPreetam KumarNo ratings yet

- Is 14329 1995 PDFDocument13 pagesIs 14329 1995 PDFSriram Subramanian100% (1)

- IS 4923 Chemical CompositionDocument1 pageIS 4923 Chemical CompositionTulasidas MalajiNo ratings yet

- Specification For Seamless Red Brass Pipe, Standard SizesDocument8 pagesSpecification For Seamless Red Brass Pipe, Standard SizesVCNo ratings yet

- European Standard Norme Europeenne Europaische Norm: Ultrasonic Testing of $teel BarsDocument13 pagesEuropean Standard Norme Europeenne Europaische Norm: Ultrasonic Testing of $teel BarspraveenNo ratings yet

- Vdocuments - MX Iso 10447Document19 pagesVdocuments - MX Iso 10447Paweł MrajskiNo ratings yet

- Bluefracturemnm 2018Document8 pagesBluefracturemnm 2018Gomathi RNo ratings yet

- C45 STD PDFDocument2 pagesC45 STD PDFJeetu GosaiNo ratings yet

- Iso Metric 32Document2 pagesIso Metric 32rahul caddNo ratings yet

- EN 288-3xDocument38 pagesEN 288-3xSyah Reza Maulana0% (1)

- Supercito (E 42 5 B 32 h5)Document1 pageSupercito (E 42 5 B 32 h5)brunizzaNo ratings yet

- Iso AnnealingDocument2 pagesIso AnnealingPurushottam Sutar100% (1)

- Is 1079 - 2009Document10 pagesIs 1079 - 2009Shradha SinghaniaNo ratings yet

- Tigweldarc Alloys: Certification of TestsDocument1 pageTigweldarc Alloys: Certification of TestsArunNo ratings yet

- Chemical DetailsDocument3 pagesChemical Detailsemmas18No ratings yet

- Astm B487Document2 pagesAstm B487Srinivasa RaghavanNo ratings yet

- Astm A874Document3 pagesAstm A874DendeNo ratings yet

- Din en 1172 e 2010-07Document16 pagesDin en 1172 e 2010-07Niko Zurabishvili100% (1)

- Sae J82-2013Document6 pagesSae J82-2013Marcos RosenbergNo ratings yet

- Material SpecificationDocument2 pagesMaterial SpecificationmasrooorNo ratings yet

- 16MnCr5 1.7131 16MnCrS5 1.7139 RM16 ENGDocument2 pages16MnCr5 1.7131 16MnCrS5 1.7139 RM16 ENGJerzy RistujczinNo ratings yet

- IS:2062Document13 pagesIS:2062Rv VaghasiaNo ratings yet

- Chemical and Mechanical PropertiesDocument5 pagesChemical and Mechanical PropertiesAristotle MedinaNo ratings yet

- Alumina-Silicate Type Agglomerated Submerged Arc Welding FluxDocument1 pageAlumina-Silicate Type Agglomerated Submerged Arc Welding FluxthindmanmohanNo ratings yet

- Alloy Data Sheet 6082Document1 pageAlloy Data Sheet 6082Prashant MalveNo ratings yet

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocument7 pages22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeNguyen Anh TuanNo ratings yet

- Data 6005ADocument1 pageData 6005AErick De La RoSaNo ratings yet

- Alloy Data Sheet: en Aw-7003 (Alzn6Mg0.8Zr)Document1 pageAlloy Data Sheet: en Aw-7003 (Alzn6Mg0.8Zr)Jorge LuisNo ratings yet