100% found this document useful (1 vote)

734 views2 pagesManufacturing Process Audit Excel Form

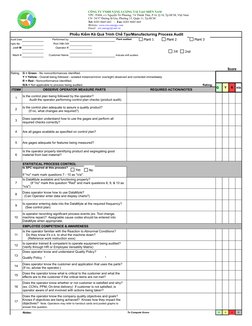

This document appears to be an audit form used to assess manufacturing processes. It contains 17 criteria used to evaluate operators and processes on factors such as following control plans, using measurement tools correctly, statistical process control, employee competence, and customer satisfaction. Operators are rated on each criteria as Green (meeting requirements), Yellow (isolated issues), or Red (nonconformance identified). Audit findings are recorded, including any required corrective actions.

Uploaded by

Tri HdyvtdtCopyright

© Public Domain

We take content rights seriously. If you suspect this is your content, claim it here.

100% found this document useful (1 vote)

734 views2 pagesManufacturing Process Audit Excel Form

This document appears to be an audit form used to assess manufacturing processes. It contains 17 criteria used to evaluate operators and processes on factors such as following control plans, using measurement tools correctly, statistical process control, employee competence, and customer satisfaction. Operators are rated on each criteria as Green (meeting requirements), Yellow (isolated issues), or Red (nonconformance identified). Audit findings are recorded, including any required corrective actions.

Uploaded by

Tri HdyvtdtCopyright

© Public Domain

We take content rights seriously. If you suspect this is your content, claim it here.

- Statistical Process Control

- Observation and Measurement

- Employee Competence and Awareness

- Audit Introduction

- Audit Scoring